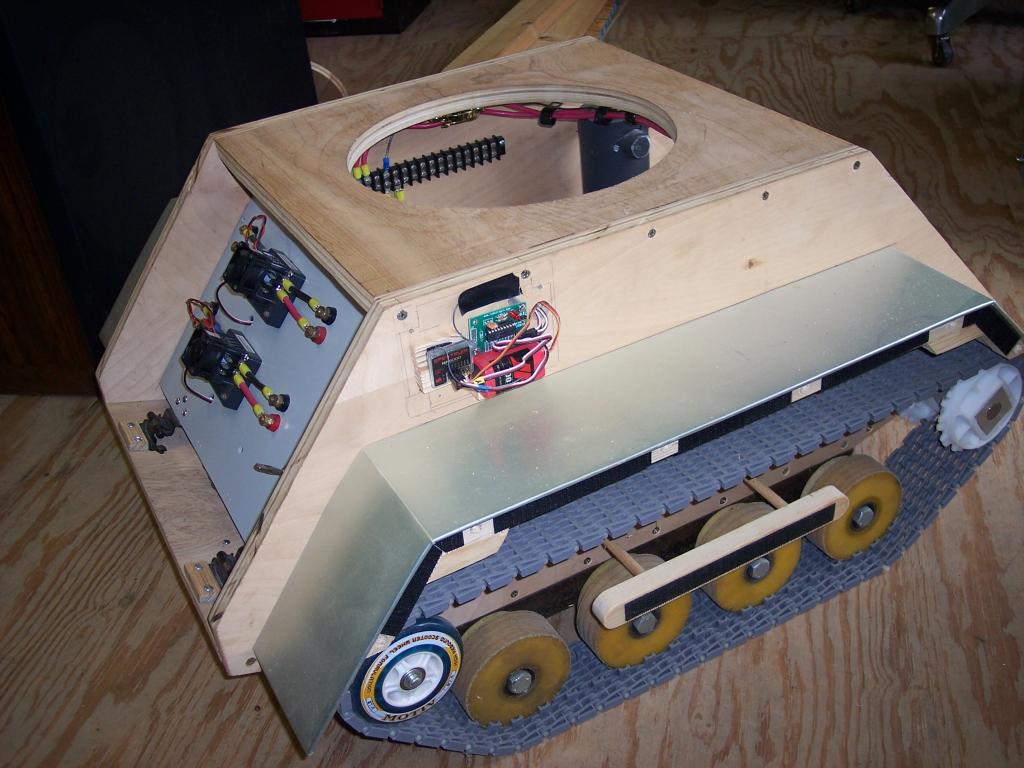

Hello, My name is Rex and I am building a large robot. His name is Magnus. He is 6 ft. tall and will weigh around 300 lbs. He has wheelchair motors driving tank treads. He looks similar to the B9 robot that appeared on the old TV series called Lost in Space but , I claim no ties to Lost in Space. I will post more pictures soon. I was very excited when I found the E Z Robot kit. I want to order but have some questions. Looking forward to discussing all kinds of topics here.

Best regards,

Rex

By rgordon

— Last update

Other robots from Synthiam community

Ezang's Mymodifiedadventurebot

Modified Adventure Bot with ultrasonic radar, camera, RGB animator and custom back wheels

Ezang's Happy Crawler 5/18/2021 And New Combination Robot...

Metal-legged robot built with Servo City parts and 4 servos, IoTiny battery, using Synthiam ARC programming to achieve...

Justinratliff's Walle Built With Iotiny

Updating software and wiring a small non-motorized WallE: servo port mapping, using stock toy switches on one ADC line...

welcome to EZ-Robot.....

WOW ....6FT....... nice build.......love the tracks.......what are the features?

Awesome build so far. There are several B9 fans here. Feel free to ask any questions and we'll all be happy to point you to the answers if already here or help you figure them out if not.

Alan

Sweet! I love the base/drive section! Do you find the plywood strong enough for your purposes? I too will be building a large bot with wheelchair motors in the near future (finishing two smaller ones first - one of which is a 2' radio controlled B9 I'm hacking). What type of ply are you using? How is it joined (glue and screws?)? Do you have any drawings? Are those tracks the plastic conveyor belt stuff?

You can fiberglass that wood base and add a few.ribs and it.could easily hold up 300 pounds. You would probably fiberglass it anyways.because you can't paint strait plywood gotta put a easily sandable finish on it. So are you just wanting.it.to look "like b9" but be your own variation?

gotta put a easily sandable finish on it. So are you just wanting.it.to look "like b9" but be your own variation?

Welcome and WOW!!!! That's going to be sooooooo cool!!!

Hello Everyone,

Thanks to all who have responded so far. Thanks so much for the positive comments. I will try to address all of your questions.

This project will satisfy a dream of mine that started about 40 years ago. I am totally fascinated with robots and my skill set is now to the point that I wanted to tackle this dream. I should have started with a smaller robot but, hey what the heck! I have been actively working on this build for almost four years now. So hard to find the time to do the things one truly loves to do... now days. I'm afraid it may be turning into a mid-life crisis It looks a little rough so far but there is lots to do! I can't wait to get past the mechanical hurdles and get to the good stuff...the electronics and controls! I got so busy (and excited) trying to get things done, since I have so little time, that I did not get a lot documented for the build. But, now that's going to change. I am going back and making drawings, creating schematics and taking lots of pictures so I can share this with others. And oh boy..am I going to have lots of questions for you guys! Welcome to Project Magnus!

It looks a little rough so far but there is lots to do! I can't wait to get past the mechanical hurdles and get to the good stuff...the electronics and controls! I got so busy (and excited) trying to get things done, since I have so little time, that I did not get a lot documented for the build. But, now that's going to change. I am going back and making drawings, creating schematics and taking lots of pictures so I can share this with others. And oh boy..am I going to have lots of questions for you guys! Welcome to Project Magnus!

To GotRobbed and thetechguru -

My goal is to build a large robot that will be totally remote controlled (for now). It will be approximately 6' tall with a cylinder shaped torso, two arms that each have a three finger claw, and a classic "bubble" head. This robot will be built to impress, so it must look sharp. It must emanate a presence when it enters a room. It will have a vague resemblance to the B9 Robot from an old TV series called Lost in Space but, it is actually very very different in almost all aspects. Magnus is unique and I claim NO ties to the Lost in Space series due to licensing issues. I would however, love to one day own an exact replica of the B9 Robot. He is so cool.

Features:

Certain aspects of the robot need to be automatic to allow me to control it more easily.

Examples include:

The robot will also have a number of special effects to enhance its presence.

These will include:

To bret.tallent and jstarne1

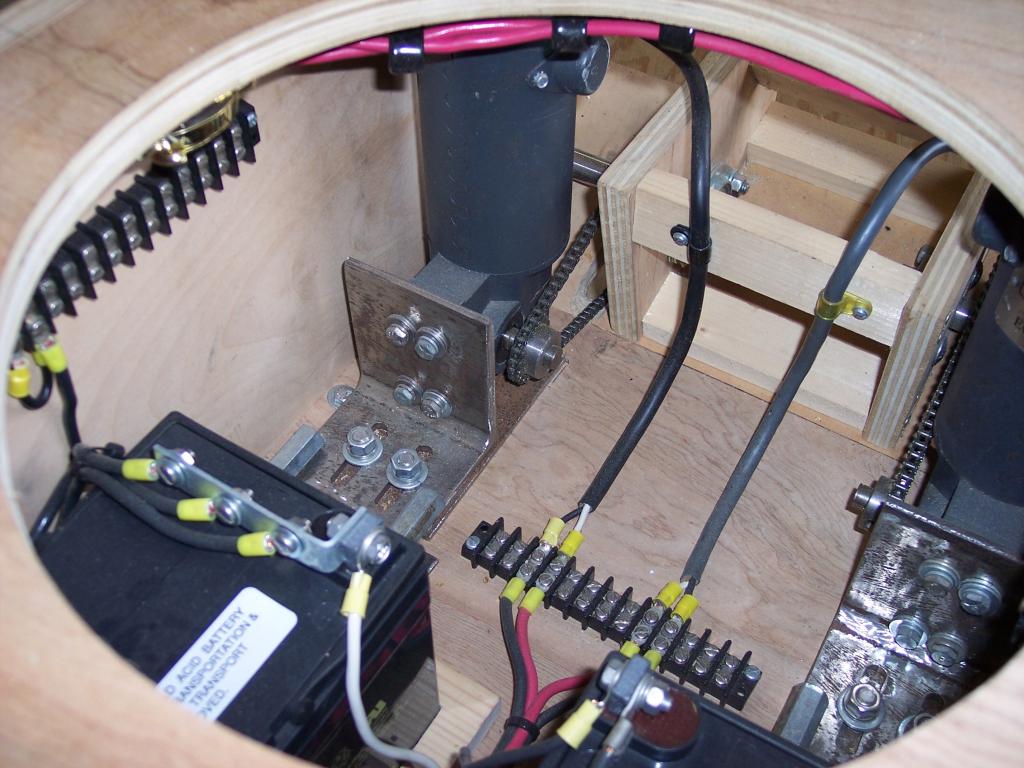

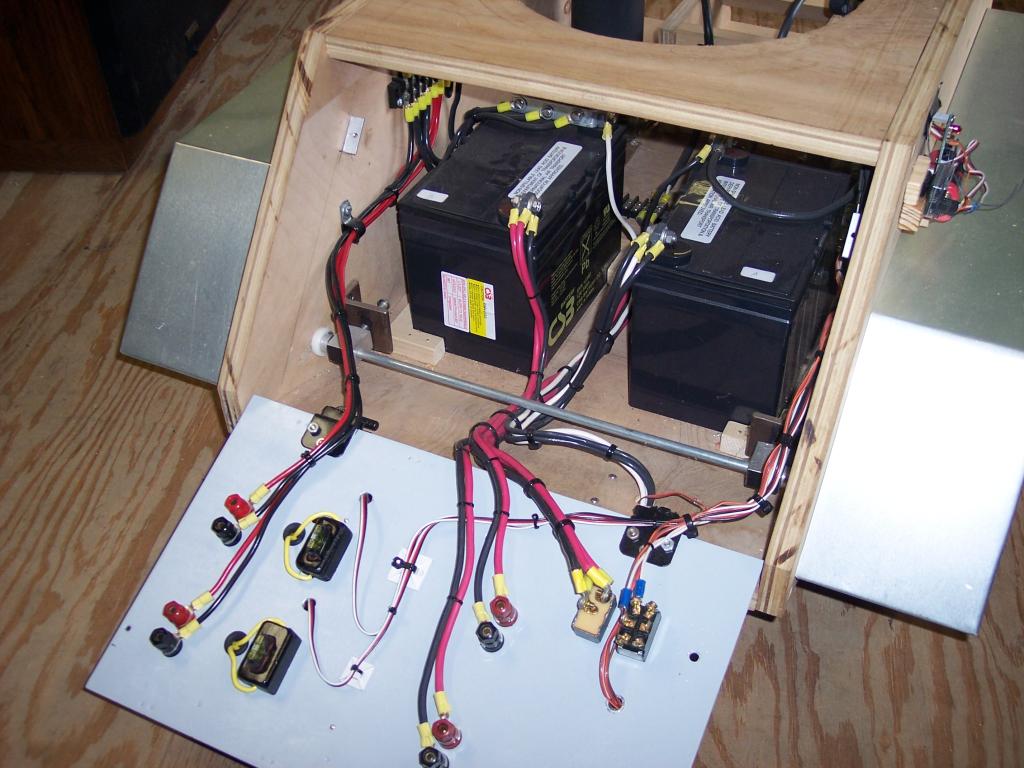

The plywood is 3/4" birch and for now is held together with drywall screws so I can take it back apart if needed. Once I get it to the point where I am satisfied I will also use glue and maybe a brace or two to make it stronger. The base weighs 135 lbs as shown in the picture and I have ridden on it with no problems. I weigh 180 ls. So load capability is good. I did find that the paint that is used to coat truck beds actually works pretty good on covering plywood if you use a good sealer first. But, I am also intrigued by the idea of using fiberglass to coat it. Thanks for the idea!

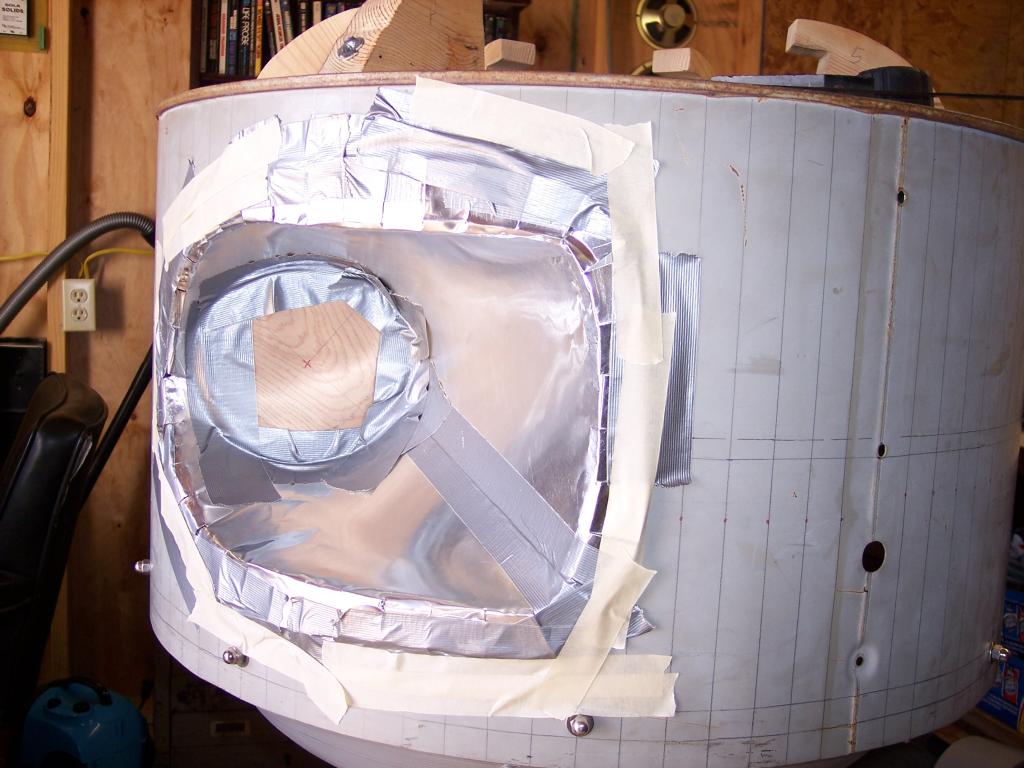

The tracks are conveyor material from a company called Intralox. They work great but, I wish they were black instead of gray. I love track drives and they are really cool but, I know that they may pose problems in the future due to the weight of the robot especially when traveling and making turns on carpet or nice shiny hard wood floors. Oh well...we'll see. The torso is made from a clothes dryer drum...hey...right size and shape and didn't have to build it from scratch. The arm sockets were tough to make though. The upper and lower domes are covers from roof attic fans Still working on models for the arms. Hope one day to be able to afford powerful servos but will use DC gear motors for now.

Still working on models for the arms. Hope one day to be able to afford powerful servos but will use DC gear motors for now.

To DJ Sures

Sorry for such a long post...can you tell I like robots ??? I am very excited about the EZ Robot kit that you have for sale and hope to purchase it in a week or two. It looks to be a dream come true. I have a couple of questions for you and the guys:

??? I am very excited about the EZ Robot kit that you have for sale and hope to purchase it in a week or two. It looks to be a dream come true. I have a couple of questions for you and the guys:

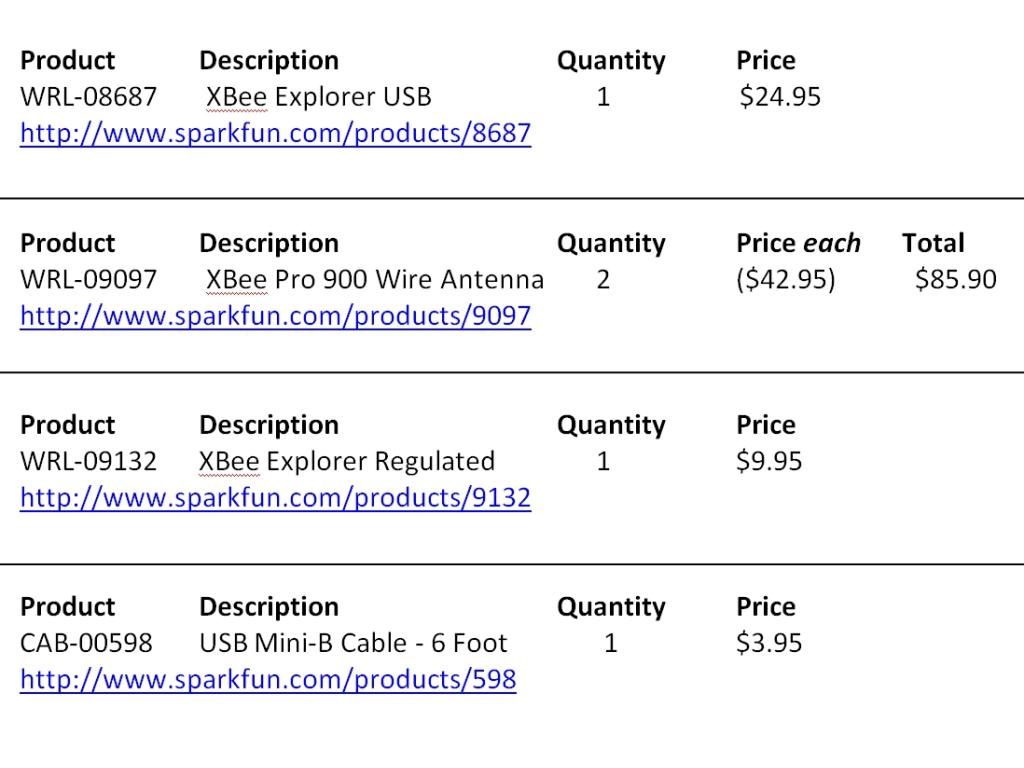

How would you rate the video quality of the camera that comes in the kit? I will need to steer Magnus when he is out of my line of sight. Is there much delay in the transmission?

Do you have any step by step tutorials coming up (or now) on how to extend the range beyond what Blue Tooth can do? I will need at least 100 ft through maybe a wall or two. Think hidden control booth made from plywood or some such. Remember, keep it simple for us old folks:)

Best regards,

Rex

now thats a claws!!!!....

very impressive build, very impressive build,....what is your timeline so far?.....

It must be great to have workspace....lol Im using the kitchen...ha ha

What are you using to power it? 24v system? How many fussblocks? are you custom building the gear system to move the arms and body?

I like to see pics of your electrical system setup......

great progress.....nice

Ditto got robbed , kitchen table is the work shop lol