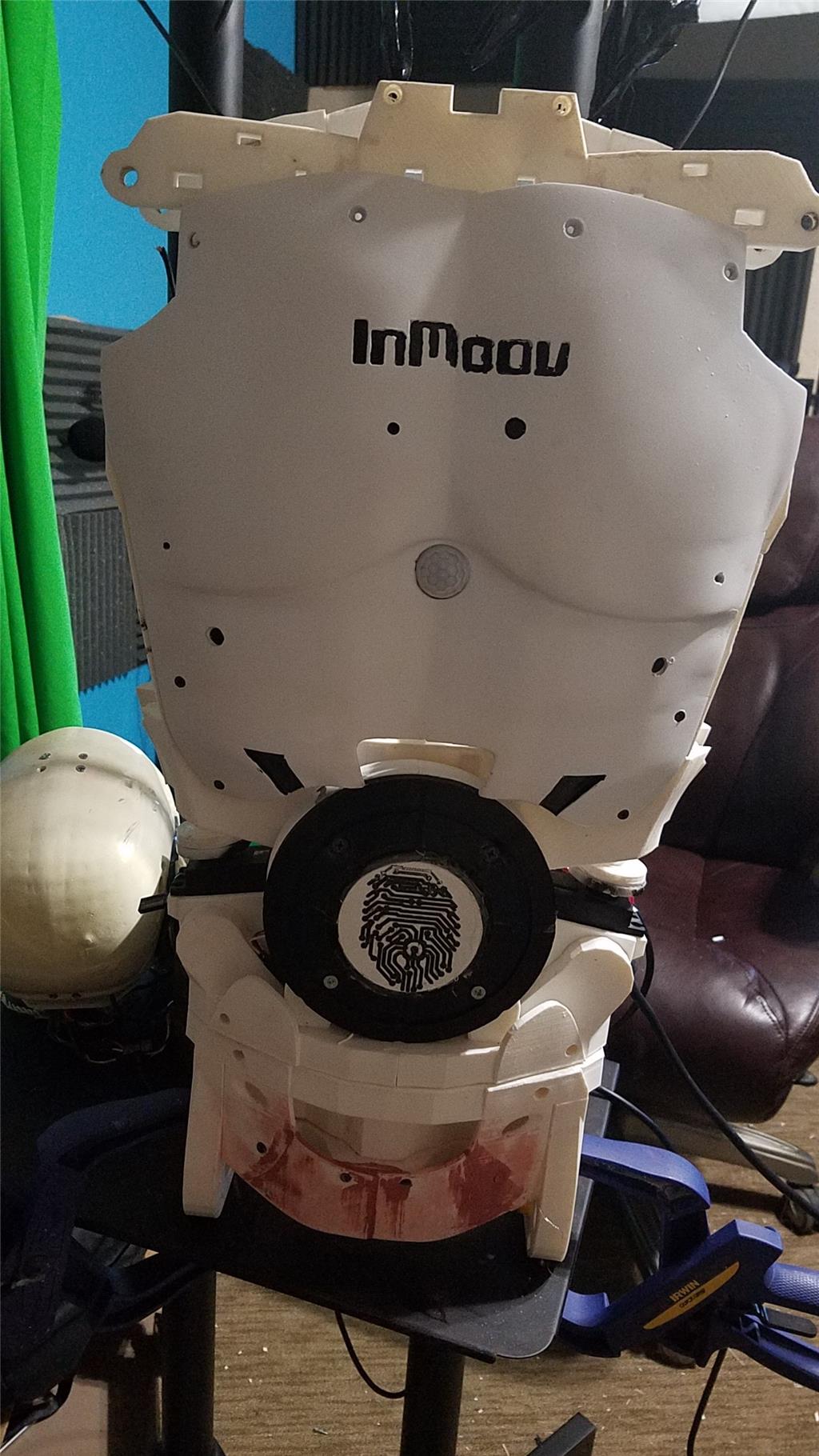

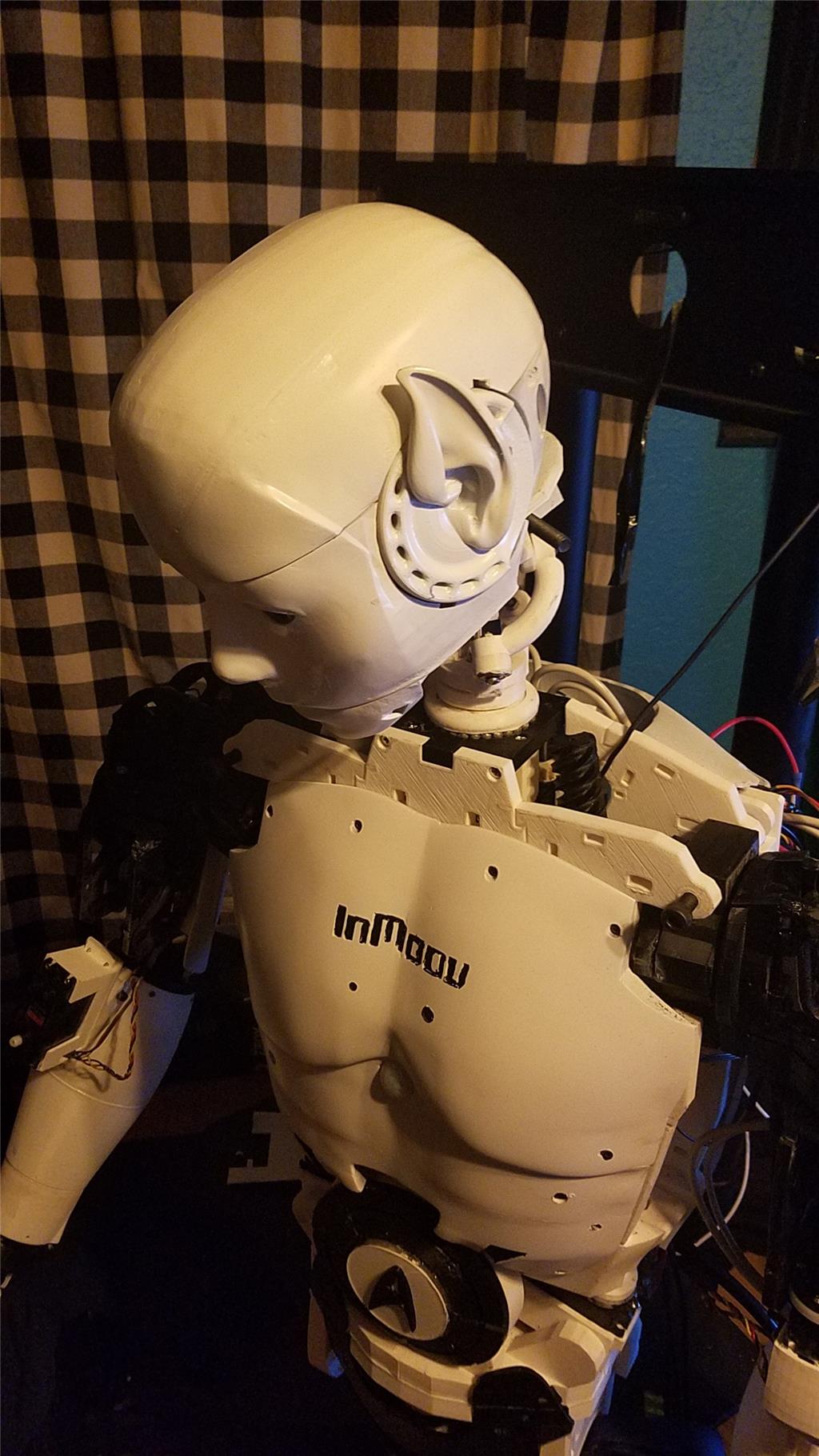

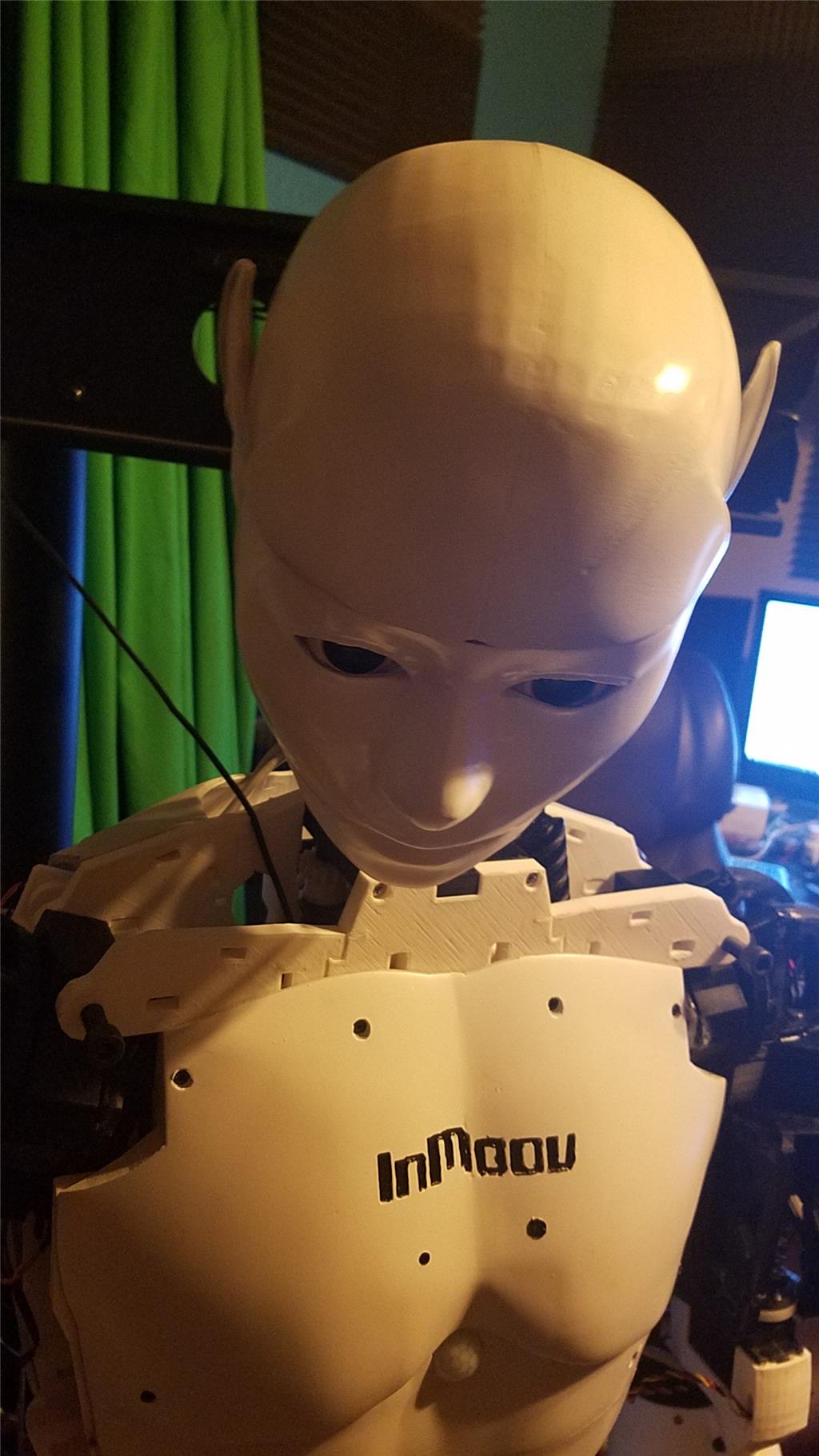

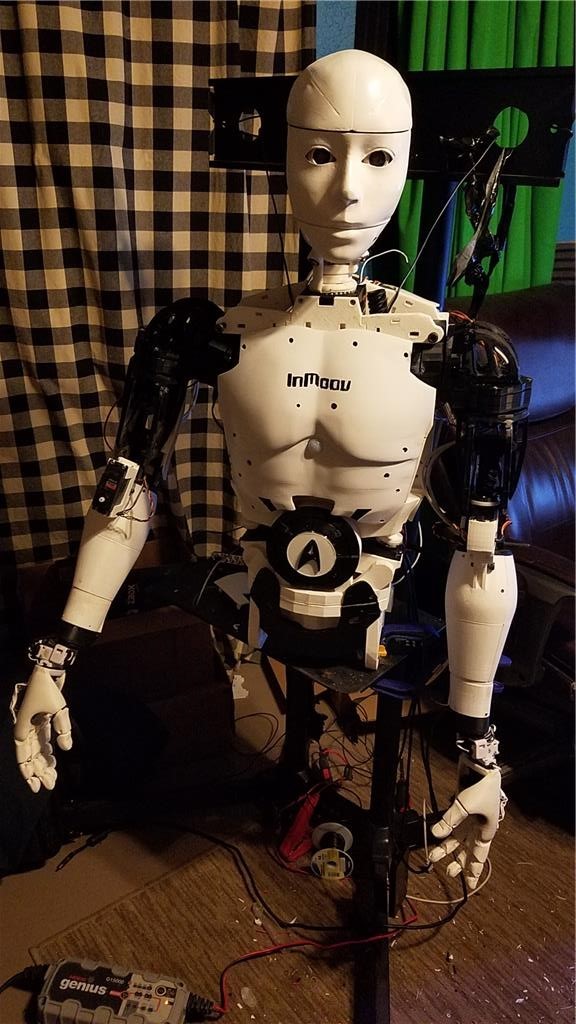

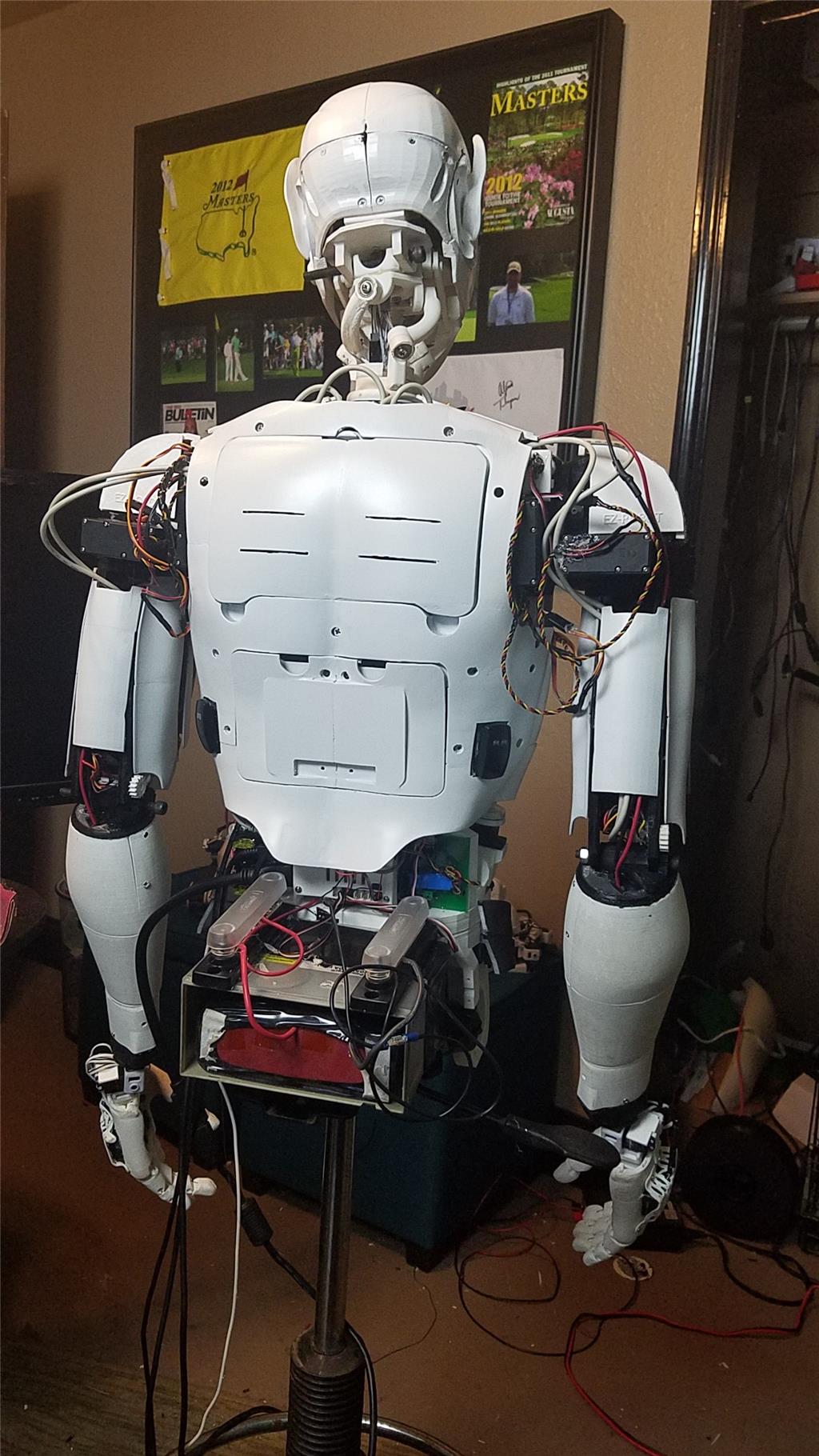

I have decided to start my InMoov project. I think I will call him Spock out of respect to Leonard Nimoy who passed away on the day that I started this project.

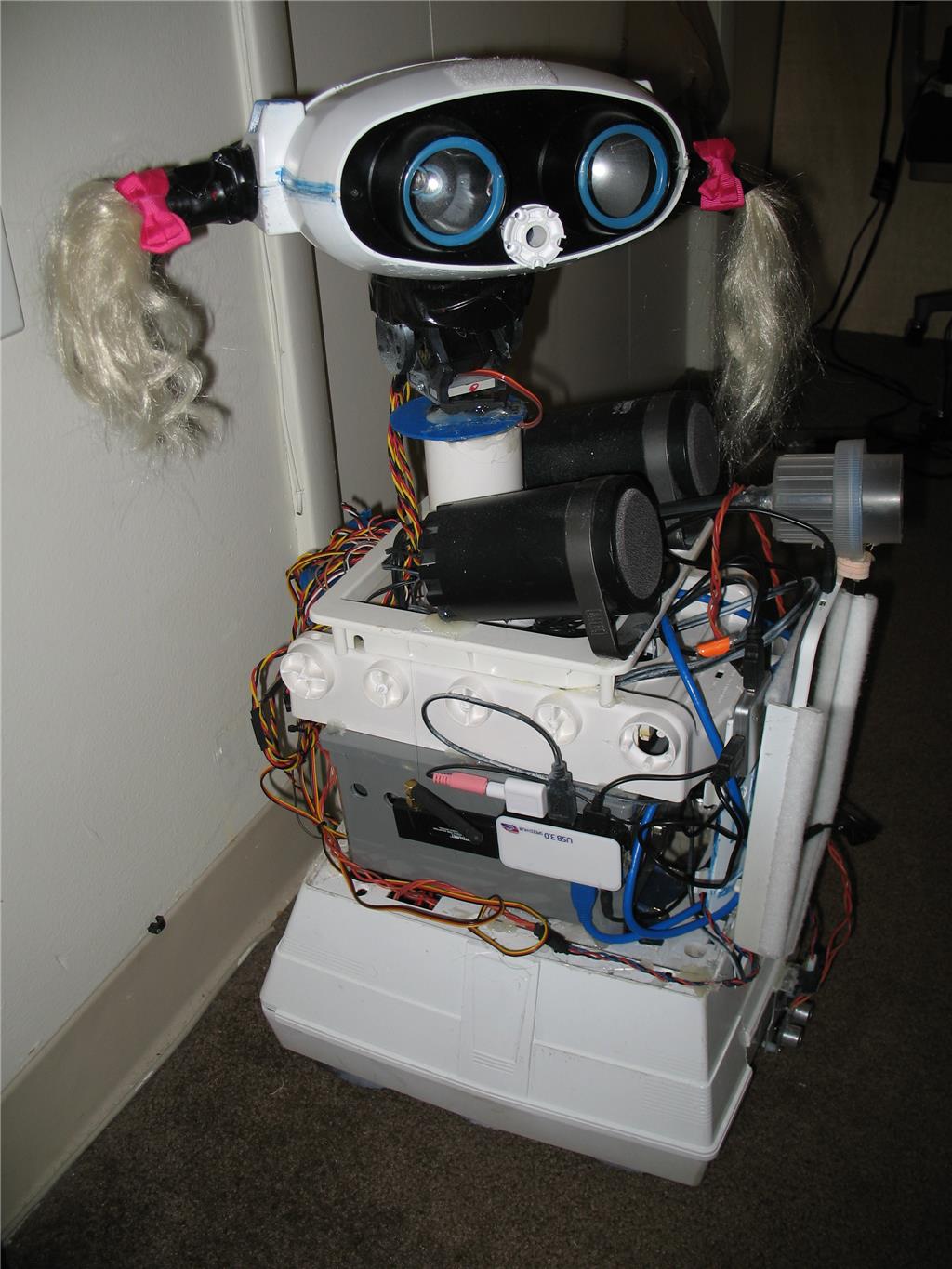

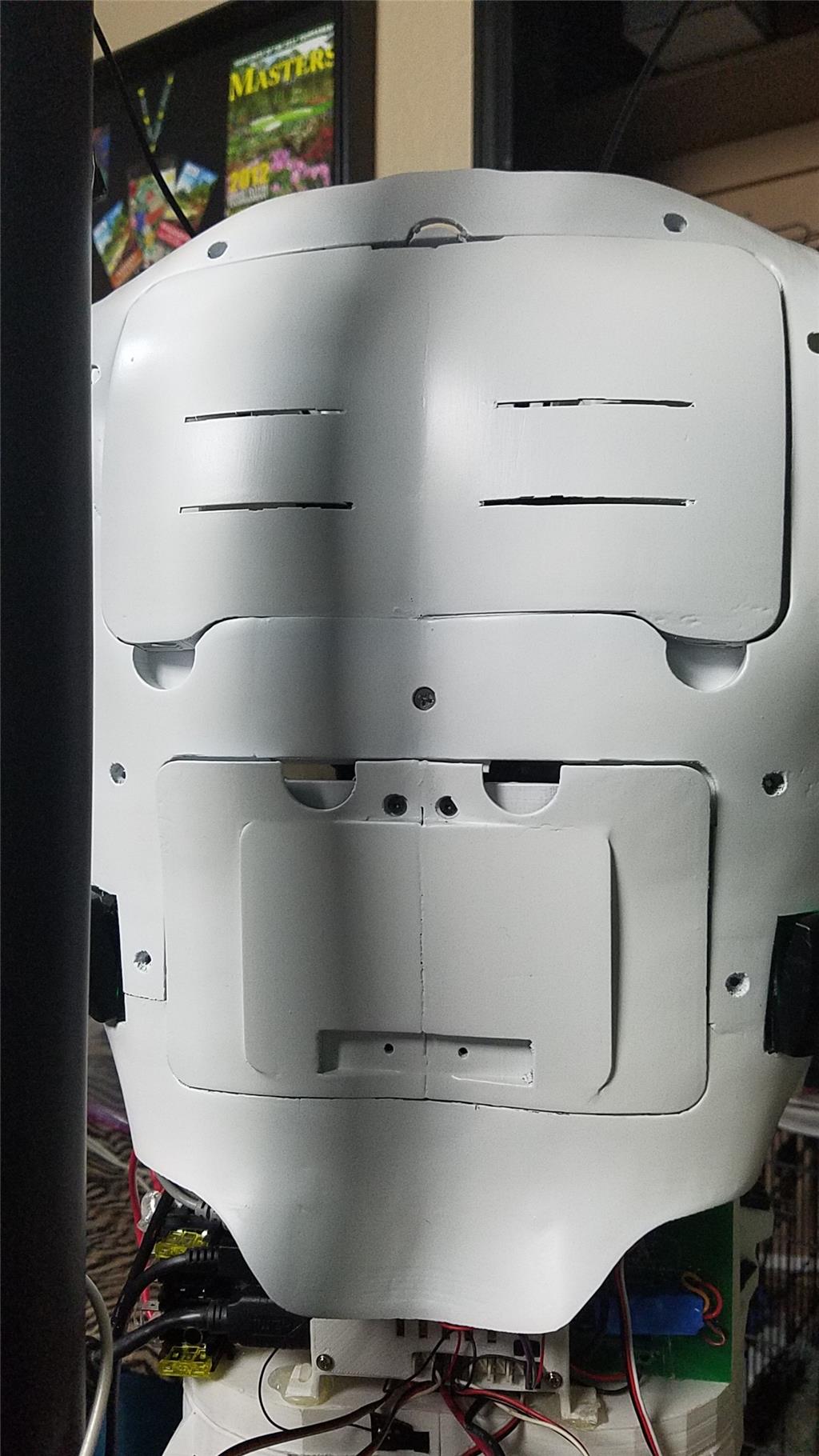

I am editing this post so as not to confuse people with the current configuration. I continue to update this post with the latest photos. If you are reading this for the first time, don't be confused. There have been a lot of changes to the InMoov over the past couple of years including starting over.

https://synthiam.com/Community/Questions/7398&page=21 Post 203 starts the rebuild of the InMoov.

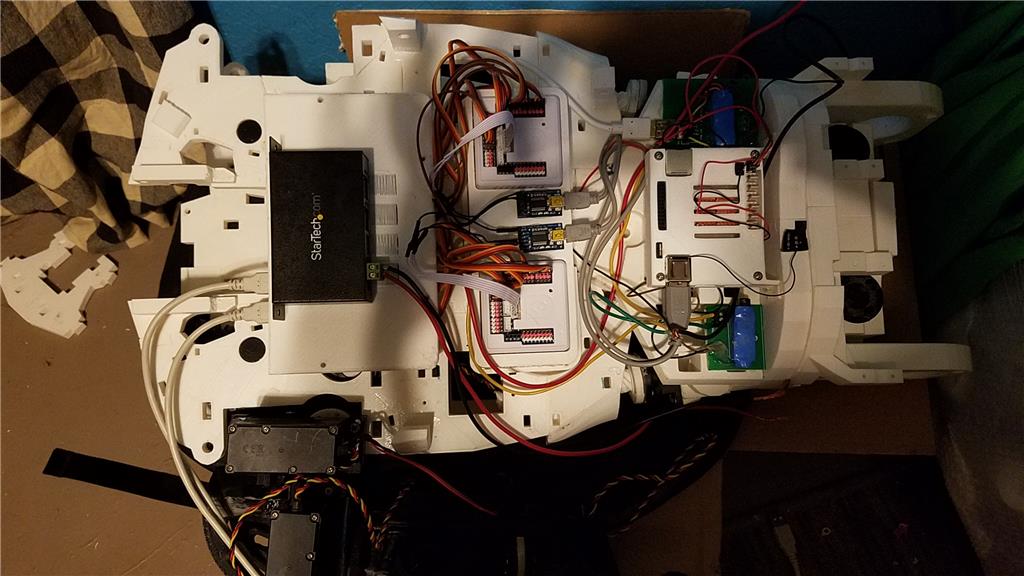

I have decided to use an onboard computer. I chose the Latte Panda due to it having an onboard arduino Leonardo and also because it uses little power.

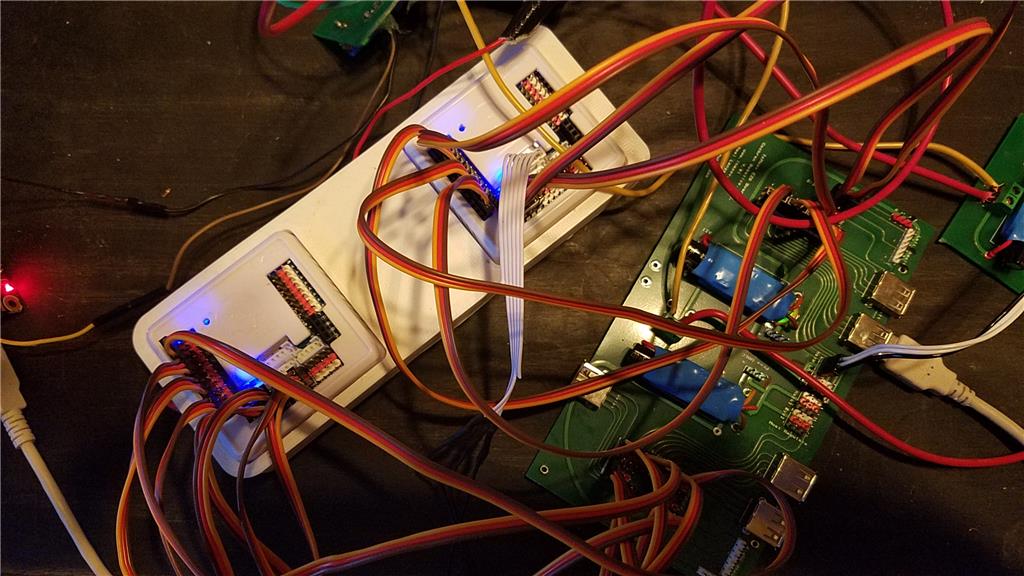

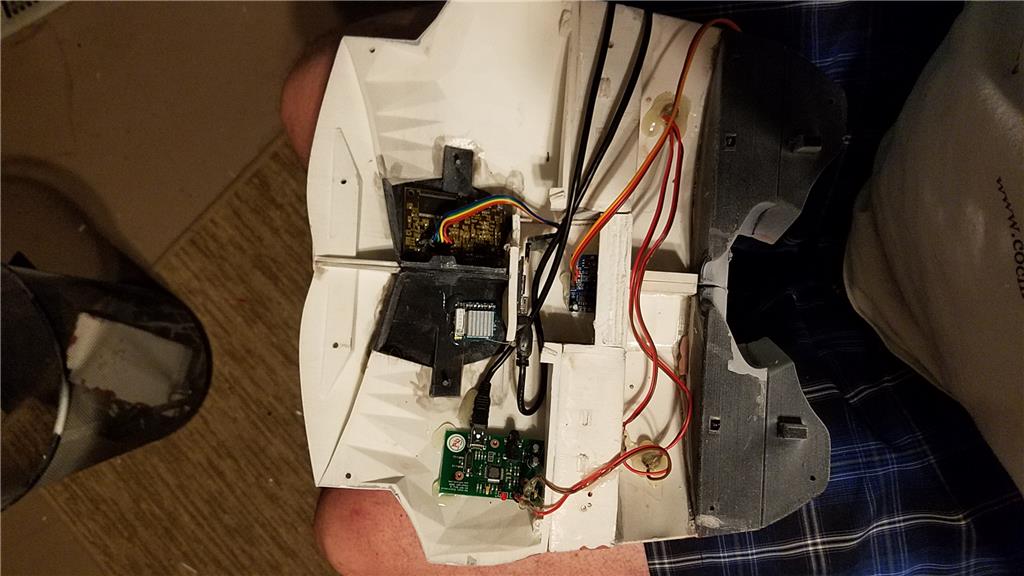

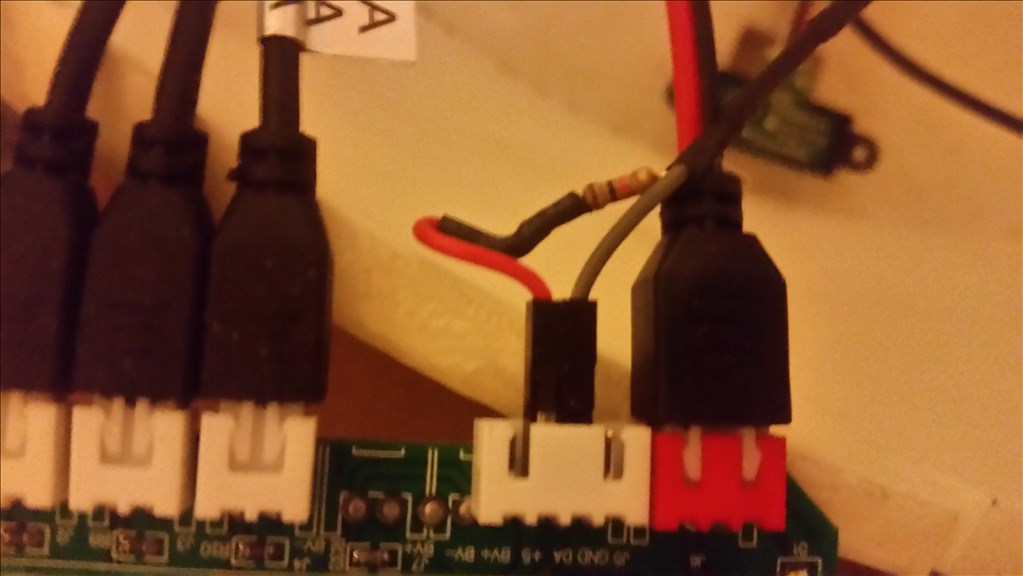

I used 2 EZ-B controllers connected via the camera port to Adafruit FTDI friend boards. This allows the Latte Panda to have a non-wifi dependent connection to the EZ-B's. I use a powered USB hub connected to the USB3 port on the Latte Panda to attach other items.

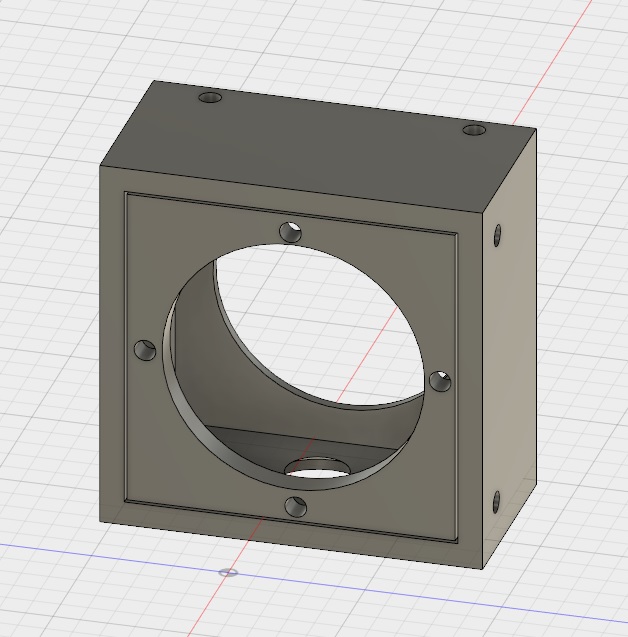

The Omron HVC-P is used to identify people, emotions, human bodies, hands, age and gender. It is attached to the Latte Panda via an FTDI friend which is then connected to the powered USB hub. It is mounted in the chest of the InMoov. I also use a 3 element microphone which is a MXL AC-404 microphone. It is disassembled and the board and microphone elements are mounted in the chest of the InMoov. This mic board is connected to the Latte Panda via a usb cable which is attached to the powered USB hub. There is a USB camera in the eye of the InMoov which is connected to the Latte Panda via the powered USB hub.

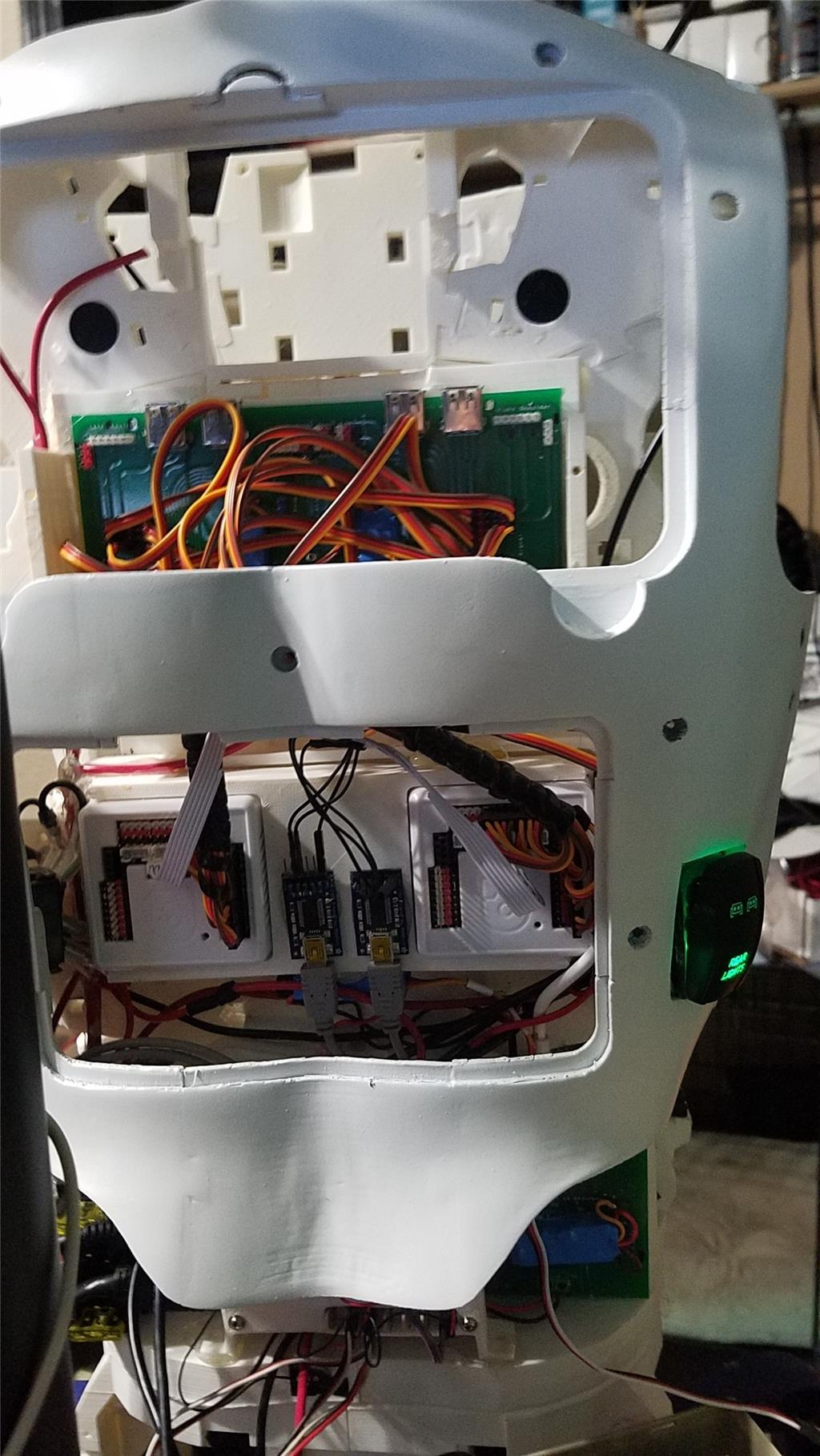

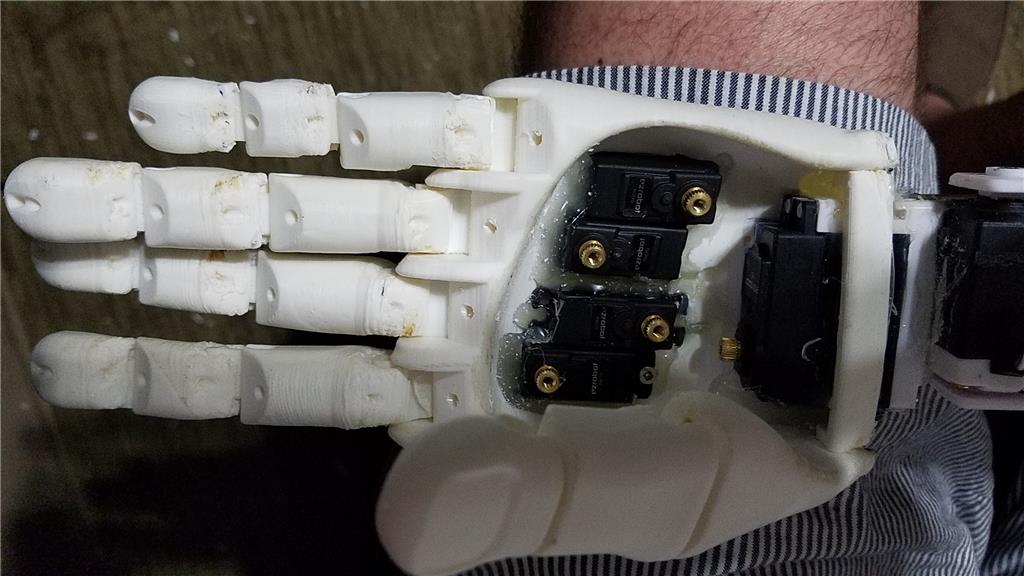

I chose to use the Flexy hand with the InMoov. The design is far more rugged than the original hand and works very well. There are 4 EZ-Robot Micro Servos in the palm of each hand which controls the main fingers. The thumb is controlled by an EZ-Robot HD servo. The wrist waves and uses an EZ-Robot HD servo to do this motion. I use the standard Rotational wrist.

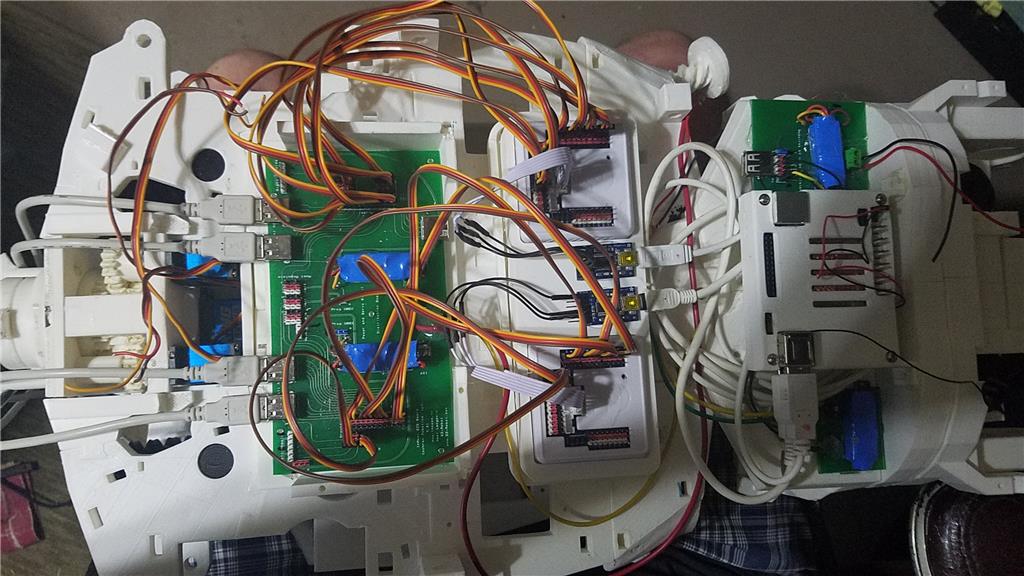

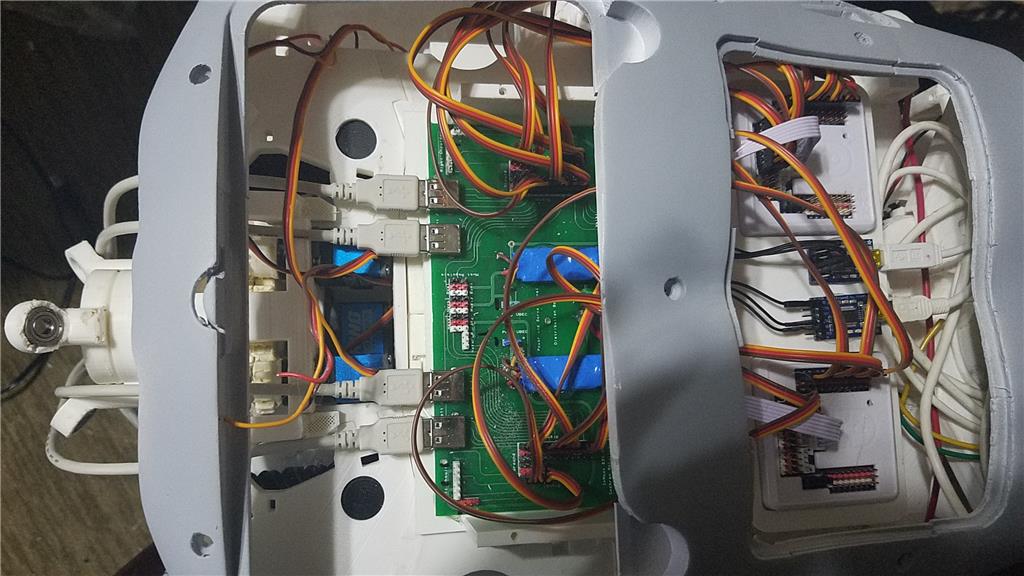

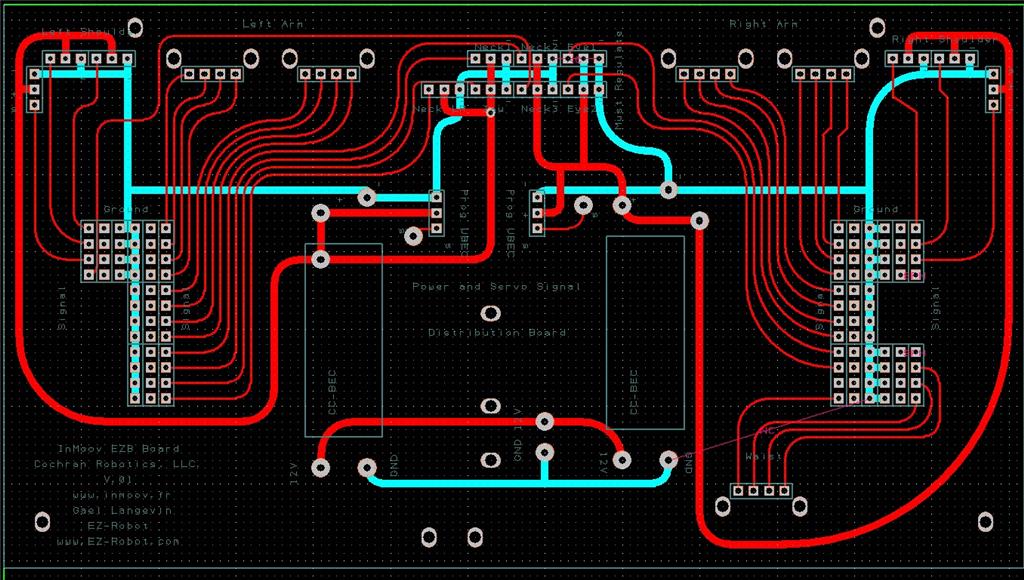

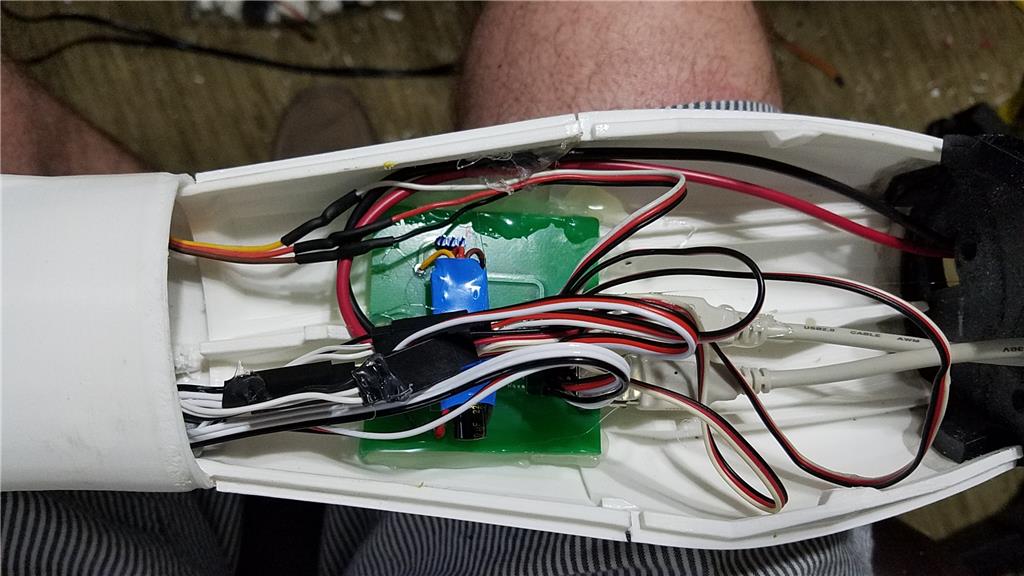

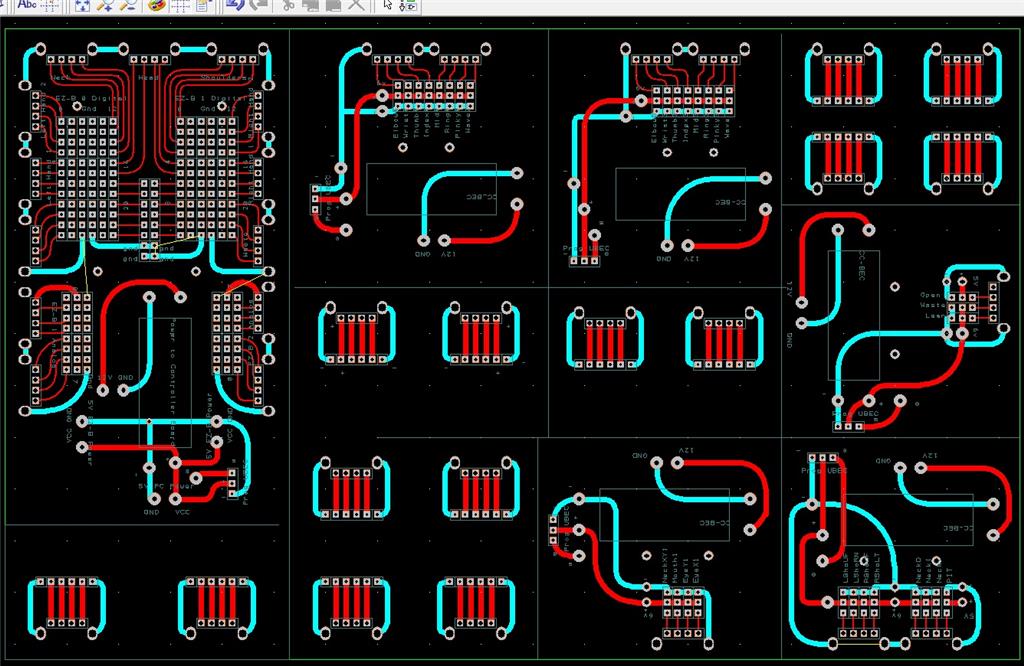

I have castle BEC's for power in the following locations set to the following voltages. Forearm's - 6.2 V - Controls fingers, wrist and elbows Custom power distribution board (2) set to 6.2 V controlling head, neck and Shoulder servos. EZ-B's - set to 6.1 V - it is mounted in the controller mounting plate and connects to the EZ-B fused power boards from a power base. Latte Panda - Set to 5.1 V and is mounted to the EZ-B controller mounting plate. Waist - set to 6.2 V and is mounted in the lower right side of the back. This provides power to the lean and pivot waist motors..

There are some custom power and signal distribution boards. These are in the forearms, lower back and in the upper back. The upper back or main board connects to these distribution points via USB cables to provide signal to the other boards for servos. The main board also has servo connector pins that are for the neck, head and shoulders. This allows the power to be distributed between multiple BEC's and also allows the servo signal cables to be shorter and more protected via the USB cables.

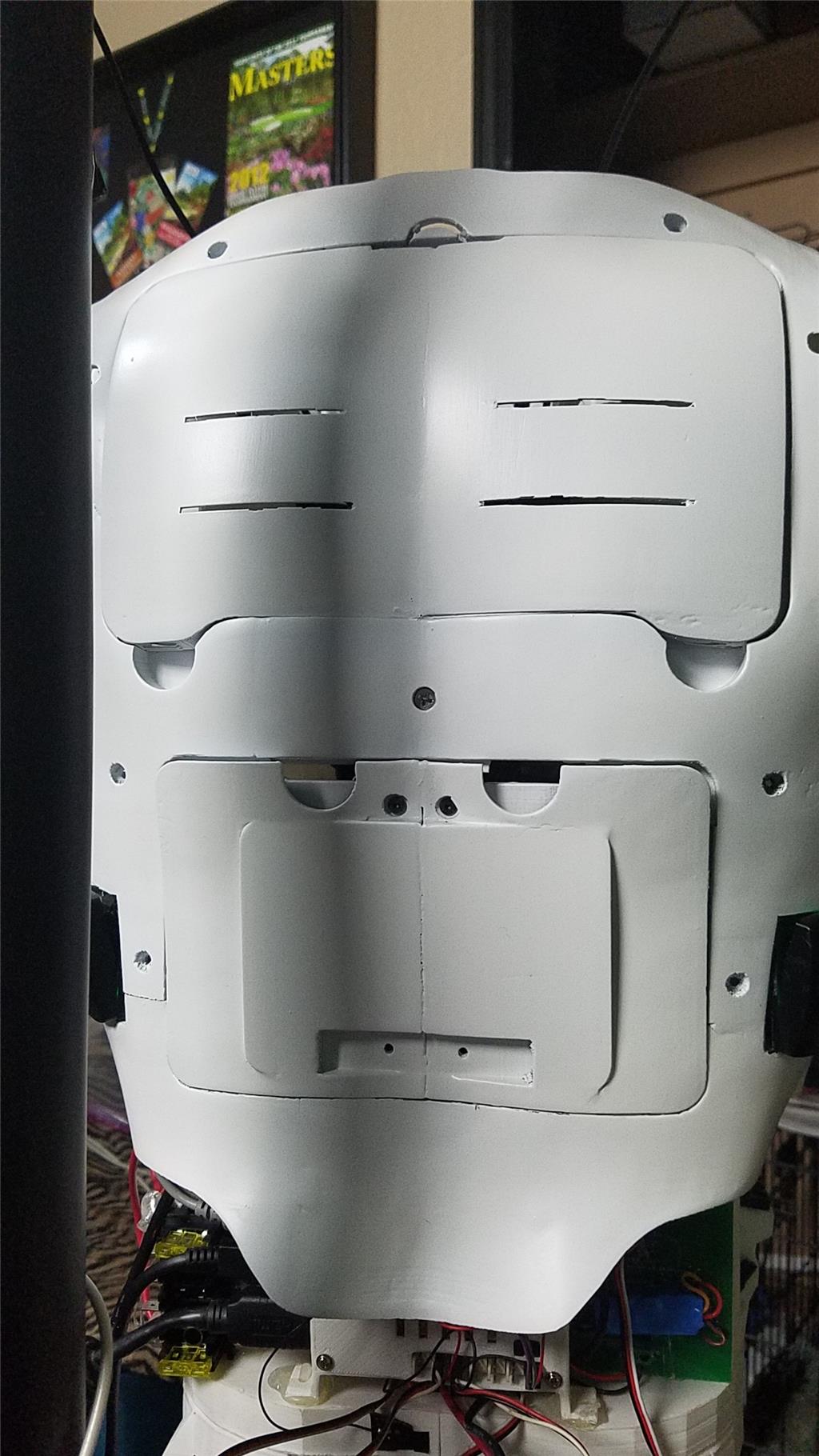

For power I use a LiFePo4 battery that is rated at 30 amps. It has the balanced charging circuit built into the battery and also has a low voltage shutoff built into the battery. This protects the battery and allows the battery to be charged with standard car chargers.

I put switches on the back on the InMoov which are rated at 20 amps at 12 volts. These are rocker switches that allow the user to pretty much slap the switch to turn it off. There are two of these switches. The servos for the elbows and fingers are on one switch. The latte panda, neck, shoulders, EZ-B's, waist motors and some lighting is on the other switch.

I also added a fuse block. This allows 20 amp fuses to be put in line to help protect things. The switches above drive the fuses for each of of the motors listed in that section.

Other robots from Synthiam community

DJ's Robophilo

Moviemaker's Latest On Sally

-636348381130562972.jpg)

-636348716348649435.jpg)

Bob,

Yes, I had tried to print those out about 2 years ago and they didnt print well at all. I have different printers and am using simplify3d since then so I will try them again.

CEM

My printers live in my garage. I use half of the garage as a workshop. With all of the sanding I had done and the nature of a garage in general, it gets pretty dusty. Its not the prime place for 3D printers.

Other than a really good cleaning and re-greasing, I take the extruders apart and clean any filiment shavings from the gears and feed paths. If i skip this step too often then feeding of the filiment gets inconsistant. I also clean the build plate by using a razor blade to get rid of any high points that have been caused by something getting on the back of the glass build plate without me noticing before clamping it down to the build plate. I do the same to the back of the glass build plate and relevel the build plate.

One printer had started to feed inconsistantly and the other had a nozzel cloug that was minor, but was enough to stop printing.

Ron,

Thanks. I hope to finish up the build this weekend and continue on the project next week on the ARC side.

In total, it should take me about 3 months to complete the rebuild. I had hoped for 2 but 3 makes the deadline that I had. The head is much better, but wont look as good as the chest until after the show, but it looks a lot better than the head that I had.

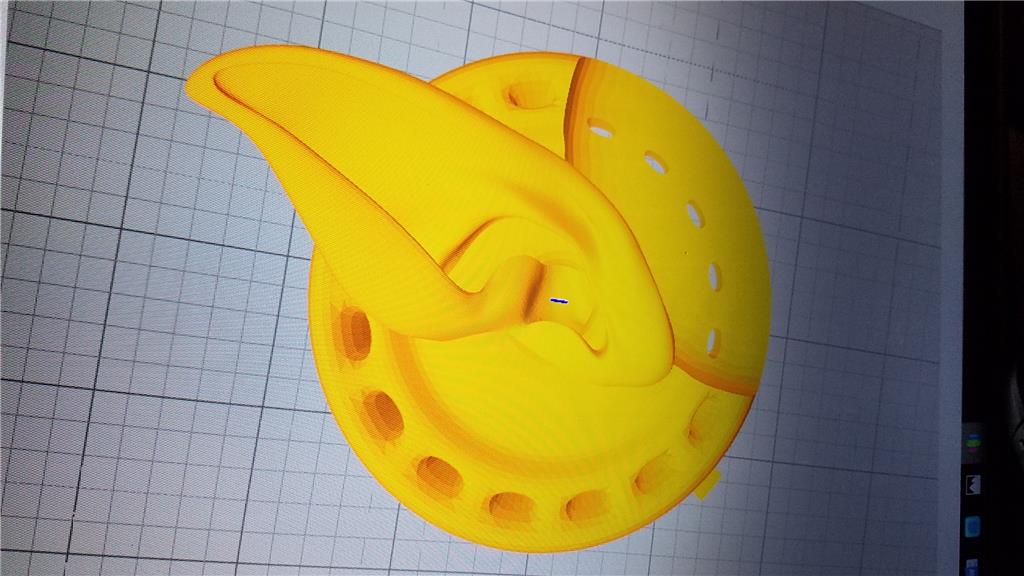

The STL on thingiverse is still junk. It is just a 3d scan of an object and as such is just a shell and not a solid object. I took a couple of good stl's and am merging them. Seeing how it prints now.

I am sure it will be a hit at the show. It should draw a lot of attention. I hope the ears work out. It would be a nice addition. If not, a future update. I hear your next project will be a " TRICORDER" for him. Don't forget "LIVE LONG AND PROSPER"

https://www.myminifactory.com/object/star-trek-phaser-type-2-from-the-next-gen-movies-in-two-pieces-11008

I had thought about making him one of these.

Yeah.. He needs one. Now that the printers are all set to go, might as well do it. It would be cool for him to pick it up if the need comes up. Don't forget to have him do Mind Melds. He has the hands for it. Lol.

I marvel at your build, but I'm blown away by your energy level! You must drink from the same fountain as Will (Huff).

Very inspirational.

Thanks for the kind words.

The ears are almost complete and they have been printing nicely. I printing at 100 microns because sanding would be a pain at best.

Ears worked out well.