By cliffordkoperski

— Last update

Other robots from Synthiam community

Steve's Navigation Test Robot With Intel Realsense T265

Navigate an iRobot Create using Intel RealSense T265 and EZB with Synthiam ARC for reliable visual tracking navigation...

DJ's The Real Wall-E

Real-life Wall-E built with EZ-B Robot Kit uses camera, servos and voice to track motion, color and faces and react with...

Waynea's Tall Tower Light Controller - Ezb V4

Monitor 19 broadcast tower strobe lights remotely with EZ-B v4-easy relay integration, fault signaling and simple alerts...

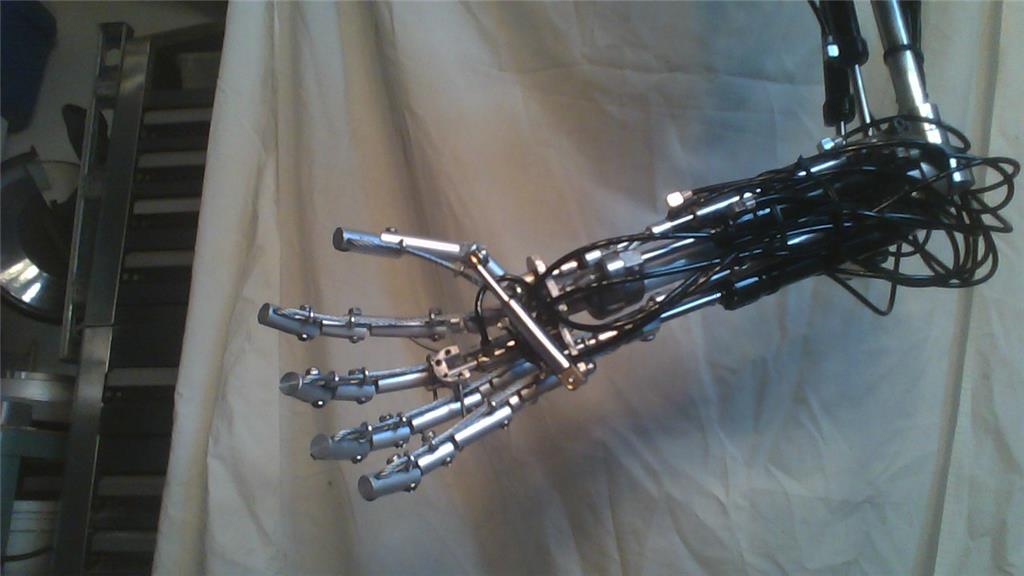

Holy crap! You win for best ezb project yet... If that is custom made you Sir "are a steely eyed missile man"... Outstanding!.... Please build the entire Terminator! inMoov who?

I agree with Richard. That is amazing! Odd how the linear actuators sound more like electric actuators. Is that the sound of the pump?

I have been thinking of using linear actuators for my "ultimate" robot, in some places, rather than servos. Seeing something like that in action has answered many of my questions on what sort of configuration would actually work out. Thanks so much for sharing the video. Please keep us informed of your progress.

Absolutely superb! great job thought he was flipping the bird for a moment there! (3:02)

thought he was flipping the bird for a moment there! (3:02)

Nice build! Can you provide some information on the systems components? Thanks, really impressive!

Sweet. I had considered going hydraulic or pneumatic for my B9 arm. I decided not to go this route due to problems figuring out speed, noise, liquid and delivery of the gas or liquid. Looks like you conquered these issues in a grand way. Very well done and very professional. It looks like you know what your doing here. I really hope your willing to share your design and how you overcame some of the blocks I had.

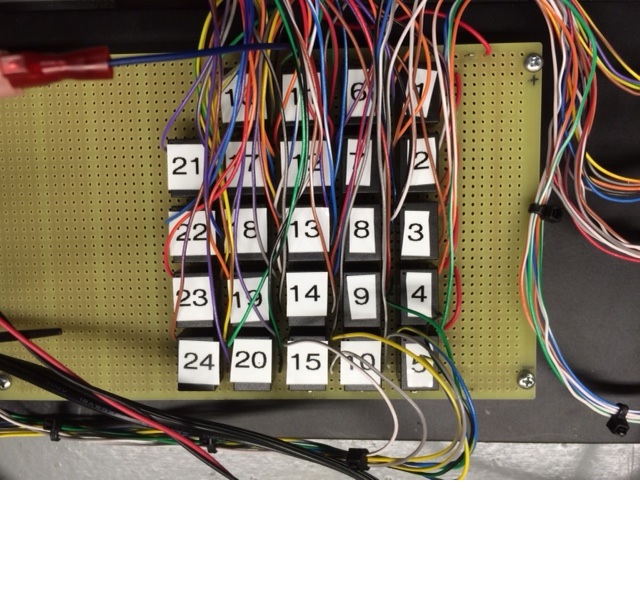

Thanks for the comments everyone I appreciate the interest. I don't wish to deceive anyone with the results of my project, so I'll just start by listing the negatives of the system. To begin hydraulics are messy the cylinders and actuator valves will drip oil after a few minutes of operation. Second there is currently no positional feed back available with the cylinders movement, actions are achieved by timing the pump with the valve. The actuator valve blocks hold three servos each, controlling three individual cylinders per valve block; eg. my arm has 13 cylinders so I have five valve blocks connected in series housing a total of 13 servos. The valves have two positions servo turns left 146 deg. cylinder goes down, servo turns right 30 deg. cylinder goes up. The pump has a brushless motor so servo control signals above 114 deg. makes pump go forward 180 being max speed and below 112 reverse. To make a frame you select what valve to open and a forward speed on your pump. To make an action you just delay each frame until there individual moves playout. On a positive note the cylinders are insanely powerful if you want something to move they'll do it. The entire arm was custom build by me, but I wasn't about to reinvent the wheel when it came to hydraulics. Valve blocks, pump and cylinders where purchased on rc4wd.com and you can find the same items they sell cheaper on alliexpress often from the main distributors in china. If anyone wants closer pictures of individual parts to compare online let me know.

I also forgot to mention this is just a proof of concept made of 6061 aluminum. I am presently tooling up to rebuild entire arm in 300 series stainless steel and will be replacing the shoulder with two 12v dc 30amp gear motors 35:1 ratio that are modified with potentiometer to work as a servo, this will provide a broader range of motion along with critical position feed back and greater strength. Electrical linear actuators from firgelli.com or LA 35 series from www.servocomponents.co.uk/ are strong considerations for replacing hydraulics all together. The goal completion date for this is a minimum 5 months.

@ cliffordkoperski Yeah, I would have used electric linear actuators as well had I done that. I have a real hydraulic system in the conversion RV in which I live. It used to be a mobile Lithotripter. It had about 40,000 lbs. of equipment in it. The only thing left is the hydraulic system. The leveling jacks are about 8 inches in diameter. The ones that bring in the walls are about 3" and there are 4 of them. Anyway it is going to be a bear to get the system working again, It used to run on 480 VAC 3 phase. Even had a 480V 3ph. generator on it at one time. Now I have to convert it to DC and batteries. Anyway, I can sympathize about leaky cylinders and other problems with hydraulic systems, large or small. I'd like to replace the wall cylinders with comparable electric ones, but that would be expensive. And there is no way to replace the leveling cylinders with electric.

Won't stainless steel be pretty heavy? Seems like it would be better to stick with aluminum.

I have gotten a couple of electric linear actuators from Progressive Automations and they did well for the applications I have. Recently, Ive noticed that Firgelli has a line of micro actuators that can be controlled directly from a PWM signal. They could be great for the fingers of a hand. The larger ones may be good for the arm. I'm going to order a couple to see what they're like. You can also get them through Robot Shop.

Keep up the great work and best of luck.