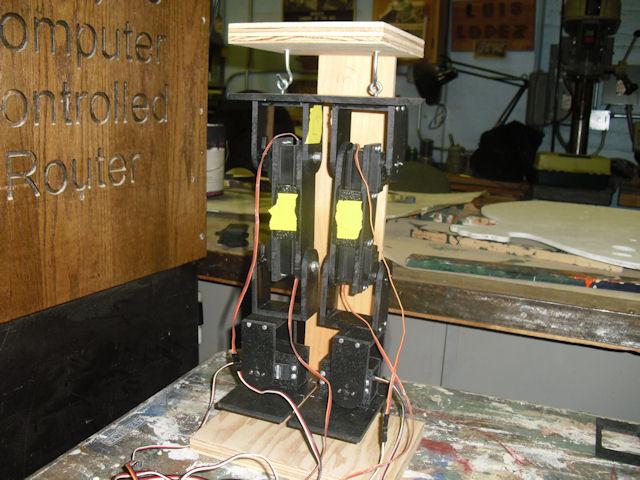

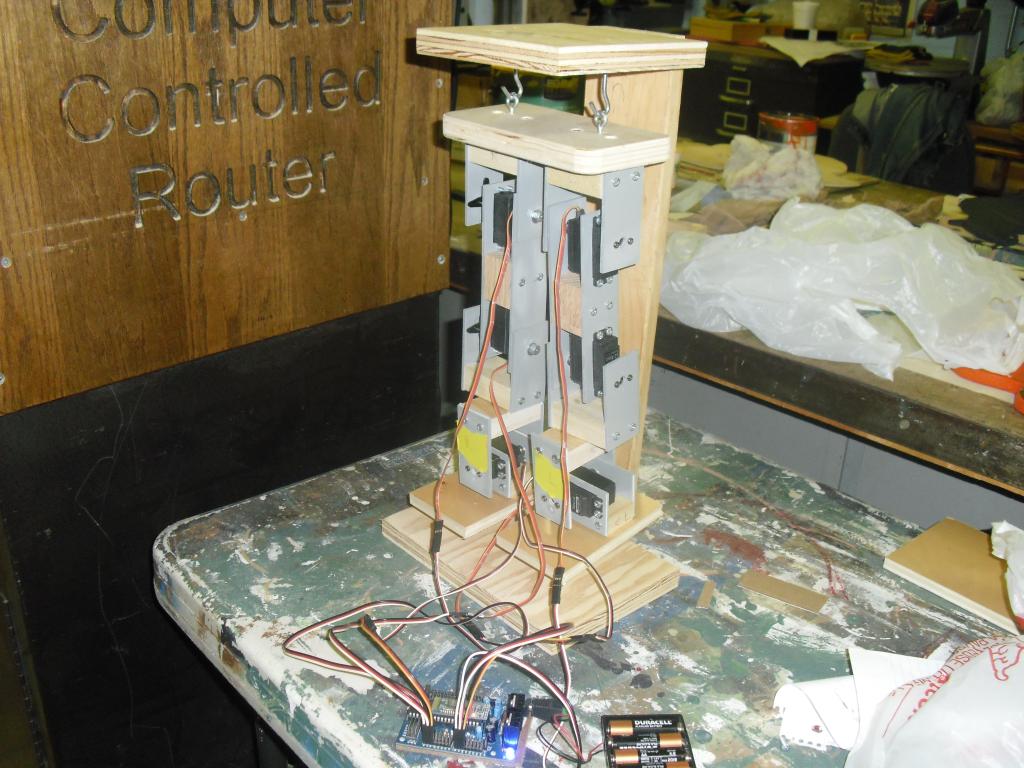

I built a biped robot but I found out that the servos that came with the EZ-Robot kit are not strong enough. The hip servos can't lift the legs up. Any suggestions for stronger servos?

By jeffmorris

— Last update

Other robots from Synthiam community

Cliffordkoperski's Cliff Robot

Cliff robot test run showing motion without gyro/accelerometer; future sensor demo planned; affordable Oak Studios servo...

Bhouston's Inmoov's Touch Sensors

Build DIY touch sensors for robots in Synthiam ARC using foil tape on an ADC port and simple scripting.

Ezang's My New And Improved Talk Servo

Enhanced ARC Talk Servo with Arduino Arc software for improved servo control and seamless Arduino integration

Amazing! your brackets for the biped are incredible !

Hey Jeff, that's really neat! You will need stronger servos for sure. I'm not certain what weight your assembly is... Are the brackets metal? You may consider making the brackets out of 2.5mm thick styrene or pexi glass/acrylic... A small digital weight scale will help you determine the difference between the materials.

As for the servos, we have heavy duty servos in our store - that have a strong lift.

Yes plexiglass is very light but plenty strong. Djs servos are pretty strong but you need to weight your robot to know what torque servos you need for sure. Also remember jeff high torque servos need a alternate powerv supply..

HI Jeff, Very Cool Biped Project ! My tronger servos suggestion for your project ;

Futaba, S3306 High-Torque 1/5 Scale ( analog )

Volts ;4.8V

Torque ;267 oz-in (19.2 kg/cm)

Speed ;0.20 sec/60

Volts ; 6.0V

Torque ; 333 oz-in. (24.0 kg/cm)

Speed ; 0.16 sec/60

Dimensions ;2-5/8 x 1-3/16 x 2-1/4 in (66 x 30 x 57 mm)

Weight ; 4-7/16 oz (126 g)

Or if you need regular size check this site ; https://www.futaba-rc.com/servos/analog.html

Thanks Michel

Hello Jeff... wow, very nice! I love the bench test hanger idea. Look forward to seeing more action shots once it gets it's hip replacement

Did you use the continuous rotation servos for the feet?

That servo is a 1/5 scale very large servo and 50 bucks each for a Analog. Either get djs futuba 160 oz in servos in the store for like 13 dollars or if you need more power pololu.com had power hd 1501mg which is 20 dollars but 240 oz in torque. Both of these servos are standard size therefore compact and are great performance for the money.

If you are ok with spending the extra 7 dollars a servo for 240 oz in (which with your setup I recommend because it weights more) then here is the next step up from djs high torque servo

https://www.pololu.com/catalog/product/1057

I love djs equipment but I also want you to have a right fit of equipment to your frame. Pull the servos off that come with the kit and keep them for your next project . Afterall they are great servos

Michael, I need standard-size servos. Gunner, I didn't use the continuous rotation servos. I used two extra servos that came from BASIC Stamp kit. I found out that HobbyPartz store has cheaper prices on servos but I'm not sure if their servos are good or junk.