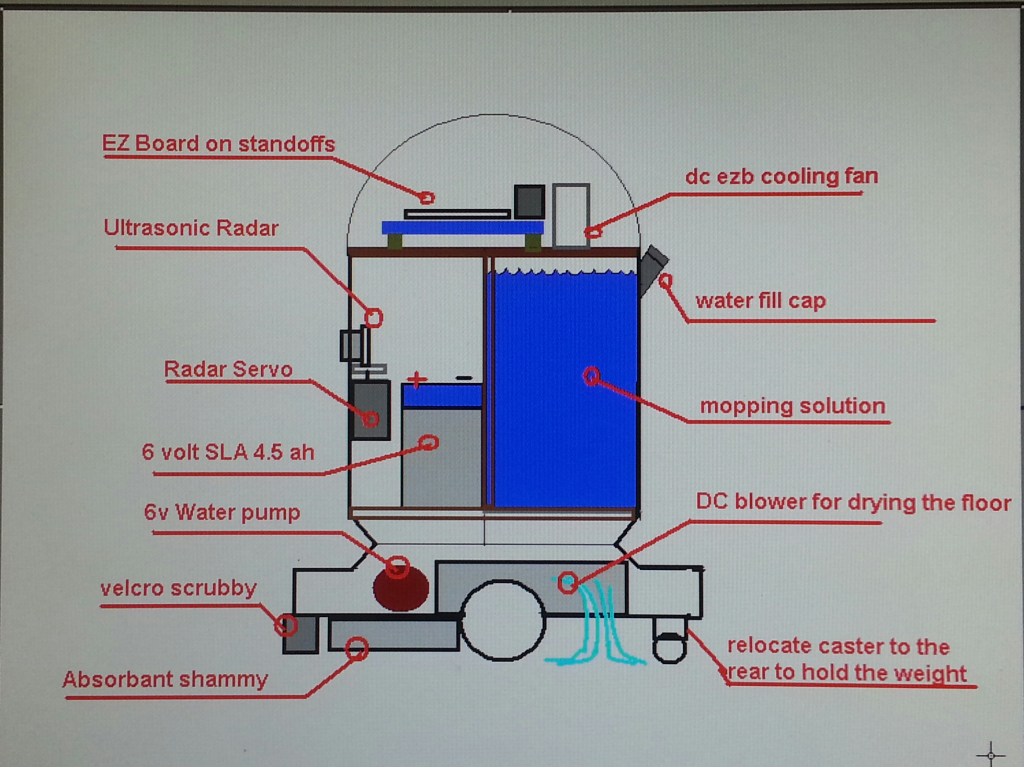

This is a simple project that hopefully I wont over complicate. Since he Squeegee needs to get as close to furniture and the toilet and bathtub as possible this my be a challenge. After all we spend most our time trying to get our robots to avoid the objects in the room. Im giving new life to a radioshack robie jr rc controlled robot.

By jstarne1

— Last update

Other robots from Synthiam community

Ezang's Life Is Like A Tight Rope, Do You Agree?

Tight rope robot squeaking by once again, enjoy

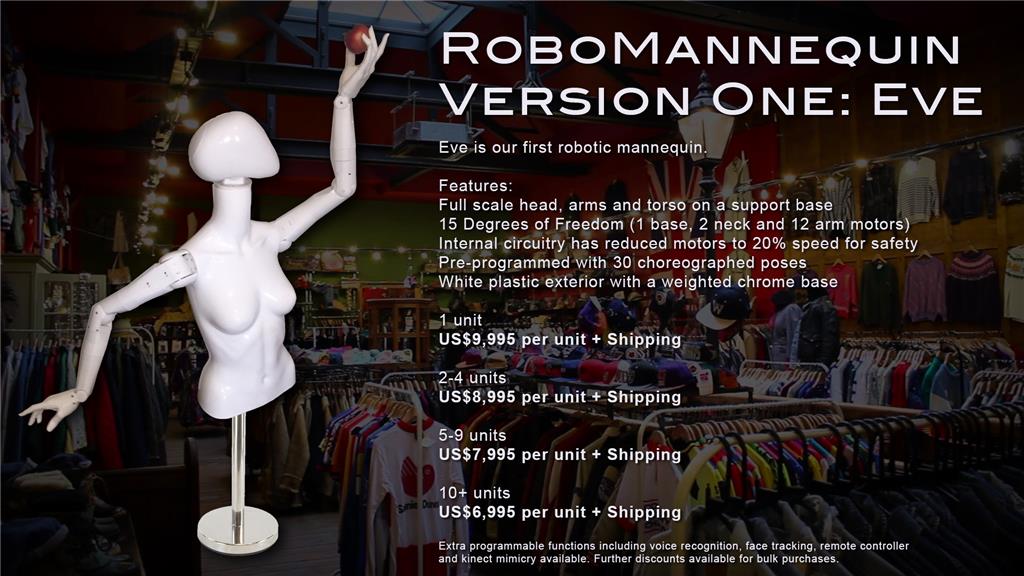

Zxen's My First Robot: Eve

Robomannequin Eve: She's my first.

DJ's Vision Tracking Robot

EZ-B Vision color-tracking test robot by DJ Sures tracks and follows colored objects with a camera head; modified toy...

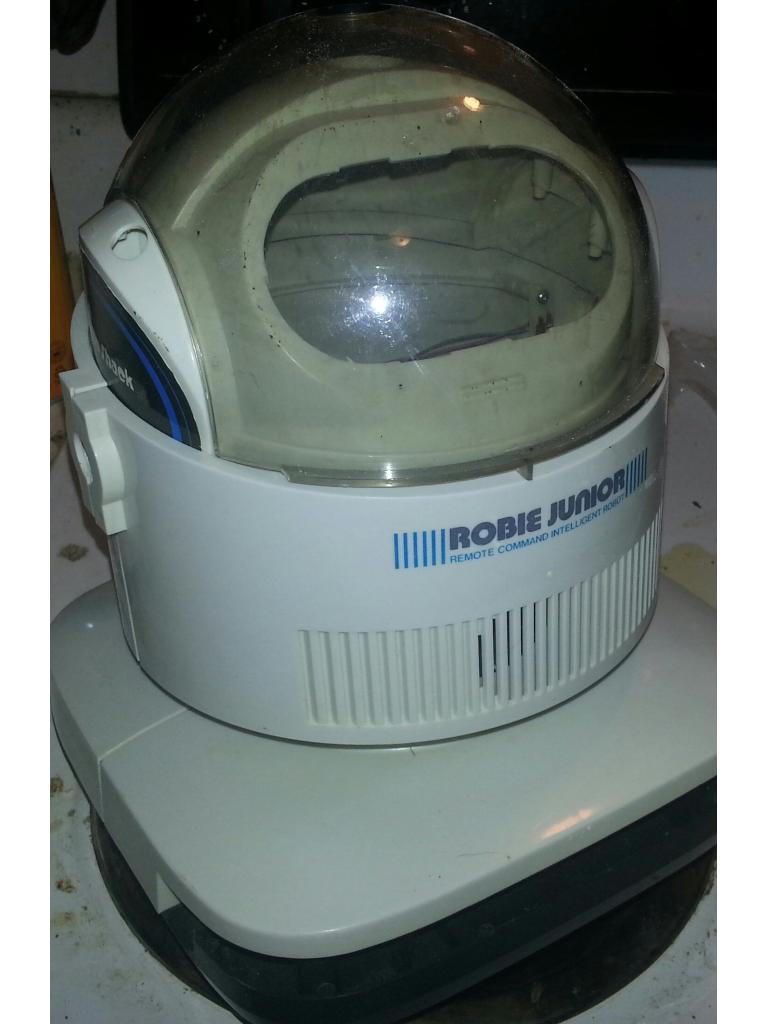

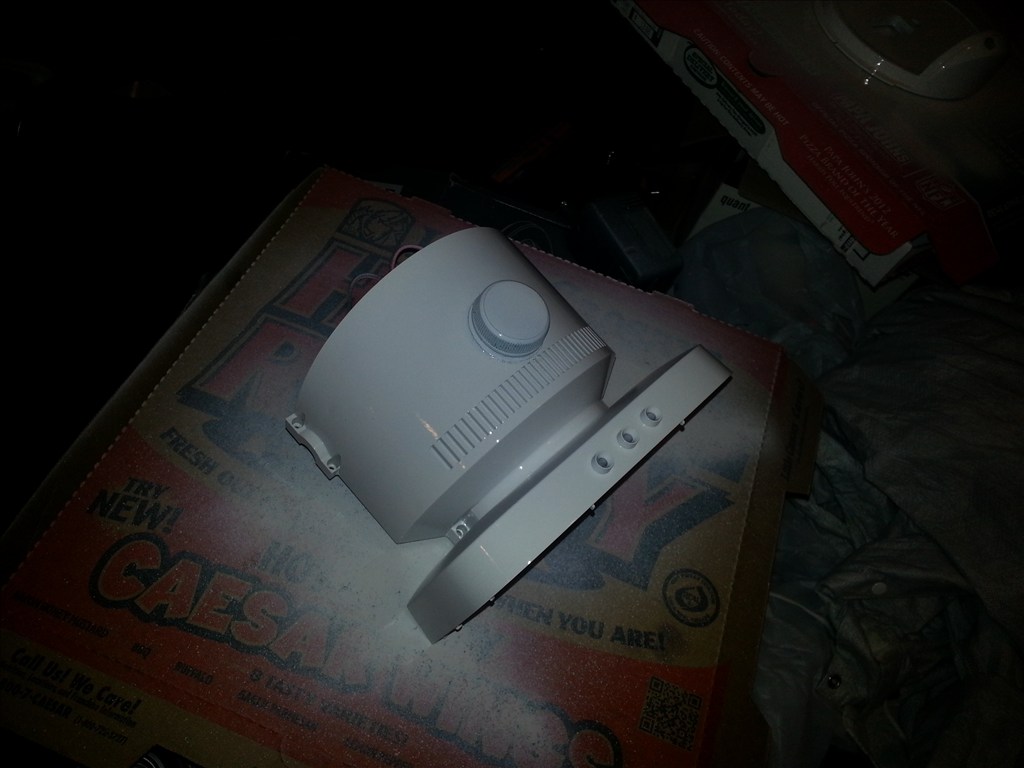

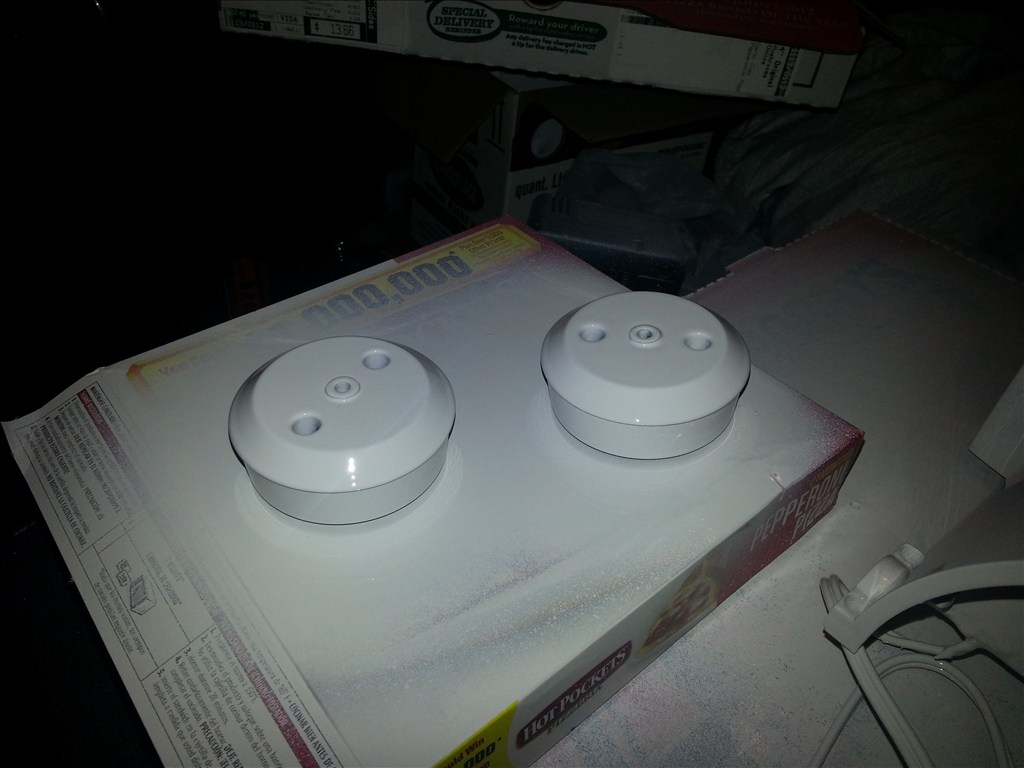

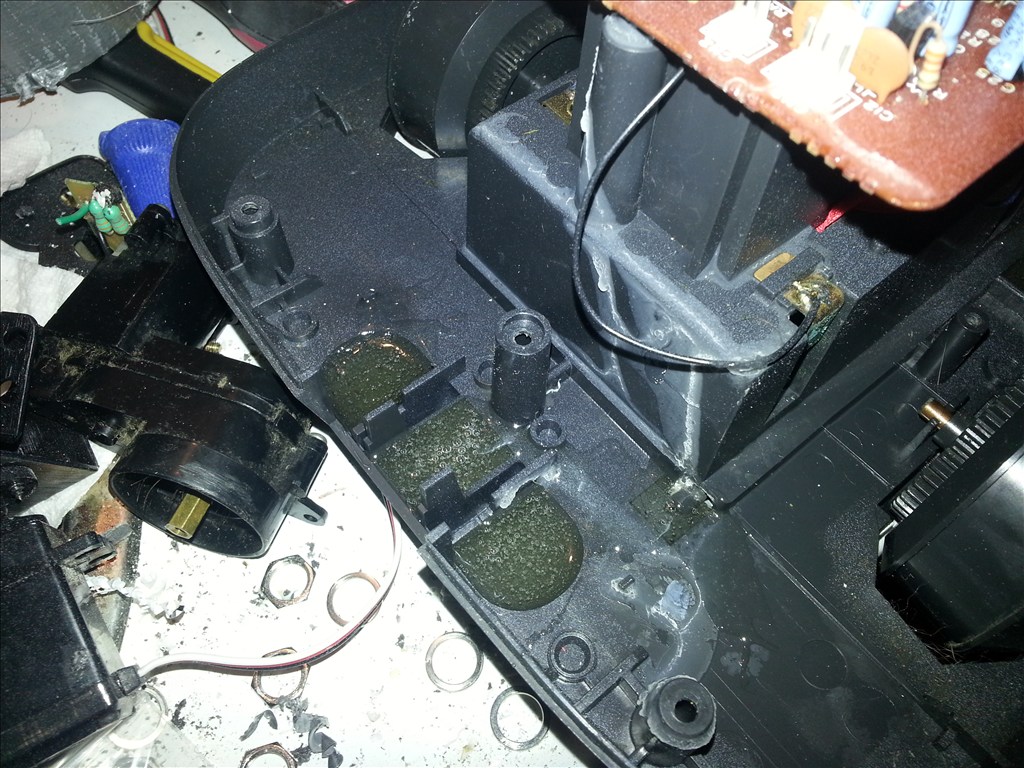

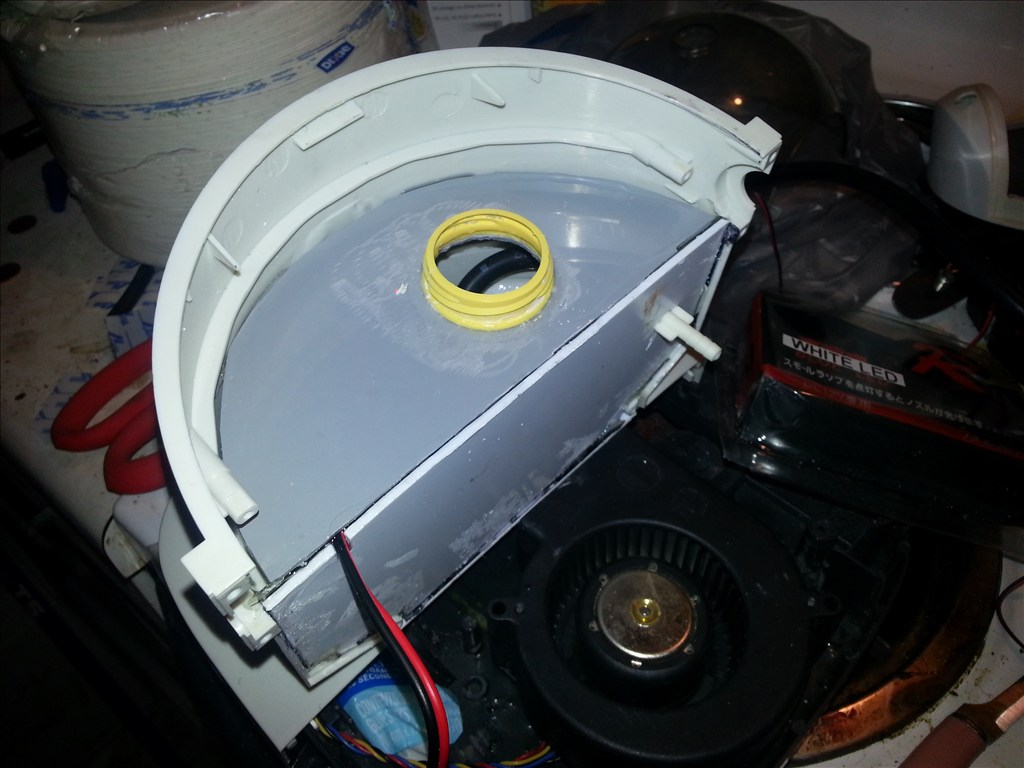

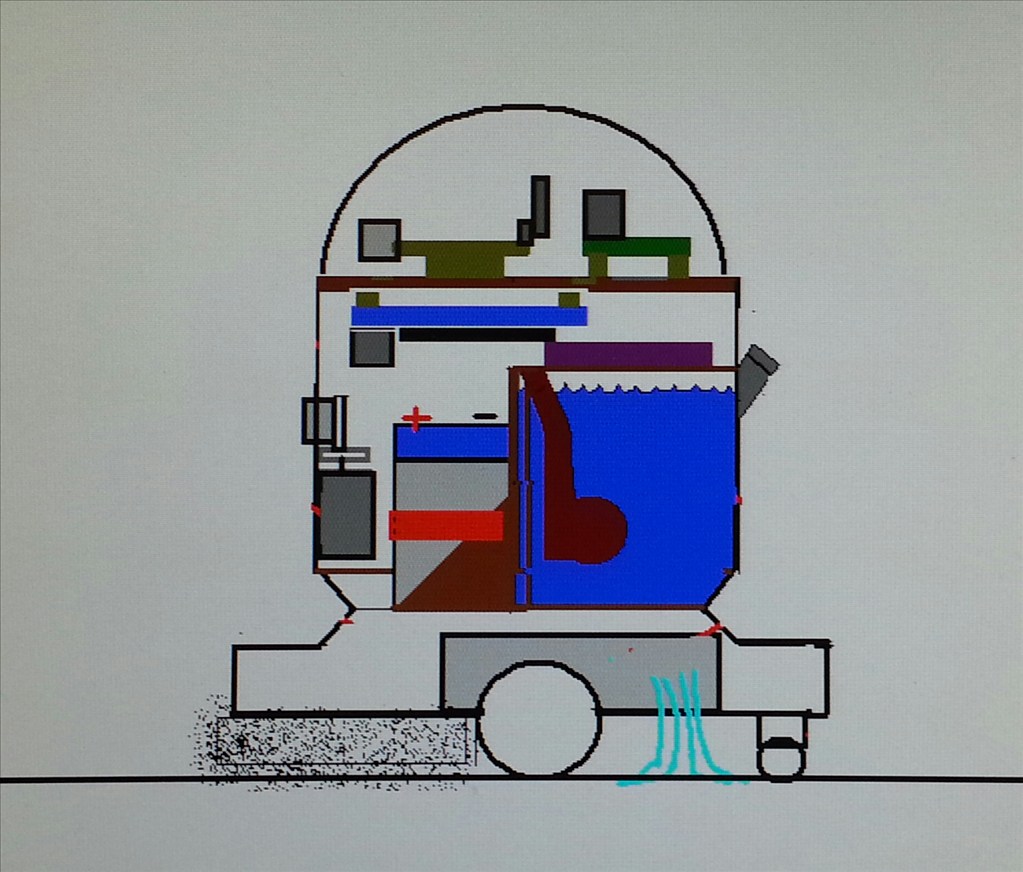

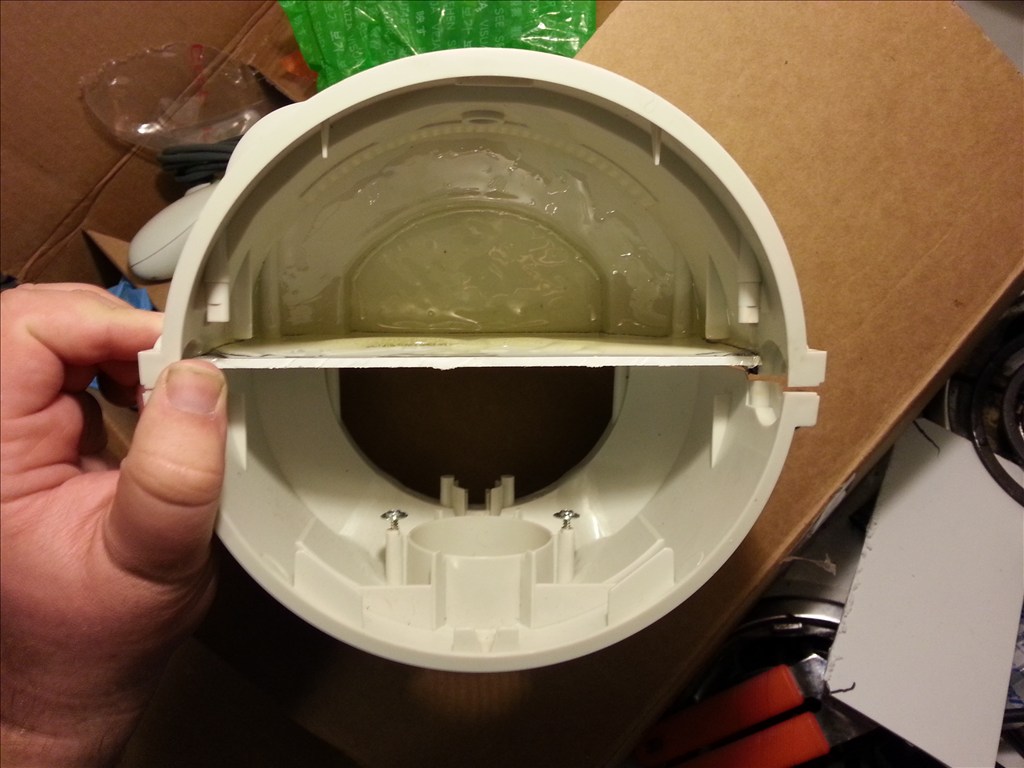

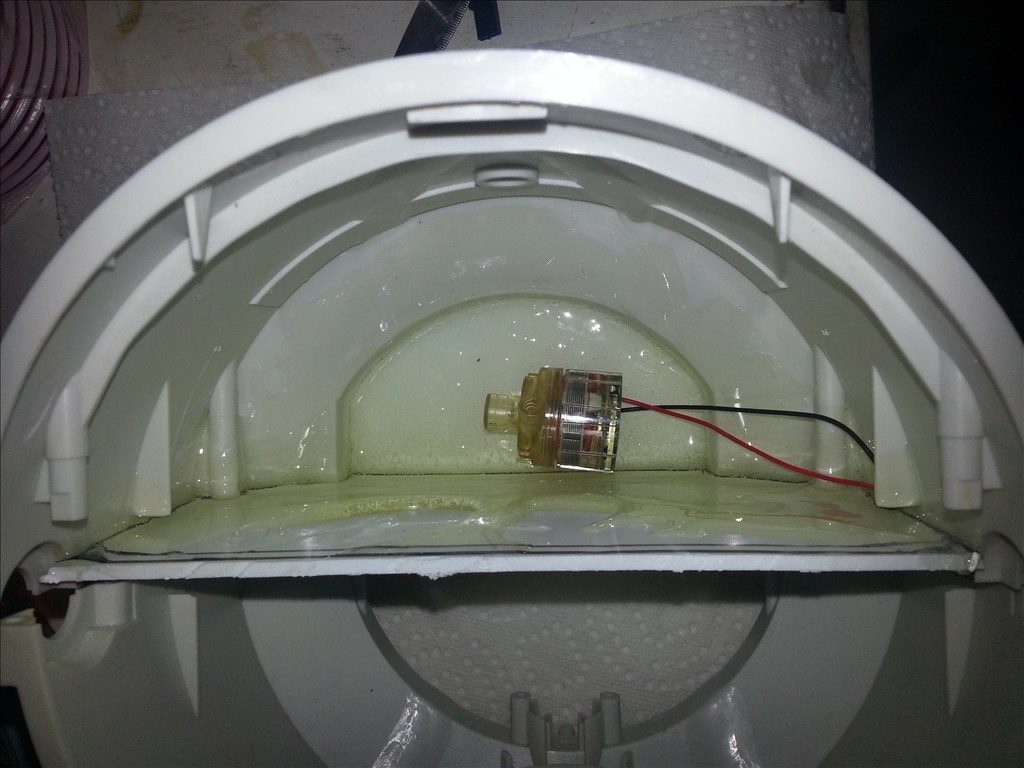

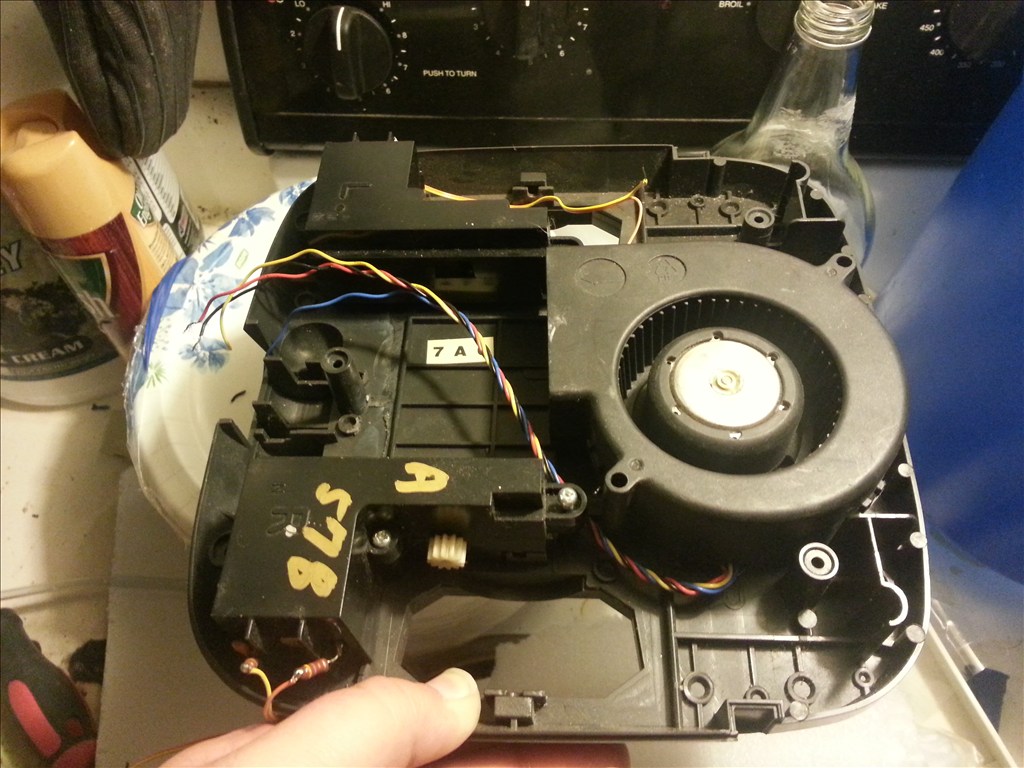

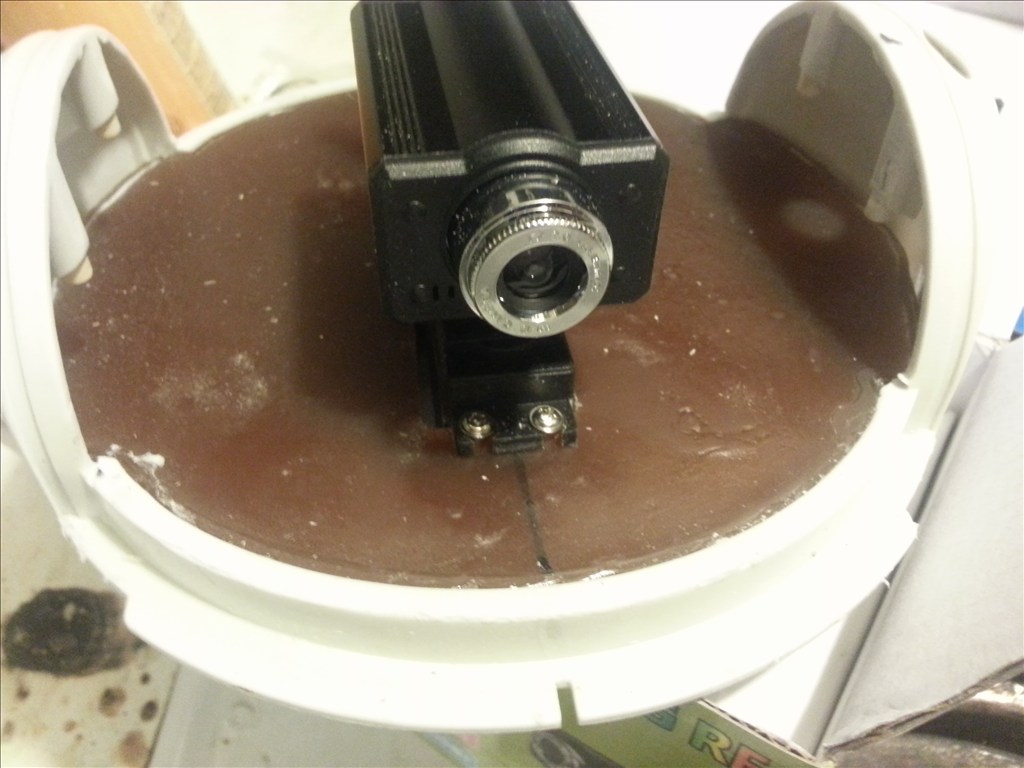

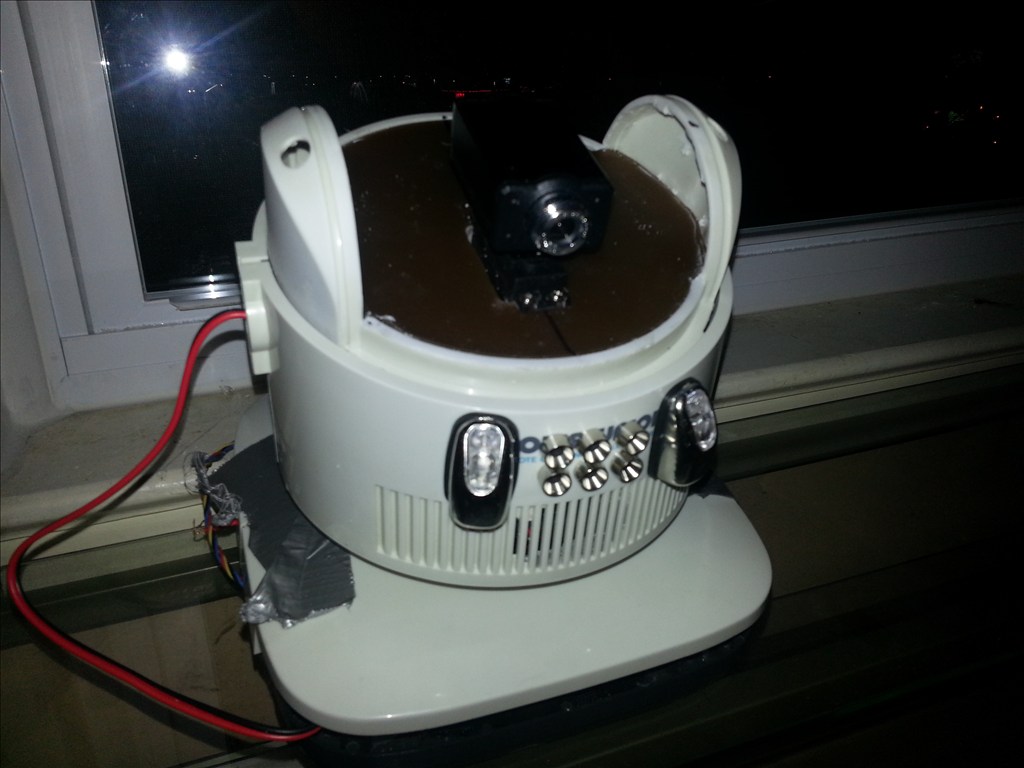

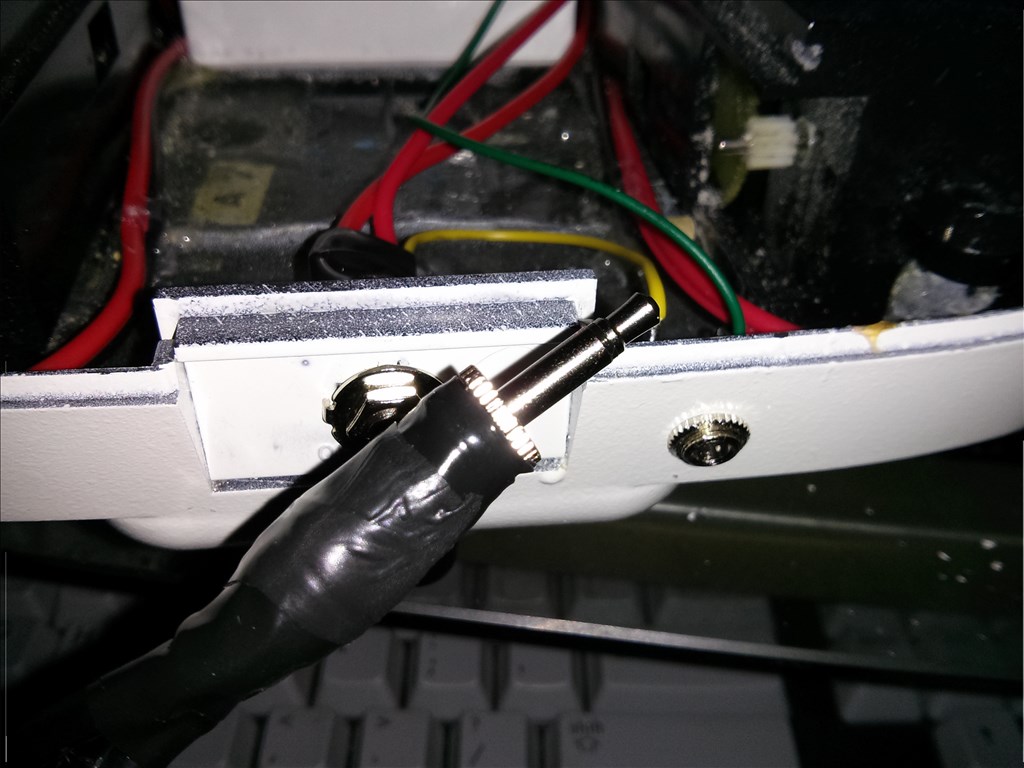

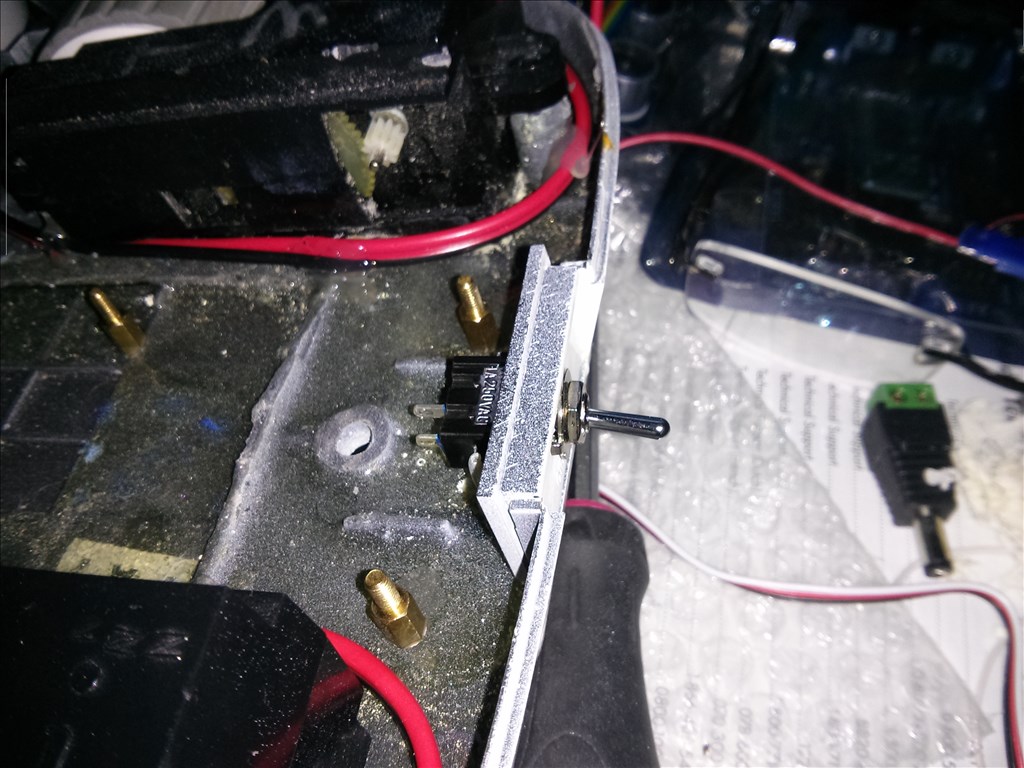

Ok first we need to see what we are working with..... I took the robot apart and removed most electronics and ran it through the dish washer. Now the robot looks very clean. I would like every ones opinion if I should use the dome or not.

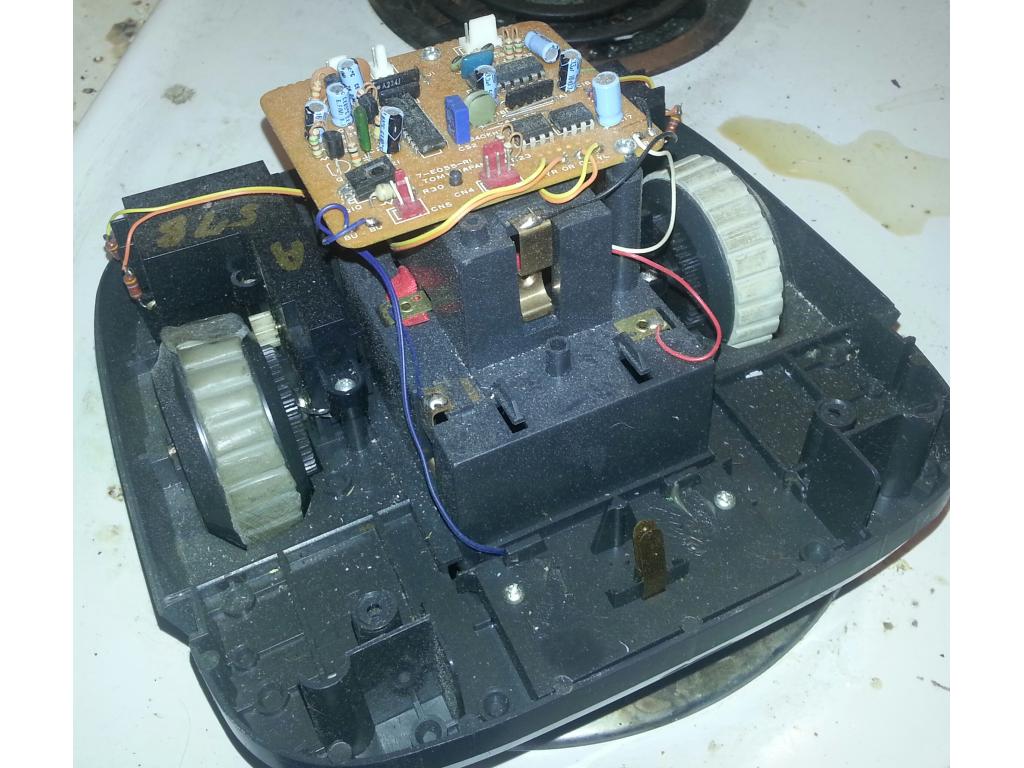

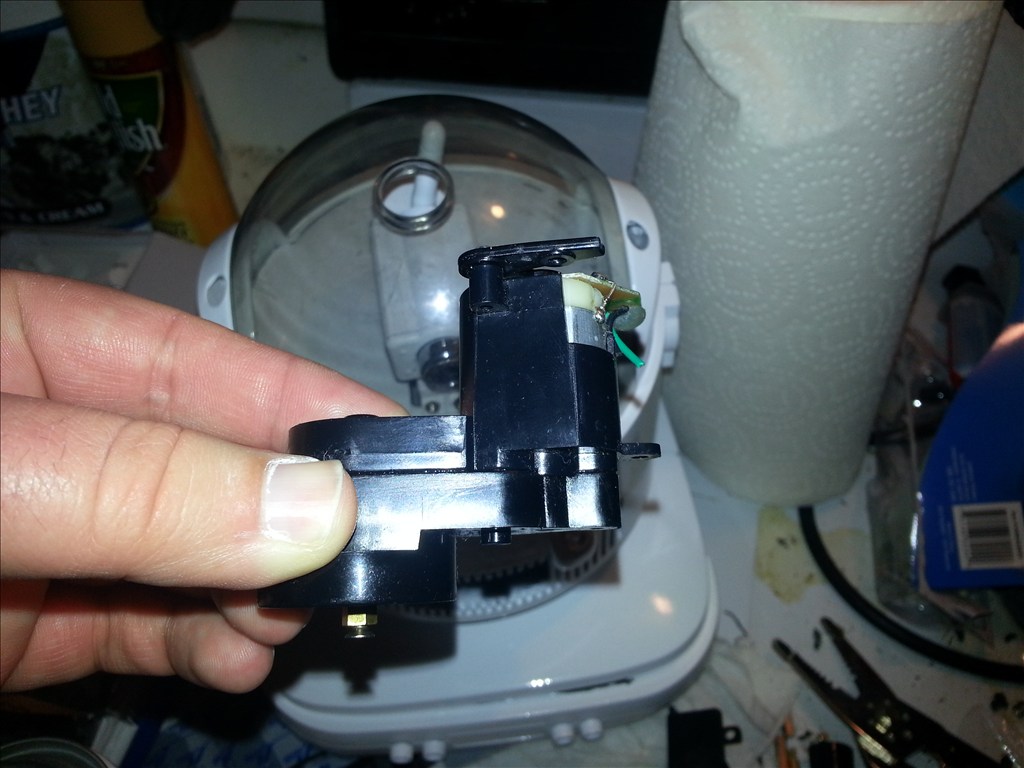

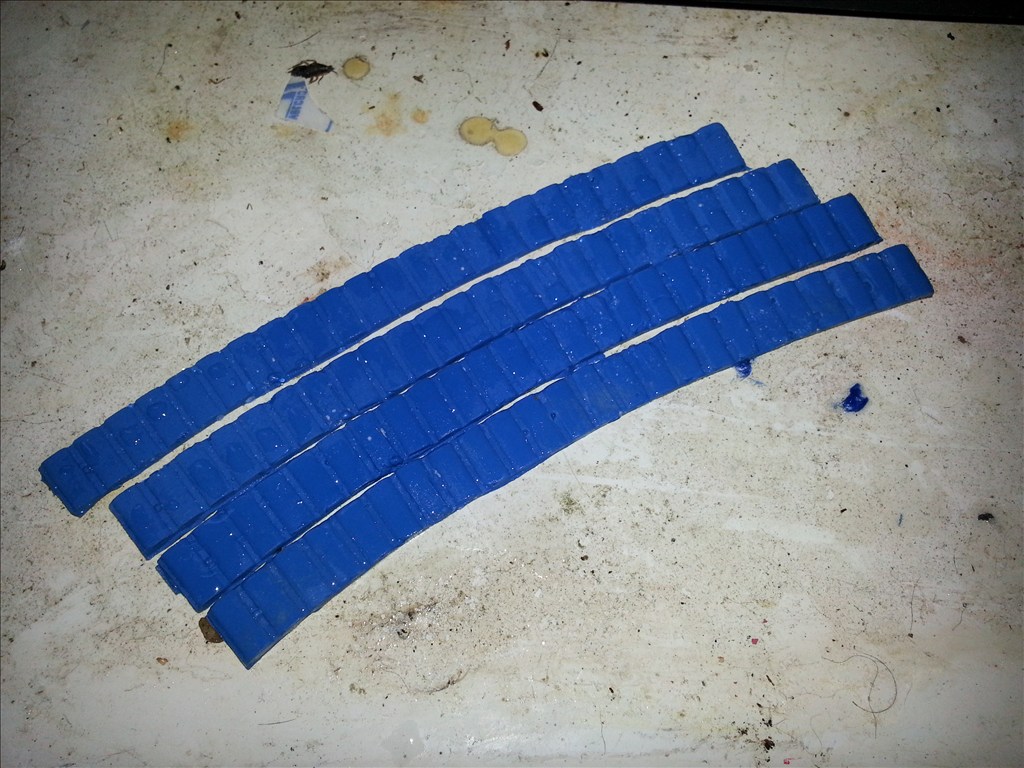

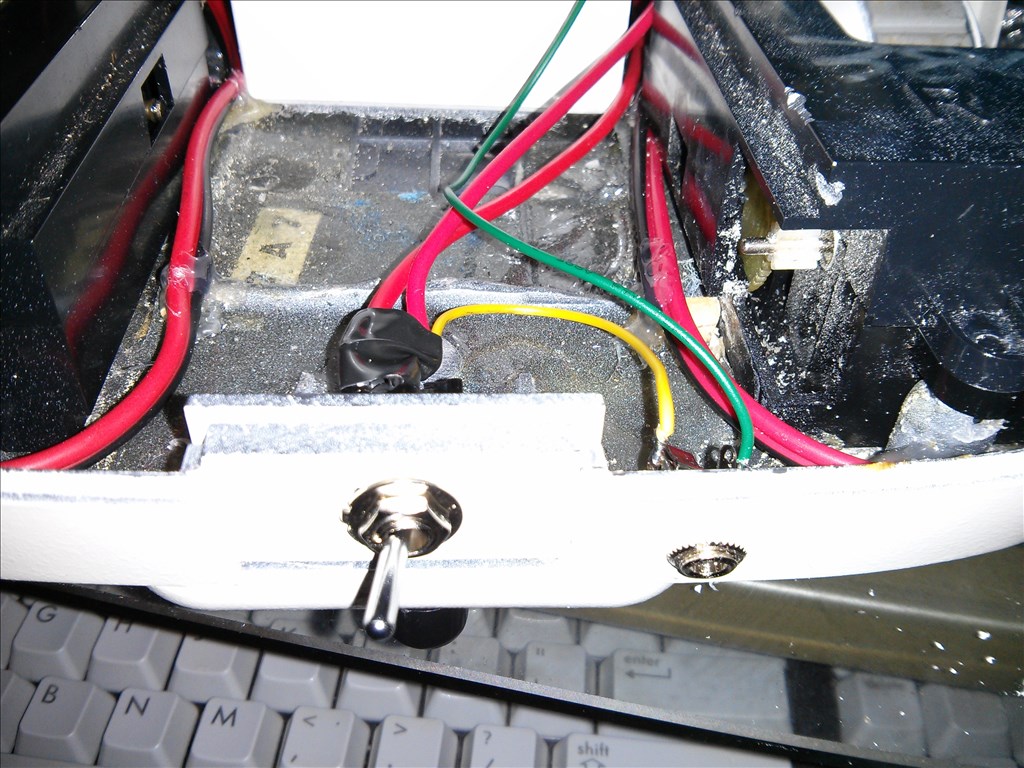

I have a small problem , one wheel has damage to the rubber. I am going to consider using continuous rotation servos and the tires with them. Well see if I can work my magic and make these wheels work. Somthing very important is that the drive train is quiet as this is really not a entertainment robot.

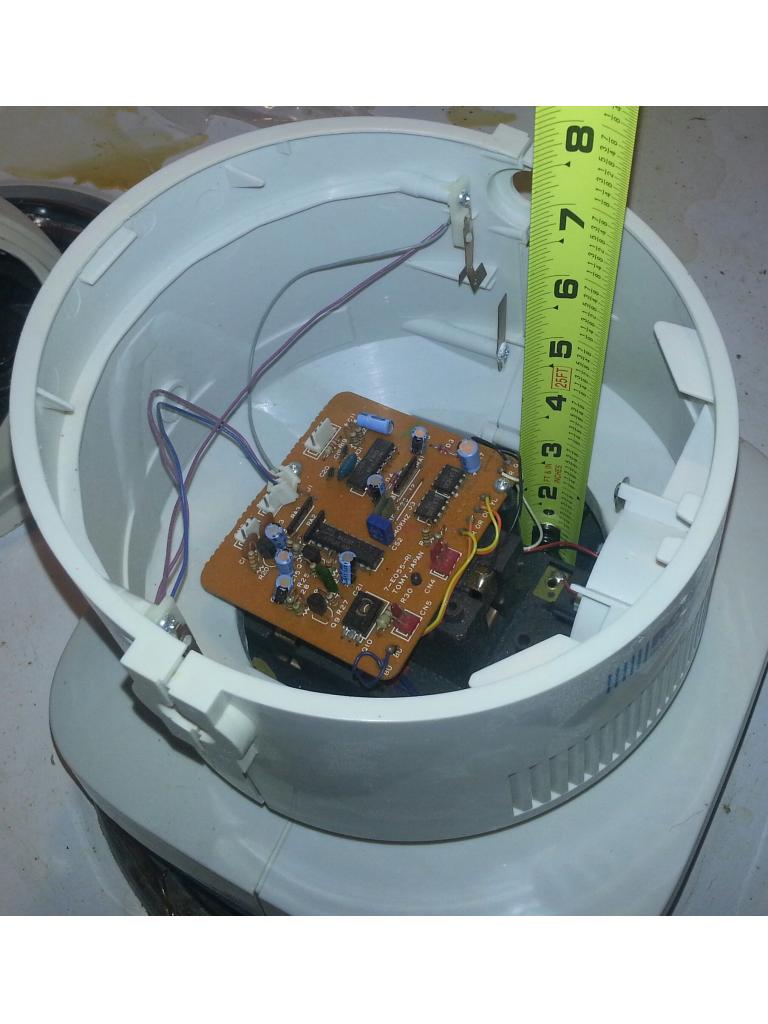

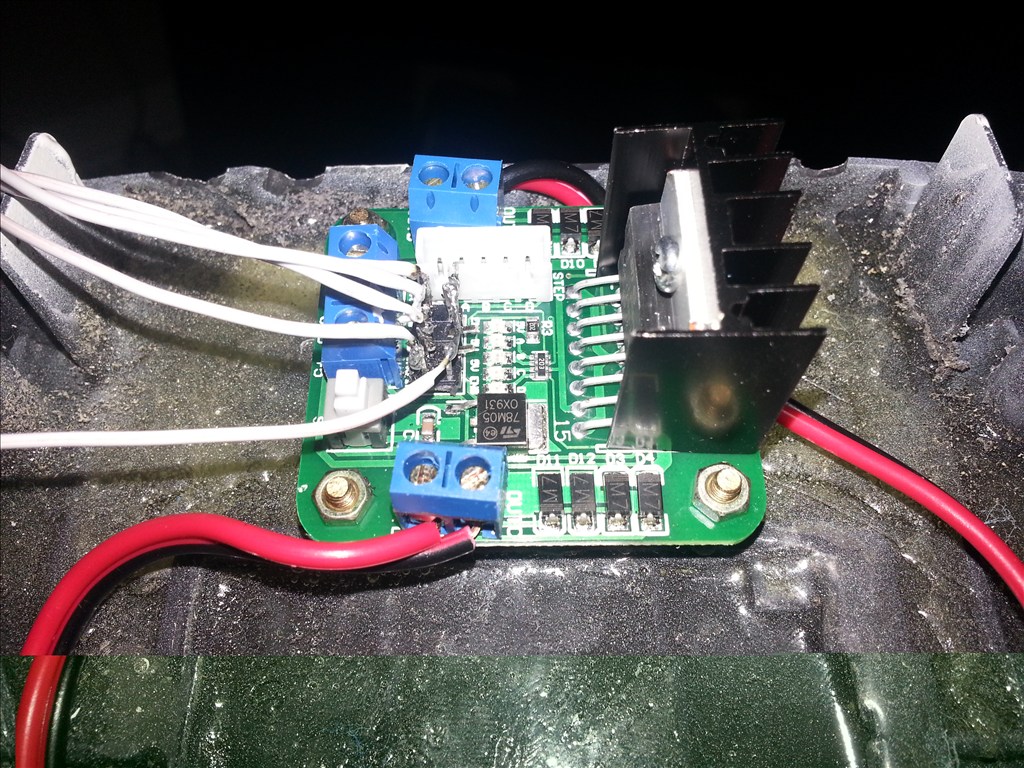

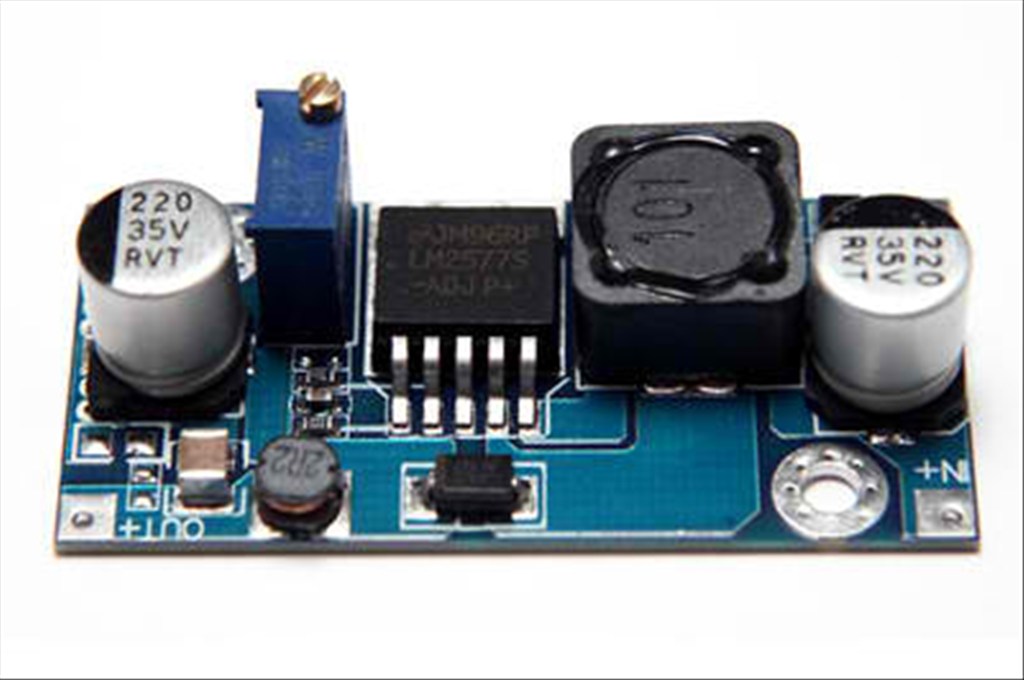

Now that the robot is generally clean we can take a look at how much room I have to work with. A huge section of the robot is dedicated to 8 AA batteries from the original manufacturer. We will see but that could be a possible mountingamounting area for a big lipo battery.

We see if you dont count the AA battery box there is 7 inches high of space and 4 inches to the collar from the factory pcb.

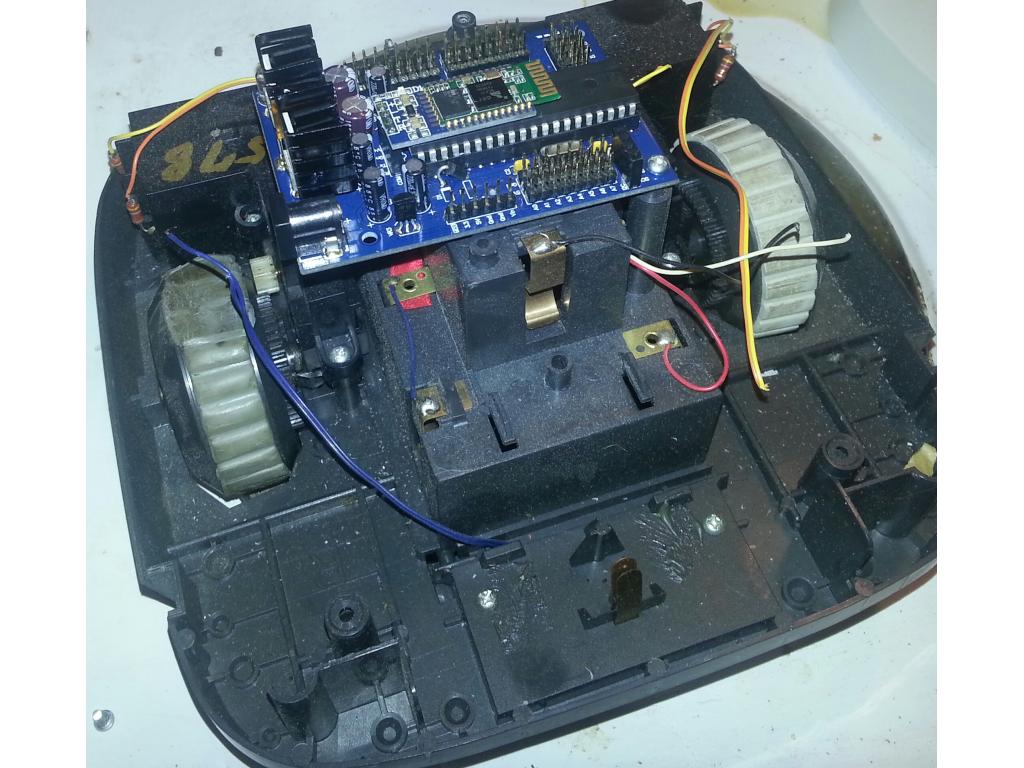

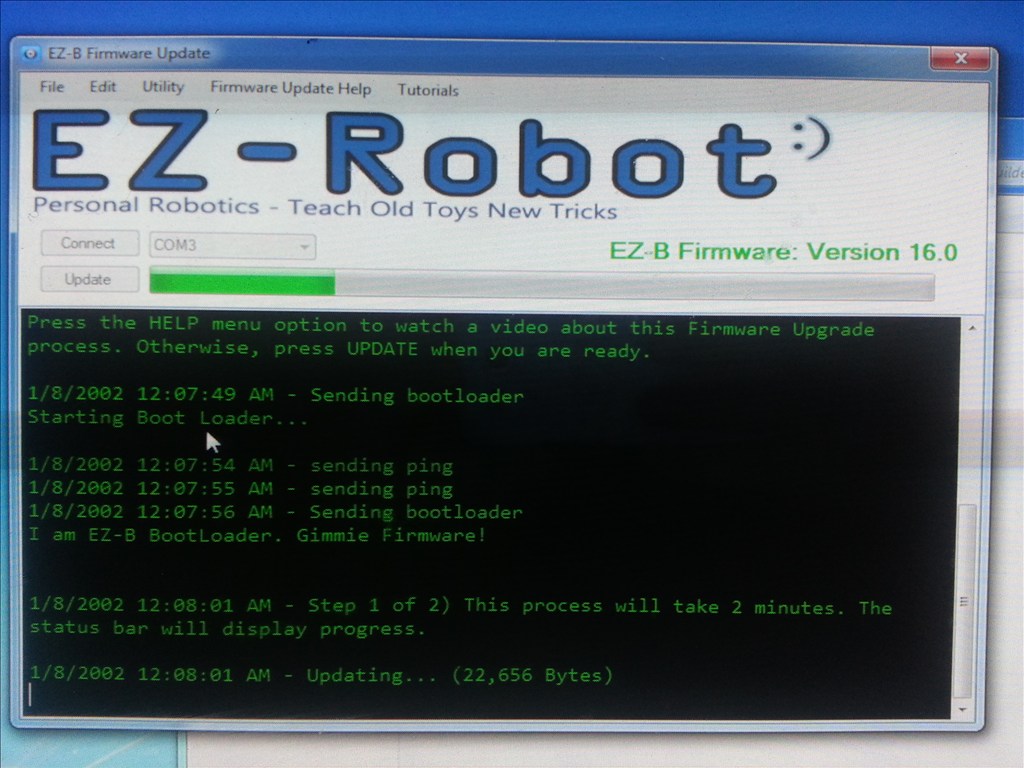

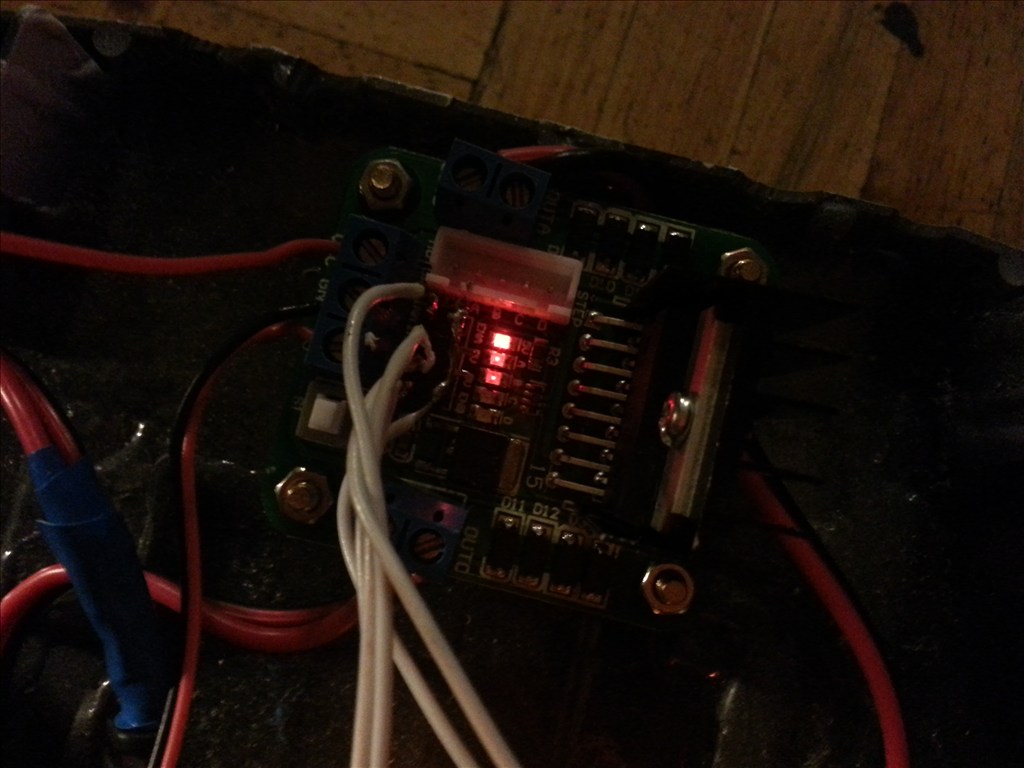

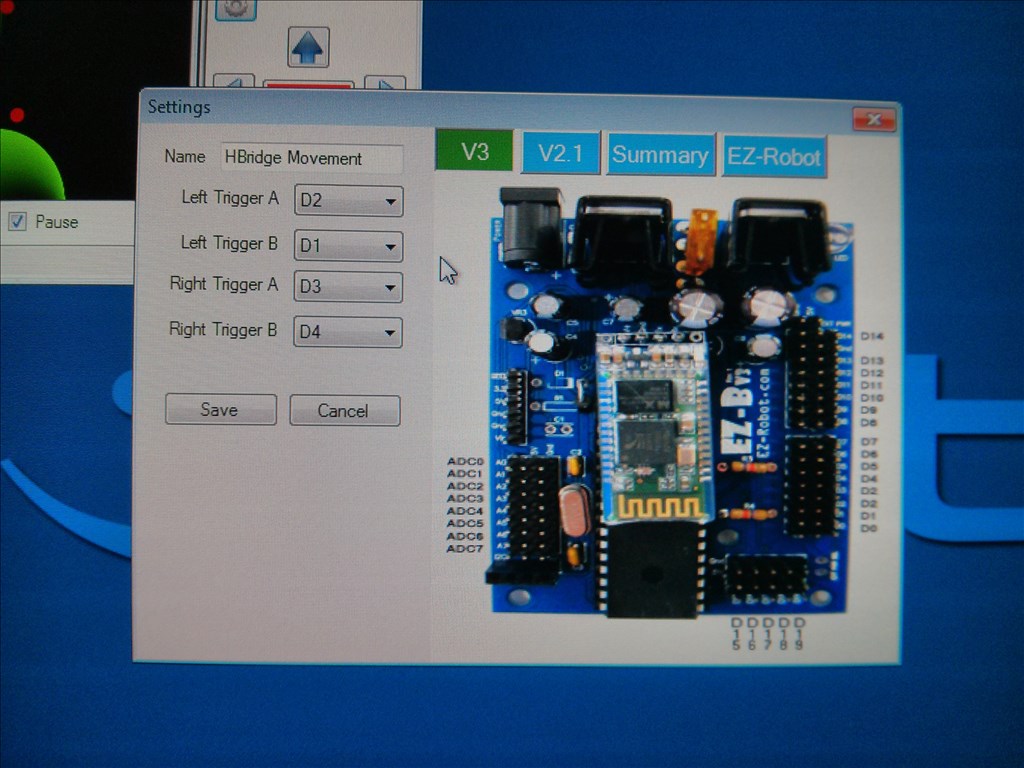

Test fitting ezb ? Sure why not

Looks like ezb fits right at home dead center of the robot. I may use a different position if I eliminate this AA battery box that is taking up soooo much room. I took a look at possible ez cam mounting positions as well.

I like the dome Josh. And it goes along with his bigger brothers.

Cool pics and nice job ! Congratz ! Now some vids ?

Greetz, PhG

Probably no vids till something can move. I dont believe I will do any kind of pan or tilt on this robot but we will see.