5.5 foot tall humanoid robot that walks and talks.

56 servos controlled by 3 ezbv4 boards working together over wifi.

On board power supply lasts 1-2.5 hours depending on activity: 7.4v 5a lithium battery for logic and smaller servos and 11.1v 10.5a battery for everything else.

DOFs? all of them

Been out of the ez-robot loop for awhile, and I have to say I like were things are going with synthiam. Plan on taking full advantage of having an onboard pc, and will be converting to arduino in near future.

Very interested in bipedal gyro control and scripting if anyone has advise on the matter.

here is a link to my project design on grabcad: https://grabcad.com/library/hal-the-robot-1

By cliffordkoperski

— Last update

Other robots from Synthiam community

Chiefavc's My Recent Projects After Getting My 3 Dev Kits

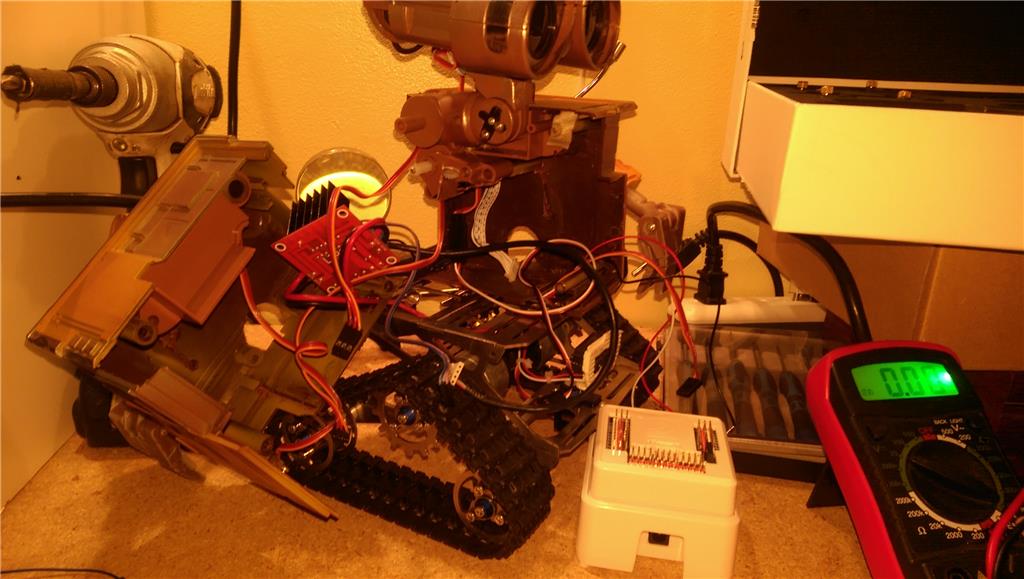

Robot photos showing multiple angles for build documentation, inspection, and troubleshooting.

Danger!'S My B9 Robot

Full-size B9 Lost in Space replica with hinge W waist mechanism powered by a salvaged drill motor; testing EZ-B...

Jeremie's Treat-O-Matic 2020

Convert a claw-style candy machine into a contactless Halloween dispenser with Atomic Pi, Arduino EZB, camera, PIR,...

WOW!! One of best robots I've seen here, can't wait to see more!! What sensors are you using for the robot to balance with?

I'm very interested in the use of linear actuators for walking robots. Are you using gyro sensors or something else, or the gaits shown are done without any sensor ? I think some balance sensor should be needed to move faster and safer than that. What are the specs (speed, strength and stroke) of the linear actuators you used ?

3dGuy , just keep an eye on my grabcad link I will be downloading individual parts there as soon this weekend.

On the topic of walking: I am currently not using any gyro sensors, I have decided first to see exactly how far I can get relying on structural rigidity alone. Test walks with my design so far I have proven that the 1/8 inch aluminum leg construction still has to much flex, which effects the mechanical repeatability of foot placement, my first coarse of action is to remake legs with 1/4 inch aluminum plate. The static load linear actuators are capable of , in my opinion are the only way to achieve rigidity in the joints a machine of this size. Here are the specs for the current actuators I am using on the legs stroke 4.00'' Speed (No Load)* 0.50" per second Speed (Max Load)* 0.39" per second Dynamic Thrust* 115 lbs Static Load 500 lbs I admittedly cut corners purchasing theses actuators, there main appeal to me at the time was being readily available. There is no store bought actuator that will fit the bill in my application, and the price of submitting a custom design to an actuator company I own my own cnc machine shop, so the obvious thing to do is stop being lazy and make some actuators that let me play with the big boys.

I am thinking rolled ball screw and brushless motors, it would be great if ARC supported rotary encoders but I will probably have to use a 10 turn pot.

So things coming soon :

I own my own cnc machine shop, so the obvious thing to do is stop being lazy and make some actuators that let me play with the big boys.

I am thinking rolled ball screw and brushless motors, it would be great if ARC supported rotary encoders but I will probably have to use a 10 turn pot.

So things coming soon :

Gyro stability is of huge interest to me now considering it's inevitable application in my build, question is how and where. My first thought would be to get a MMA7361 accelerometer and modify a script written for a two wheel balanced robot, you could have the program control two servos in the abdomen instead and use the upper body as a pendulum. This technique could probably be applied to the leg actuators as well, the real trick would be juggling walk commands and balance commands at once. Another idea is to not completely rely on electrical correction, and instead use a physical spinning mass offset from center of balance and induce the entire body of the robot into gyroscopic effect. I found a cool youtube link that demonstrates this. As always let me know what you all think, we are all here to learn.

Just wanting to share...

How do they do that "retargeting " ????

Its Disney, so its not open source...they dont share their magic!!

But it looks like there is a dynamic layer in top of the desired animation layer, and they invented an algorithm that is matching the dynamic one so it is as close as possible to the desired animation!

Very cool, I know a company " teknic" which has a product called clearpath servo and provides free auto tuning software which works very much like this. Actually used there product in a cnc mill I built while back, during the auto tune process the servos literally shake and vibrate the machine like a tuning fork feed back the results to the software and establish optimal performance. I am talking out my back side here so forgive me but I bet the software Disney uses focuses alot on the oscilloscope type feed back of the servo.

Does anyone know the brand or type of servos Disney typically uses in these applications?

so forgive me but I bet the software Disney uses focuses alot on the oscilloscope type feed back of the servo.

Does anyone know the brand or type of servos Disney typically uses in these applications?

I believe that Disney Research uses a bunch of different types of Dynamixel servos. I believe this because I found a similar video with the OpenCM controller by Robotis at the bottom of the shot: