5.5 foot tall humanoid robot that walks and talks.

56 servos controlled by 3 ezbv4 boards working together over wifi.

On board power supply lasts 1-2.5 hours depending on activity: 7.4v 5a lithium battery for logic and smaller servos and 11.1v 10.5a battery for everything else.

DOFs? all of them

Been out of the ez-robot loop for awhile, and I have to say I like were things are going with synthiam. Plan on taking full advantage of having an onboard pc, and will be converting to arduino in near future.

Very interested in bipedal gyro control and scripting if anyone has advise on the matter.

here is a link to my project design on grabcad: https://grabcad.com/library/hal-the-robot-1

By cliffordkoperski

— Last update

Other robots from Synthiam community

JT's Jts Robie Sr.

Restoring a Robie SR for EZ-B-ification: raising height ~6 in, adding a turning/tilting neck, new paint, learning...

Robotdude's Bad Jokes

LieutenantCommander Data greeting droid has run 24/7 for two years; uses SpeakRSSDescription RSS jokes in Personality...

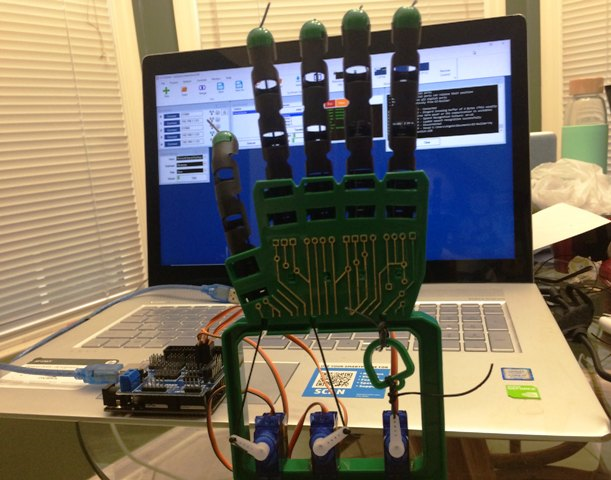

Ezang's Here Is A Picture Of The Hand I Am Practicing With

Photo of the hand I am practicing with

@cliffordkopersky I'm awaiting HAL rev.B !... Will you use your cnc lathe to make your own linear actuators? how will you make the feedback sensors ?

The CNC lathe will be invaluable when the time comes to make dozens of proprietary pins, screws, and bushings. However, I may not even use linear actuators next build, but if I need to I will certainly make them myself using brushless motors and cheap china import ballscrews. Concerning feedback sensors, I will just use off the shelf rotary encoders and connect them directly to the motors shafts like a DIY ac servo motor. Robot position will be dictated by revolution count not degree of rotation giving me much finer position commands something in the ball park of 1000 to 100000 counts per rev:)

Using ballscrews and rotary encoders you could make high precision control systems , like in machine tools . Perhaps such precision is more than is needed . For a large walking robot you will also need high mechanical rigidity and , above all, a gyroscopic stabilization system. In my opinion this is the most important matter to study and experiment.

I recognize the smaller Actuonix actuators. I have been using the ones that can plug in to any servo controller...lower power but no separate controller boards needed.

1) Are the larger ones in the legs the 12V heavy duty line from ServoCity? 2) Do you use their little controller boards (using 1 per actuator) or a regular motor controller?

I found some motor controllers that can drive 4 motors. I have been thinking about trying to use one to drive 4 of the large actuators...I hope this is a valid approach.

Yeah I used servo city's heavy duty 12v actuators, but really any will do as long as they have pot feed back. I chose the lowest speed gear ratio they had available to maximize leg strength. I purchased the model without a integrated control circuit and ran them instead with drivers from Pololu. Sorry I cant remember the exact model of the driver off hand but I used one per actuator and found the software features Pololu uses on there driver very easy to modify to accommodate the actuators. If your interested in knowing exactly what I used let me know and I'll let you know later tonight.

Very cool!! There is a ton of time and knowledge involved to build Mr Hal