hi all

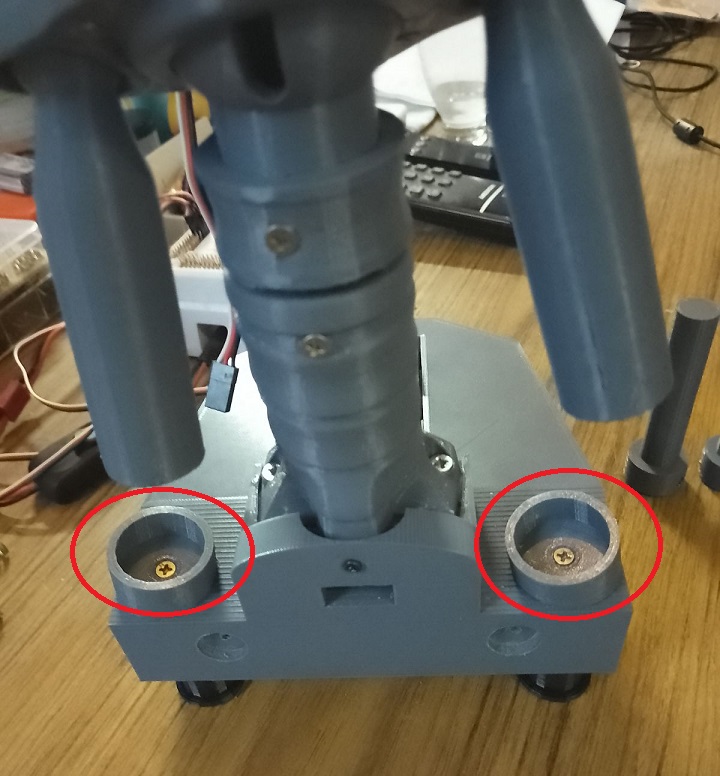

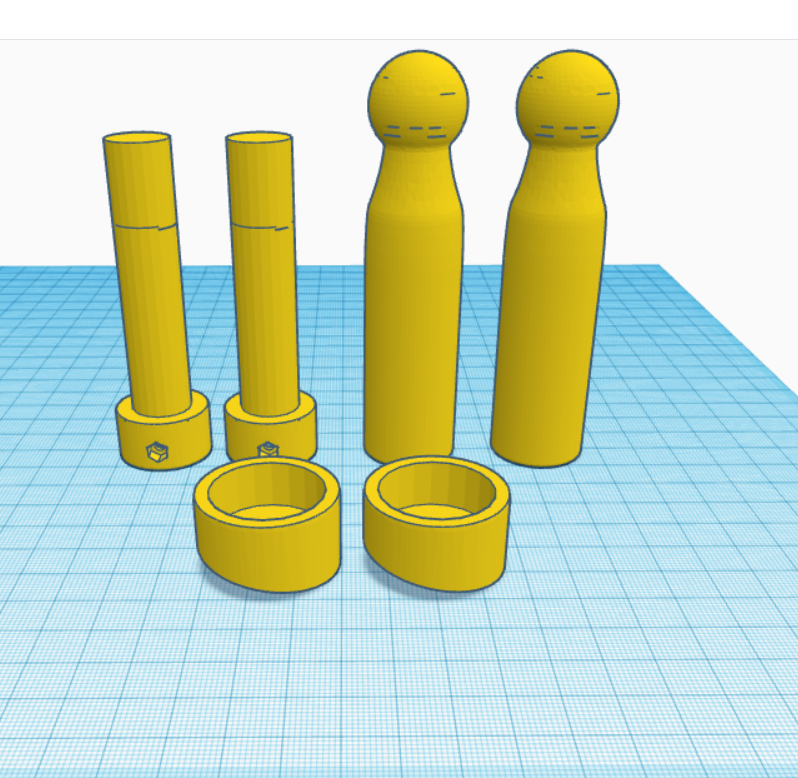

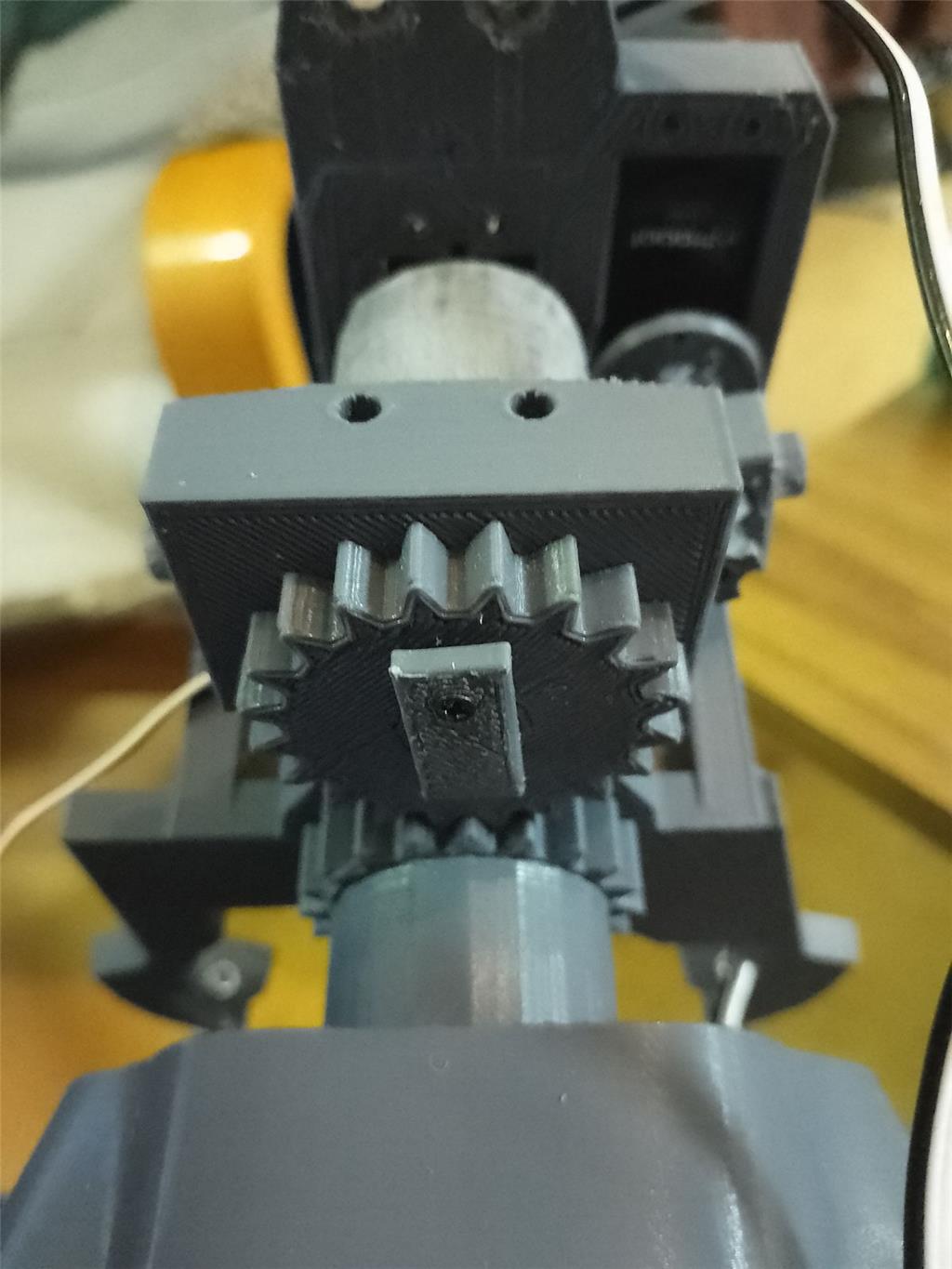

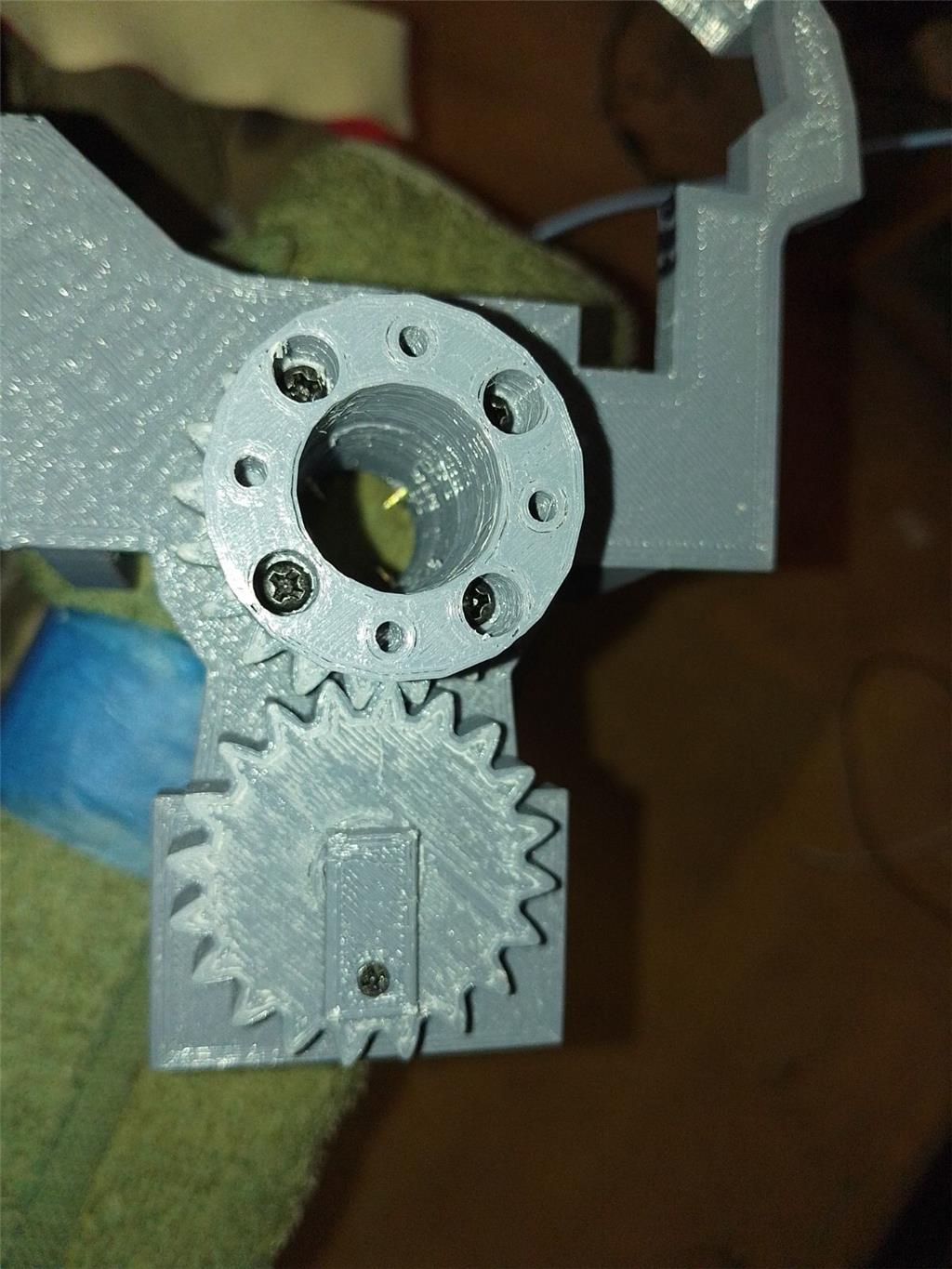

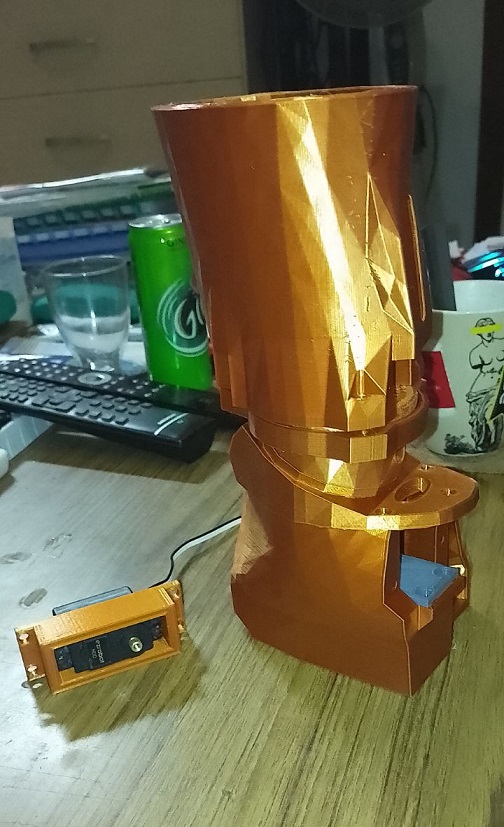

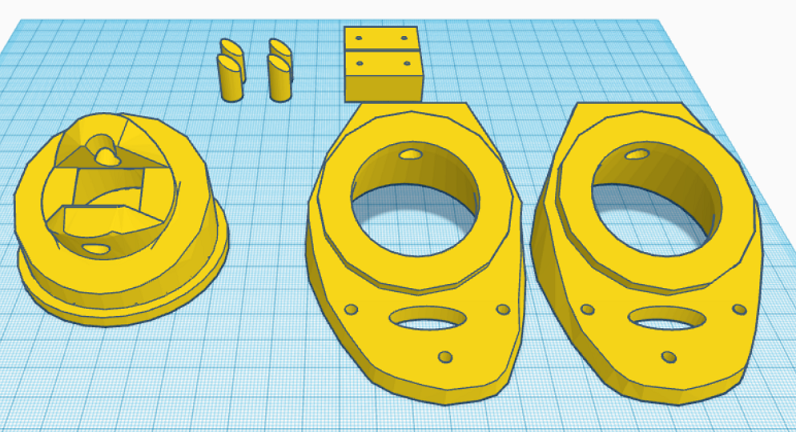

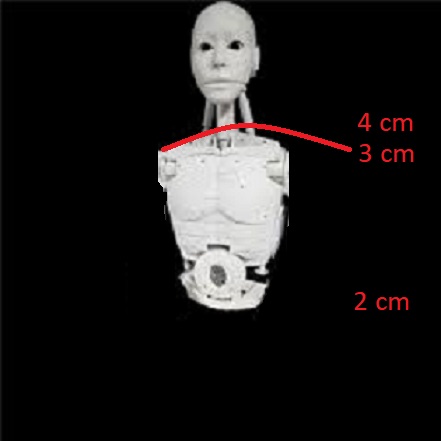

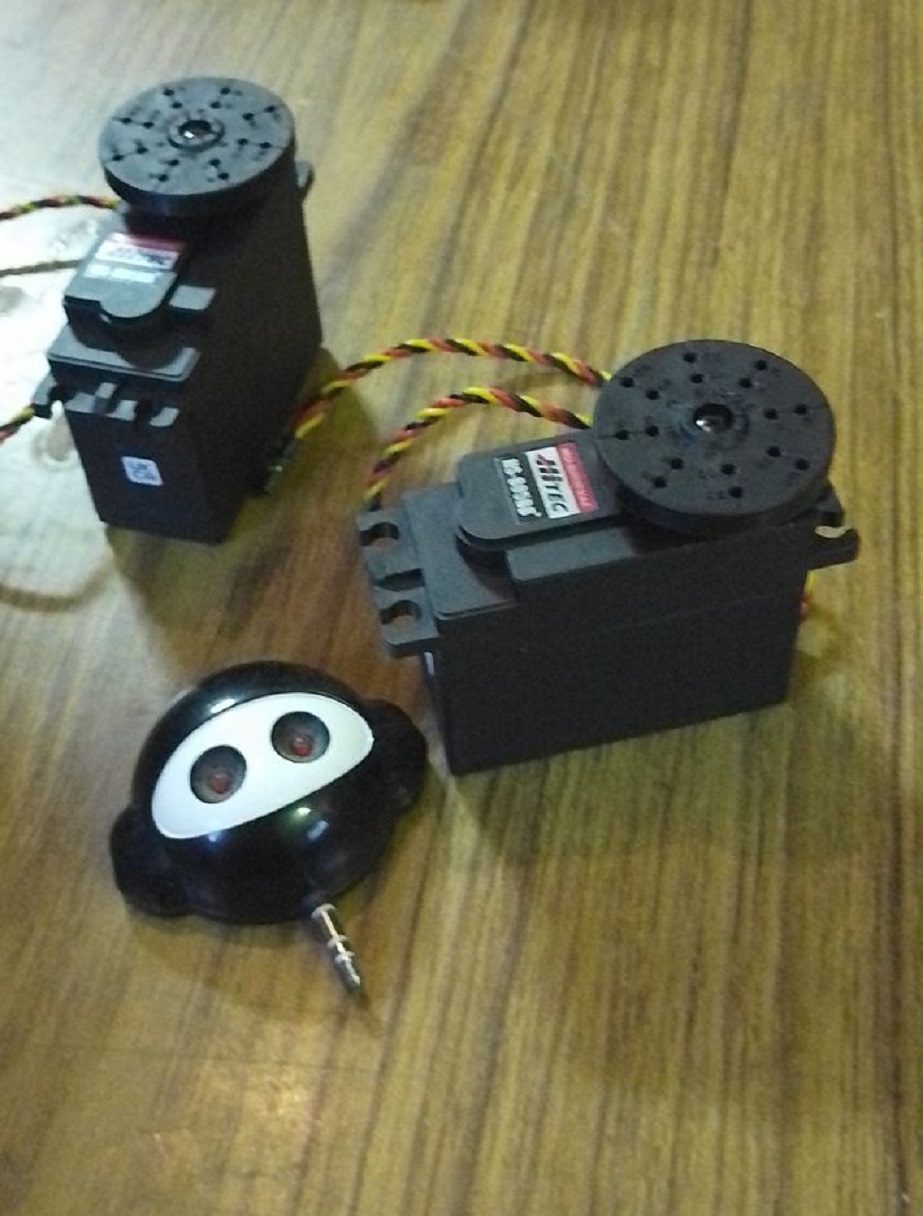

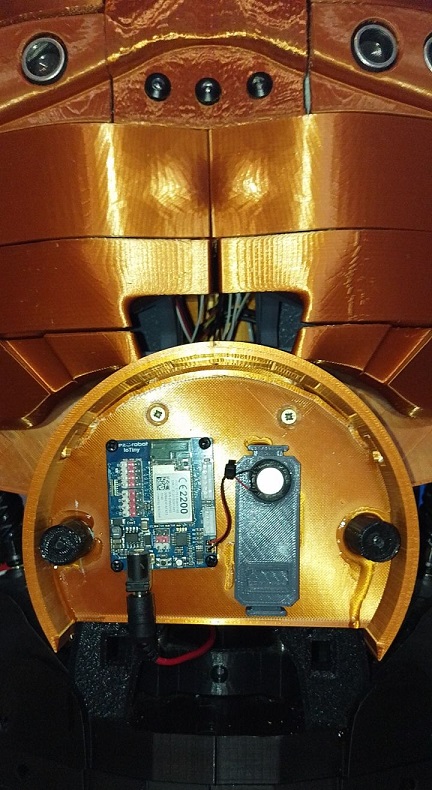

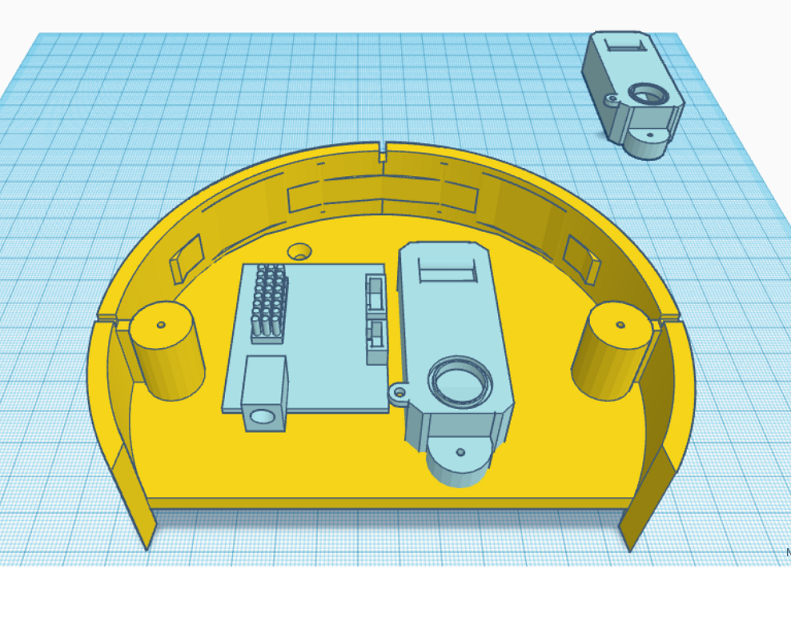

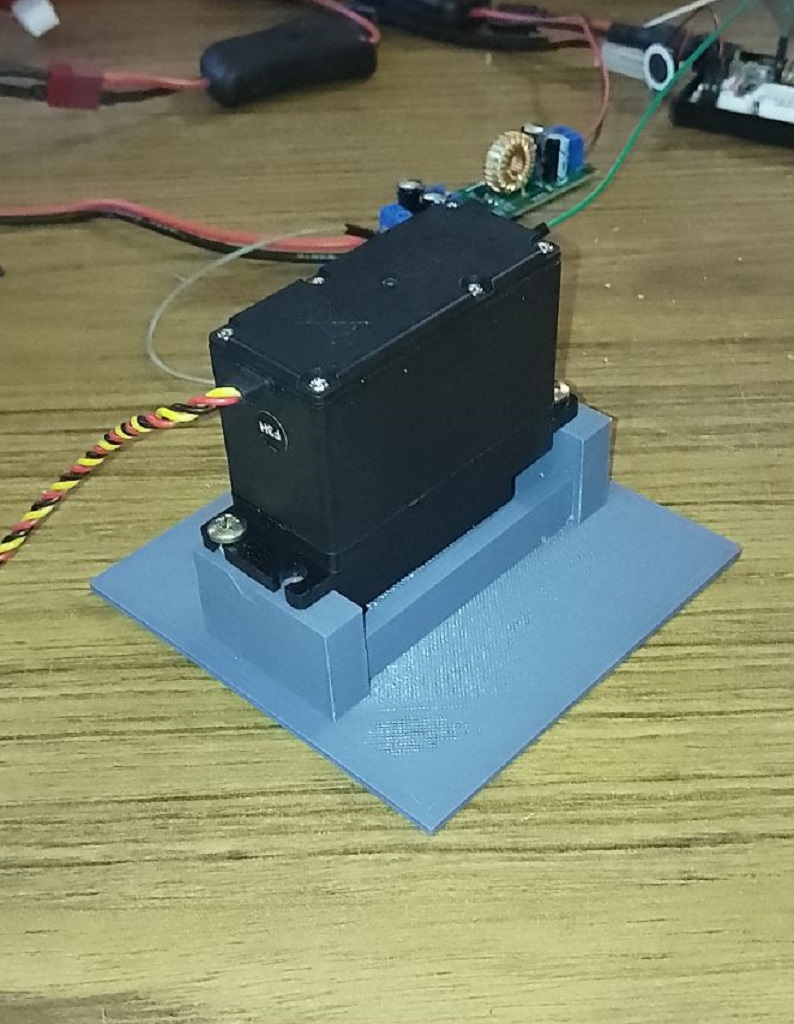

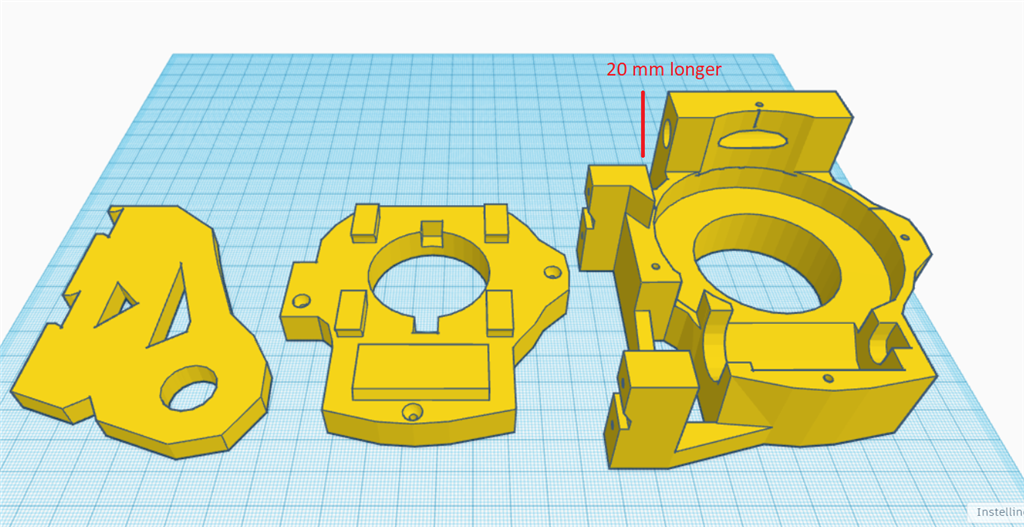

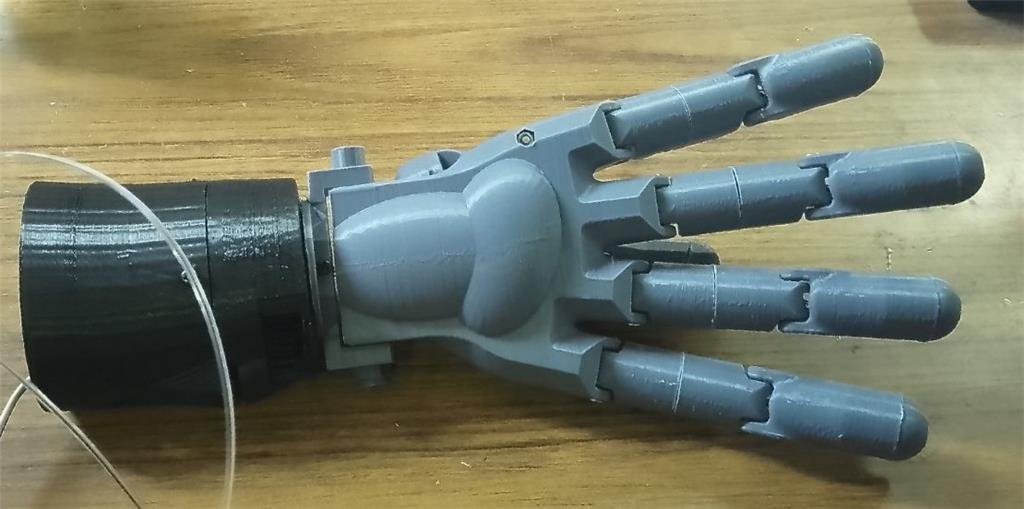

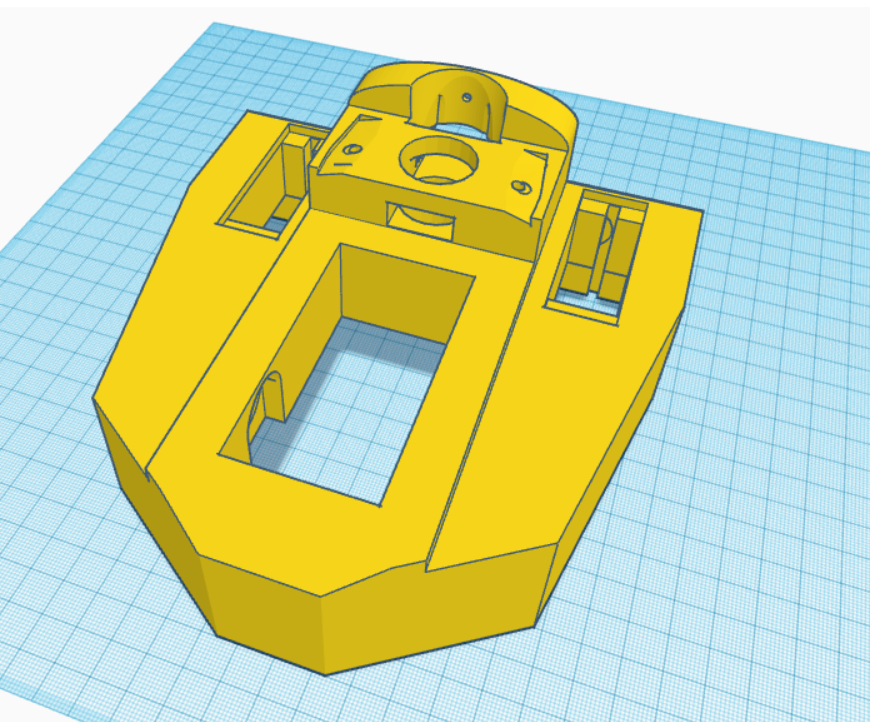

I've created a modified version of the EZ Robot head, featuring both side-to-side and up-and-down (yes) movements. This new design includes an improved base for the head, accommodating three additional HDD servos. There's an option to install two cameras, with the base designed to allow passage for a second camera cable. This setup is ideal for incorporating additional IoT devices or EZBV4, for instance, for LED lighting. Conveniently, there's no need to remove the potentiometer from a servo, as the 1 to 180-degree range provides ample movement. The base height is 7.2 cm.

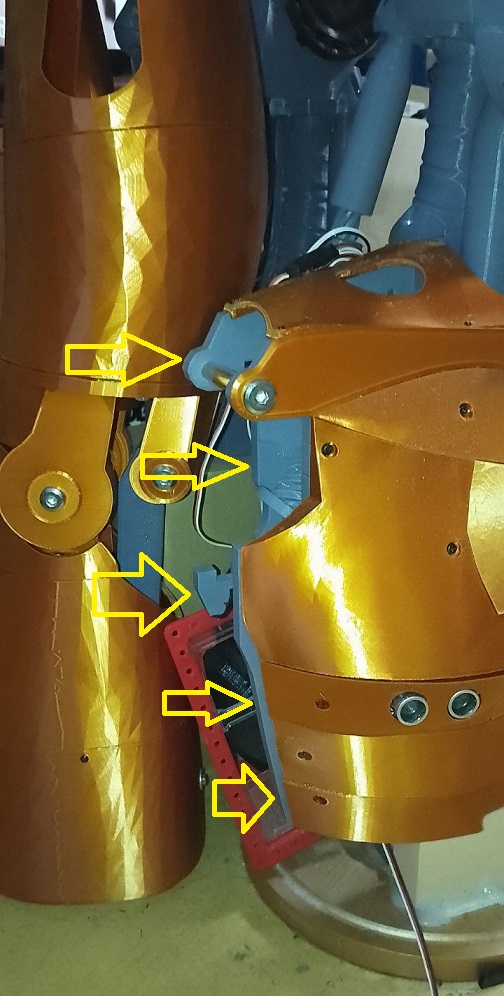

The pistons are original components from InMoov, and the neck base in EZ Robot is correctly designed.

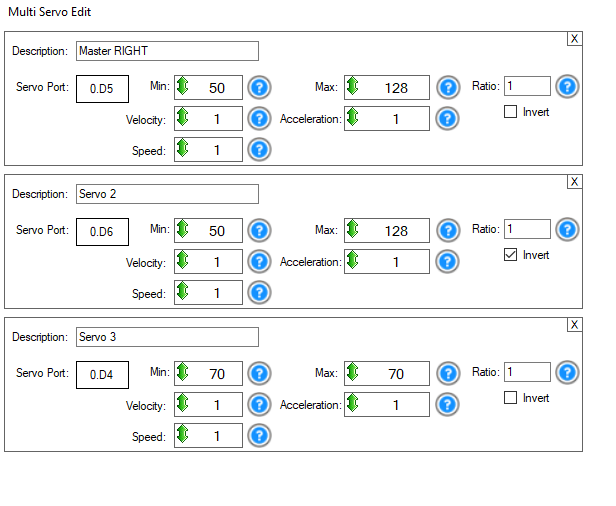

For moving the side pistons, adhere to these settings:

Filename: basesmalpistonIN.zipProgramming

Adjusting the side pistons can be a bit complex. Start by calibrating your HDD servos. Then, align the inner piston with the holes in the piston base and secure it with a screw. For the second side piston, align it similarly, then disconnect the IoTiny. This allows you to manually adjust the previous piston to properly position the second one. The original documentation on EZ Robot is extremely helpful in this process.

Parts & Materials

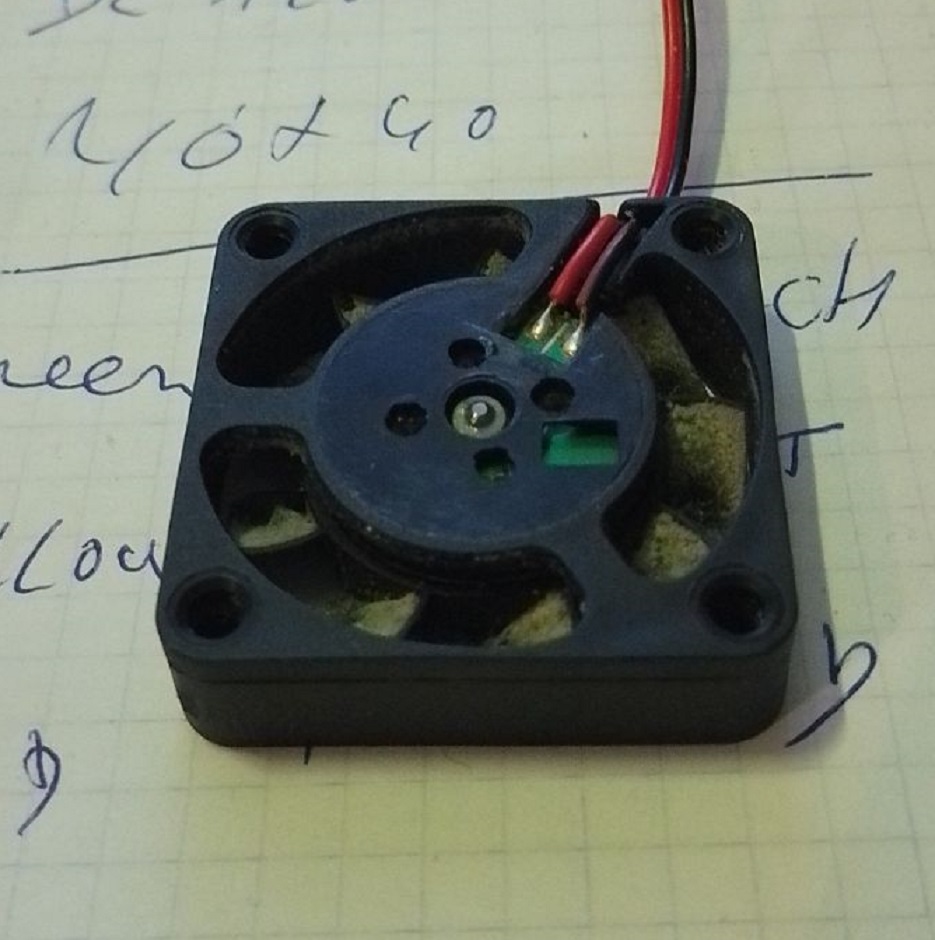

You'll need 3 extra HDD servos and grey PLA filament. The drive shaft parts should be printed with a 35% infill and a gyroid pattern in your slicer for enhanced strength. Other parts can be printed according to your preferences. Additionally, there's an optional neck extension, offering one to three extra vertebrae for more piston movement space. In my experience, the two-vertebrae option works best.

Other robots from Synthiam community

Oakmot's Chloe Project

Pittom's Rc Rock Crawler

hi all

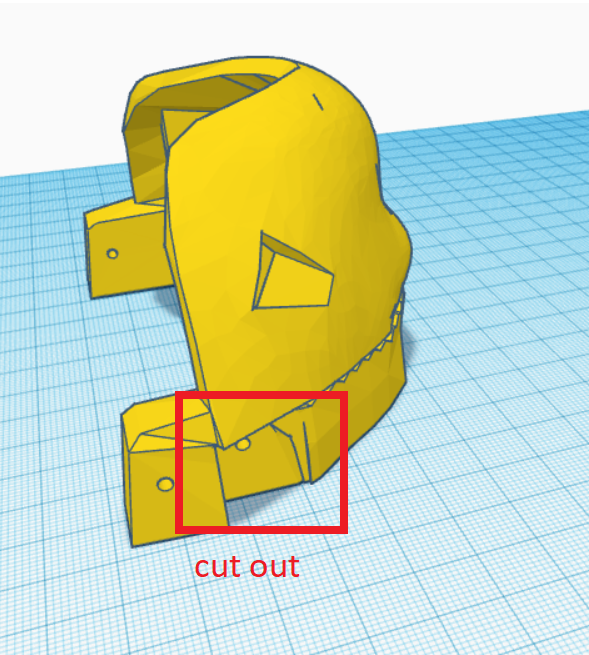

i notest that the mouth not fully closed . i made some mods .

jaw has a cut out and also the jaw hinges are modiefied .

new folder sendfolder.zip

little video of the jaw problem .

Great work nomad! Looks like you spent a lot of time on it with good success! Thanks for sharing. Looking forward to seeing what you do next

@dj

tomorow printing the new jaw and testing . then its just finishing the head .

do it all over for my full inmoove robot .

thanks for the kind words .

hi all

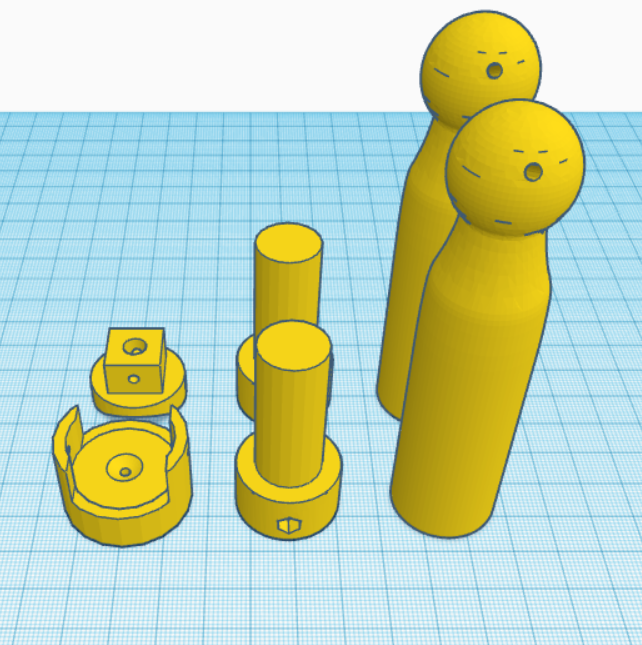

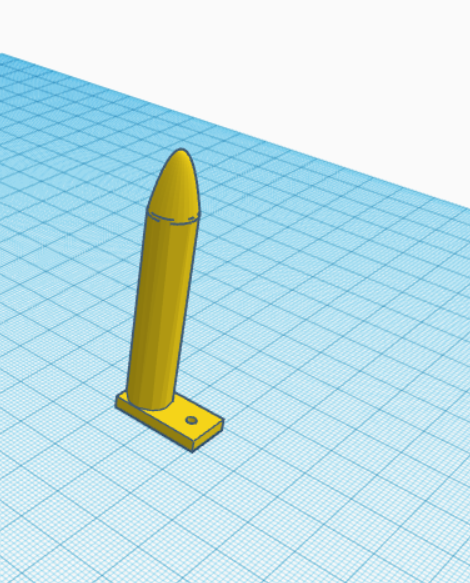

i made a new base if you want only the yes motion . so you need only one working piston .and two springloade hollow pistons .

only yes base.stl

hi all

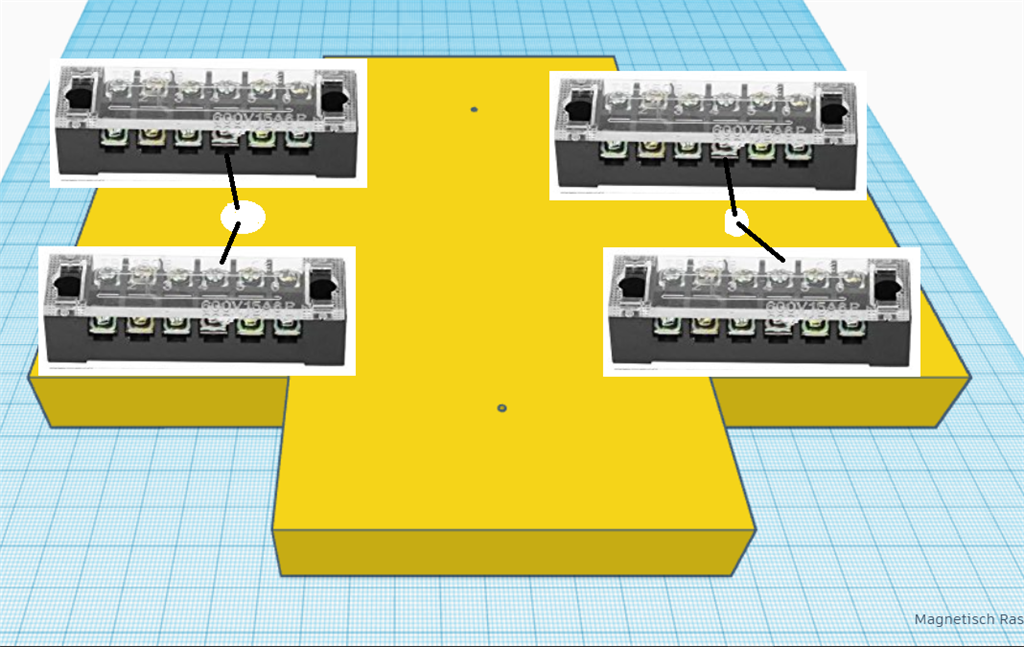

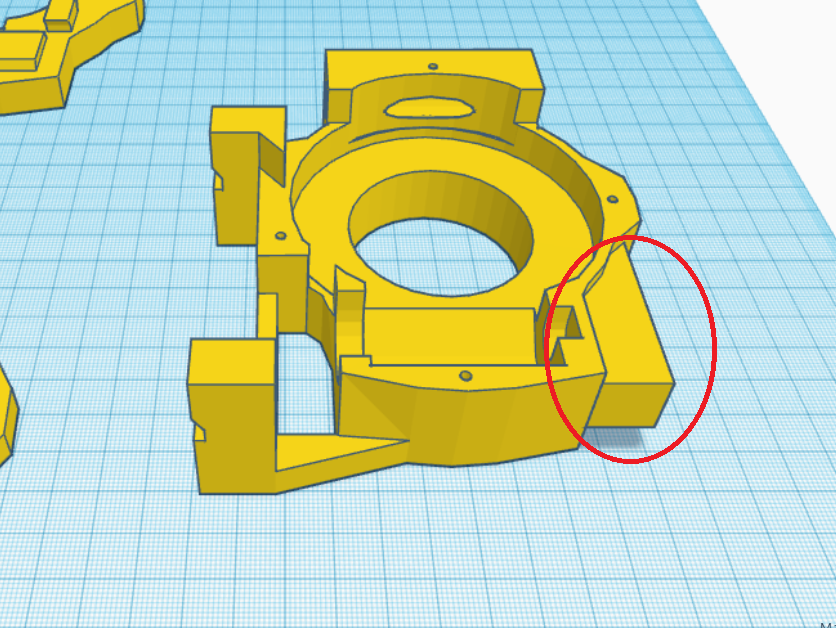

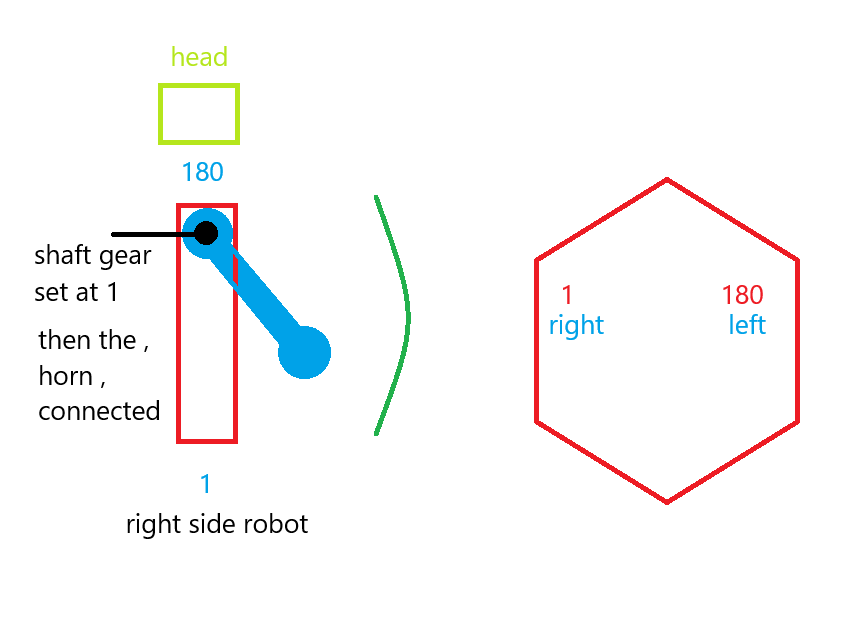

i made hollow springloaded pistons for the only yes base . this to keep the head level . on the left side picture . the two , small pieces wil be moveble to get inline with the neck base , were the tree pistons are housing . video soon .

Commenting to follow progress!

Nice work Nomad. I am wondering how to move forward. Do I do this mod and if so will it align with actual inmoov? What is Jeremie working on? Will I head in one direction and then have to change to another. I think I may as well go forward and build the entire Inmoov (I put filament on my Christmas list) but I would like to have something that is at least loosely supported and a roadmap. InMoov changed direction and primarily uses MRL but its a terrible platform to work with so I don’t want to go down that path. If I wanted pain in my life I would use ROS.

hi nink

i will test the new mouth in a few houres . then i can post a video so you can see the improment there . a complete inmoove is allot of work . there are so many files old and new together . its easy to print , the wrong parts . personally i find the arms to most diff to do . i didn started that part yet .

thanks