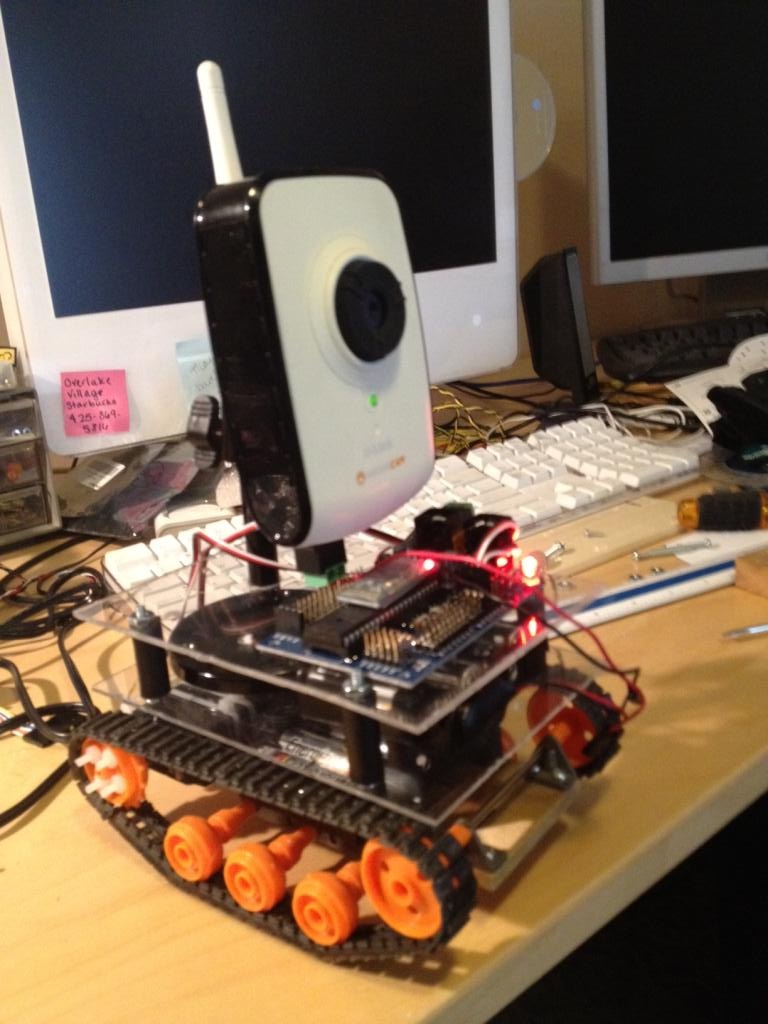

Here is the prototype of robot I am testing for warehouse distribution.

Nothing special at this time

Standard Thumper body ..usual EZ Robot parts.

I need to add lifting platform and naviagtion system.

I plan to implement with a current warehsouse system in use.

I will be using .net, probabaly vb.net.

Any ideas on a lifting platform woudl be appriciated.

I using this basically be a platform to work out the software.

Has anyone used Microsoft Robotics Stuio with EZ ?

By jphillipsnj

— Last update

Other robots from Synthiam community

Smitheken's My Track Driven Video Bot

Tracked base with EZ-Controller and wireless IP camera; power camera via 5V (4×AA) pack and use separate battery for...

Mita's First Robot From Bits Around The House

Build a 4-ft robot from an EZ kit using household parts: voice-activated head, Wii control, DIY sensors and kid-friendly...

Tezsmith's My Robot Story

Synthiam ARC controls Revolution JD and Meccanoid, integrates computational algorithms, laptop/wifi and custom...

We were going to add support for Microsoft Robotics Studio, but I don't think it is a very good application - in my opinion. One of the reasons I created ARC was due to MRS not doing what I wanted. You can use the EZ-B.DLL with MRS, but I've never done it.

If Microsoft wanted a real robot control environment, we'd merge ARC with some features of Microsoft Robot Studio

I understand completely. I need to develop a standalone application controlling multiple robots.

It may or may not run on each robot. Depends how far the project goes.

The plan I have is up to 20 robots. Depends on funding.

Each will be dispatched via web based application written in .Net.

As each robot is dispatched it will go to a location, pick up a rack with the parts and bring it to a packer. Similar to what Amazon uses now. I threw everything on this robot I could to test all components and features you provide.

The backend database is SQL Server. I need to be able integrate with this application.

Currently jobs are assigned to an individual picker and he or she goes out to the floor to pick.

I want a system that simple "picks" can be achieved via a robot.

Lot of work to do .. just starting. Anyway I do this I will be using Visual Studio ( I live in Visual Studio all day.. not necessarily proud of that) and your components for controlling the robot... not necessarily with blue tooth though. I am find range a problem.

Thank for a great product and any help you can give me.

Some reason picture did not upload before. Trying again.

Are you talking about this?

Hi Rasad,

Exactly what I want to duplicate... in theory. Their system cost starts at $1 million and goes up.

I will have a lot smaller warehouse to work with we are now designing, at about 10,000 sq. ft. They will not deal with something that small.

Also we have in house software that I wrote that I can adapt to these robots.

I have in house engineers and in house plasma cutter I could use for the racks and robot parts if necessary.

I like their lifting method but I need to keep the robots price tag down to $2k each.

I was think along the lines of a scissor jack?

I am thinking that racks, with product will be around 300lbs. when in use.

They will make a one way trip of about 200 ft. per item. that is max.

I have warehouse utilization subroutines in place for product positioning by turn count.

Thanks for the input. Let me know what your thoughts are.

@jackphillips1953

Here is a very nice looking actuator. Have not found a price on it yet. I'm still looking....

KATAKA spec sheet

WOW! That looks exaclty what I need. Thanks for the help. Let me know what you find out.

The size maybe to big for this prototype, but that is probably the design I want to use.

looks like a motocycle jack