Hi all! I'm excited to share this project with you, this is the robot RSP, I bought my second ez-b (v3) and having checked with my first robot(MY ROBOT)

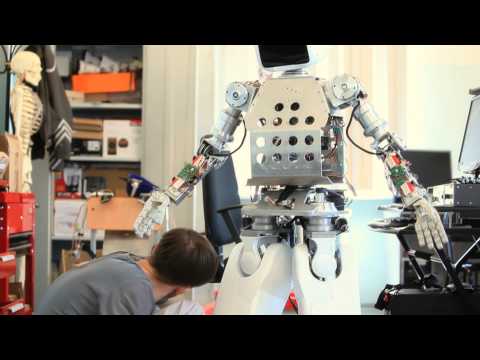

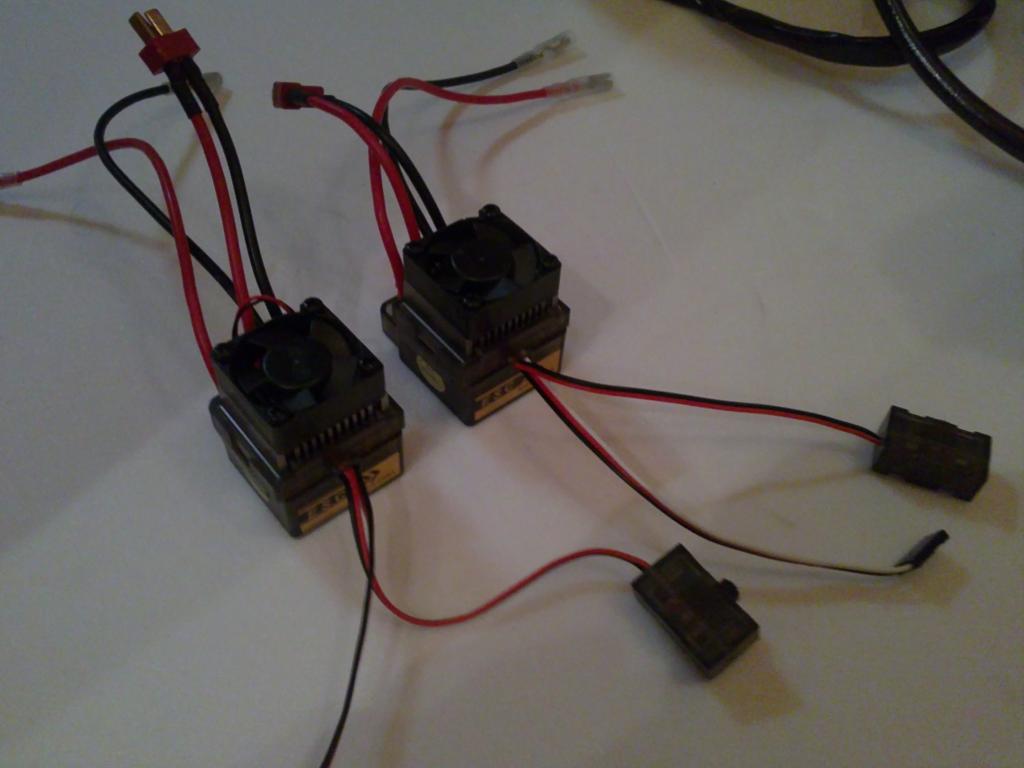

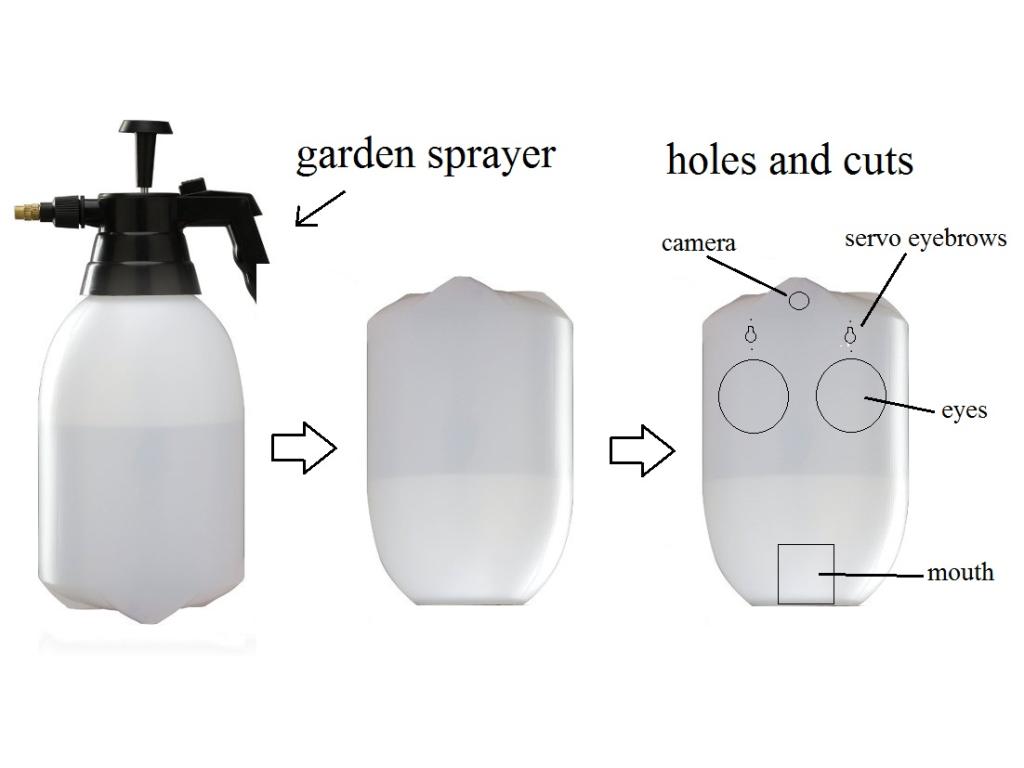

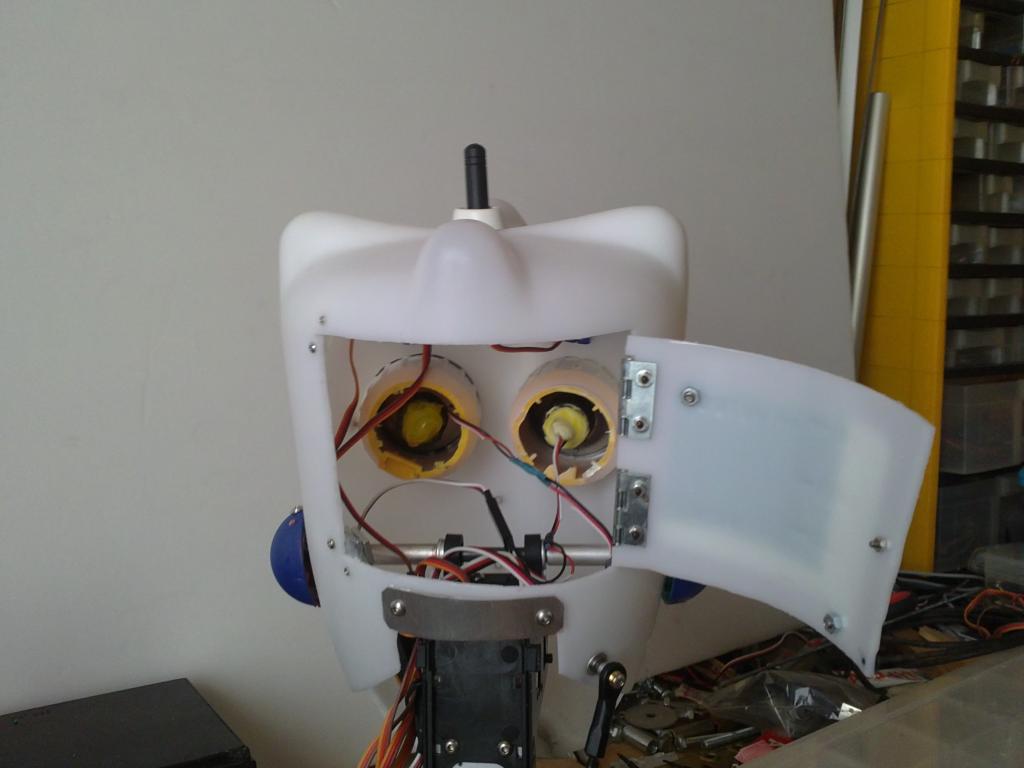

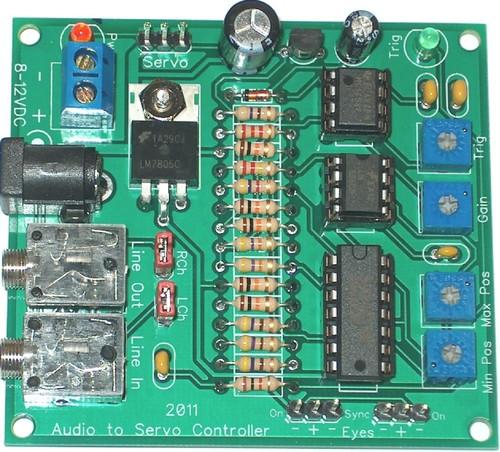

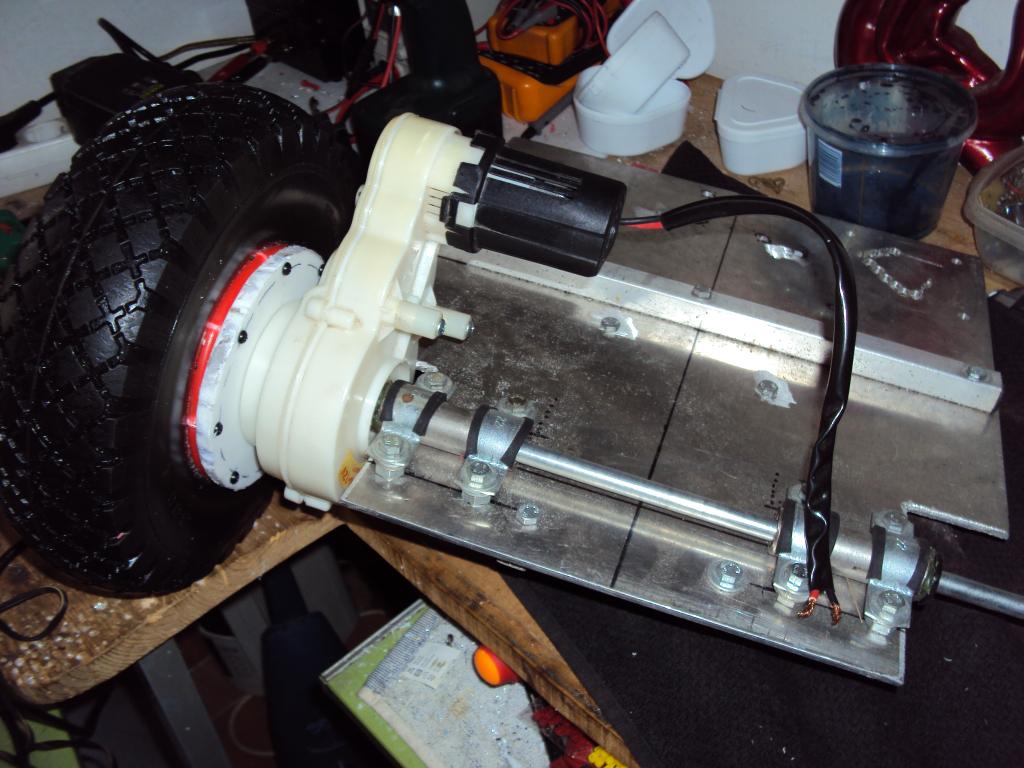

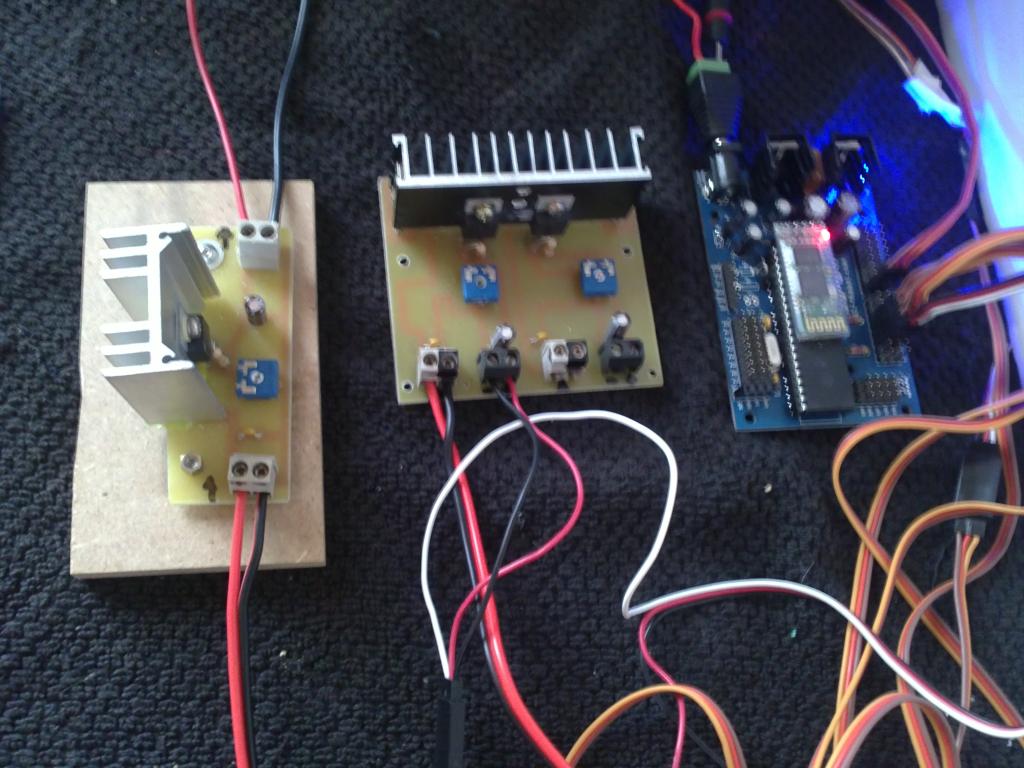

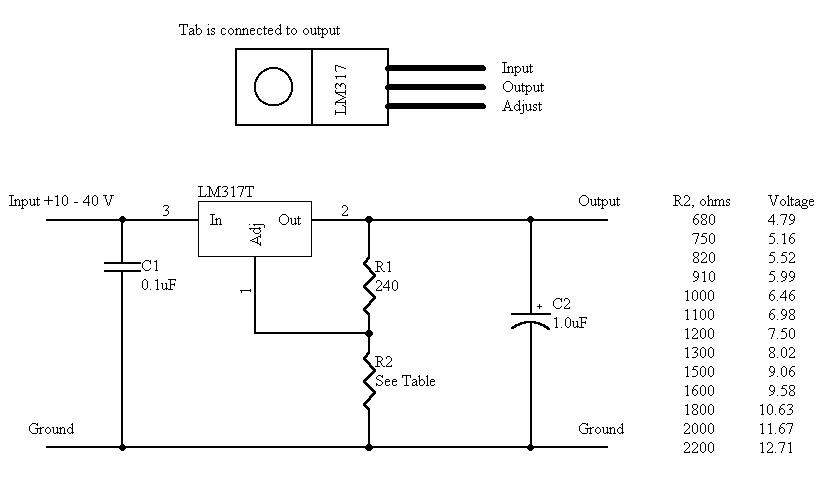

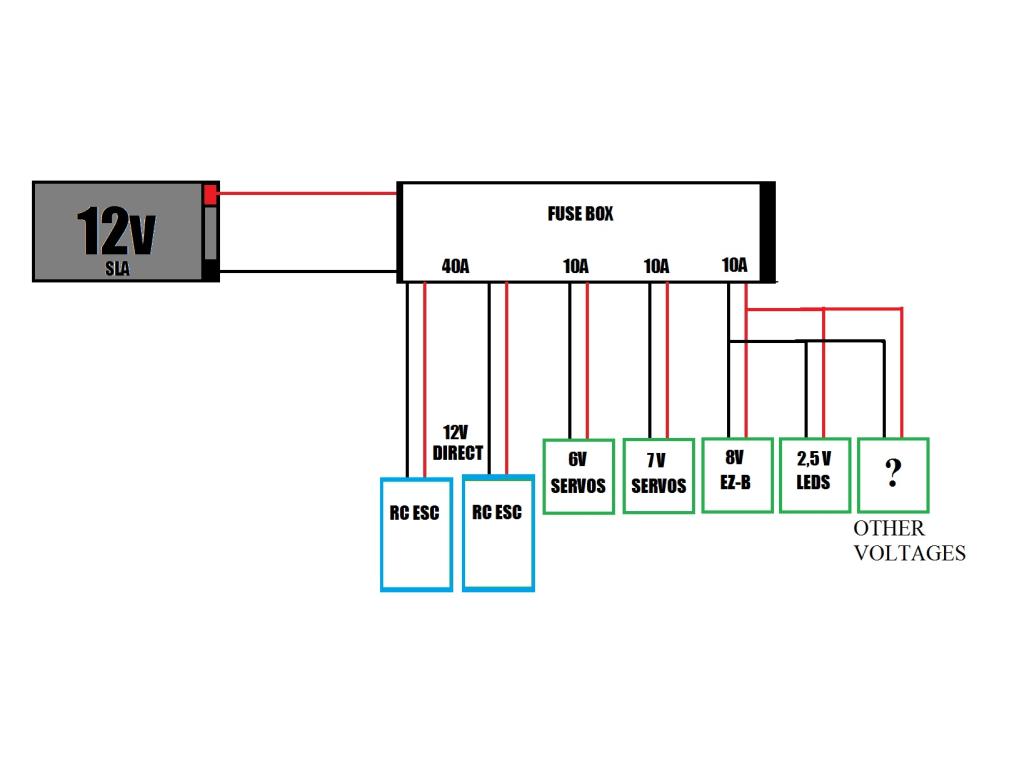

, I decided to undertake a larger project, its height will be of 5.4 feet (1.65 m), currently under construction I have the head, and gathered the materials for the traction system, some voltage regulators, 2 rc esc, several batteries, etc..

I enclose a drawing of how it will look when completed and some photos and video. I hope this project will have a mutual sense of teaching and learning for the entire community that will inspire others and that I may be inspired by all your valuable ideas, more information soon.

By R2D2

— Last update

Other robots from Synthiam community

Ericez's I Create Baymax Doll Robot For Robot Theater Using...

Interactive Baymax robot for Big Hero theater: handmade costume with internal robot, Ez-B v4 for speech and...

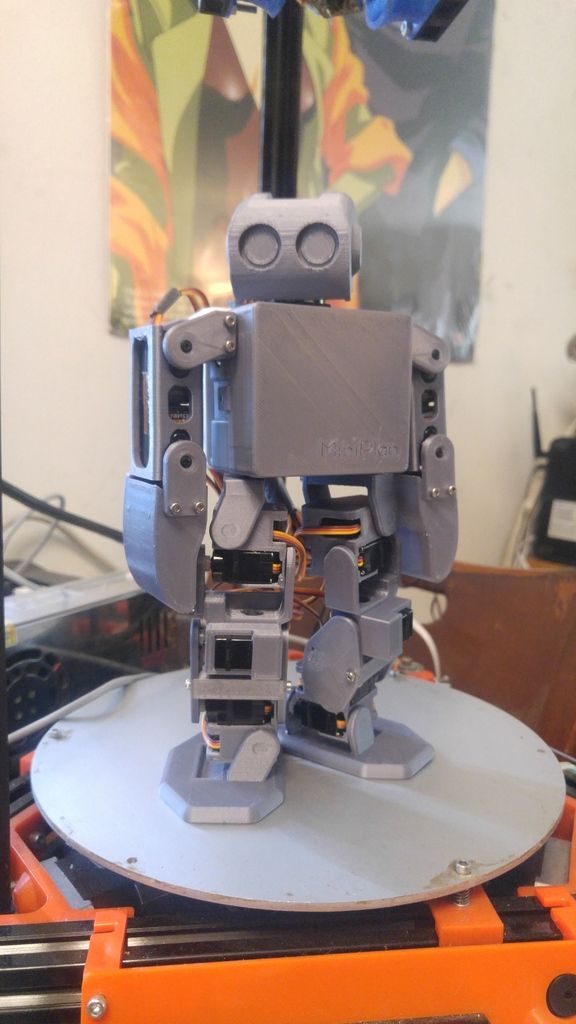

Kenny's Humanoid #3, The Miniplan

3D-printed humanoid built on a FLSun Kossel Mini Delta from Thingiverse, photo build progression and upcoming motion...

Steve's Meet Aegis

AEGIS robot built from junkyard scrap: steel box-section chassis, drain-chamber torso, car window twist motor, truck air...

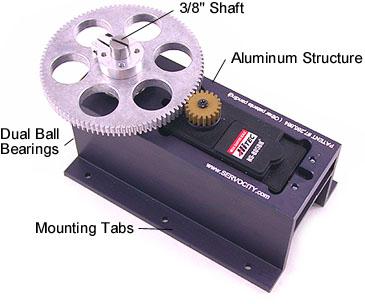

Hey buddy , I picked up robotzone gearboxes that can use standard size servos (or larger servos if you get the next size up) and they are made to withstand 200 pounds on the smallest model. They have various gear ratios , I picked 5 to one but they have higher. You could use these for shoulders , elbows and even your gripper. Servocity.com. I bought the hsr5995 servo for mine which is 414 oz torque and I'm putting it in the 5 to 1 ratio gear for over 2000 oz torque from a standard size servo , the servo was 59.99 and gearbox 59.99 , great deal.

, the servo was 59.99 and gearbox 59.99 , great deal.

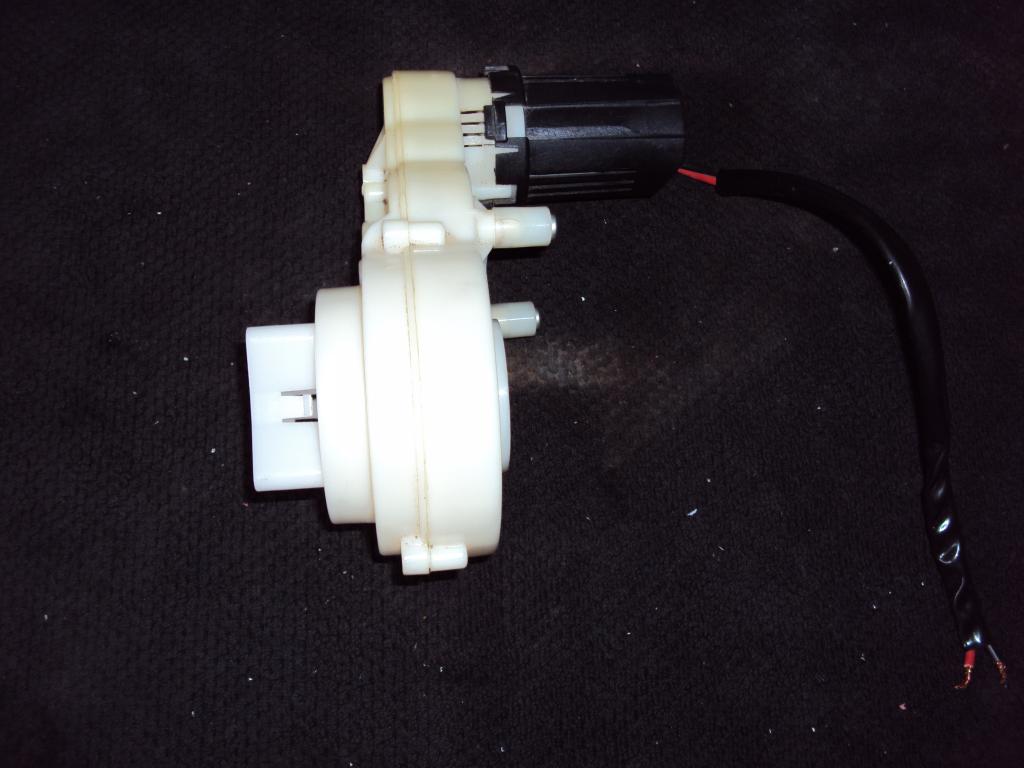

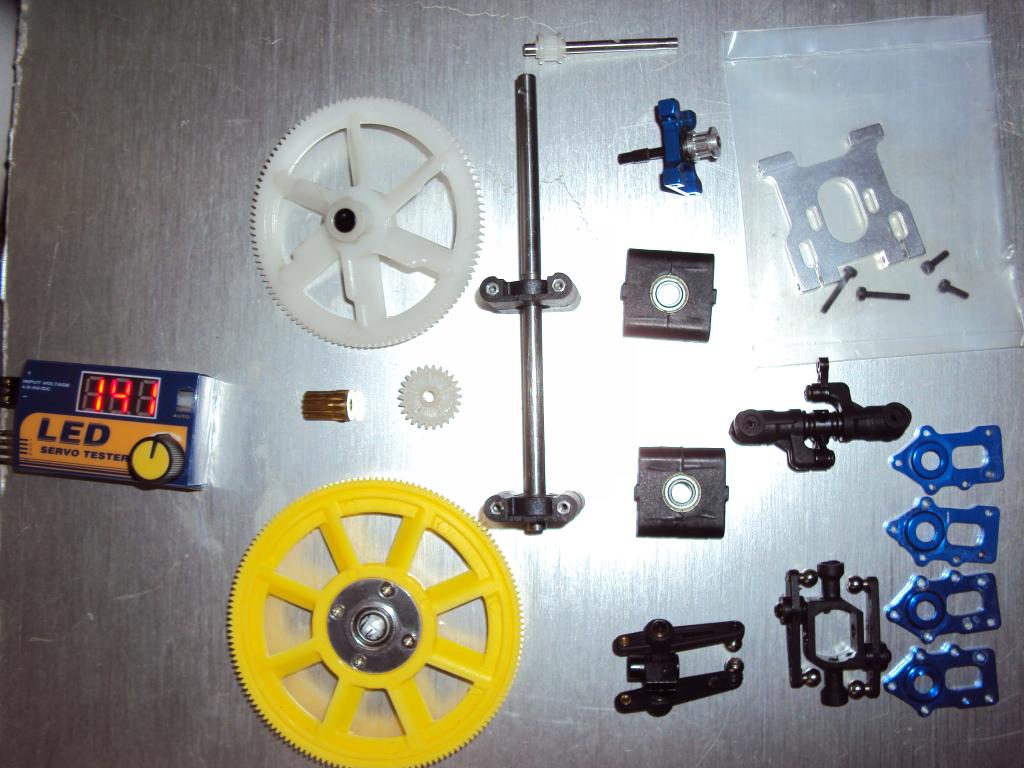

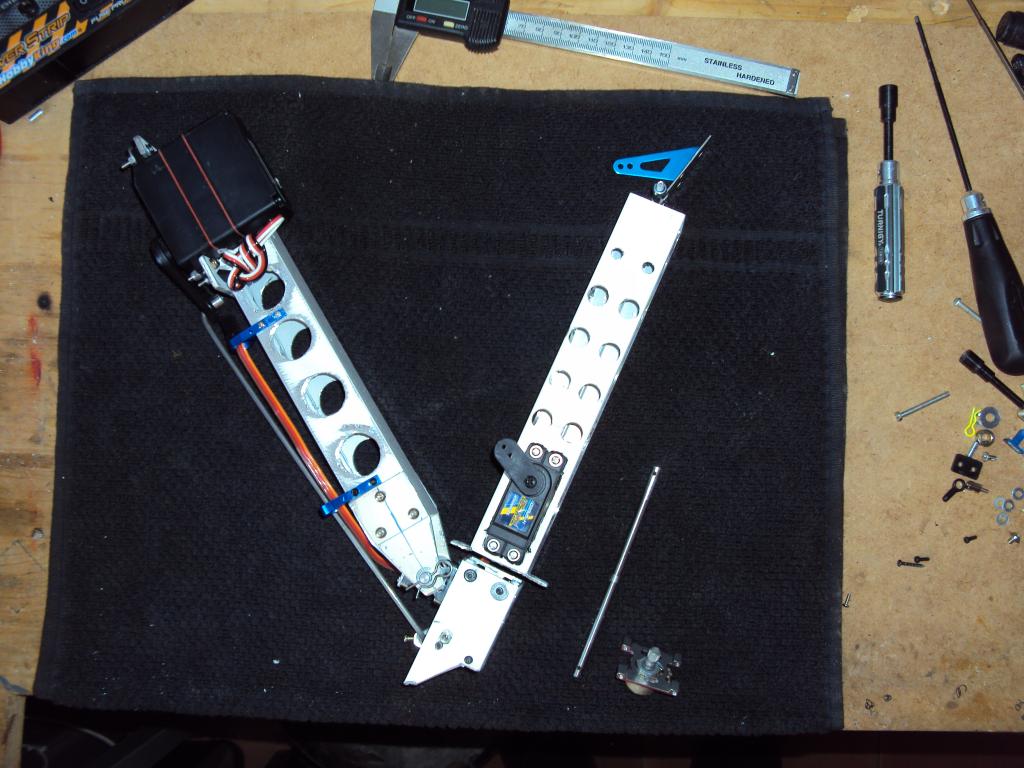

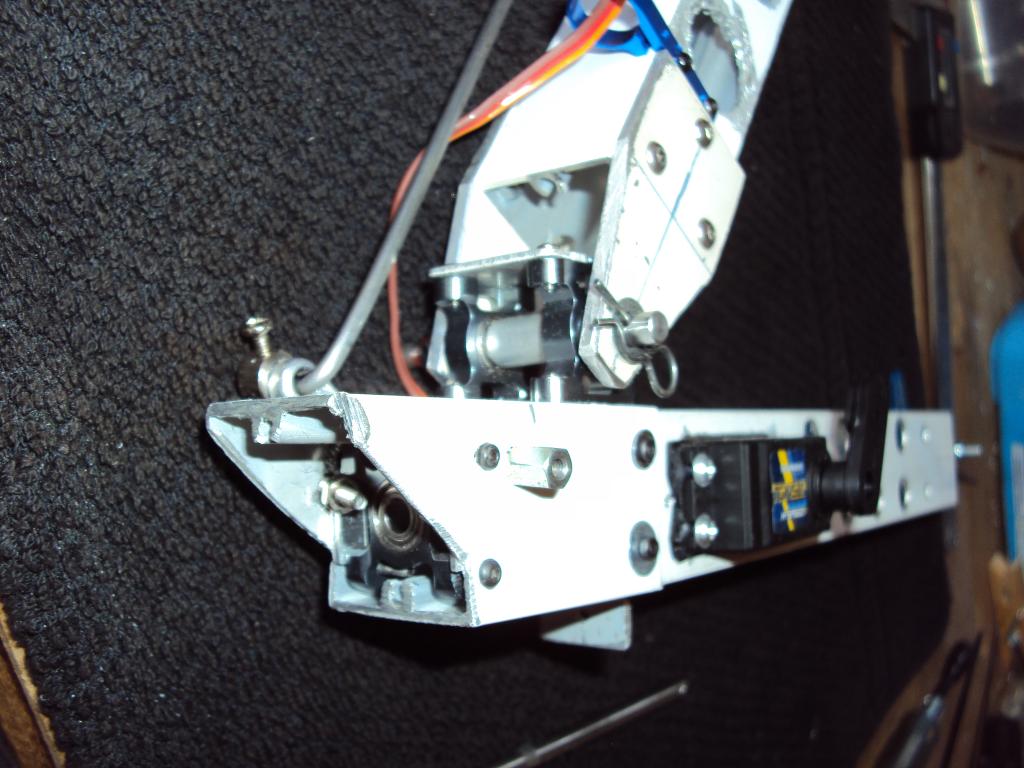

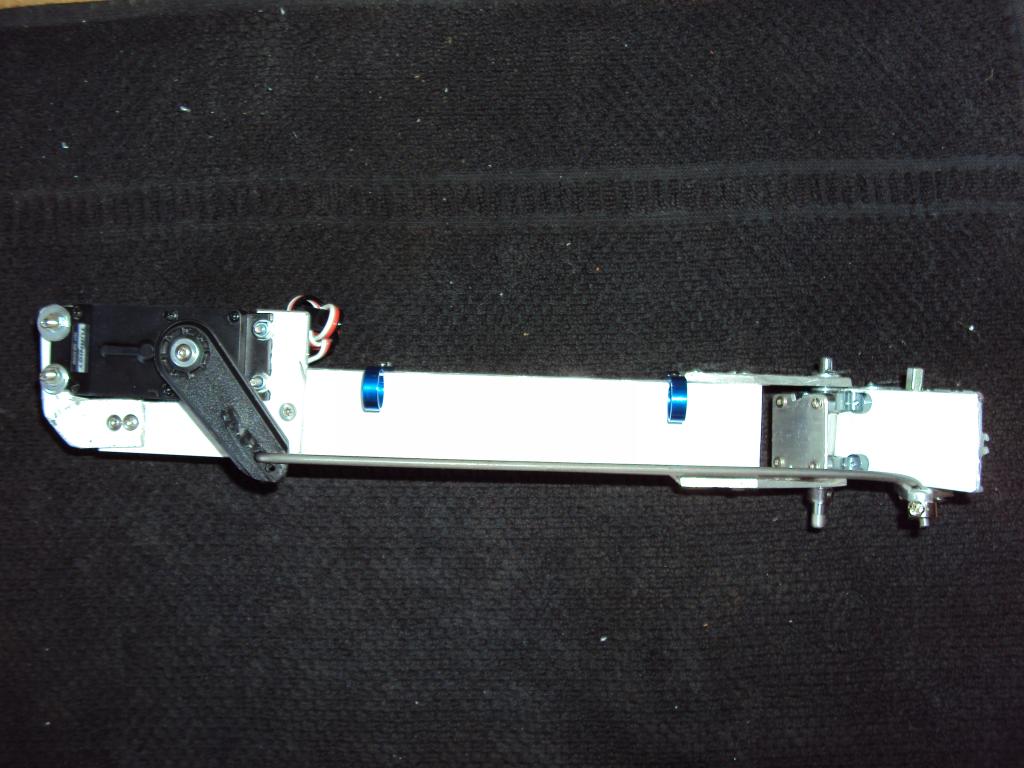

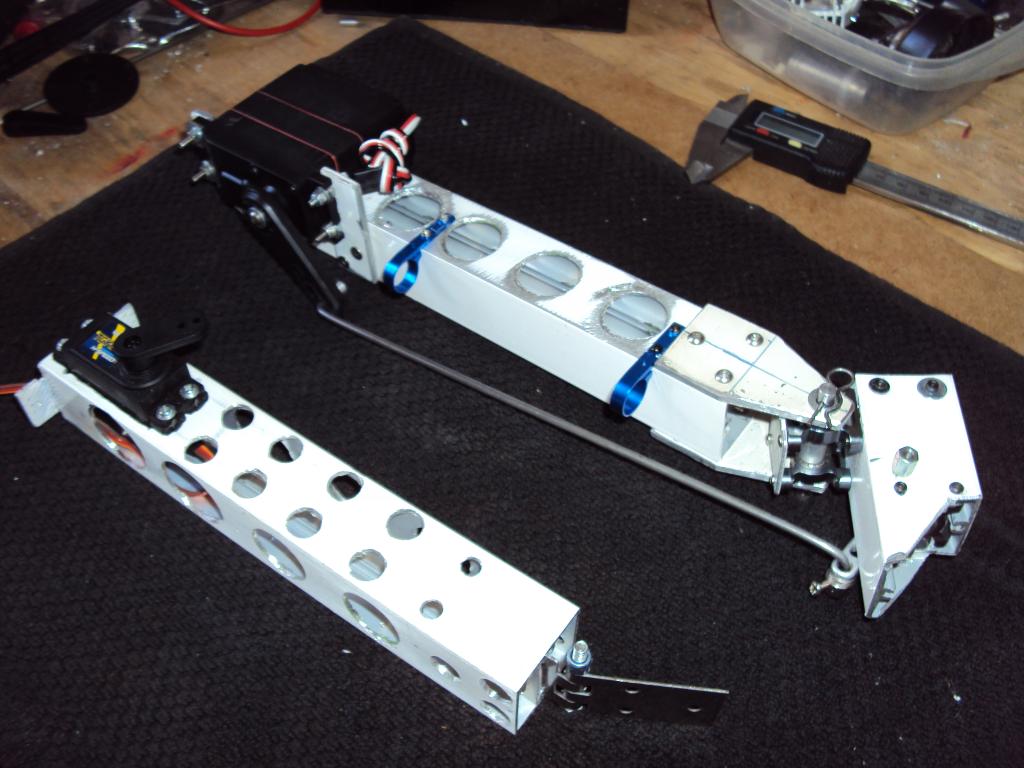

Looks like you've seen my designs on the webcam! Shoulder effectively use a similar one I thought of servocity Also with a 5:1 ratio and plastic gear, I think the best option for the point of the effort arm, the Turnigy servo is mounted above the axis of the shoulder to act as a counterweight, and the transmission works with a rod steel on the hinge of the elbow. www.servocity.com/html/spg805a-bm_standard_rotation.html

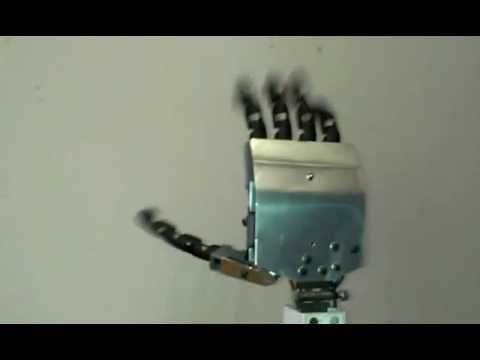

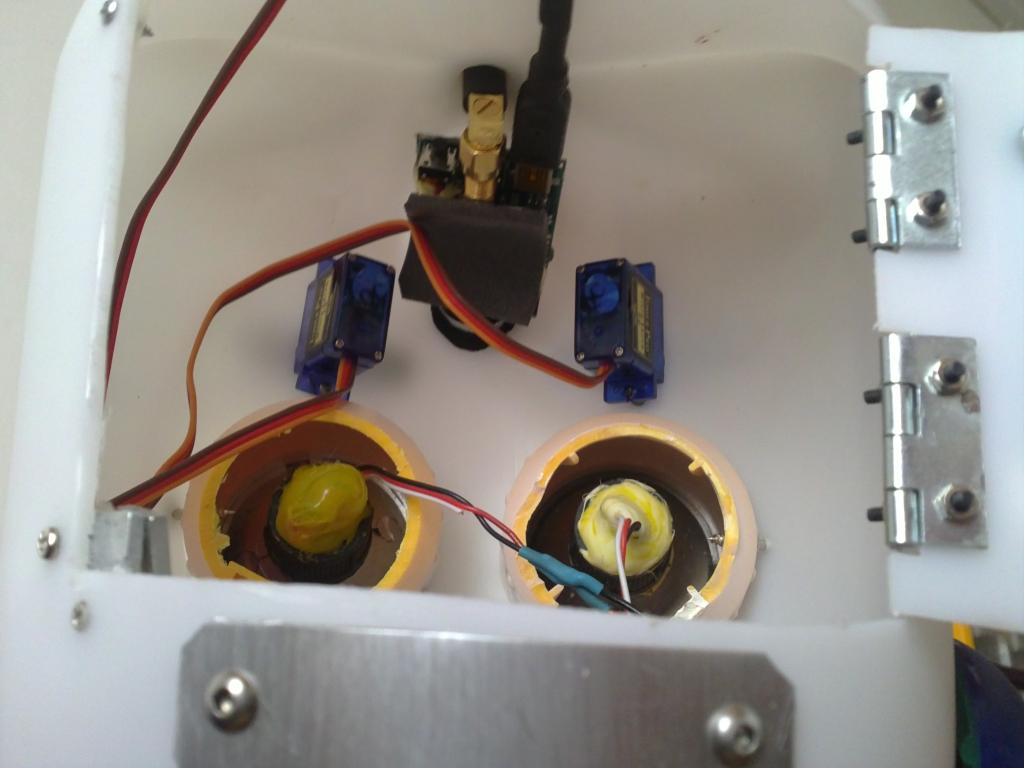

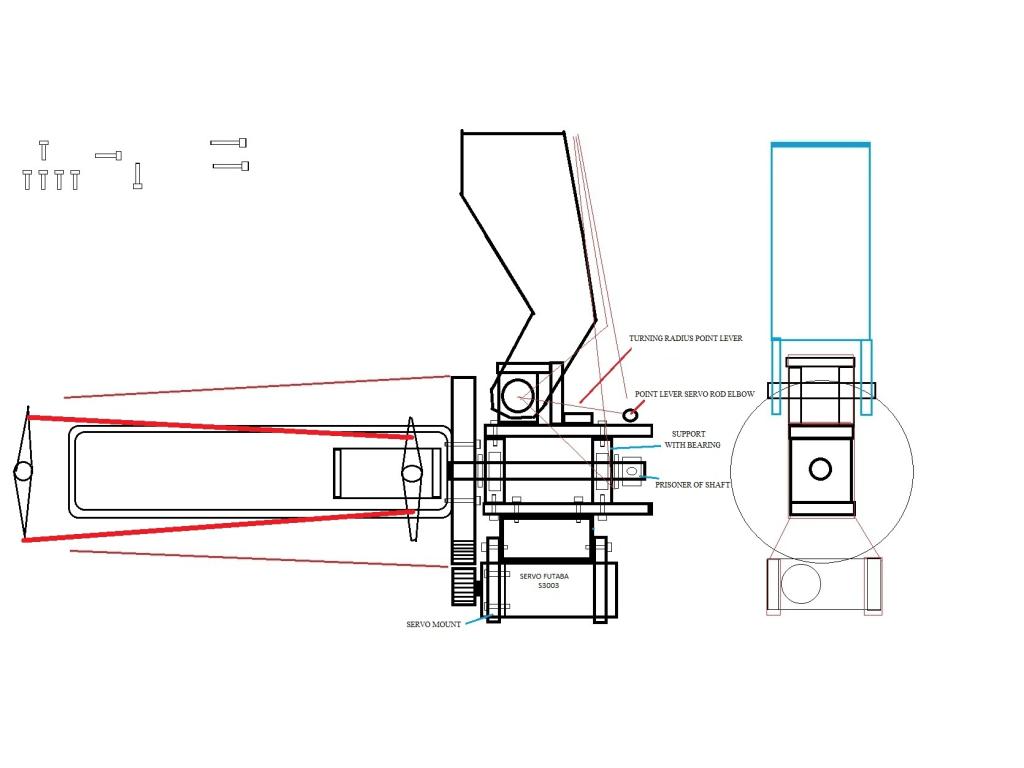

New update, I'm working on the design of the arm, concretamenete at the elbow wrist and hand. First I decided the degrees of rotation of each moving part for what I do. The shoulder has 180 degrees of rotation. The elbow is 110 of rotation. The doll has 135 degrees of rotation The rotation of the wrist is 300 of rotation.

In the picture above add the servo that attacks the large gear is not a continuous rotation servo, but the potentiometer or adjustable resistor is mounted outside the servo coupled to the long axis of rotation, with a belt and reducing pulleys to match the 300 of rotation that I intend. Removed the mechanical stop and adjusting servo got multiply adjustable resistance force servo and reduce its speed but with control over their positions. I have found that some servos can not take the 99 positions ARC, only approximately 70 positions, it is logical for the PWM limits. So if 70 positions and 300 of rotation calculated by 4.28 position.

Nice design.

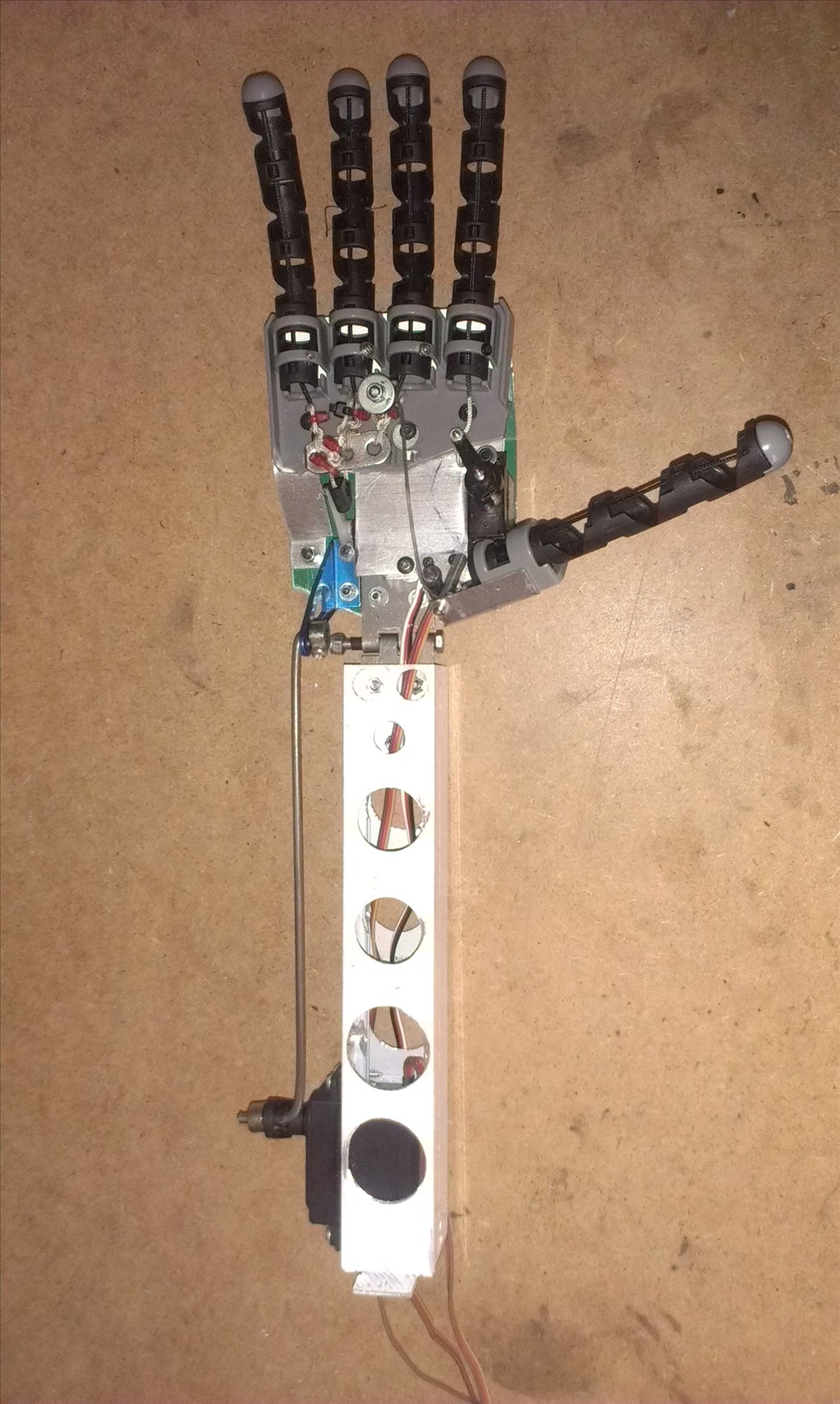

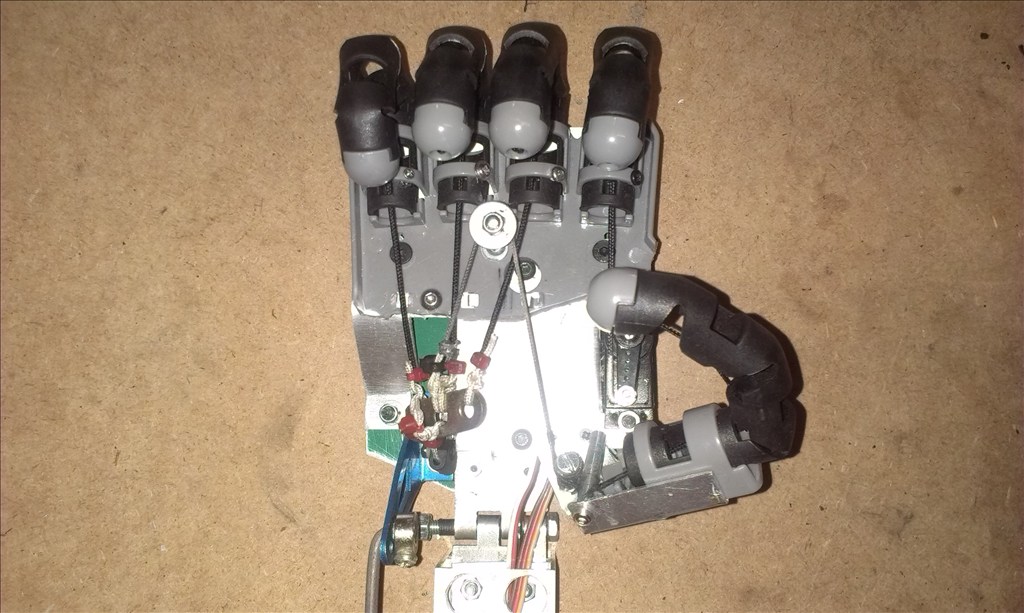

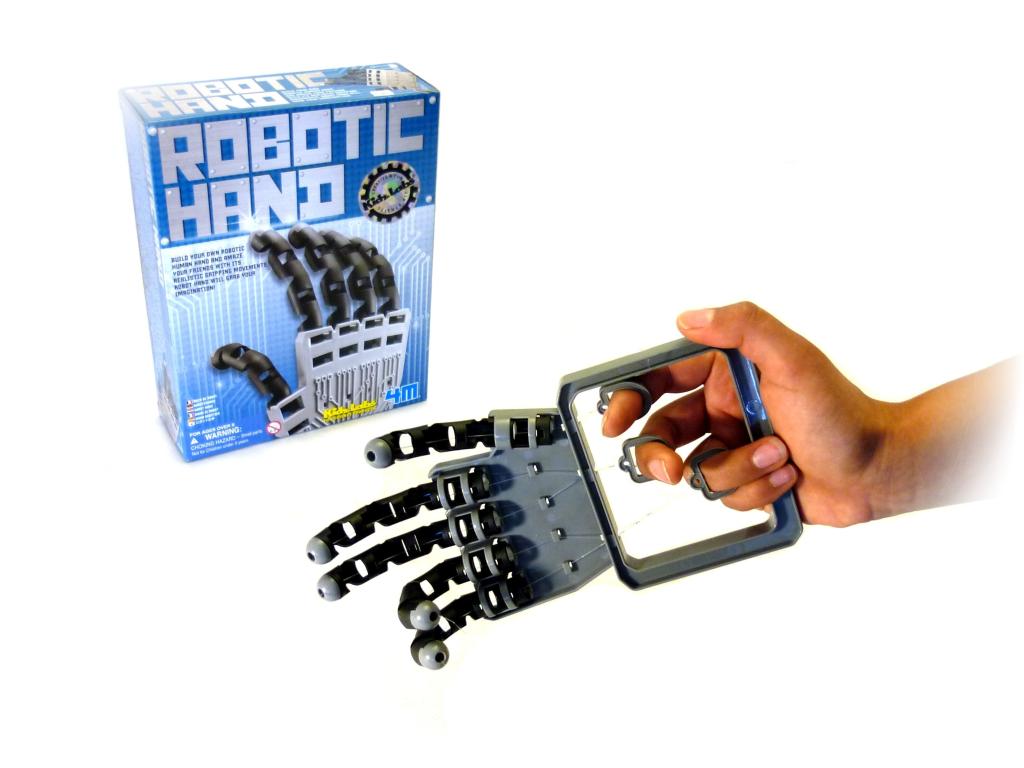

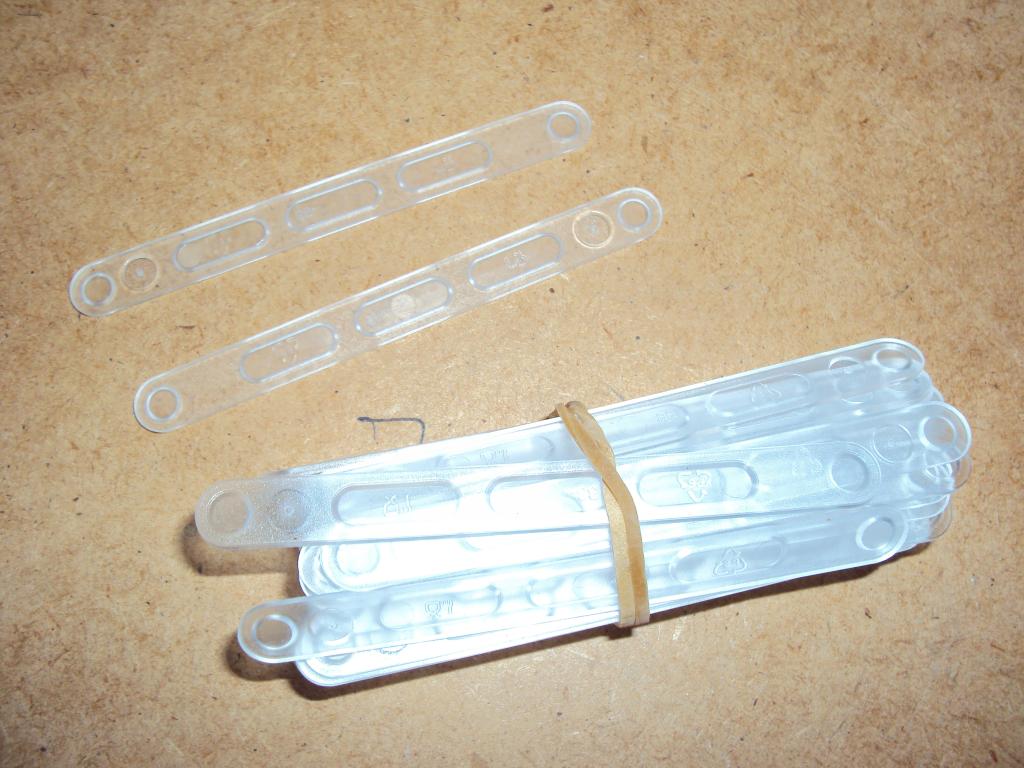

Thanks Bret, I'm also starting the construction of a hand from "plastic coffee spoons," the idea is a rubber band over the toe and a thin nylon rope below the finger to close the finger to pull the servo . Spacers and screws and bolts holes function as hinges for each knuckle, silver spray paint does the rest.

cool

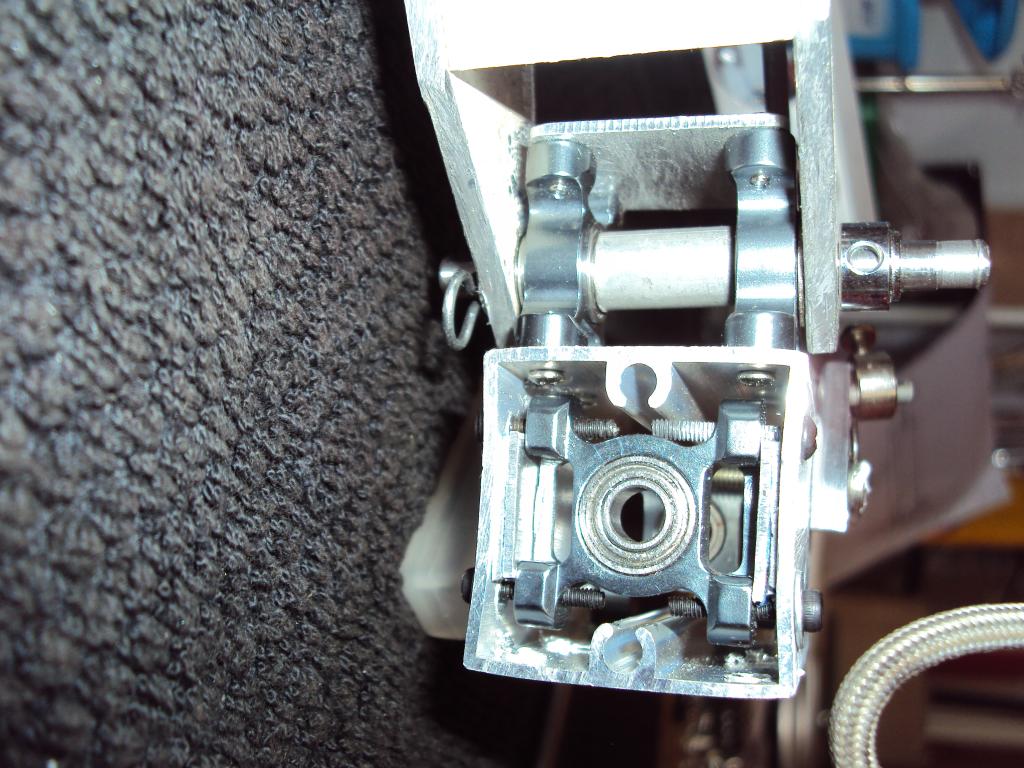

Progress in building an RSP arm with perforated aluminum square tube to relieve some weight, stands with main shaft bearings 450 RC helicopter, steel shafts, and molded aluminum foil and steel fasteners most. Hard work for building solid reliable but hopefully a long time.