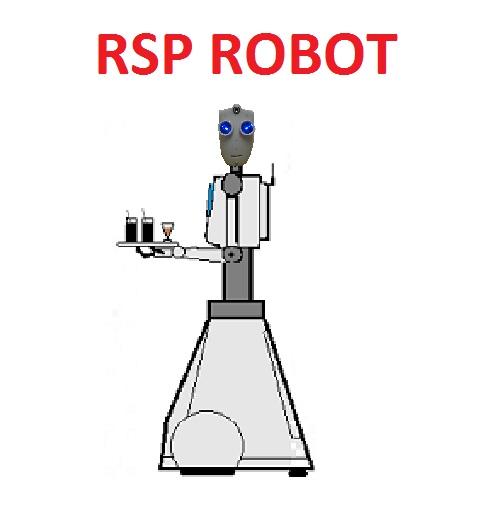

Hi all! I'm excited to share this project with you, this is the robot RSP, I bought my second ez-b (v3) and having checked with my first robot(MY ROBOT)

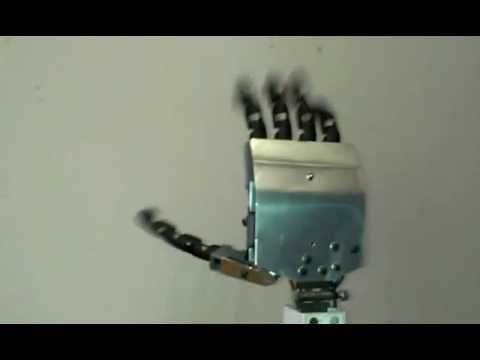

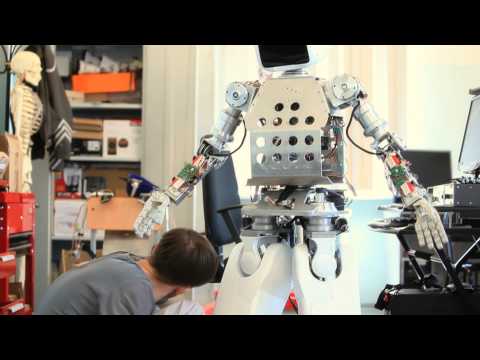

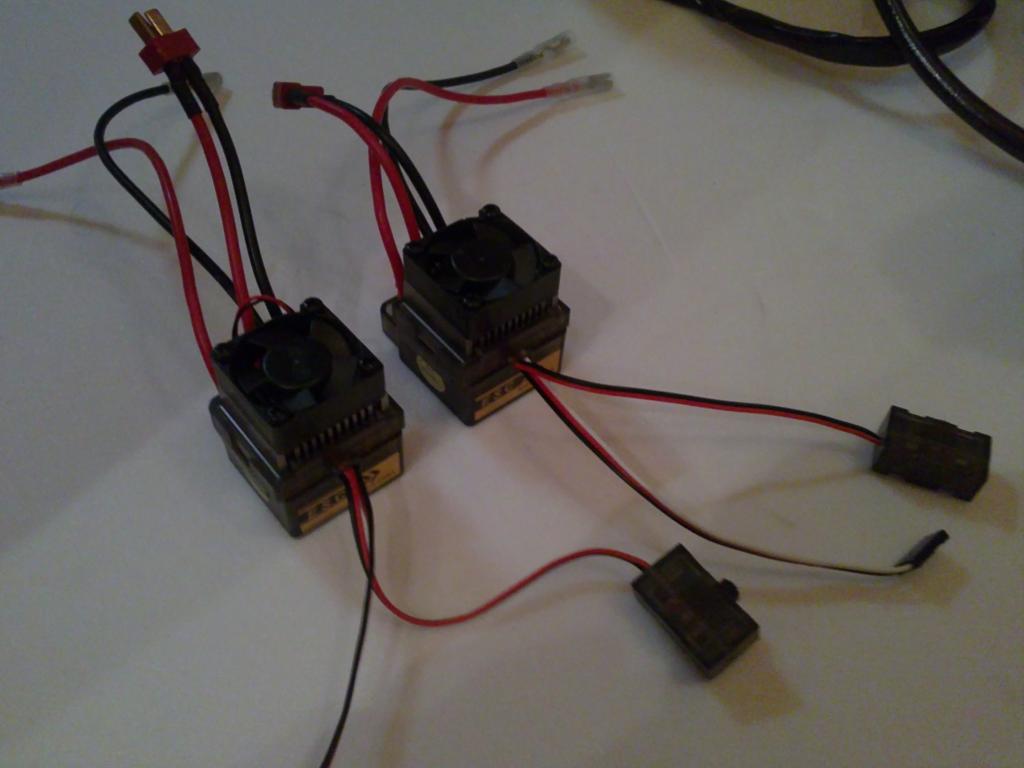

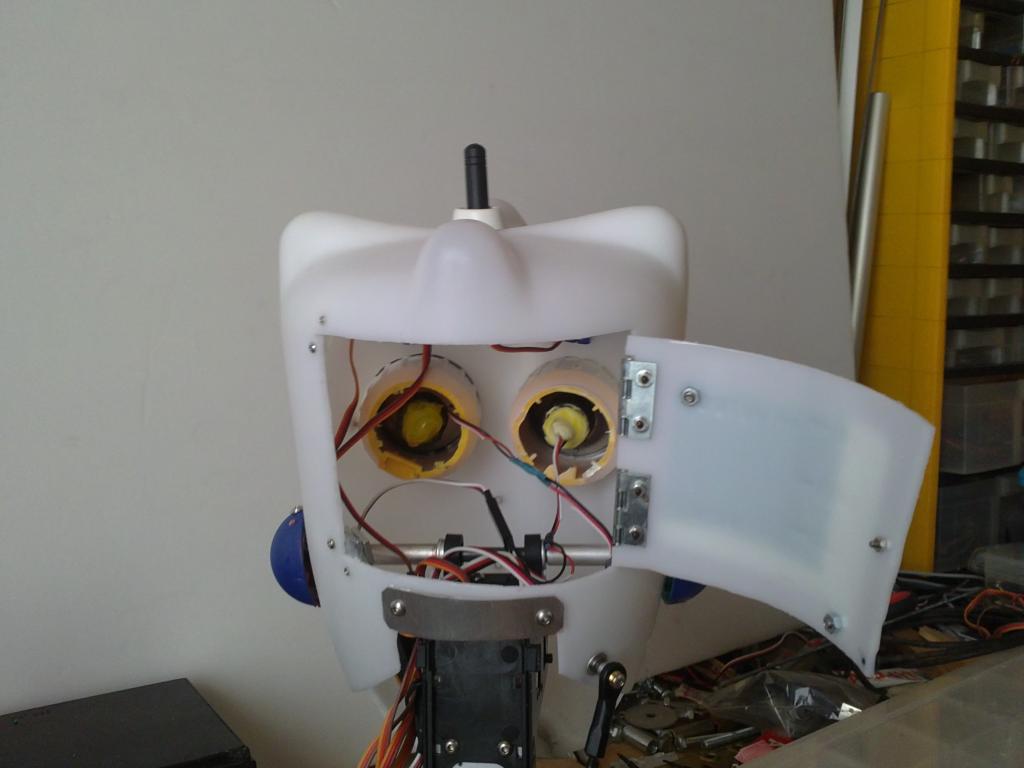

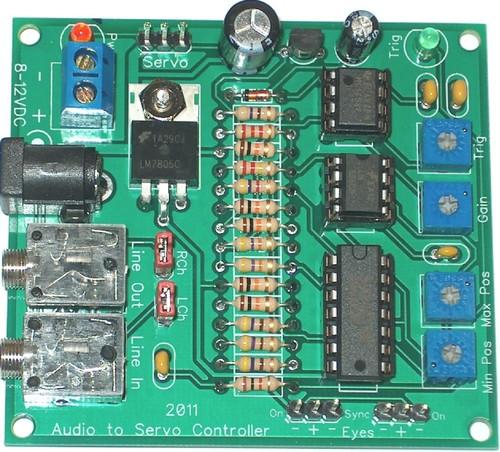

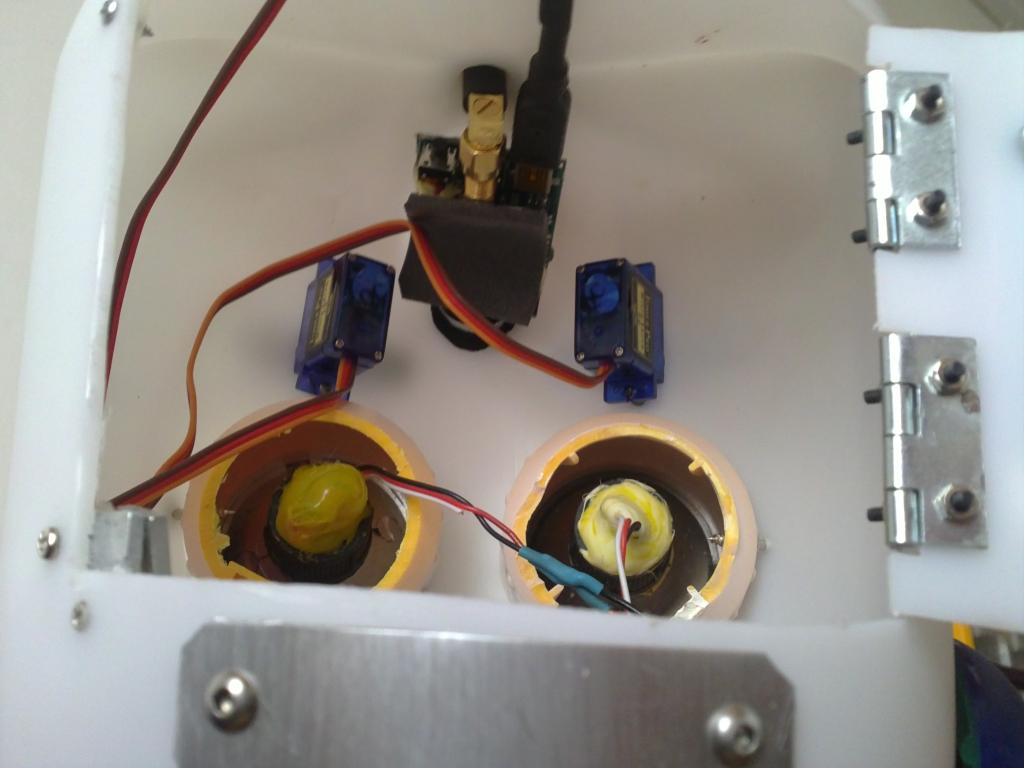

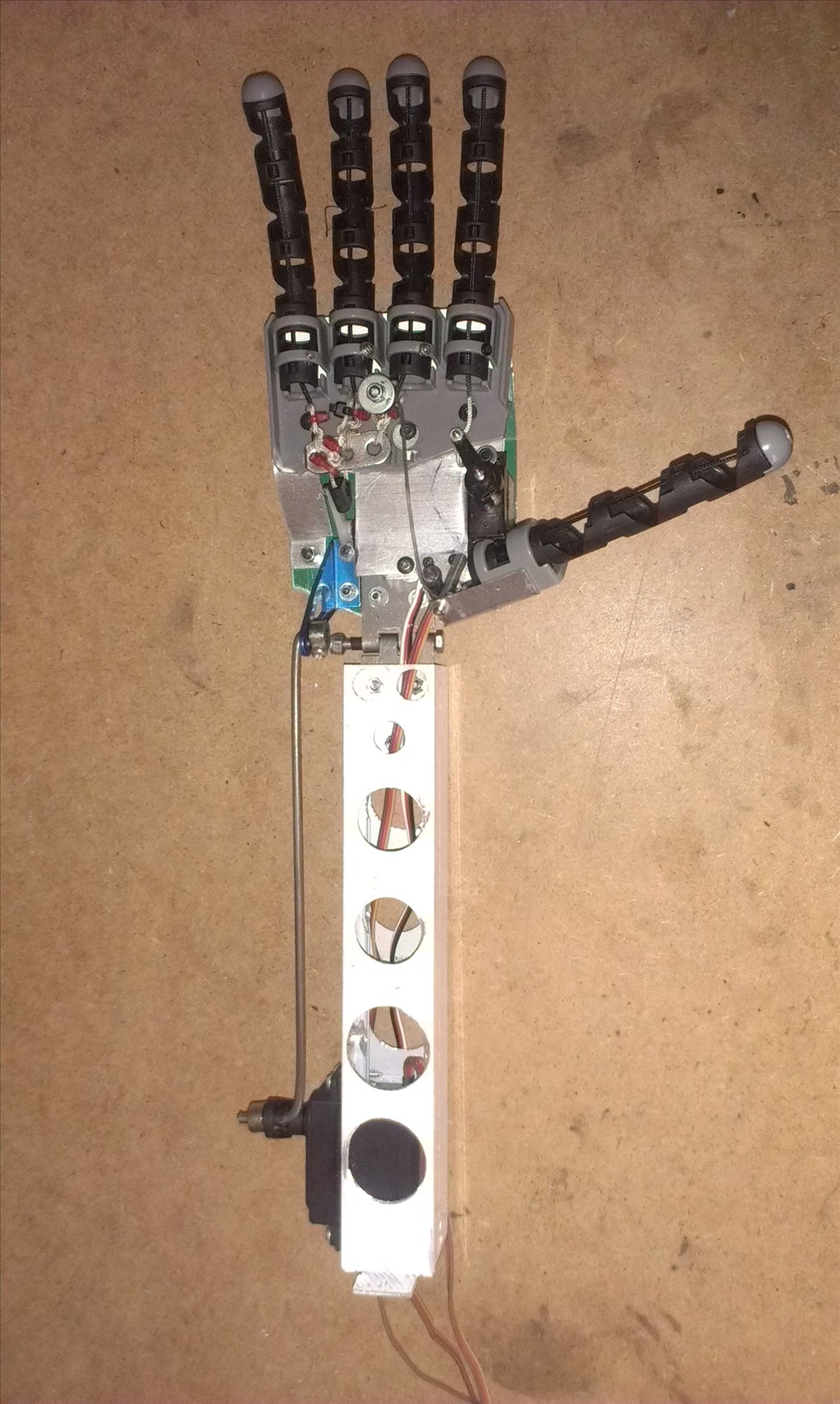

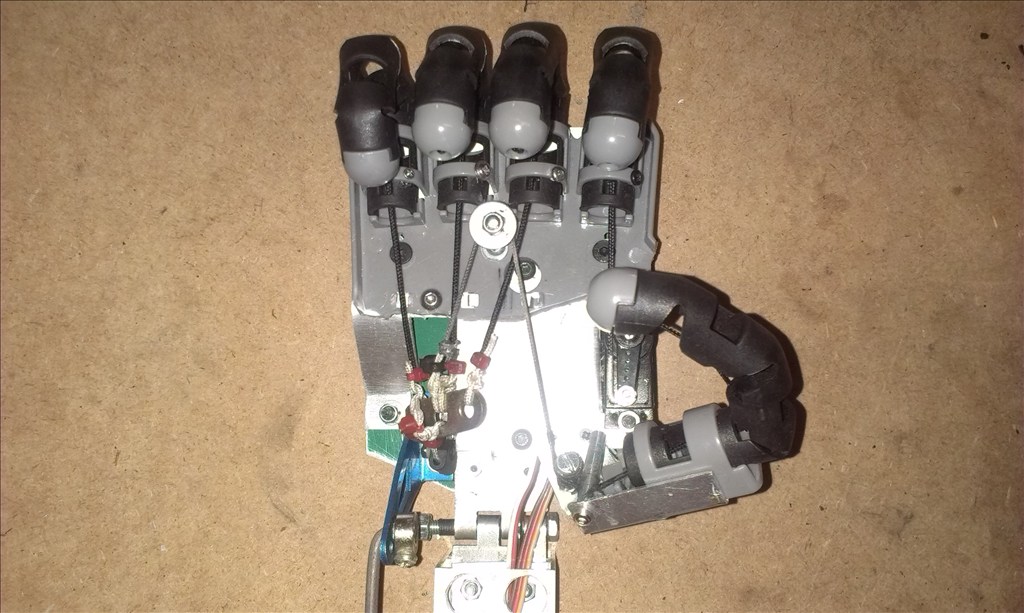

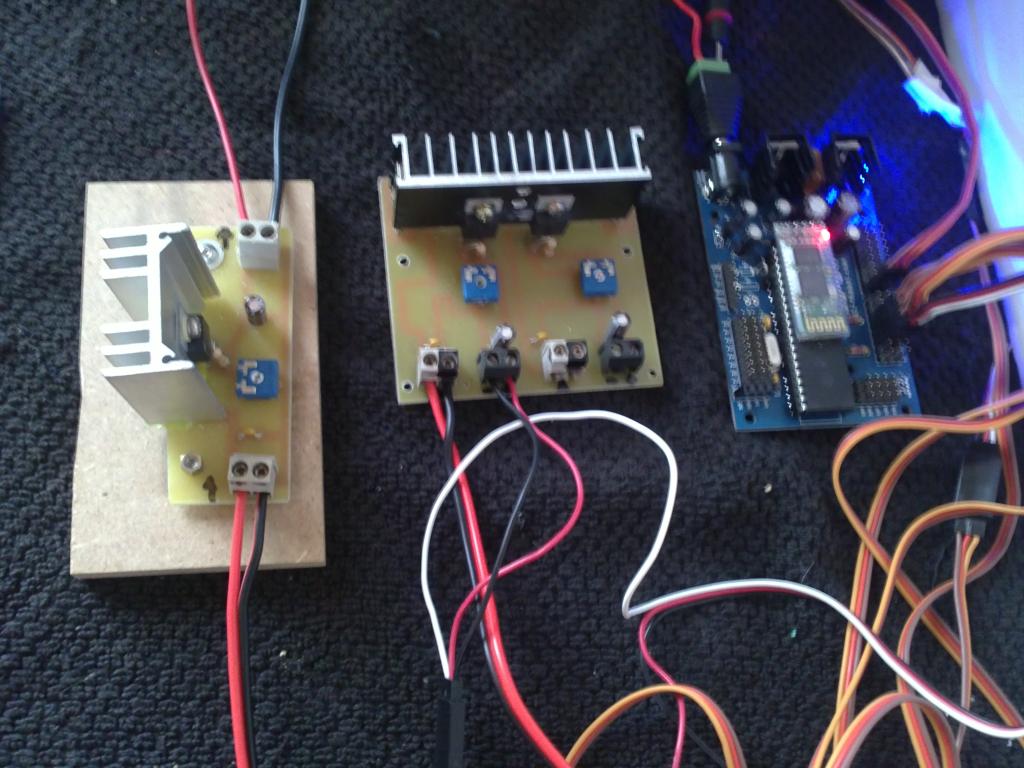

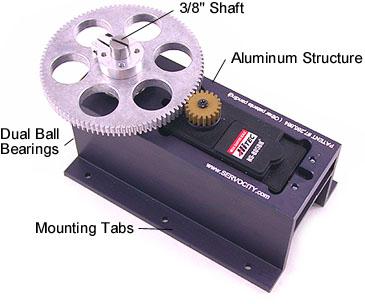

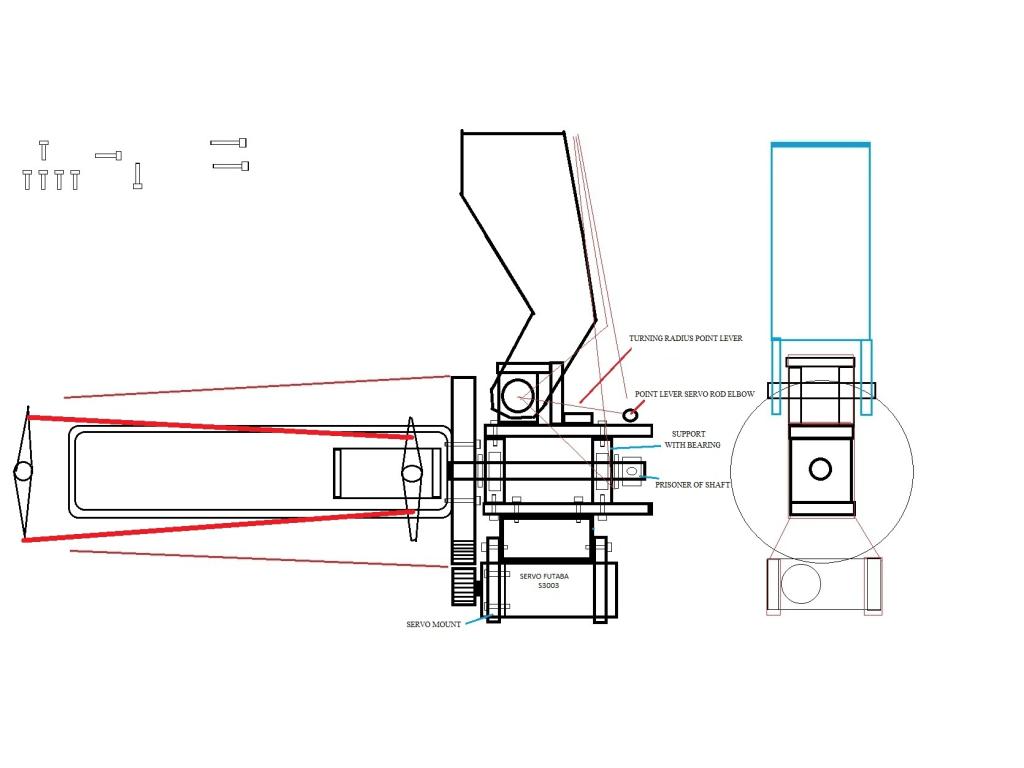

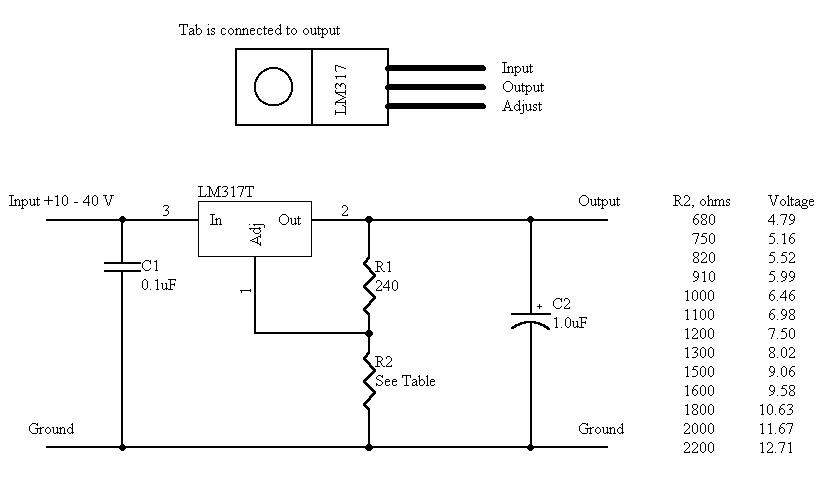

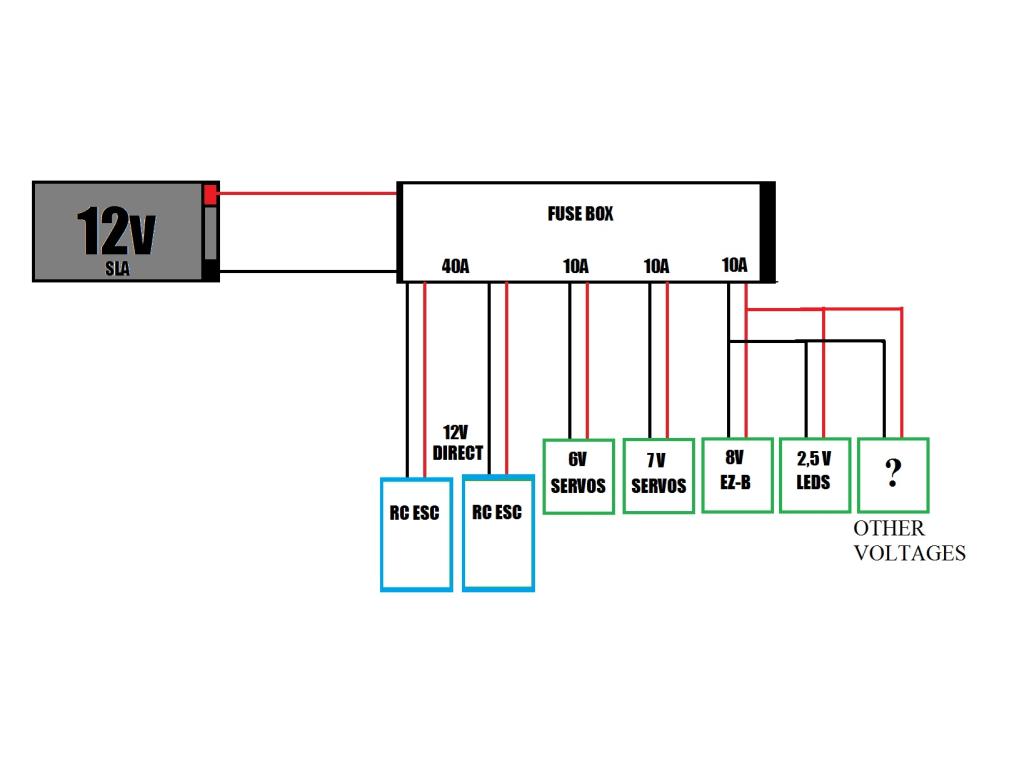

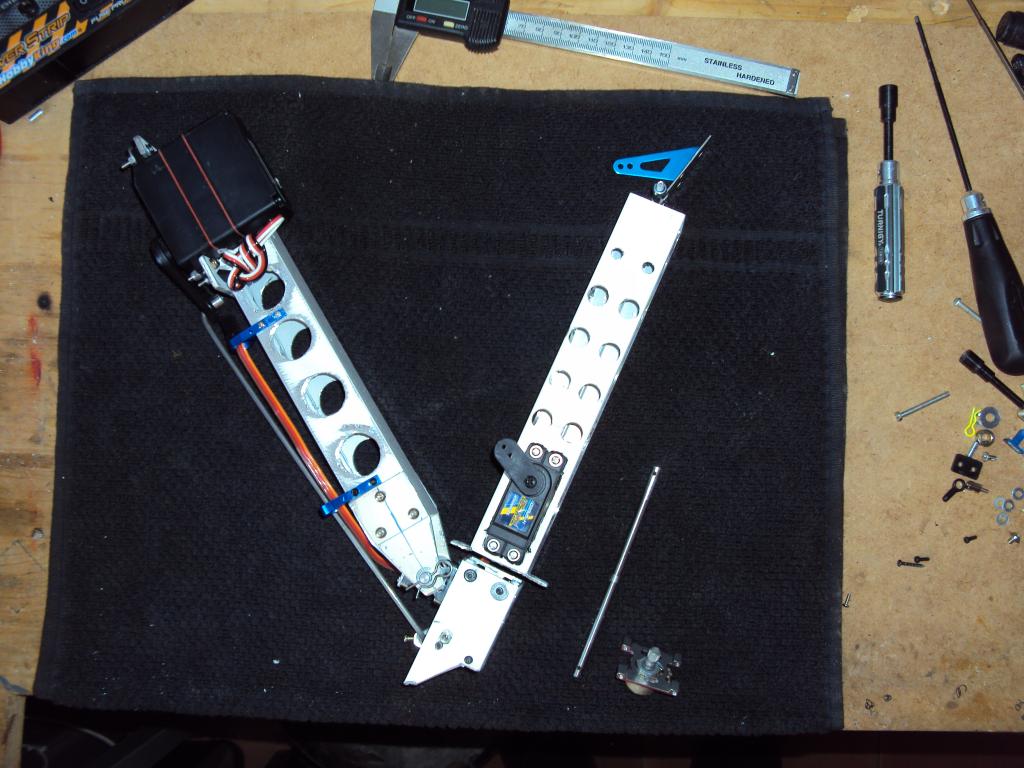

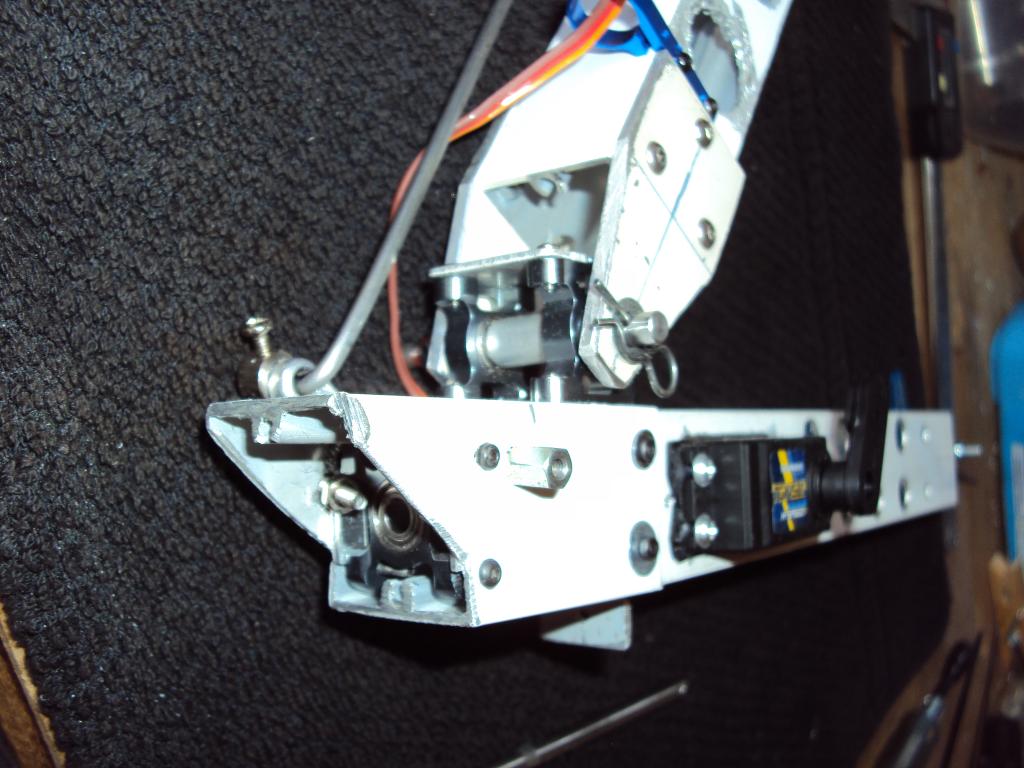

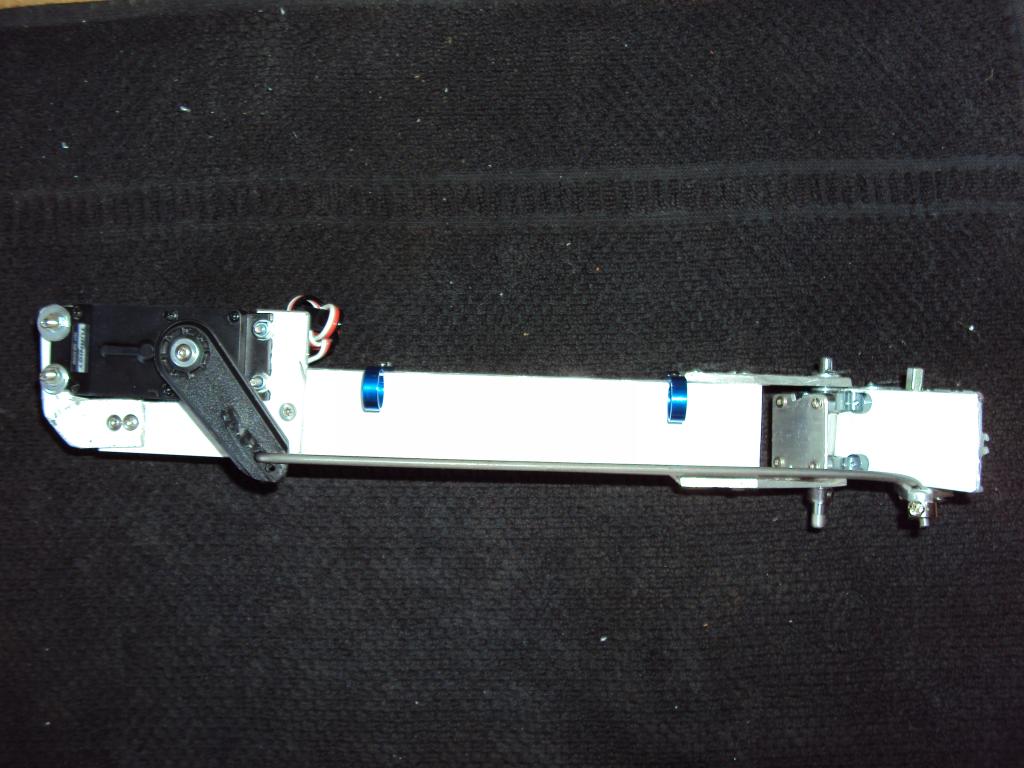

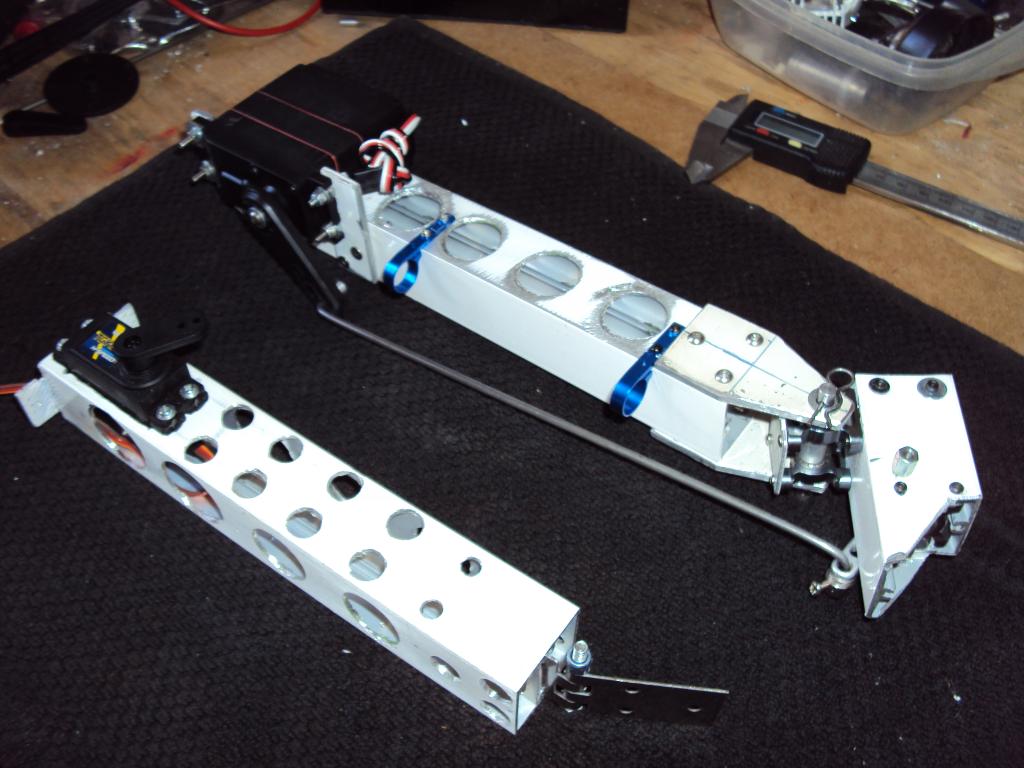

, I decided to undertake a larger project, its height will be of 5.4 feet (1.65 m), currently under construction I have the head, and gathered the materials for the traction system, some voltage regulators, 2 rc esc, several batteries, etc..

I enclose a drawing of how it will look when completed and some photos and video. I hope this project will have a mutual sense of teaching and learning for the entire community that will inspire others and that I may be inspired by all your valuable ideas, more information soon.

By R2D2

— Last update

Other robots from Synthiam community

Dave's Bimbo The Clown

EZ Robot revives classic amusement games with DJ's Bimbo The Clown-fun retro entertainment and creative community...

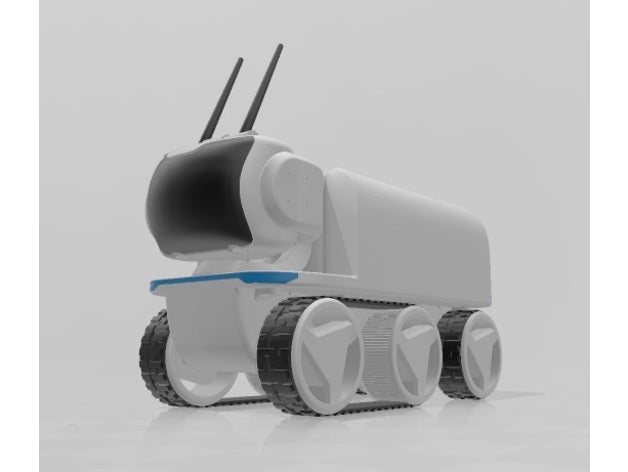

Jstarne1's Calling All 3D Printers! Get The Stls While They...

LEVi Rover 3D files assembled and ready to print, with model cuts for smaller beds and community tips for printing and...

Hazardbt's I Have A Telemetry Suit-Contro

EZ-B controller simplifies telemetry-suit Cyborg Zombie setup-controls servos, cameras and speakers for a mobile robot...

Very Cool!:)

LOL, I started Vacuum Forming some custom parts for a Scratch EZB Robot Build as well, with Camera mount and "EYES", similar to yours...lol!:) Very Nice.

R2D2 thats really cool !

Very cool!) nice work! Reminds me abit of one of the older models from the movie: I-Robot ,,,

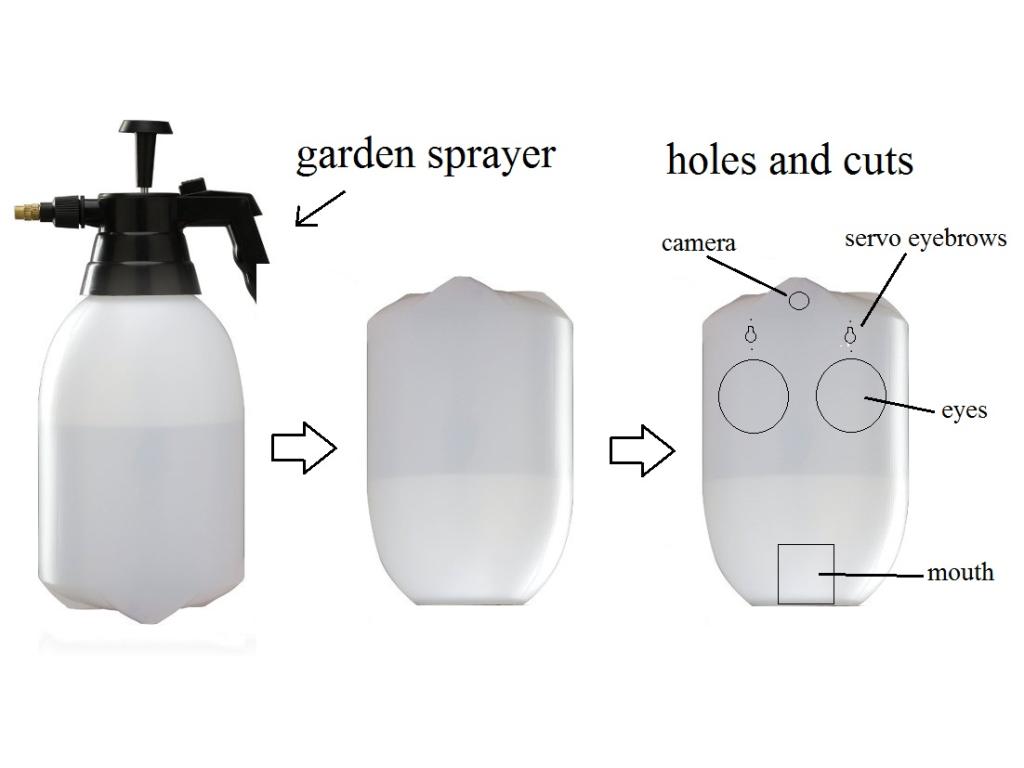

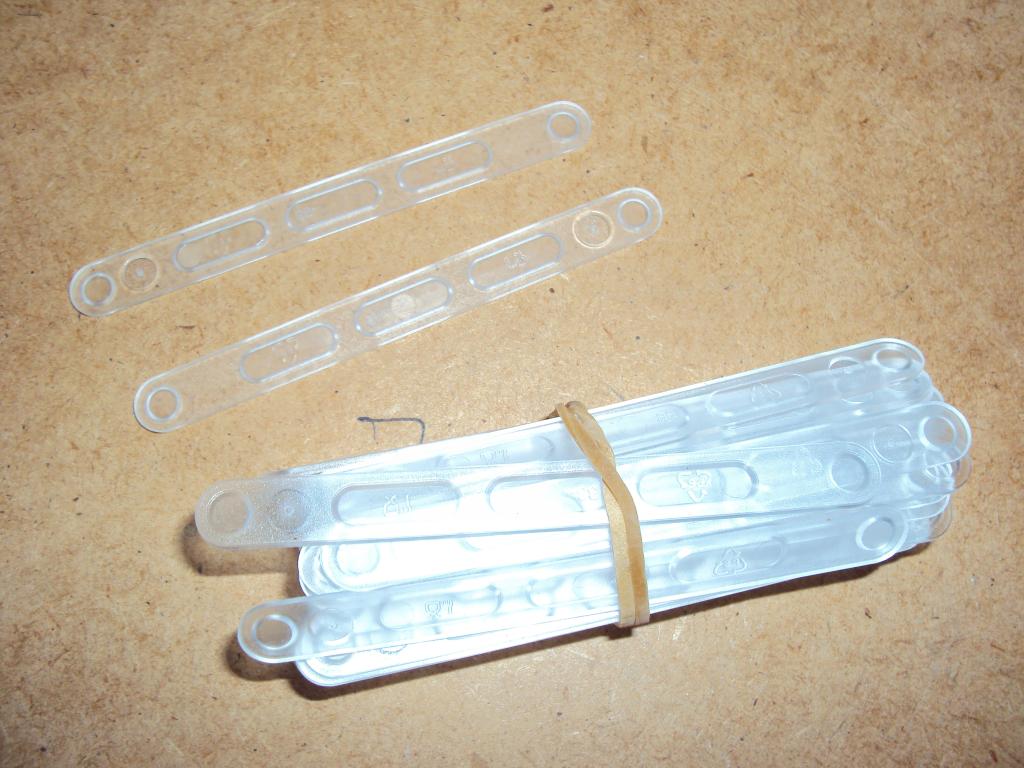

Indeed RR333! the robot from "I robot" has been an inspiration to me, but I do not use titanium to build it, use a sprayer, garden should be recycled plastic and is a very hard blows, but easy to drill.

This is so cool! I too am planning on a large bot (after B9 of course) - I will be following your progress closely for ideas and inspiration.

Brilliant!!!!!!!

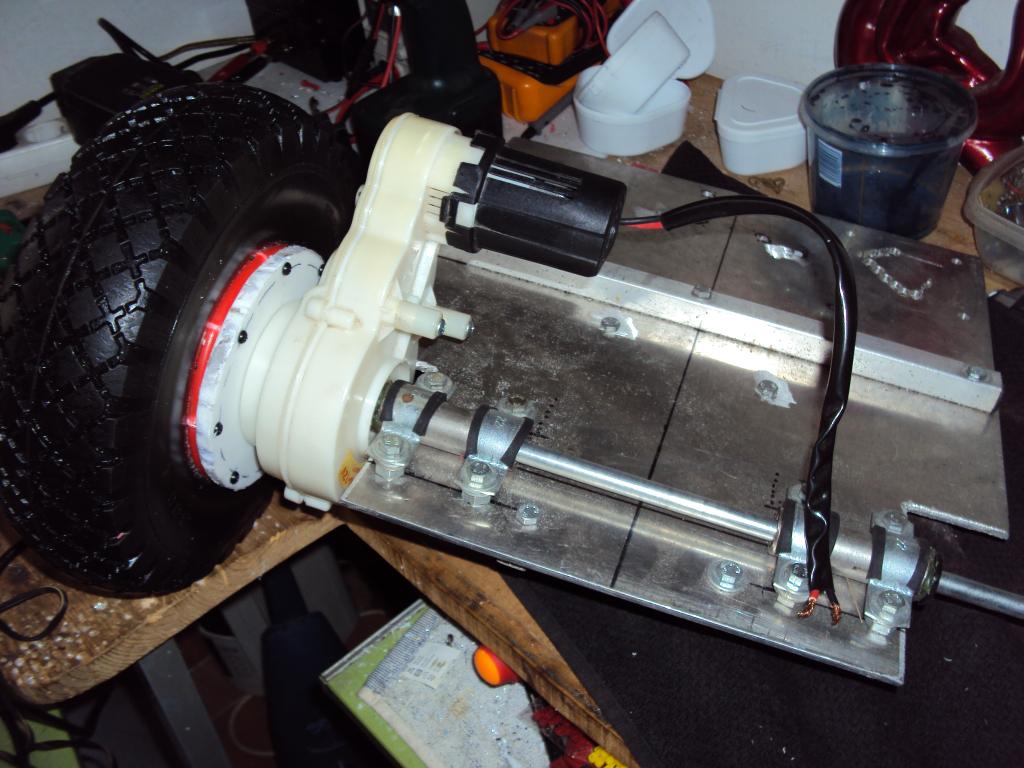

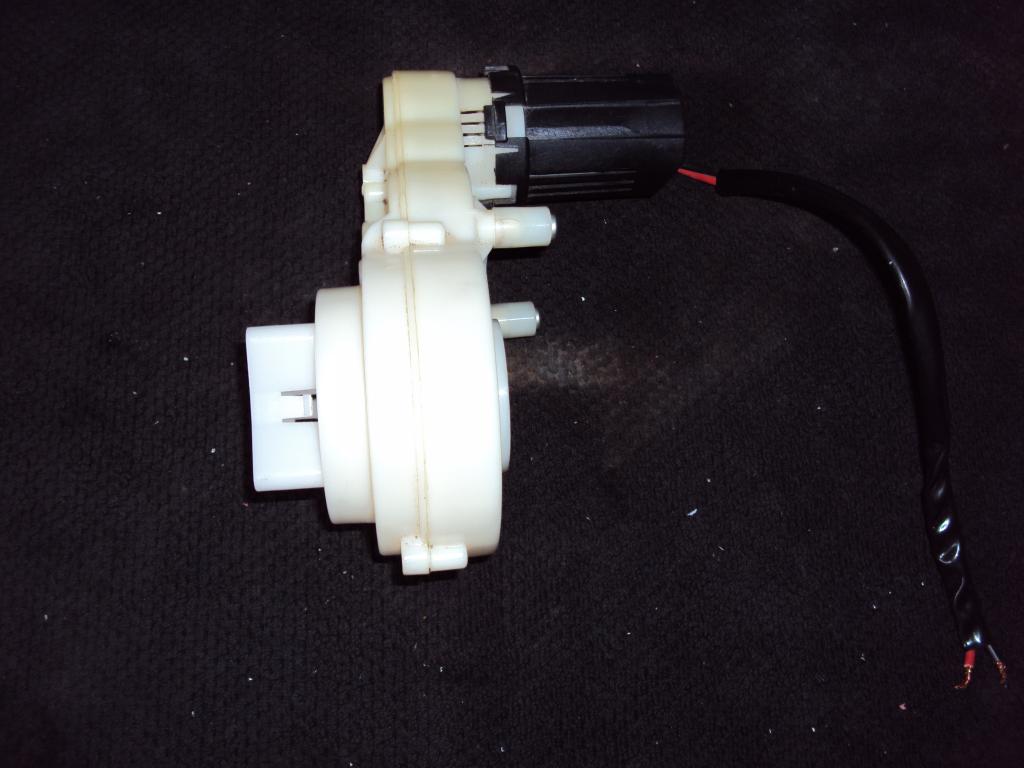

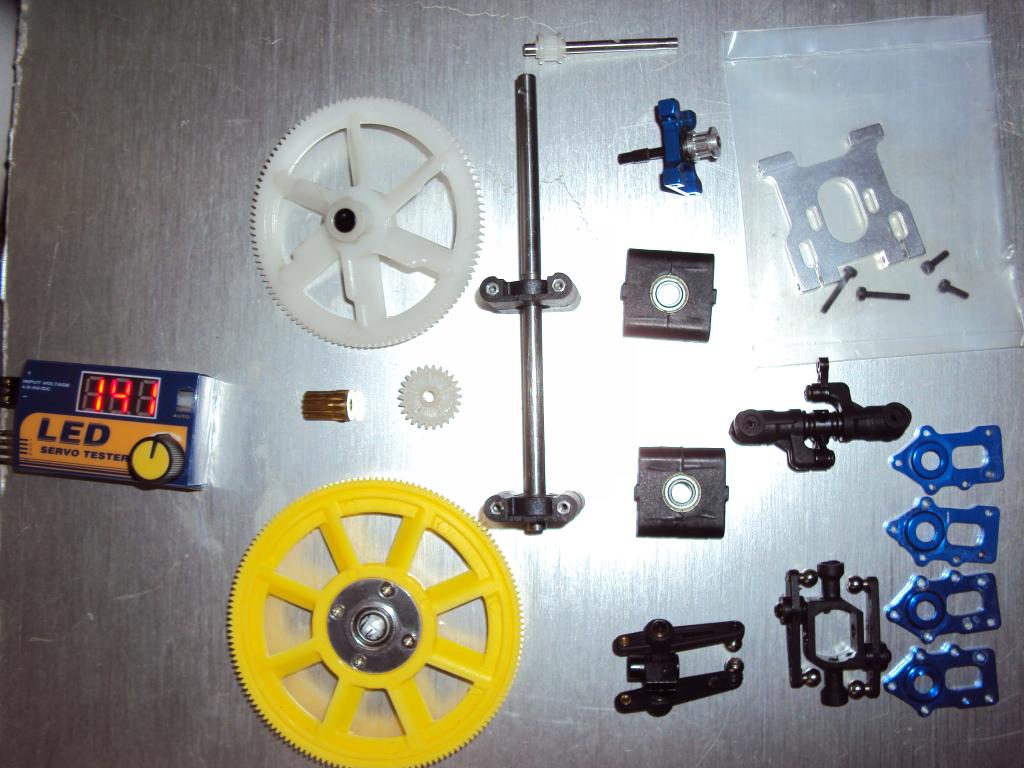

Go! few lovers of big robots, I'm glad there's another story for recycling. After searching and searching for a strong traction system, reliable and economical, escontre this: DAREWAY.

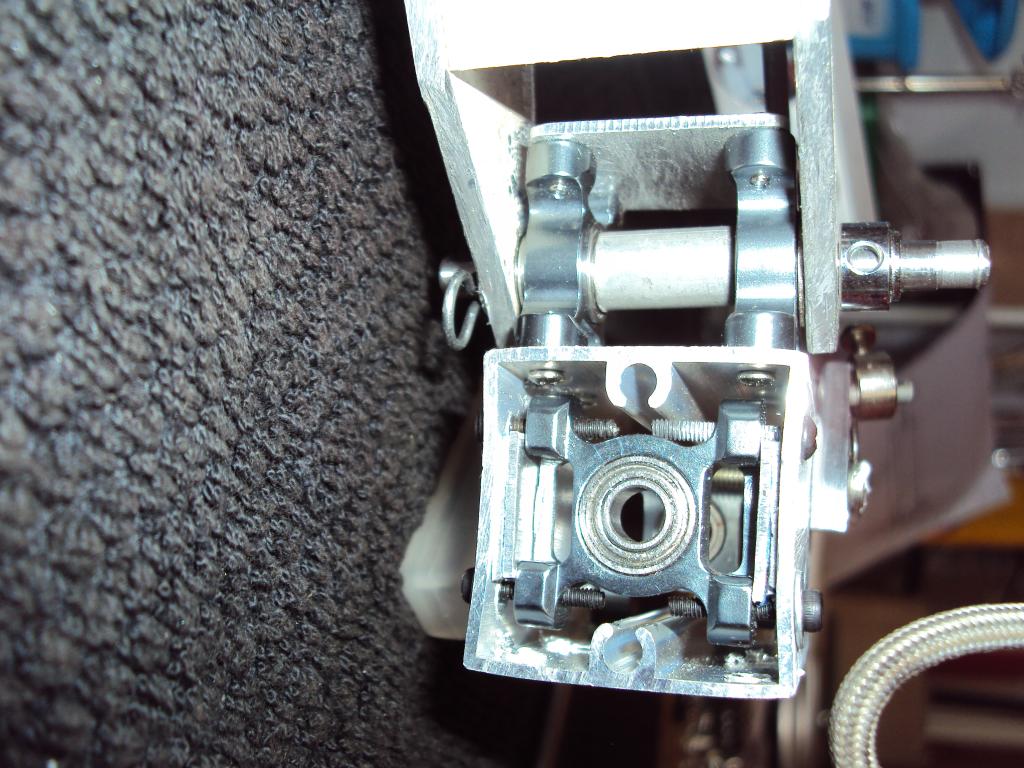

is the child version of the Segway. I could buy one used and extract their powerful engines with gearbox, a 12V 7A lead battery and the axis of the wheels (very important so that the weight does not damage the gear reduction) all riding on an aluminum cut to size. The original wheels were discarded because they were dareway plastic in return bought a wheelbarrow rubber wheels that offer much more grip and traction.