Hey Guys,

I've read lots on the forum, and posted a hand full of times, but I thought it was about time I launched my first major project (well, my second really, I converted a wall-e, but I thought there was enough of those on here).

So here is announcing OmniMC, an Omnibot 2000 media centre

The idea is to make him all RC and to also house a Raspberry PI running RaspBMC as the media centre bit. I'll then add some speakers and maybe some under-bot lighting

I'm wondering if then I can control the whole thing with one of these:

Other than that, I'm kinda just winging it and seeing what other bits and pieces I come up with.

To start with though, I've done the usual thing of gutting him and sticking him through the dishwasher

So right now, he is prepped and ready to go.

I've already got my EZ-Robot kit, and a few components such as 6v battery

Some blue replacement bulbs

My Raspberry PI (which arrived today) and I've just won a screen for his chest

While I'm waiting for some other bits, I've also been looking at making some replacement tires which you can see details of in one of my other posts

So that's pretty much the state of play at the moment. I'm pretty much a novice at all this, so I'm looking forward to the challenge. Lets see if I've bitten off more than I can chew

Other robots from Synthiam community

David's Home Depot R2D2 To A Real R2D2 Robot

Bhouston's Another Inmoov Modification

Hey mike, yup. I have no idea how to do thoes though . I may look at the gearbox for the wheels and see how i can keep the 2 speed setting.

. I may look at the gearbox for the wheels and see how i can keep the 2 speed setting.

One other thing i want to setup is switching on the eyes. I know i can produce a signal for switching something on or off, but what should i use as the actual switch? Ie, i need the ez b to signal to open a switch to let through a direct battery connection to the lights.

I also think i may need some alternative ducting to hide the neck, as the grey stuff isnt long / flexible enough. If i change that though, i could do with some matching stuff for the shouldes too.

Iam sure you will find a duct that fits. There was somebody here in the forum talking about that stuff once. jstarne might have gotten some of that once and might be able to help you out if you ask him.

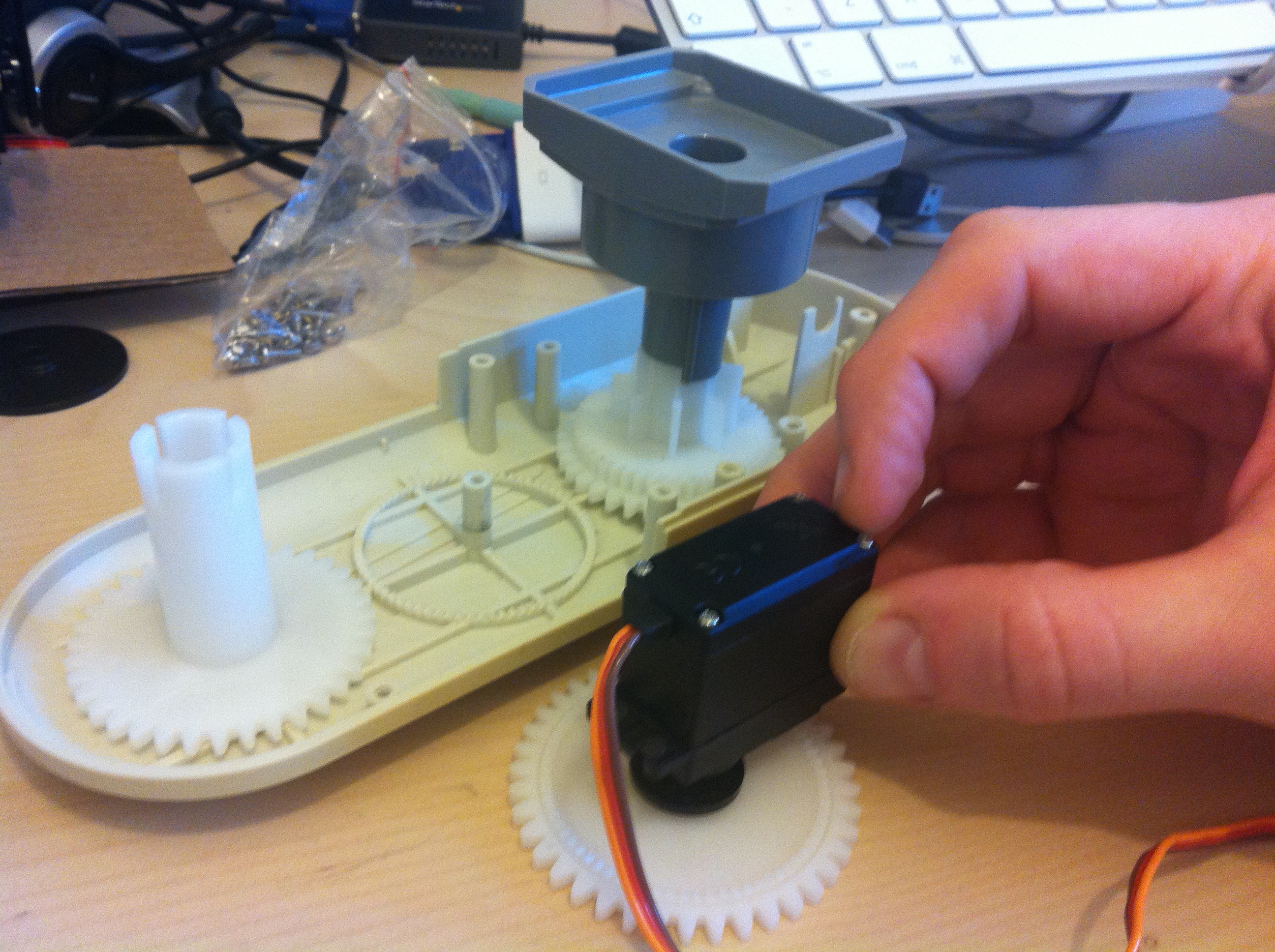

The lower arm is tricky! I couldnt image how to do that - especially since you have rotation and hand-movement in there.Maybe you can keep one of the original gareas in there - lets say you keep the original motor for hand rotation and try to change mechanics for hand (open/close). I dont have a lower arm in front of me right now so Icant really image how this would look /have to be made in real life.

Ok, bit of research and it seems something like a TIP122 should do the trick for the power switch to the eyes. Pretty cheap on ebay too which is good

Having spent an evening trying to figure the hands out, I'm really not sure how to go about it. The obvious thing would be to just re-use what it came with, but that would only fix one hand.

As much as it pains me, as I really want to keep it as stock looking as possible, I've been considering some off the shelf grippers.

AX-12 Dual Gripper

The upside would be, it just works, and they would be a lot easier to control and fit. The down side, I'm not sure if they would compromise the aesthetics of him, and I'm also not sure how much weight they would add to the arms putting even more strain on the upper arm servos.

Any thoughts?

@Matt hey buddy checked in on your project. I recommend tip 220 switching transistors , small and effective and support up to 1000ma current. Also your previous issue of gear selection can be solved using 2 ports from ezb. One digital on off for the tip 220 to move the gear selection.motor and the second port would be wired to the gear selection switch which is triggered when the motor has successfully switched gears. I took. Look at the claw. It appears the servos and brackets are much to large to fit inside omni 2000 forearm or wrist. I did find one that will fit however https://thinkbotics.com/products.htm

https://thinkbotics.com/products.htm

I found since this gripped includes the servo they are one third the price of those.others too. Since one servo drives it you can fit it inside the arm and it is easier to control

Hey @josh thanks for the feedback. I can't seem to find any tip 220's here, bit the tip 122 is rated up to 5A so I think that should do the job. Good thinking on reusing the original motor and switch for gear selection. I'll give that a try.

Re the gripper, I did see the one you suggested, I listed wanted one with a rotating wrist too. My thoughts were to use some lynx motion servo mounts plus some offset c brackets to replicate the hand I linked to but using standard servos. I then just have to make the fingers and fashion some kind of bracket to fix it to the wrist servo.

What do you think?

Hey Matt , first off i want to say sorry for the spelling errors and just overall weird sentences. In using a junk phone that edits things the way it wants when i click submit. I will have my new galaxy s3 by Dec 10 though so i want deal with this long. Anyways about the arm. Going back to the one you linked controlled by two series. I don't see that there is enough room. The idea of lynx motion brackets will work! If the serve is horizontal in relation to the wrist the serve bracket that comes with the pan and tilt bracket kits could allow you to attach it right to the end of a servo horn to give wrist twisting on your claw. Just to clarify i am imagining a servo position on your claws like the one i pictured.

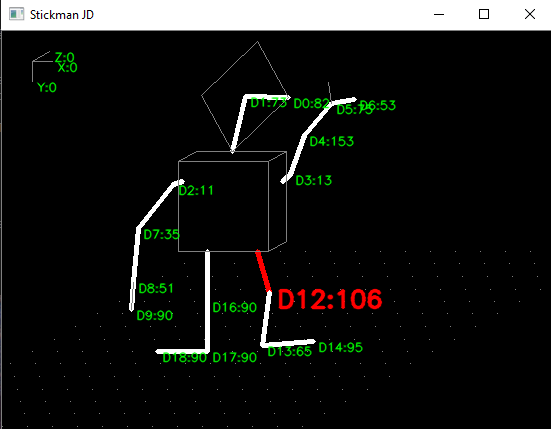

If this is not what you meant can you draw it?