This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

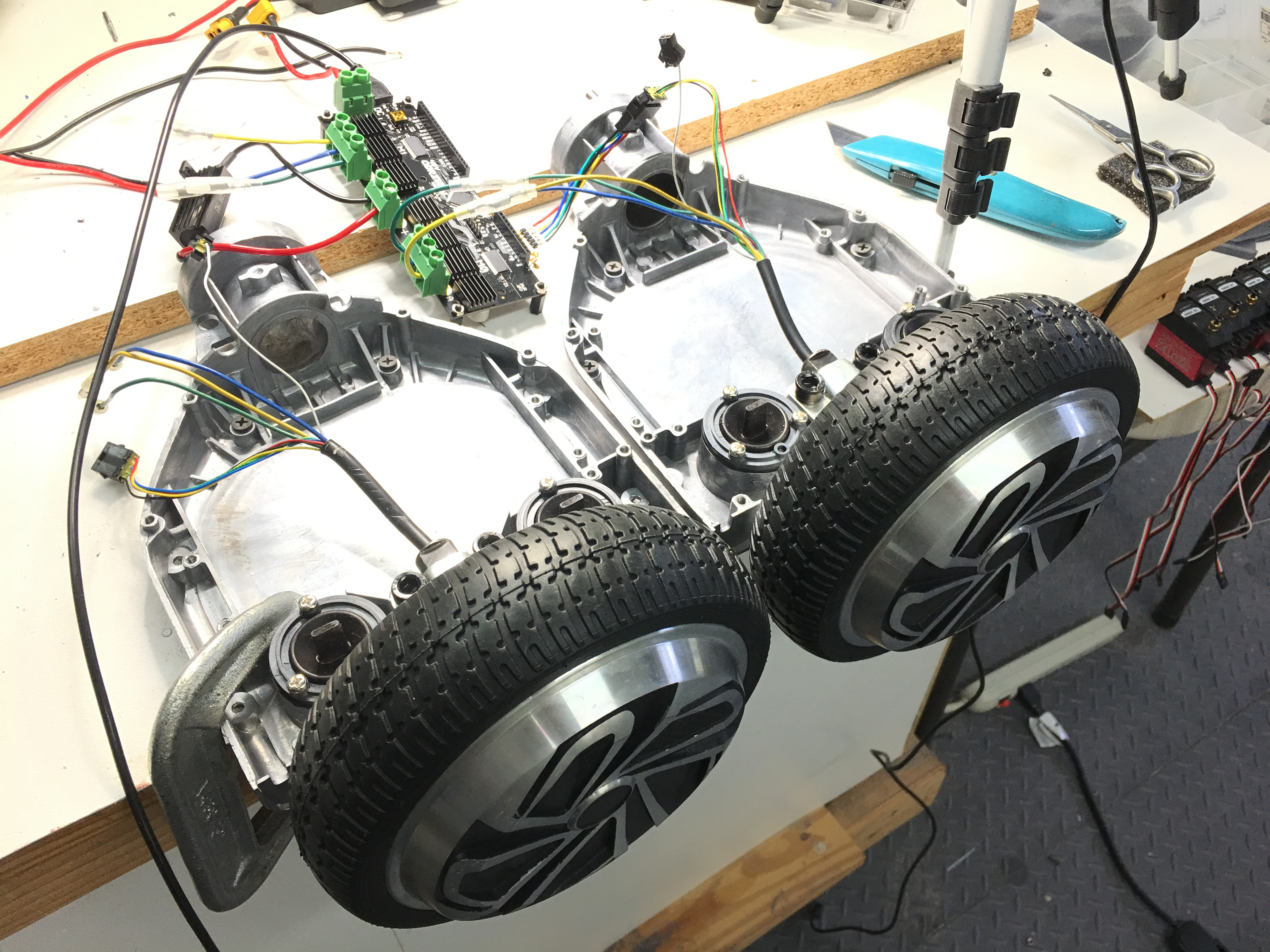

Fxrtst's Untitled Hoverboard Project

Build a robot base with cheap hoverboard 3-phase motors and Flipsky FSESC VESC - programmable ESCs, servo connector,...

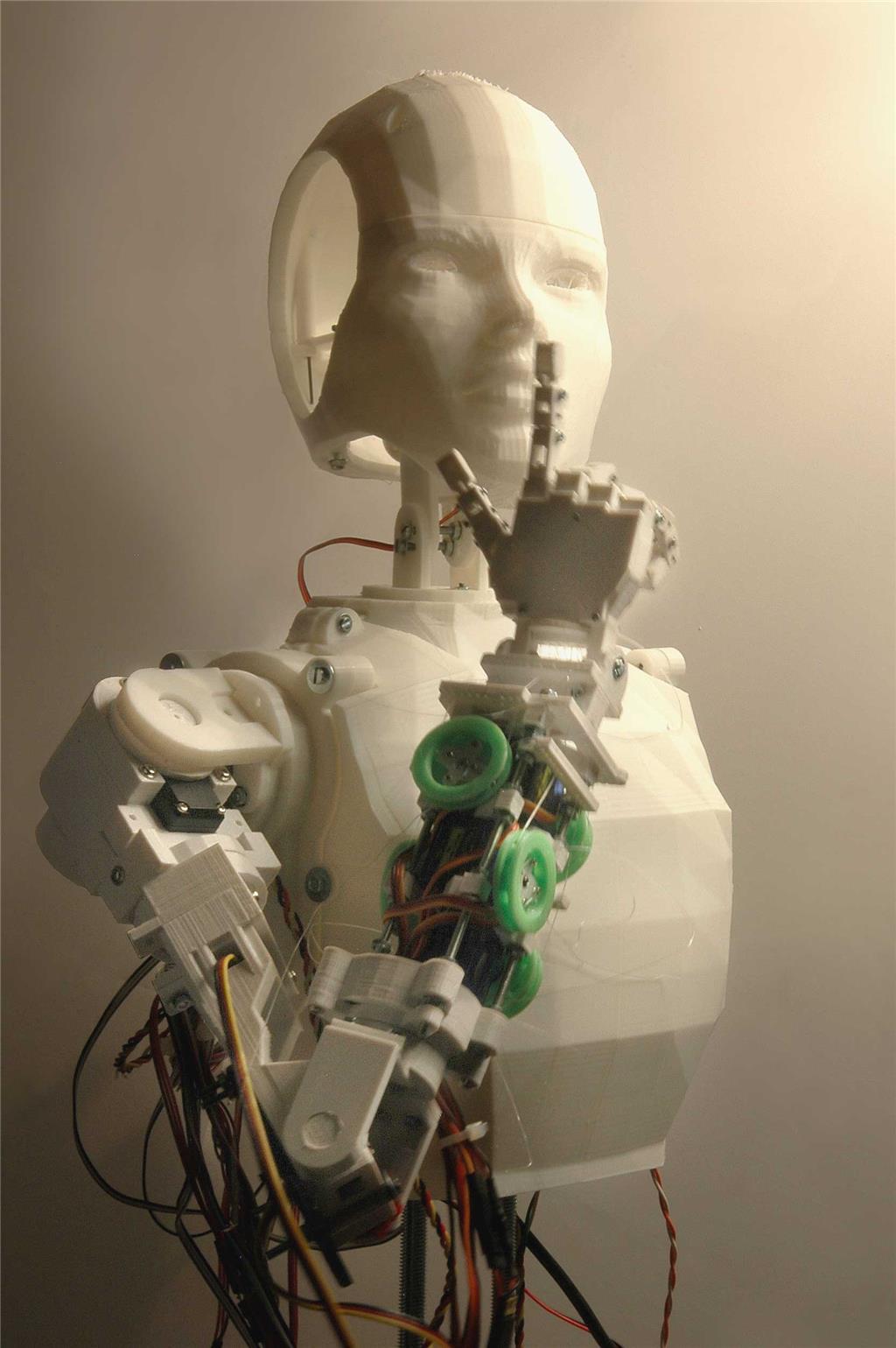

Buratino's Buratino - Humanoid Animatronic

Buratino 50x50cm 3D-printed humanoid with 23 DOF, heavy-torque servos, EZB camera motion tracking, speech recognition...

Kenny's Motion Activated Camera Pause Toggle

Synthiam ARC toggles camera recording with CameraRecordPauseOn/Off using motion-tracking scripts to auto-start and pause...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

Truckee is near lake Tahoe. More of a ski town.

Ok update on Jarvis , plan for gripper , strong , quick and most importantly accurate.

This is a linear actuator made from a tube epoxy glued to a servo horn , the other end has the screw on it. The servo used must be modified for continuous rotation.

Josh how are you monitoring power levels?

This thread is so huge it's hard to find info...

Jarvis has a visual LCD showing volts , Watts consumed and amps. The power supply I have has a USB interface showing battery levels too which is super cool. I used the control board from a apc battery backup 400 watt version.

SFOY sking is much much fun,mosty rent mine at the resorts i stay at,and water sking i do ,i think i like it more

JOSH the idea you have there looks ok,and should work ok,only problem it takes up much room,i am looking at other ideas ,just as strong and accuracy is still great i am also adding force sensors on the tips and flex bend sensors on the arm and elbow

Well there is enough room , I could have used smaller components but I wanted it to be strong enough. Anyways I decided to use the 5995tg servo for either the elbow or side to side shoulder movement. Now I just need a way to hook up a 6 turn pot on that shaft.

on 240 oz and since not using a arm you should get close to 15 lb holding power,but at only a few seconds,since thats stall torque,and you go use much less like 10 to 12 lb holding torgue,so be very carefull you dont go near the 15 lb holding grip or servo will burn up

Do you think that's good for holding power? Considering he needs to grab beer bottles and wine bottle? One benefit we realized is with a screw type once the bottle is gripped the servo could release and it would not drop the cup / bottle.