This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

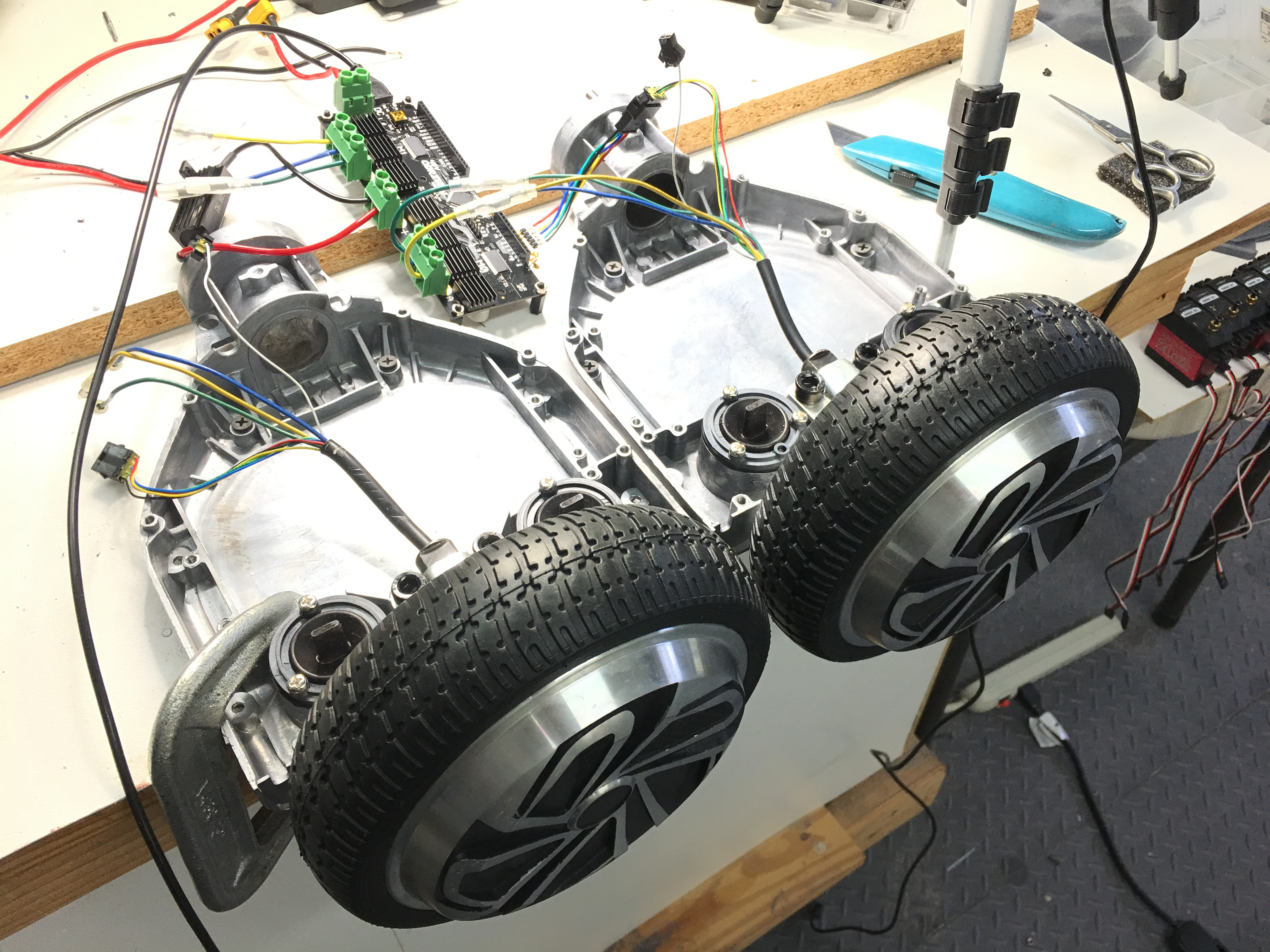

Fxrtst's Untitled Hoverboard Project

Build a robot base with cheap hoverboard 3-phase motors and Flipsky FSESC VESC - programmable ESCs, servo connector,...

Jdebay's What Should I Do?

Decide whether to wait for a replacement servo or use a faulty servo as a placeholder to fine-tune your JD robot's...

Perry's Mini-Move Project

Synthiam ARC mapping/nav and Roomba movement panels power Mini-Move: a .64-scale inmoov on Create 2 with scaled servos...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

LOL well my servo for wall-e's head is a micro servo and that is way to small once I added more stuff in it. So it cant bend its head too far before it cant come back from it. I put him on the back burner. OMNI is soo much more fun! @Josh I cant wait to see what you come up with!

Yeah I got to try it out , have we really figured out the best torque for the shoulders , think the 130 oz in is enough or should I go for bigger servos like the polulu 240 oz in or the turnigy 400+ oz in. I got to say that turnigy servo is tempting to get for shoulders ! I'm pretty sure I'm going with placement in the factory area the way you did troy I was really impressed. Now we gotta figure out the elbows.

same mount you are using for your arms is about same i design for mine,except design it have a lot more torque 400 0z 0nly good for 25 lbs ,but there is a problem you have a 12 inch reach may be more,so you are looking at 2 lb lift,go to servocity it tells you about this too ,and that stall torque also not real torque so about 1 lb lift then you haver the elbow to add and hand you need much more then 1000 oz or like my design 2000 oz way to get 2000 oz is very simple,2 ways one use a window glass motor or it a gear box witch i am using on mine 5-1 ratio

If you are needing to find out how many pounds a servo will lift or push with a 1" arm, simply divide the oz-in. number by 16. Servo speed is stated in seconds. Just as a car has a 0-60 mph time, a servo has a 0-60 degree time. The lower the 60 degree time the faster the servo operates. oz-in. / 16 = pounds of force (1" arm) If you are planning on using a 2" arm, you will then need to divide the pounds of force once again by 2. Example: An HS-425BB has 57 oz-in. of power 57 divided by 16 = 3.56 3.56 would be the pounds of force with a 1" arm

If you were to put on a 2" arm on the HS-425BB: 3.56 / 2 = 1.78 1.78 would be the pounds of force with a 2" arm

If you were to put on a 3" arm on the HS-425BB: 3.56 / 3 = 1.18 1.18 would be the pounds of force with a 3" arm

btw did you see the size of the turnigy servo? Its not standard so you have to plan on that too.

Found a hhd tray and I realized I could mount a ezb on each side and HDD inside , hmm just trying to find space efficiency.

I had to figure out how to actuate the elbows, I'm thinking of mounting the servo stationary in.the arm and maybe using one of the factory gears to.move it obviously I could take the typical RC approach of putting a standard servo horn on it and a couple pushrods and clevises.

Right now im thinking of keeping the factory motors and gears because I don't know honestly.how I would actuate it with a servo , right now he has both gripping and wrist rotation.

@troy , wow yea it wont be much , well all I want is for him to grab a drink.

Here is the link to the arm design discussion.

Josh have you tried the factory motors? To see what they can lift? If at all possible that is best. Otherwise I think you may want to jump in other arm discussion and then redesign. That could always be an upgrade later.