Other robots from Synthiam community

Jeremie's Voltron Robot

3D printed walking and talking Voltron robot built from Juri's 3Dworkbench design-100+ hours printing, ~$100 filament,...

Ezang's RGB Arduino, Python Code With ARC

Control Arduino RGB LEDs via Synthiam ARC serial monitor with Python code; ask a color and watch R G B light up.

Lars1989's Omnibot 2020 - The Next Generation

Revive Omnibot 2000 with an ez-robot kit and L298N motor controller; add small servos for arms and test a 6V 5Ah gel...

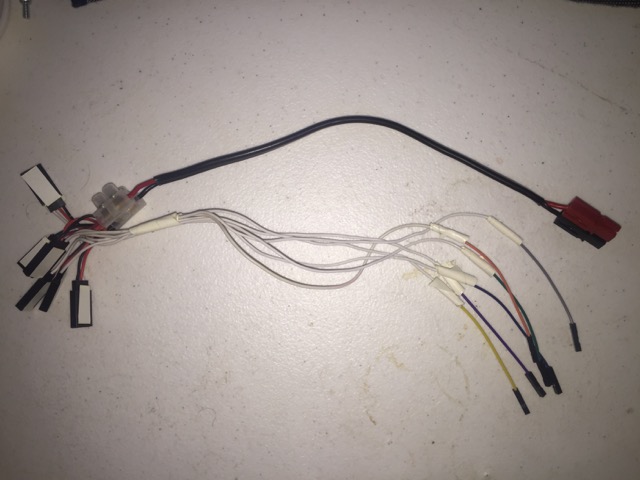

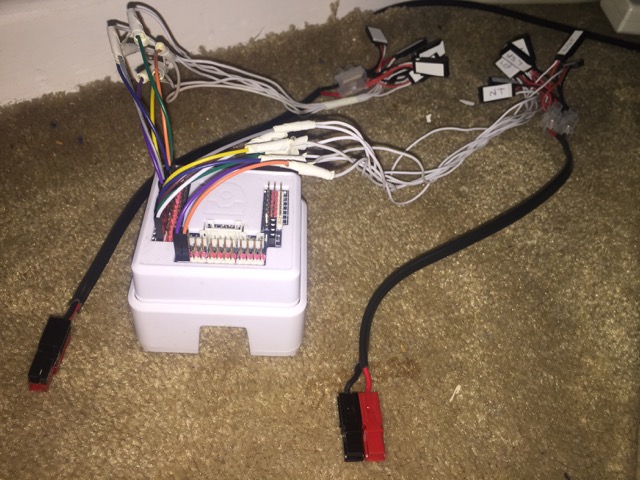

Here’s the wiring system I have used for my robomannequin. Here’s a year’s research summarised into a single page.

Here is an adapter cable I needed to make for a six servo arm. It includes 6 male PWM ends, 6 female single data cables and a 15A powerpole connector.

To power all the 7.4V servos in my robot that each peak at around 3A max, I use a Meanwell 7.5V46A power supply. I have attached two 15A powerpole connectors for the servos, one round connector for the EZBV4 microcontroller and a female servo cable to plug into the DPC-11 and DPC-10 servo programmers (they allow me to reduce the maximum servo speed to slow the robot down for safety and to prevent smashing).

The Meanwell power supplies do not come with safety cases, meaning I’m always exposed to 240V electricity. At least this one comes with a little plastic shield. To shut it down, I need to rip it out of the wall socket.

I’ve had to label both the wires coming out of the robot and the adapter ends so I can re-assemble the system. The colour coding is somewhat useful, but the colours do not exist anywhere else so the colour coding is somewhat useless. There are only seven colours in the rainbow and red and black would be confusing, for data wires, so any useful colour coding would require several colours or patterns instead of solid. Importantly, you can see that only one data wire is required in this case (data signal sent one way from the microcontroller to the servos) rather than needing the red and black power wires from the servos to the mc. The mc is controlled via a Windows PC initially via a WiFi router, then from my iPad, game controller or VR headset. All these methods of control are vastly inferior to the capability of programming by posing the robot (which requires a receive wire from each servo to the mc). This particular microcontroller, the EZB version 4 from ez-robot.com shuts down easily due to excessive current. Also, accidental contact from a charged servo wire has often resulted in short circuiting (my bad). Wiring is important and needs to be neat, safe and thought-free (intuitive) for the user. The adapter cables I have had to make to bypass the mc power pins and go straight to the power supply should be commonplace but I do not think they even exist commercially yet.

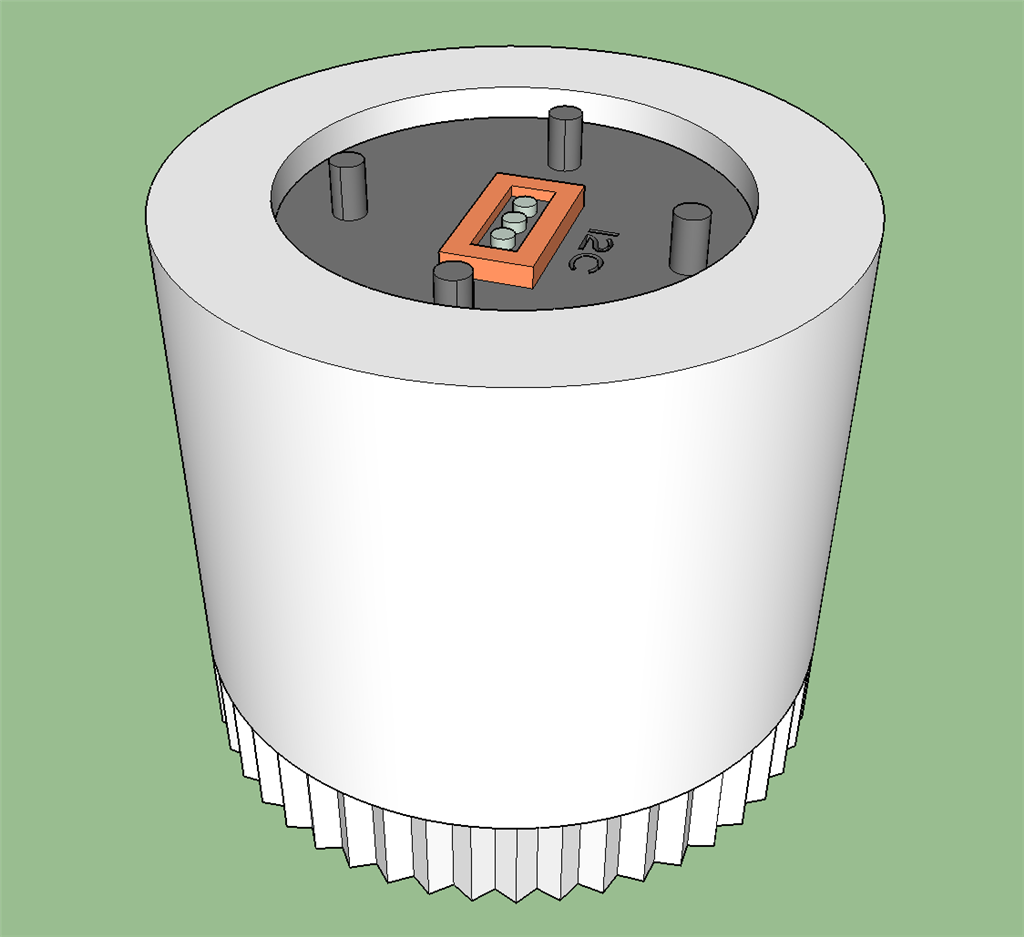

I am currently commissioning servo modules that will run on 12-24V, include internal holding brakes, have centered shafts and click together like leggo. They will have infinite rotation but will rotate to an exact position, even after thousands of rotations. eg. Rotate 10,567 degrees. They will daisy chain using I2C rather than PWM, they will tolerate a chain of up to 100Amps, and they will have bi-directional send/receive data lines for pose-frame programming.

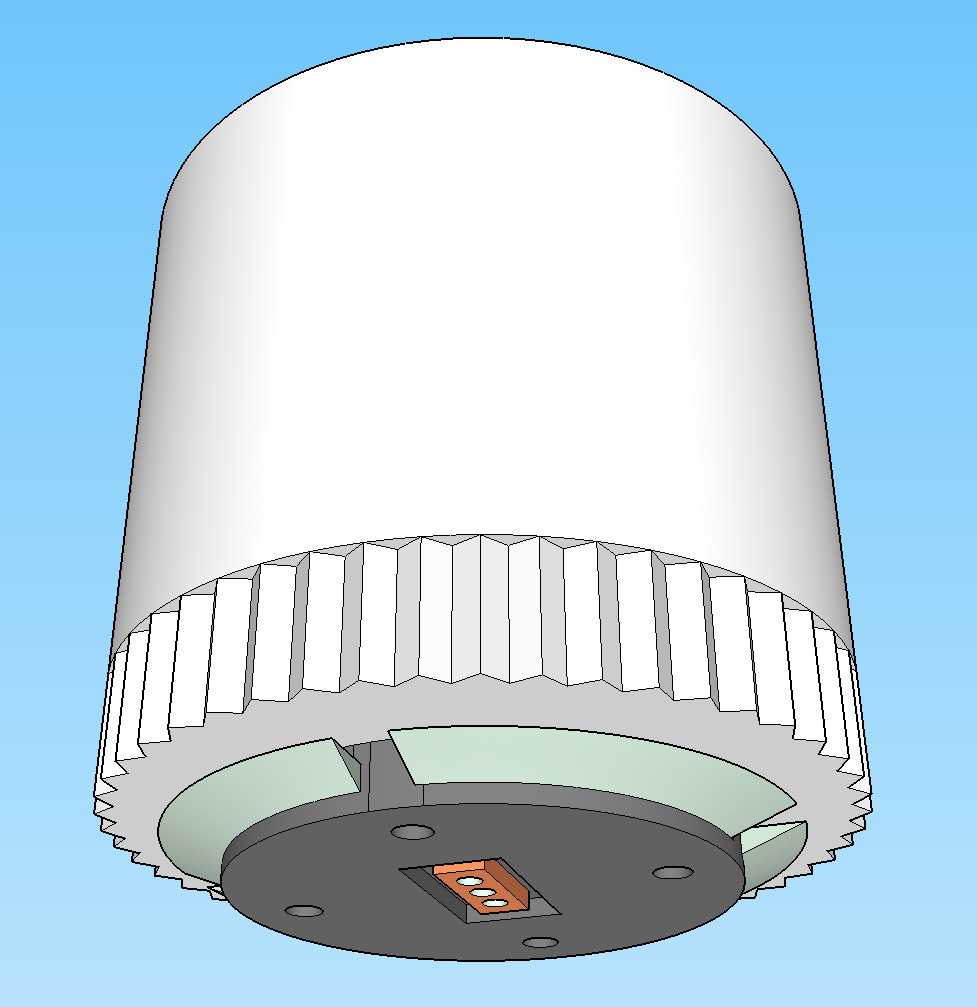

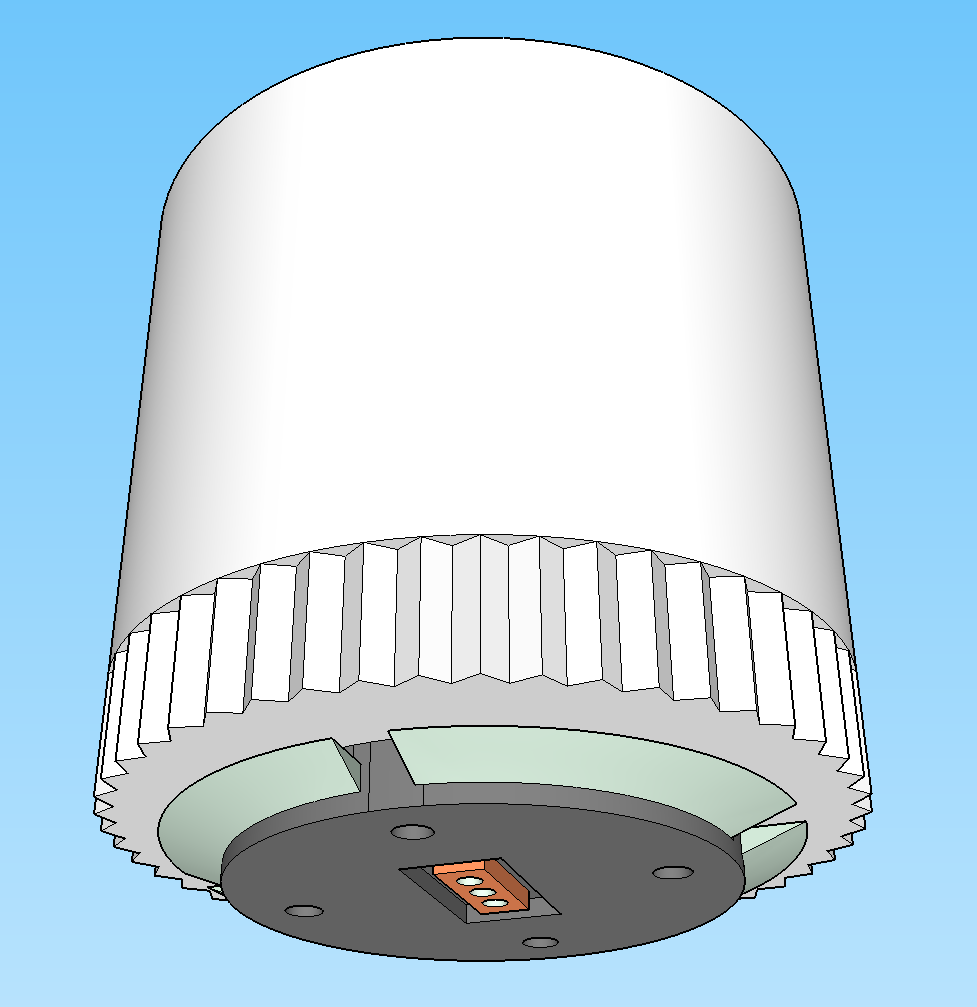

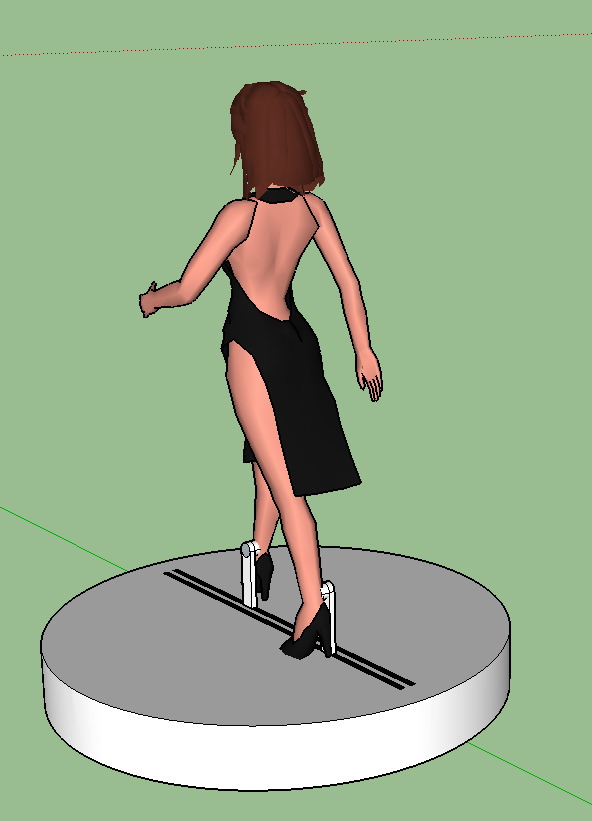

Here's a vague mockup I made for my mechanical engineers to get an idea of the outward appearance of my servos. This design does not accommodate bevel tilt hinge modules, so it will be refined.

These servo modules can be scaled up, so can replace car engines by placing electric motors in the wheels. They have hobby, medical, aeronautical, hospitality, mining and industrial applications. Servos are only one type of attachment for these robotic modules. You will be able to build such things as a walking dinosaur, an exoskeleton, an intelligent crane, a motorbike or an autonomous drill to create a network of underground roads (undergroundroads.com) by clicking pieces together. We will work on programmable gearing too, so there will be no need to buy different servos for speed versus torque.

@Zxen,

Impressive work.

Regarding the prohibitive cost, ignore it... There's a lot of work, research, trial & failures so you more than anyone knows the right value.

The mortar and brick stores are facing enormous challenges, less foot traffic, online competition from pure online retailers (e. g. Amazon ) , no community shop spirit (support the local commerce), shoppers with less time for store shopping, etc etc. In other words and generally speaking the traditional retail is agonizing and dying, for most small and family businesses the mannequin cost seems high.

The retail major league e.g. department, high end destination stores the price is not the first factor and there's demand for unique & creative solutions, more robots and cool stuff.

@Zxen Dude, I hope you have liability insurance. From what you have created here I am not sure all those off the shelf hobby components you've slapped together are not a fire or safety hazard... No offence but lets hope your mechanical engineer is also an electrical engineer.... True you have done a lot of work but I am going to say you probably will have trouble convincing brick and mortar stores to buy something that wasn't created and made by a large company with proper engineering and consumer safety testing standards. Not even sure there is a market anyway for such product. Moving manikins are the stuff of horror movies, aren't they? LOL. ... Anyway, Sorry just my honest opinion but good luck...

Good sales pitch, ptp, hadn't thought to frame it that way.

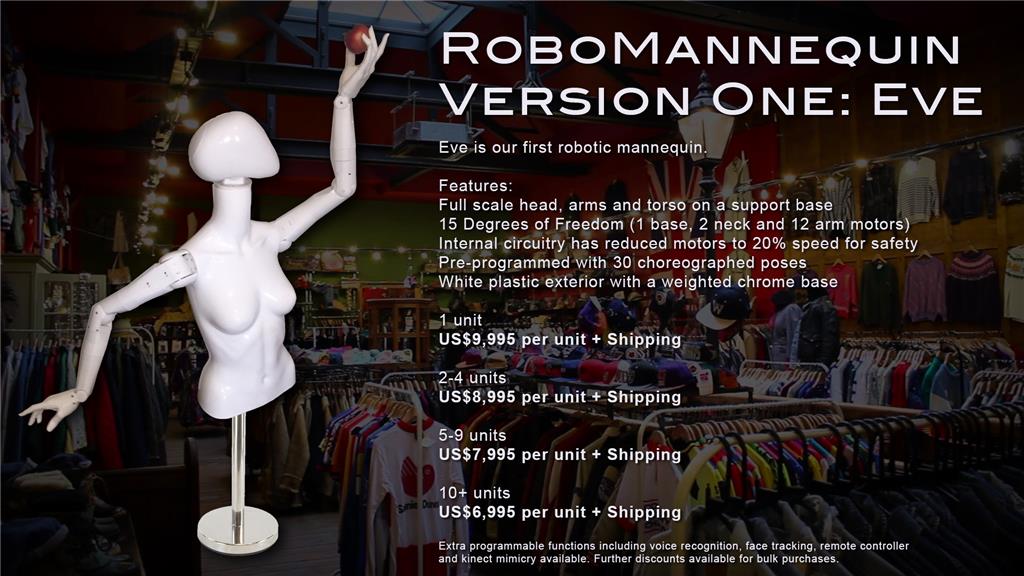

Yes, Richard R, it is not ready. I will find the money, even if I have to rent them out for a while and pay for liability insurance. I might go to kickstarter as well. The poster I placed at the beginning of this article with the prices I have only shown to you guys. I'm glad I did because the feedback is really useful.

DJ Sures says i2c is no good for the servos I'm developing and I should use UART. I can only afford to do it the right way. I'm meeting the engineers on Monday. What do you guys think? Has anyone plugged a daisy chain of servos into UART before?

Dynamixel servos use serial communication (UART) and can be daisy chained. They are not cheap, but they have a lot going for them, including position feedback.

Serial communication is a very old, very well understood, and very stable protocol. Search google for i2c EMI or i2c interference, or i2c issues and you will find a lot of discussions about how it can be difficult to get right.

If you are working with electrical engineers, those issues can be overcome, but I wouldn't put MY money on the line using that protocol in something I planned on selling (using it for my own robots, where my tolerance for pain is higher is a different story).

Alan

So of all the 'protocols', whats your vote?