Hello all!

It's been quite some time since I've posted here. My last piece of work was my Halloween display which while it was quite rough around the edges, it was very well received at the office.

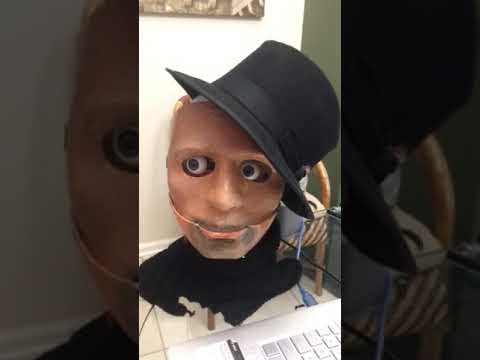

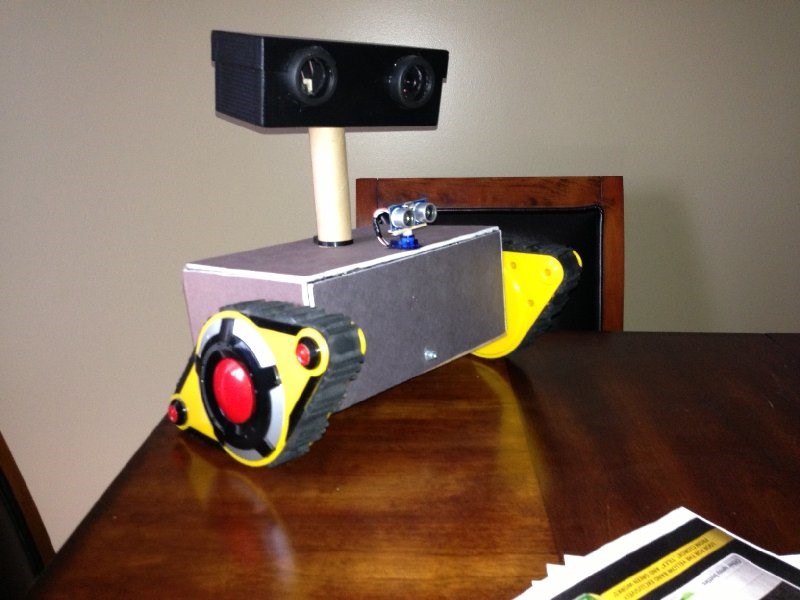

Today I am here to show you my new creation; Ray.

I decided not to re-build Wall-E and wanted to go with something a little more custom.

He is a type of box-bot that evolved from different cardboard boxes to what he is at this moment which is part foam board and part fibre board wood. I was given a scroll saw by my grandfather and man is that thing fun!

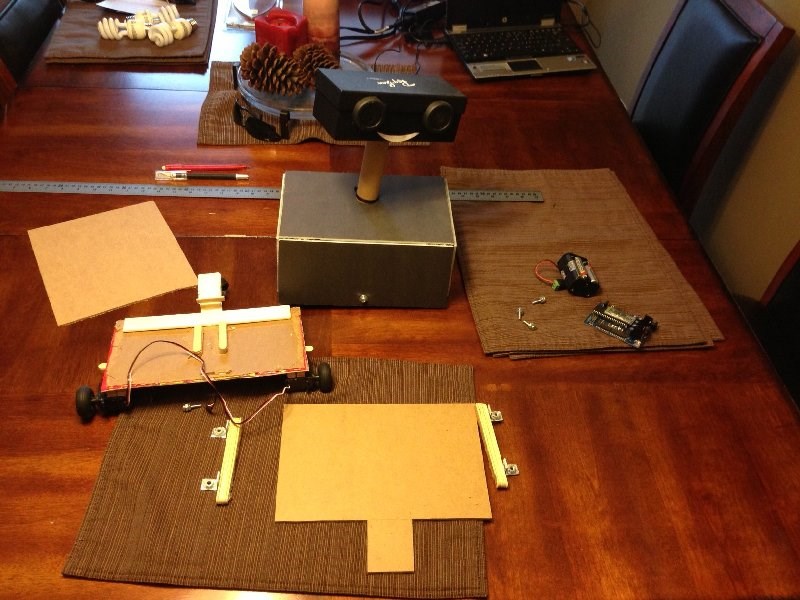

Here are some pics of my progress:

The beginning. Head and body:

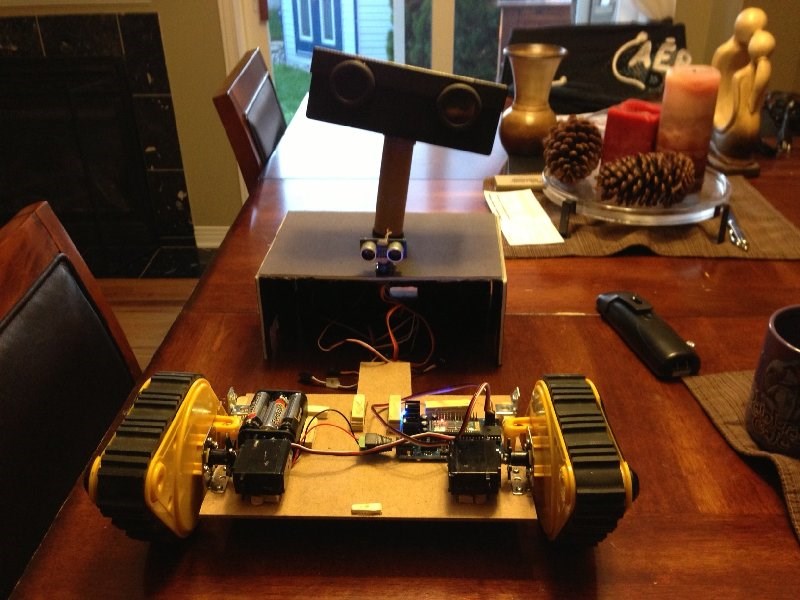

Together now:

Gotta have wheels!

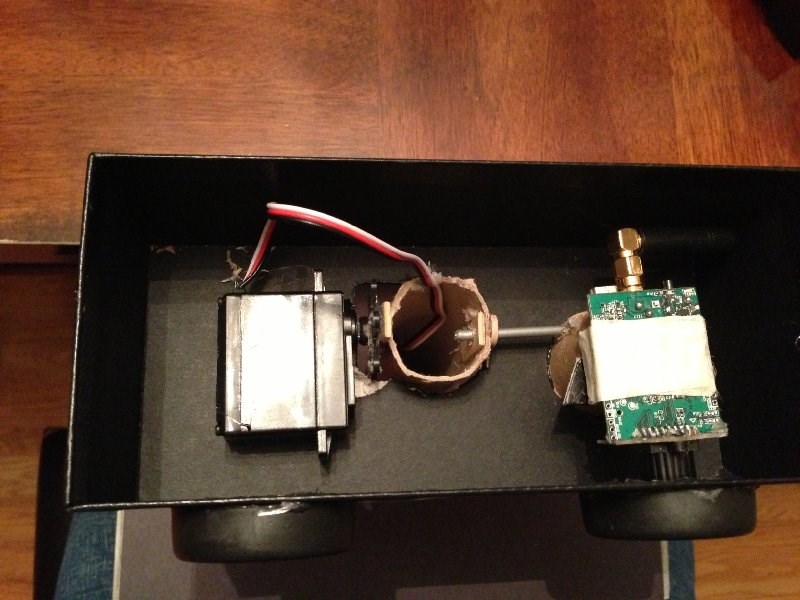

Brains:

Eye:

Head vertical movement:

Tada:

Fibre board base for better stability:

After I added the ping sensor... look what I found for $10 at a garage sale!

Lets see what we have in here... Pretty much only using the tracks for now.

Look at those tracks! Can almost go rock climbing now!

So this is where we are at:

So far I'm really happy with him, but unfortunately the tracks are too hard for the little servos to push. What would you guys/gals recommend? Should I go DC with an H-bridge? I have the gearbox from the original robot, but they're LOUD. Or should I go with a stronger servo than those that came with the kit?

Let me know! I hope you like Ray!

Other robots from Synthiam community

Ericez's My Real Size Wall.E Have A Job As Sales Promotion...

Steve's Meet Aegis

Very nice! Great project to show how EZ it is to build a bot. Before you spend a ton of money, try modifying the tracks to turn easier by sanding or waxing or loosening....I am thinking those tracks are stretched really tight!...perhaps to tight. All servos have the most torque closest to the shaft...as wheel becomes bigger and bigger, down goes the torque.

Great project to show how EZ it is to build a bot. Before you spend a ton of money, try modifying the tracks to turn easier by sanding or waxing or loosening....I am thinking those tracks are stretched really tight!...perhaps to tight. All servos have the most torque closest to the shaft...as wheel becomes bigger and bigger, down goes the torque.

Hey, Ray looks great so far! Really good job

Before I can really recommend anything, how much torque do you approximate is needed to turn the tracks? Like @irobot58 suggested, modifying the tracks a bit to loosen the them a bit might be the best way to go. Let us know how the modification goes!

You can get 7.2 volt drill motors and use those to power the tracks and remove the gearbox. If you really like the gearbox you can fill it with marine/ lithium grease and cover the outside of the box with dynamat. Those two things I find are the best at reducing sound.

Thanks for the recommendations guys. The tracks are quite loose actually and they roll easily. I think there is just too much surface area on the bottom of the tracks.

It's also very possible that the shaft connection isn't EXACTLY centered. Might try adjusting that before I go too far.

However I've never thought of the small power screwdriver motors. I actually have 2 identical power screwdrivers that no longer hold a charge. The battery is built into the driver... Looks like I may need a bigger body for him, but at least I know the tracks are large enough. Then I'll need to find a new power source too... hmmm...

Thanks for getting the gears in my head moving now! Love the inspiration and motivation from this site! I don't get much time to work on my robot nowa days but I'll update when I can!

Love the inspiration and motivation from this site! I don't get much time to work on my robot nowa days but I'll update when I can!

-DaMan