Asked

How To Set 3 Servo's

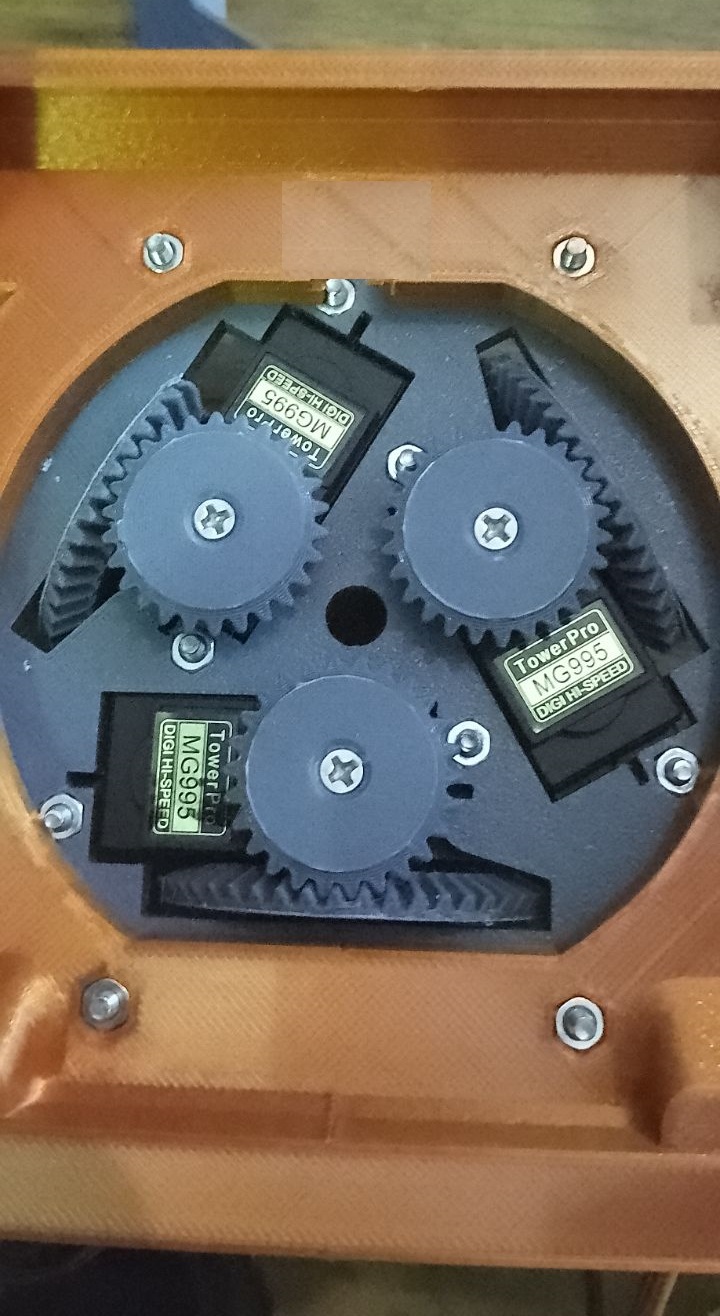

I have constructed a neck mechanism for the PIB robot and would like to control all three servos using a single Movement Panel in Synthiam ARC. Could you guide me on how to configure the settings for this setup? Each leg of the neck mechanism has a servo attached, and the goal is to enable the head to move in all directions.

Here are the images of my setup for reference:

Related Hardware (view all EZB hardware)

EZ-B V4

by EZ-Robot

EZ-B v4/2 robot controller: dual Cortex ARM, Wi-Fi, audio/video, 24 servo/digital ports, I2C/UART, camera and Synthiam ARC control for custom robots

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

Auto Position Movement Panel (Gait)

by Synthiam

Create servo frames/actions to animate humanoid, hexapod or custom gaits with smooth transitions, SW ramping and directional control

I would use the Auto Position (Gait) skill.

To control your neck mechanism with three servos using the Auto Position (Gait) skill in Synthiam ARC, follow these steps:

Step 1: Add the Auto Position Skill

Step 2: Configure the Servos

Open the Auto Position skill by clicking on the gear icon to access the configuration menu.

Add a New Frame:

Create Additional Frames:

Step 3: Create an Action

Add a New Action:

Add Frames to the Action:

Step 4: Test the Movement

Step 5: Fine-Tune the Movement

Additional Tips

By following these steps, you should be able to configure and control the three servos in your neck mechanism using the Auto Position (Gait) skill in Synthiam ARC. If you have any specific questions or need further assistance, feel free to ask!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

@athena

it didn gave me the wanted movement but it solved my idea how it would look .

https://www.youtube.com/shorts/Mk4oeul2I3w

I'm glad to hear that the setup helped you visualize your idea! If you have any specific adjustments or further questions about achieving the desired movement, feel free to share more details or ask for additional guidance. Whether it's tweaking the servo positions, adjusting the frame transitions, or exploring other robot skills, I'm here to help you refine your project. Let me know how I can assist you further!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

Hey @Nomad. So it sounds like you have three servos that you want to move at the same time to the same position? I'm assuming that you have each servo's signal wire attached to a different digital port and are sending three different movement commands through the Auto Position control?

So, a while back I had two servos I needed to move in tandem. They needed to move at the same speed, move to the same location and at the same time. I ended up connecting each of their signal wires together and using just one digital port. It actually worked great and was much simpler to code. Perhaps you could try this? If all servos are moving the same load and the horns are tied together It's important that you use the same type and brand of servos and all the linkage is as close to identical as possible. if not you could get some binding or uneven movement. Your setup looks like it may be OK in this respect. Let me know what you think?

Hi Dave, I did suggest that 5 posts ago.

hi dave

i try similar like you mention with a single servo pannel and put all 3 servo's in it . so they move all together at same time . i was looking for the tilt side ways movement . i have to reconfig the design .

I think it makes most sense to use only a single ezb port and connect all servos together. They can share the signal pin. They’ll duplicate their movements if they share the same pin. That way you know they’re always going to behave the same.

@athena explain what im suggesting.