Asked

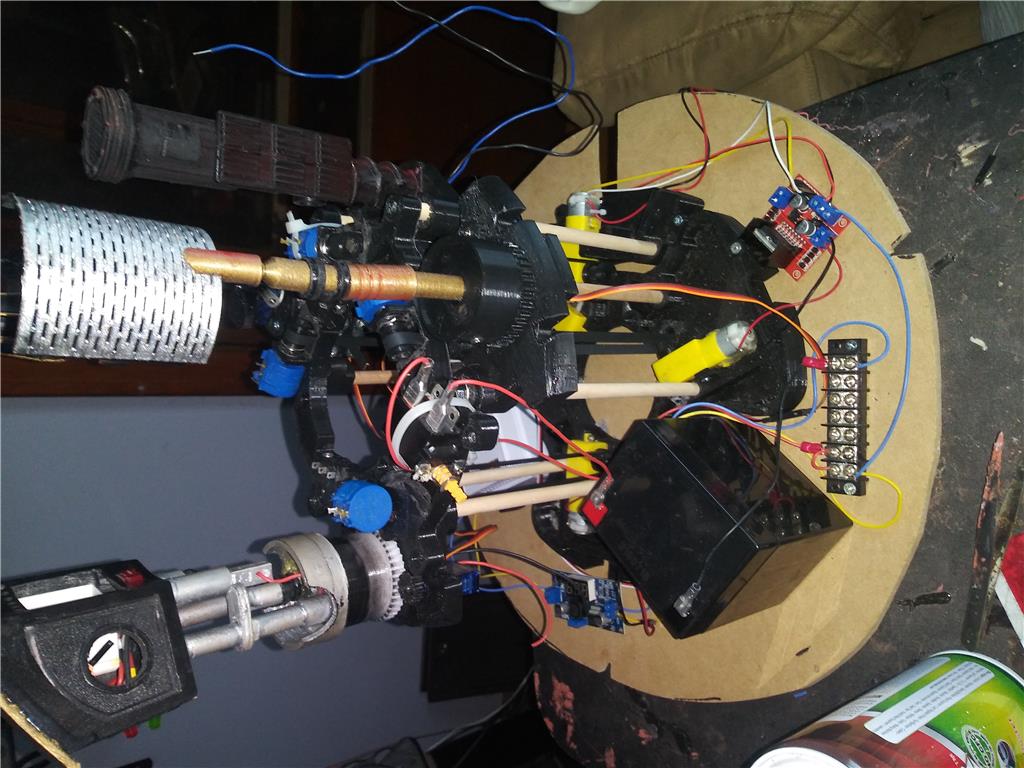

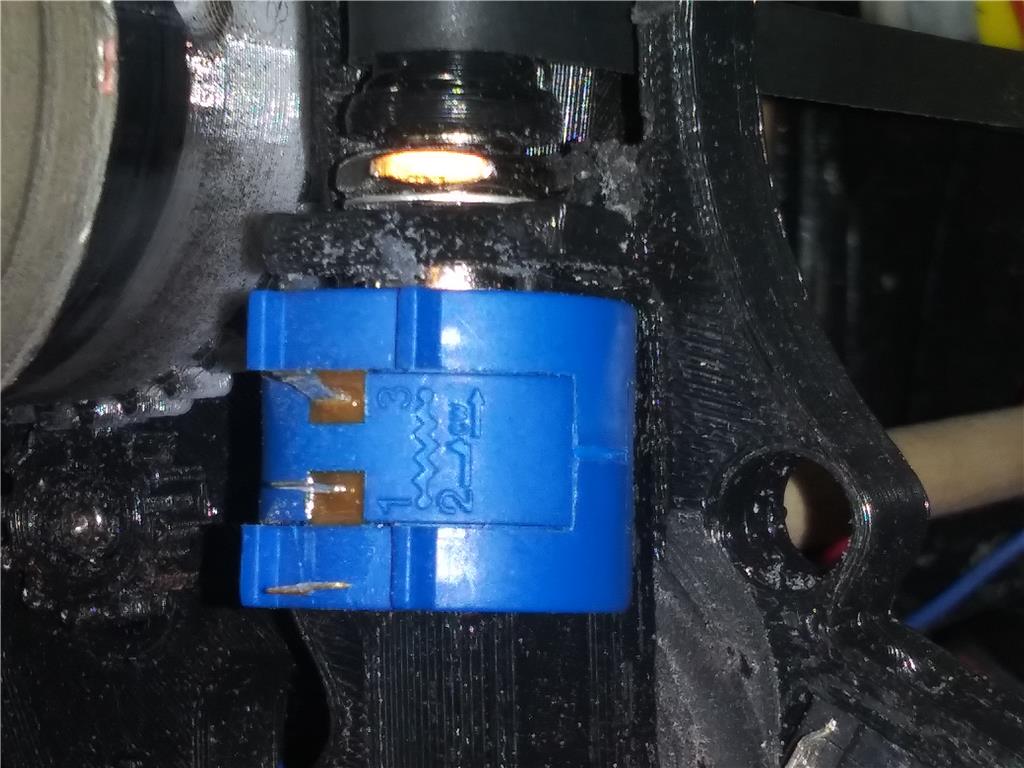

I want to use a precision 10k pot for positioning feedback for hbridge control.

For my R2 I'm adding lifts for the periscope, radar and zapper but im unsure how to wire it for the ADC.

Im using a bourns pot, i understand pin 2 goes to the white pin of my adc port, for the reading, where do i get the power from for pin 1? I have 5 volts running the exb because that's the max my micro servos can take and i have 12v running into the hbridge for motor power.

Ive been looking through a lot of posts, and cant find reference to this, just not to get the power from the adc port.

This is a second ezb4 that will only be controlling 4 dc motors for lift, 4 micro servos for spinning the stuff, an led for the zapper and a 3v air pump for smoke.

Related Hardware (view all EZB hardware)

EZ-B V4

by EZ-Robot

EZ-B v4/2 robot controller: dual Cortex ARM, Wi-Fi, audio/video, 24 servo/digital ports, I2C/UART, camera and Synthiam ARC control for custom robots

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

ADC Value

by Synthiam

Display ADC port voltage and 0-255 linear values (0-3.3/5V); configurable board/port, units, multiplier and sample interval.

I found the problem, the pulley on my pot is smooth causing the belt to slip, so I'm not getting any changes. I'm off to the printer to print them again, with teeth for the belt to grab.

awesome! I’m super glad to see someone implement my hbridge servo pcb combo

finally!

I keep telling everyone, ez-robot, ARC make everything "easy".

more h-bridge activity today -:)

working 2 car chassis now

both cars are on the road already - cheers!