MovieMaker

USA

Asked

— Edited

I thought I would start a new page. I would like to completely delete the old stuff. I will have pictures soon. They are already taken. I have had my struggles, so i named her Botchy instead of Sunshine.

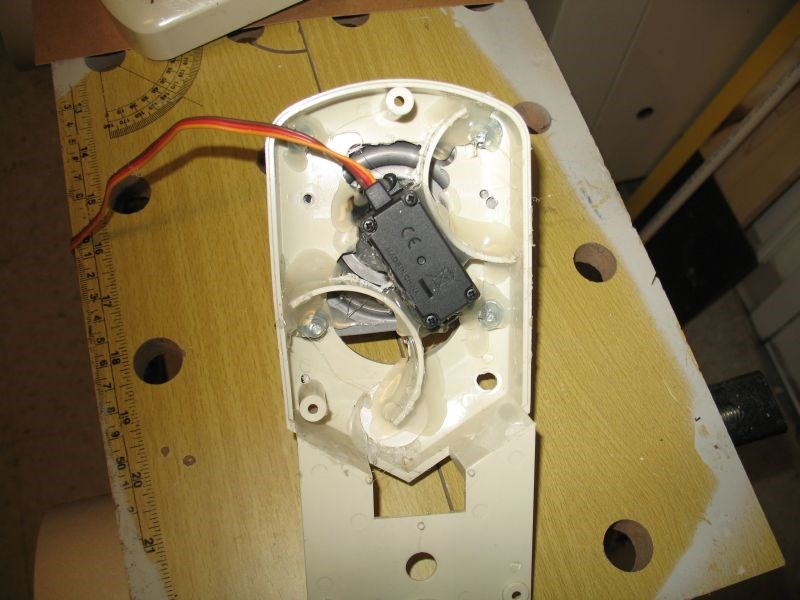

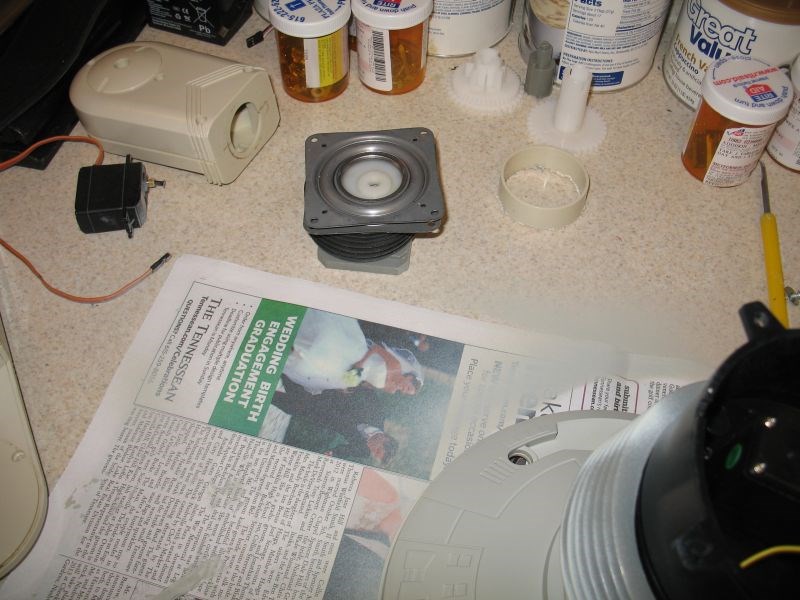

Here are some pix:

Thanks for your support!

:D

That is what I have so far.

Your Sunshine seems a bit tall! hopefully it has sufficiant bottom weight! ......Botchy? NAH! You have put a lot of work into Sunshine and once it has been painted and detailed the sun will appear bright! Also remember the story of the ugly duckling!

......Botchy? NAH! You have put a lot of work into Sunshine and once it has been painted and detailed the sun will appear bright! Also remember the story of the ugly duckling!  ....Maybe Patches ?

....Maybe Patches ?

Movie Maker, I agree with Irobot 58. I like your original project name. There is nothing wrong with improvements. You have put a great effort in building your new robot! I give you credit for your great work and effort. Hang in there and make any necessary changes you want. Steve s

I think it looks great! Good work.

Good job Mel , you can tell it's coming along!

I agree with all. Great job Mel. I'm glad you're pressing ahead.

Well, thank you. I was thinking it wasn't very good.

I do want to say "HAPPY DAY!" I got my second omni in and I am happy about that. I called it Botchy because I botcher her up. But, I just finished painting her again and she looks good in white! The problem is (temporarily) that I painted a lot of the black items that should've been black white. But, I will go back and hopefully do something with that.

Also, I made an important discovery. After spending almost $100 on paint, I found out that $4 Krylon Paint at Walmart will stick to plastic, will cover all, and will dry in about 15 minutes. Instead of a dozen cans of 3oz. paint, ONE simple can of Walmart paint for $4 was all it took to give her a complete and total paint job. Like I said I will have to go back and touch her up a bit, but I am now more optimistic about the whole thing. My wife bought me 3 cans, so I have enough for touch up and a spare can for later.

I am almost there. I have to wire her. I know HOW to do this, but I can't see very well, so that will be a hassle. But, I am so happy I am to this point.

@aameralis, about the neck. I wanted her to be as tall as possible. So, I made her that way on purpose. also, believe it or not, I have a cable for the camara, LeftUpper, RightUpper,LeftLower,RightLower,Lefteye,Righteye,HorzPan,Verttilt, and that is lots of cables going through there. That gave me a hard time. I could have just went with on/off one port of left and right eye leds tied together like I did in the past, but I wanted to copy off of Loki. I like the way it works. But, it was hard because the size of the eyes were not large enough for the led strips.

Also, on the neck, If I change her at all, I would have to completely re-do her setup. I am not saying that I won't do that, because I am a very opened mine type of guy. I just have to think about it and possibly raise the funds.

Also, the shoulders are sealed so i don't know where to ENTER the wires for the arms. I have four each of those. I was thinking under the arm pit maybe. What do you guys think?

@Roboti58, I might change the name back to Sunshine if she comes out better. Because she is a tribute to my wonderful wife of 20 years. But, if she doesn't come out right, she will be just another project.

@all of you. I feel like Dorothy on the wizard of oz and I just woke up and all my friends are here. I can't tell you how much your support means to me. I literally threw a turtlebot away in the Dumpster because I could not figure it out. But, I have since become familiar with ROS. It just takes a long time. When I have friend encouraging me, there is NOTHING I cannot do.

Thanks!

hey, if you would be willing to sell that homebase-cardboard and send it to germany, pls let me know (sorry, saw it on one of your photos-along with the remote control) mike

Mike, it will cost you a TON of money in shipping. What is your financial state? If you are well off, I will take whatever you see fit. If you are poor, I will give it to you. You will need to pay the postage.