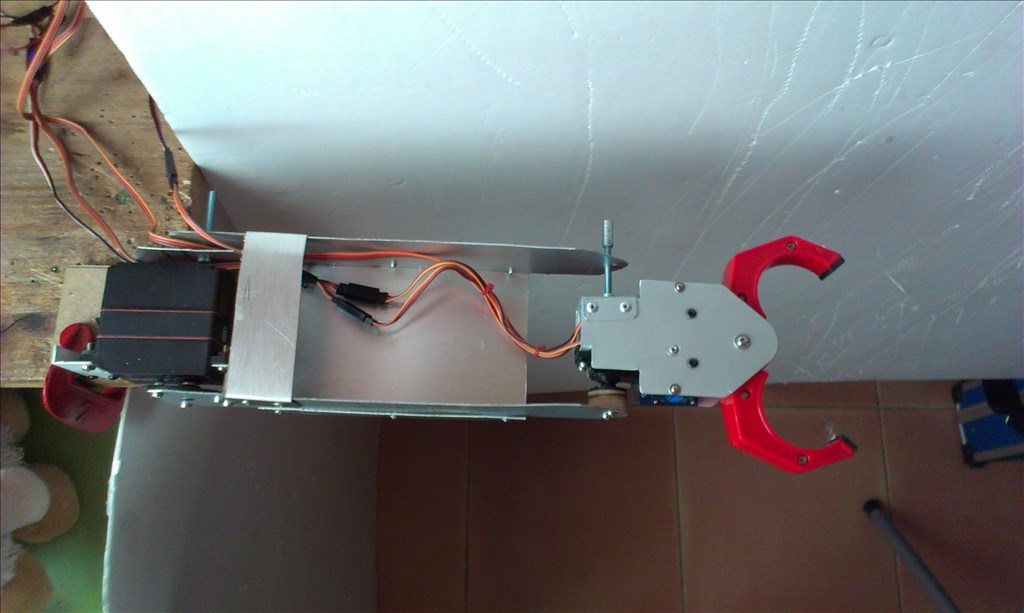

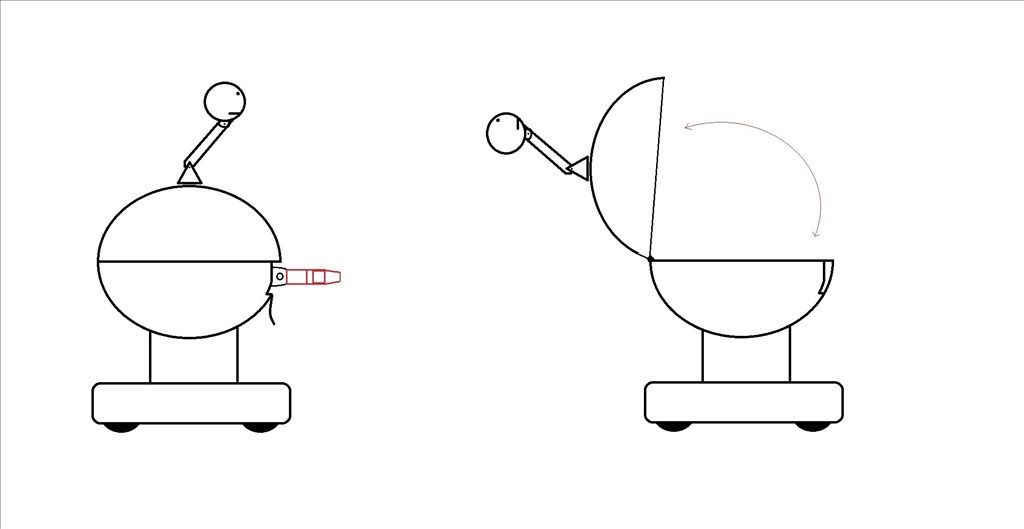

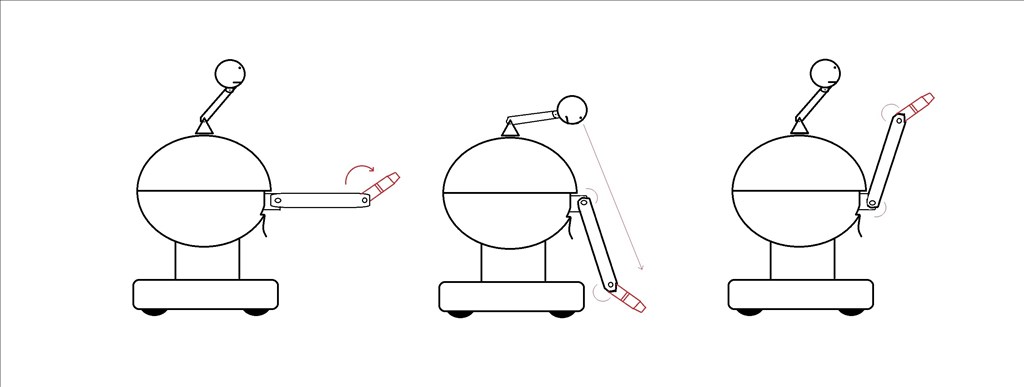

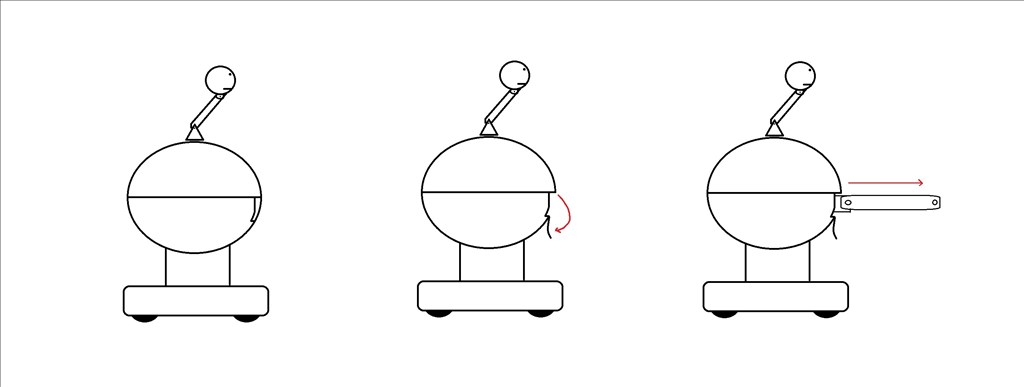

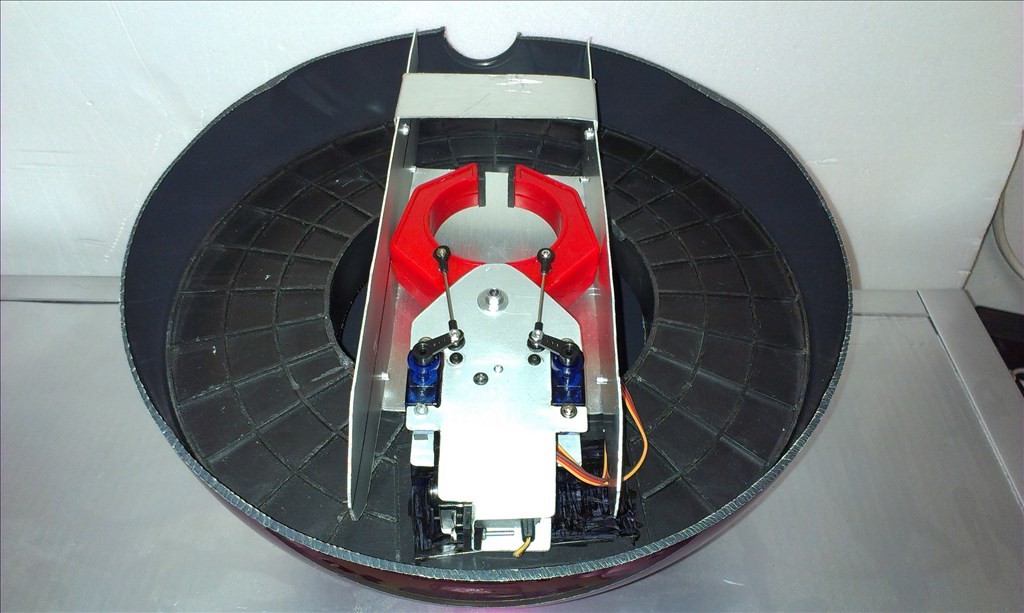

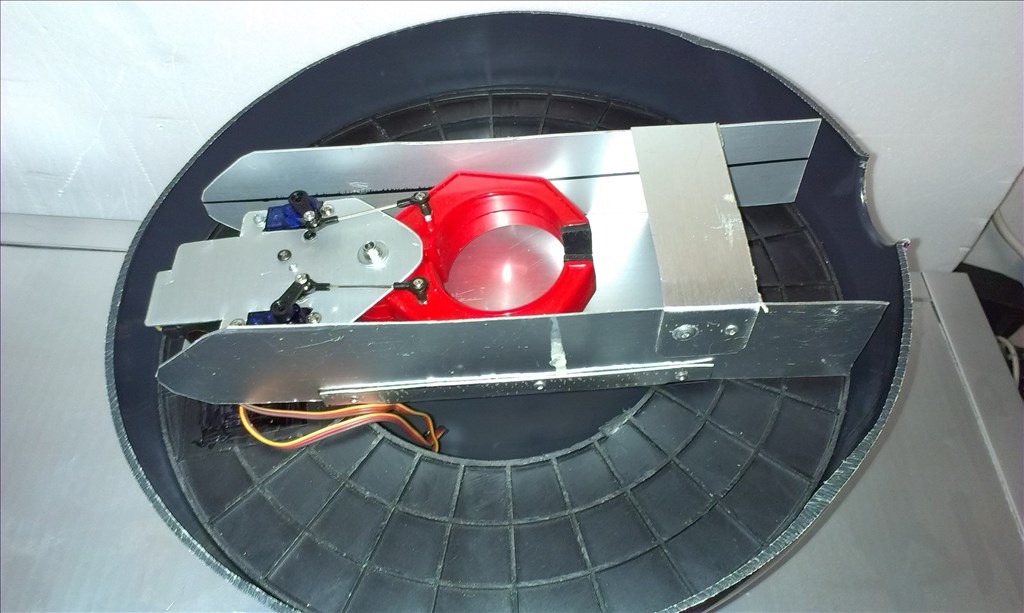

This the result of too much free time lately, the new project is a robot drawing a sphere, using the low-cost approach to the selection servos and other components, with a retractable arm that comes from inside through a gate and once inside collected no space and is also protected when not in use.

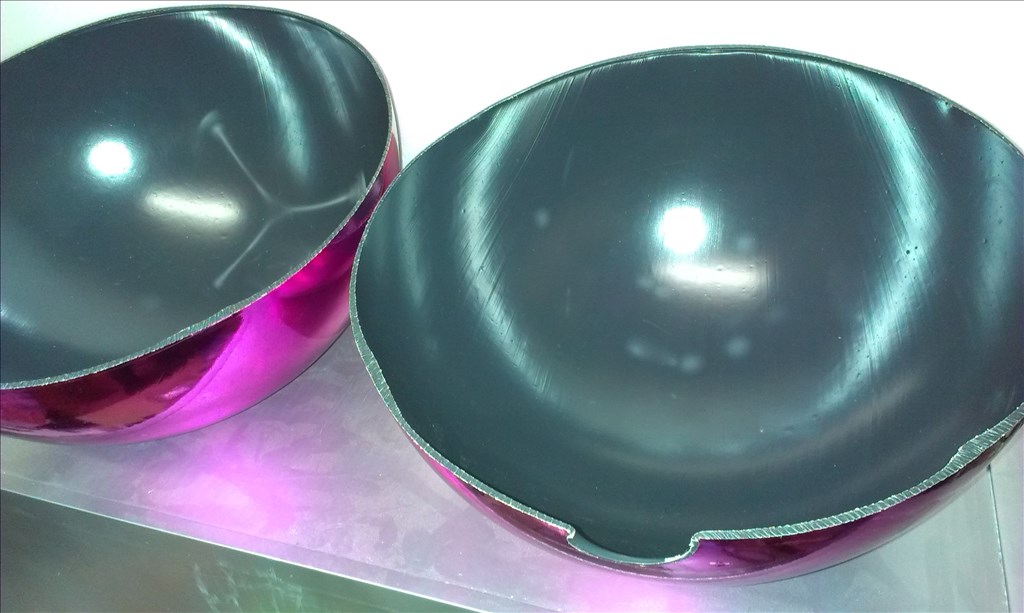

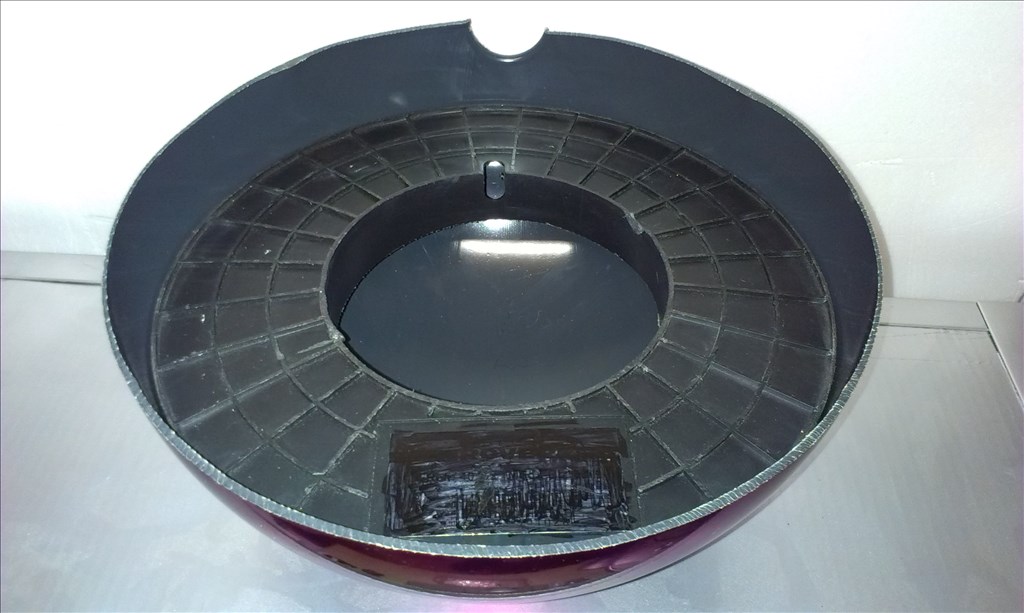

This is an area of 28 cm in diameter (11 inches) of PVC, is a large Christmas ball, once cut in half I've noticed that need structural refurzos to hold its shape once installed all the electronics and mechanics. So I will use sections of an empty roll of wire for reinforcement.

By R2D2

— Last update

Other robots from Synthiam community

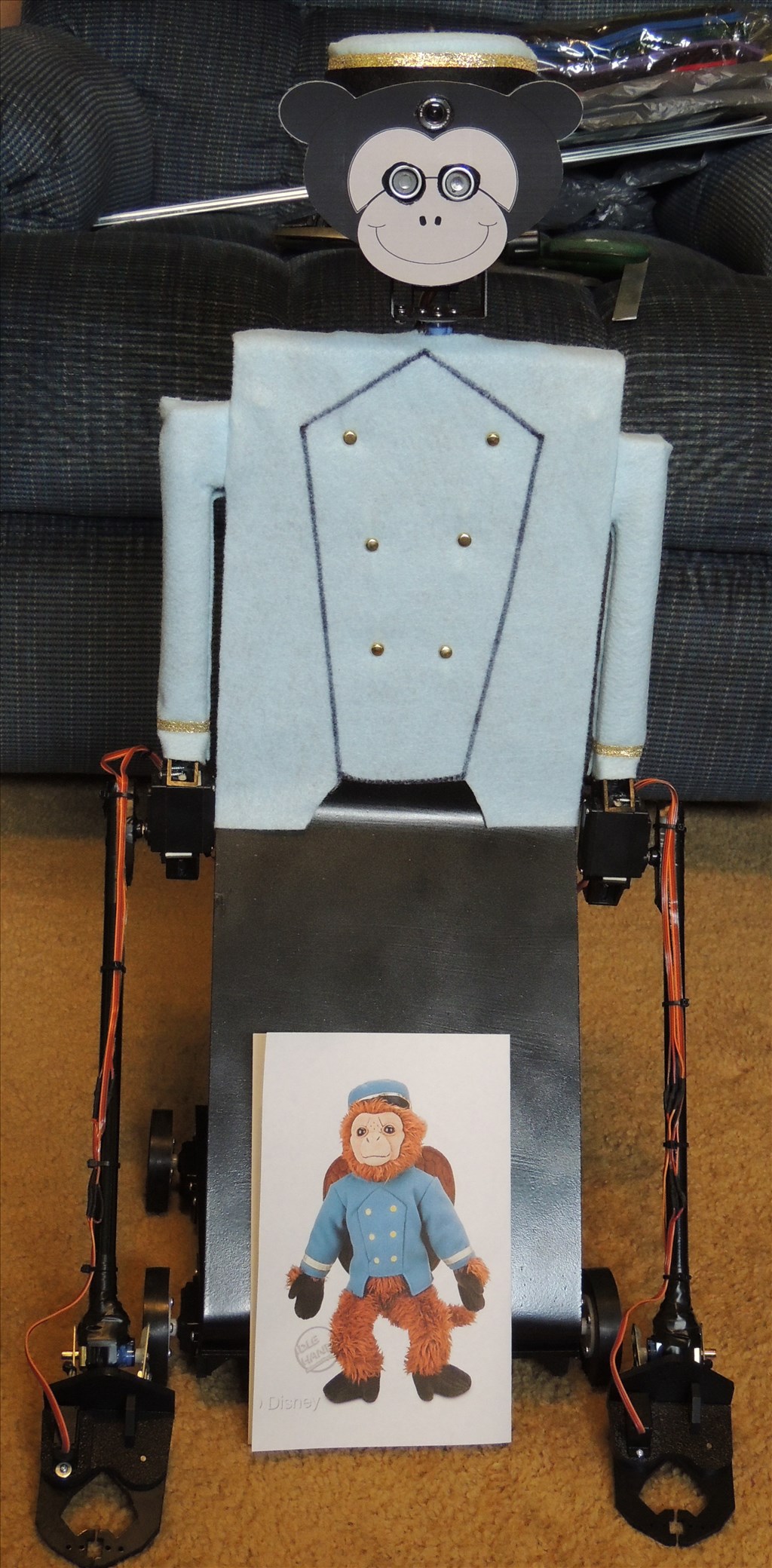

Ezang's New Creation - Mr. Roman 2 Video

Mr. Roman with scarf and hat and a little blue Arduino-based friend

Justinratliff's Finley Themed Robot

Finley robot with EZ-B v3: 12 servos, PING sonar, camera, grippers, built to pick up objects and integrate with Synthiam...

Hablijack's Project: Marvin

DIY MARVIN robot: USB-powered camera, moving head, OWI-arm hand with servo; arms next, feet TBD.

Thanks Technopro, I think your drawing helps to understand your words, I guess it is a regional expression that google translator can not overcome, if your robot is going to have a sphere will be willing to open your project post to comment or suggest .

ok thank.

Do you speak espanol? If i know i can put my posts in english and spanish. or what ever language you speak. this could help our comunication, with us both doing similar projects.

For me it would be much easier esribir in Spanish, but I think as I respect most who speak English, and we all understand it is best to stick with the English. Normally I have no trouble understanding the messages (with some exceptions) Greetings.

ok.

i hope i didnt affend you in any way.

i will be working on my robot today so be watching for the project in project showcase.

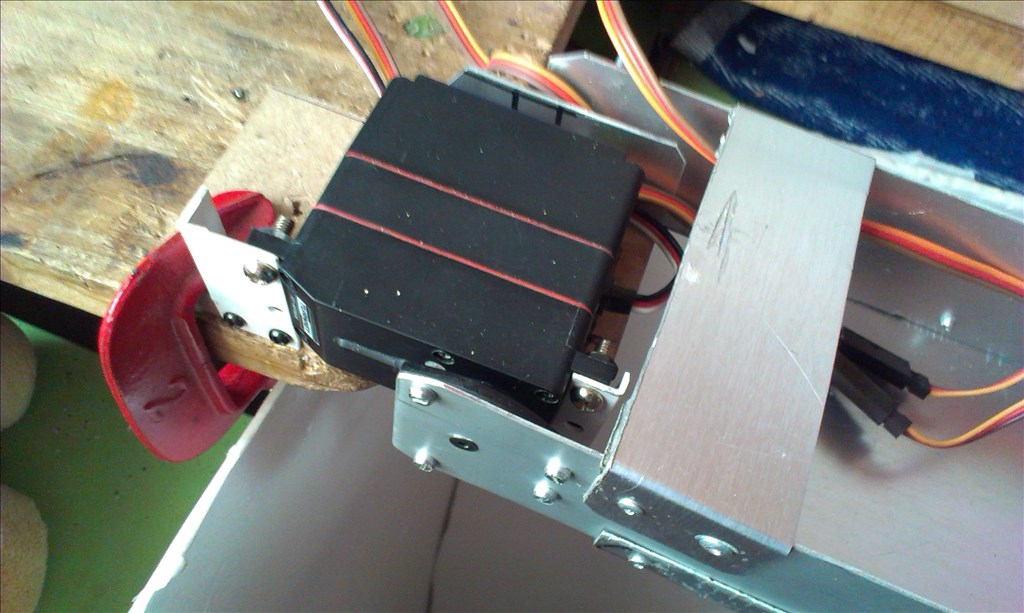

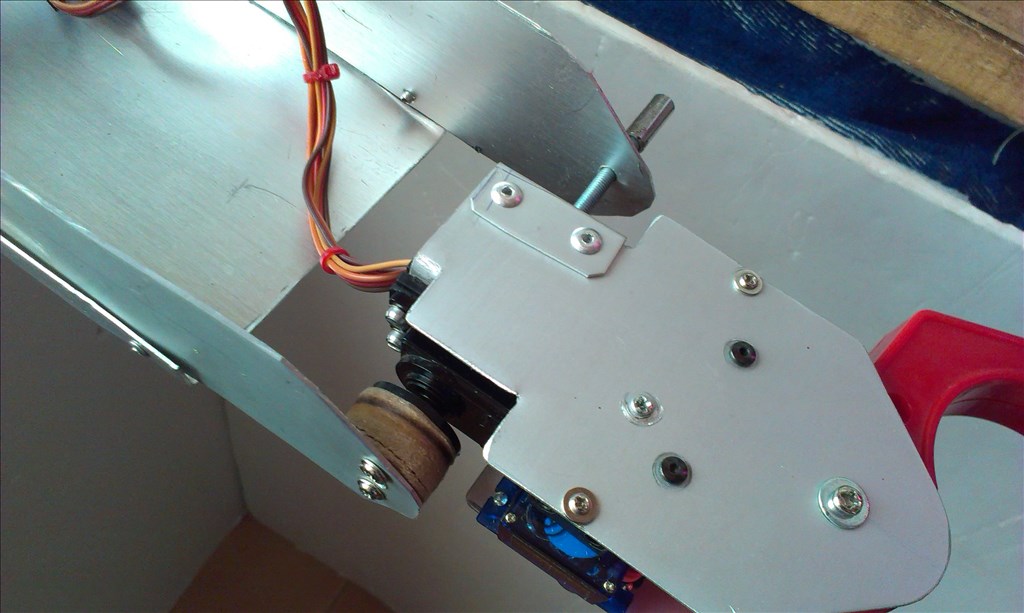

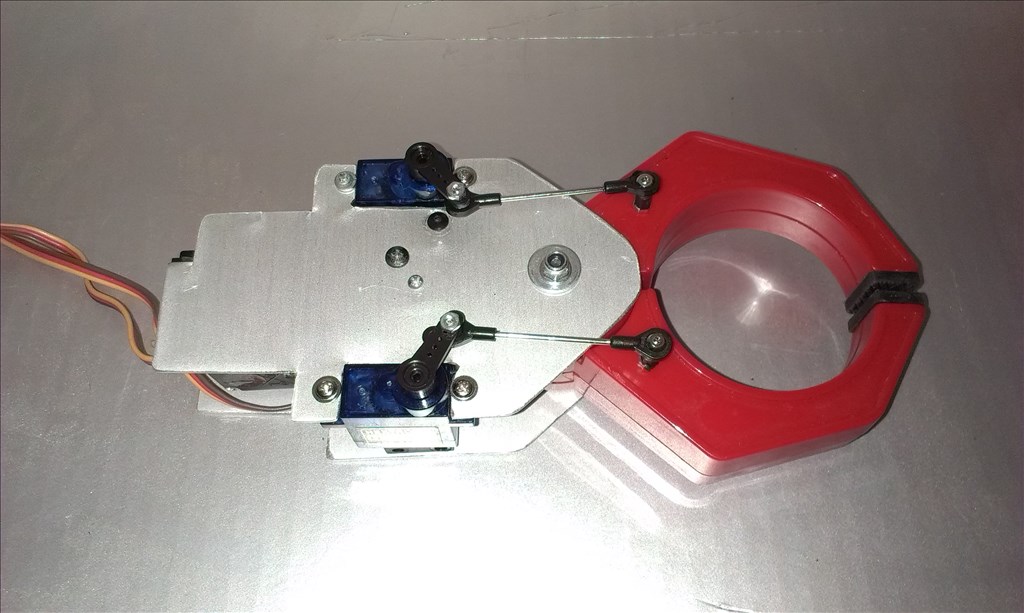

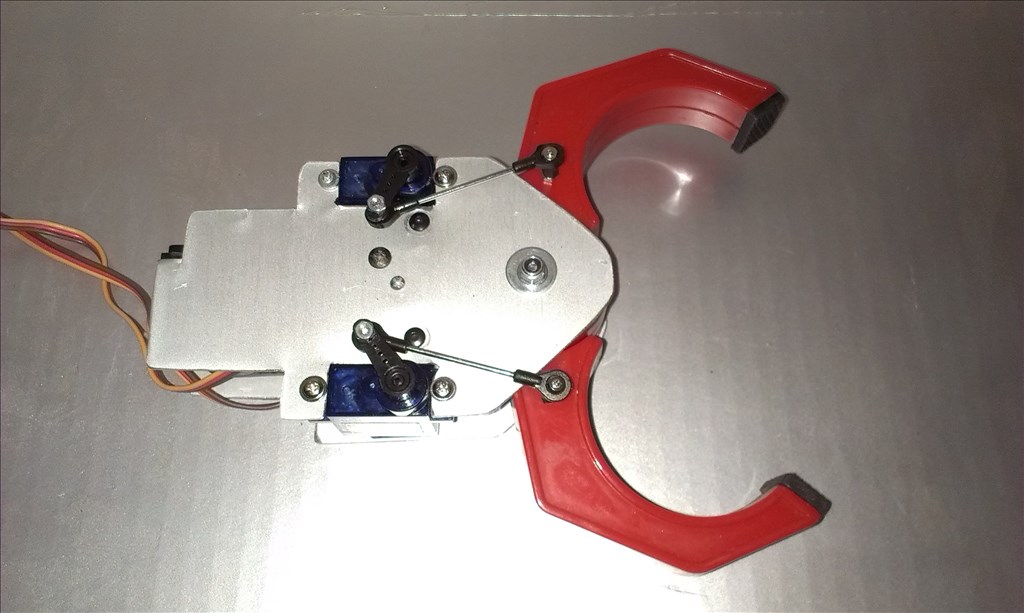

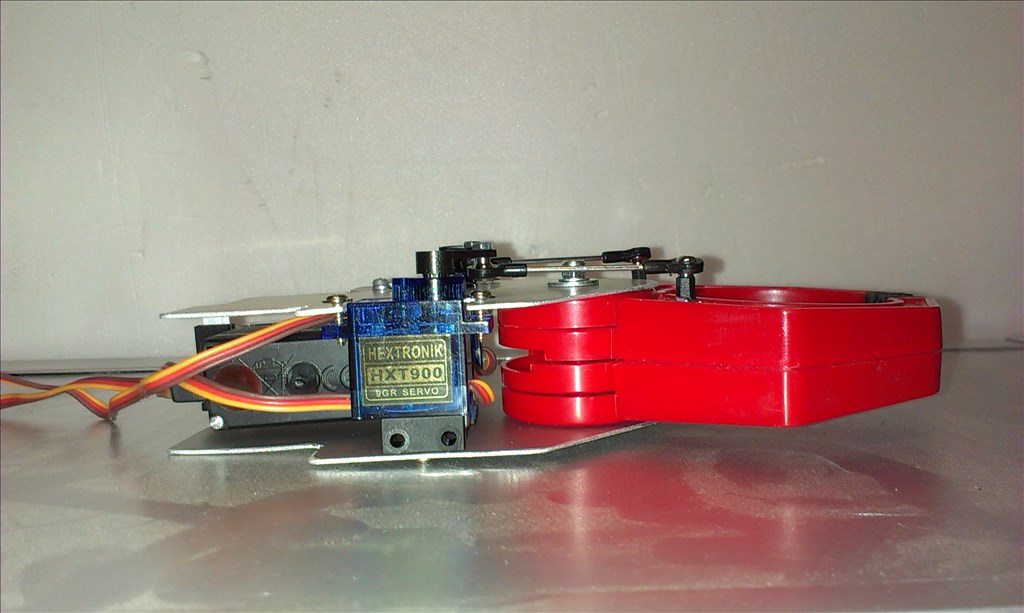

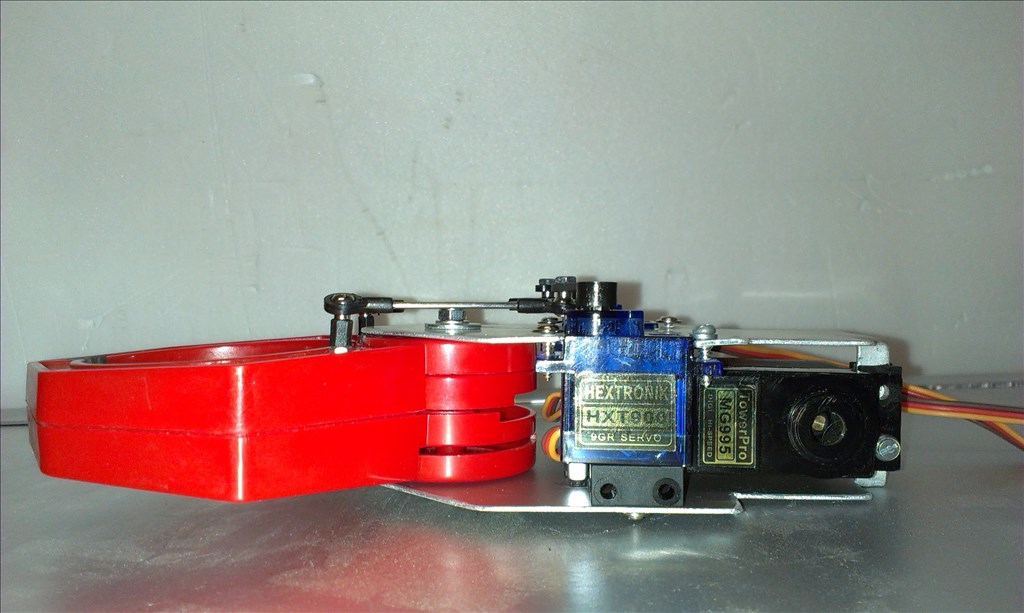

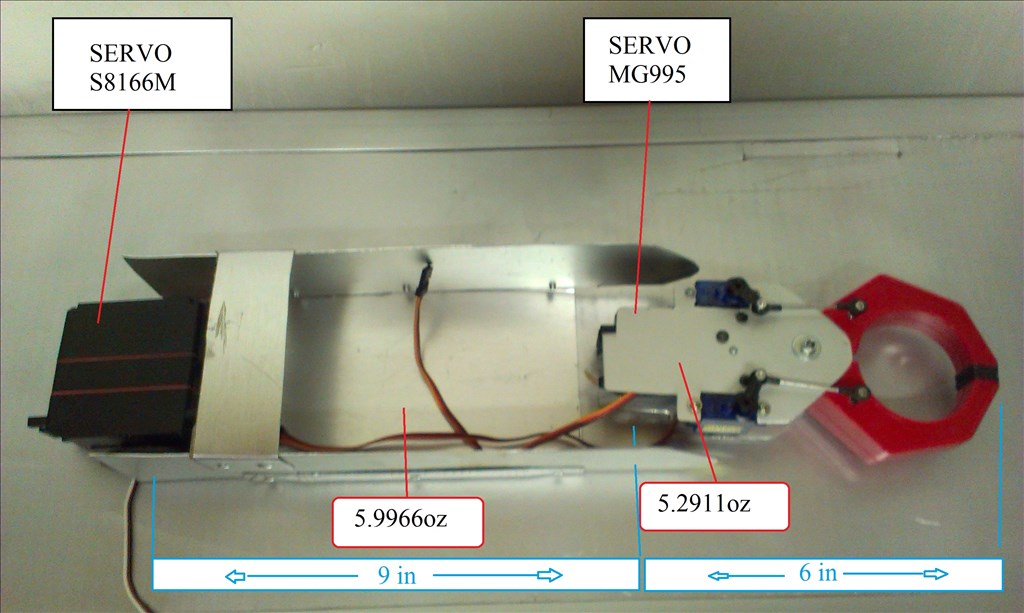

Following progress on the project, the arm works better than I expected, has successfully raised objects 370 grams (13.05oz), more than estimated. The arm is pretty hard so I will make another arm of the same thickness of aluminum, but with better quality, more rivets and correct some misalignment.

The speed of the servo (servo speed control) is 4 for elbow and wrist servos, servos speed 1 for the claw. The independent power of the elbow and wrist servos is mandatory. The servo s8166m goes up to 2 amps of consumption when working with weight.

:)

that is a really nice arm design. nice movement