This the result of too much free time lately, the new project is a robot drawing a sphere, using the low-cost approach to the selection servos and other components, with a retractable arm that comes from inside through a gate and once inside collected no space and is also protected when not in use.

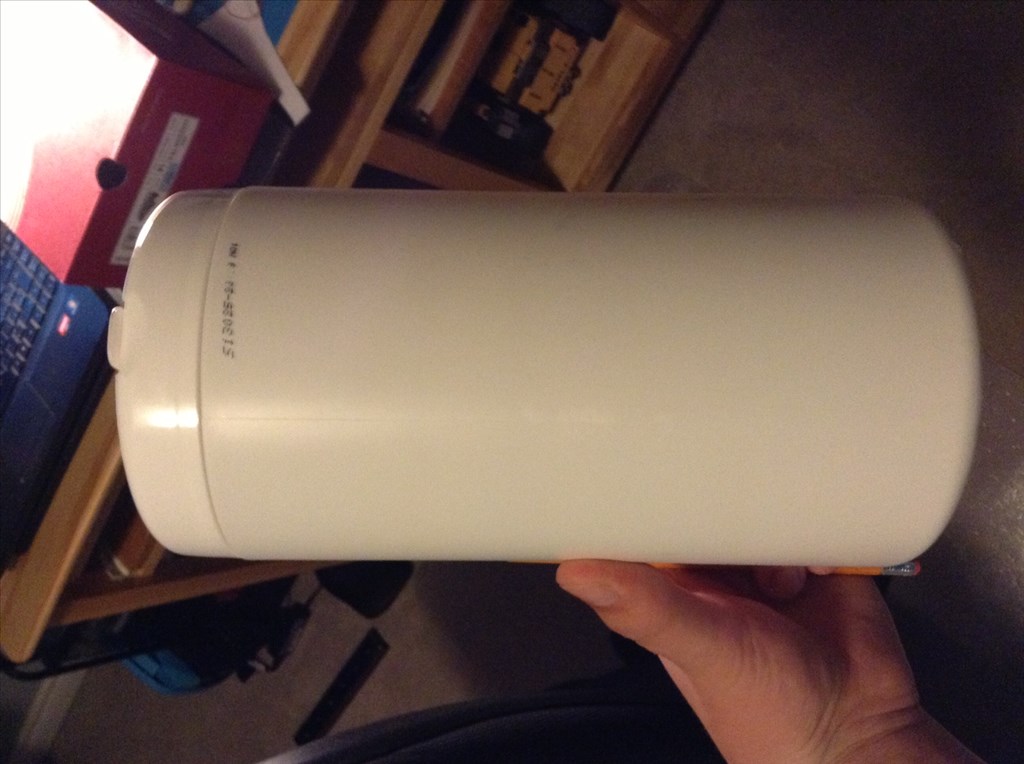

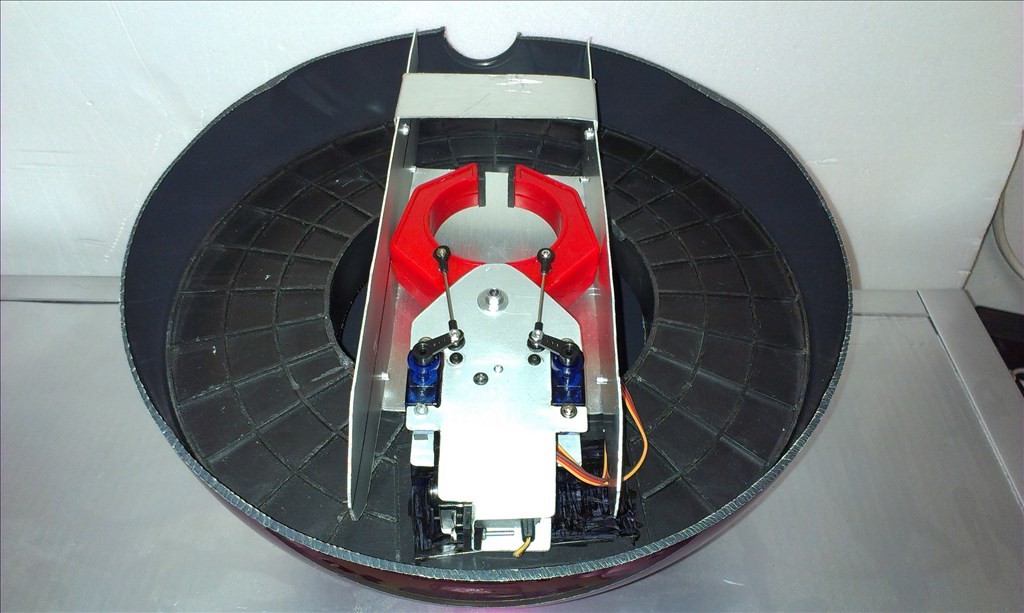

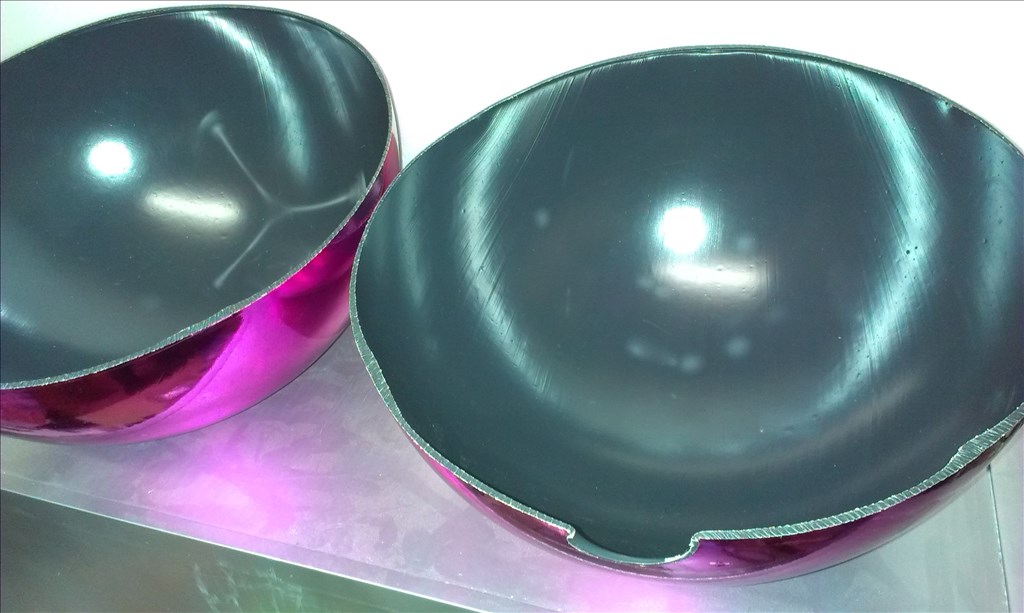

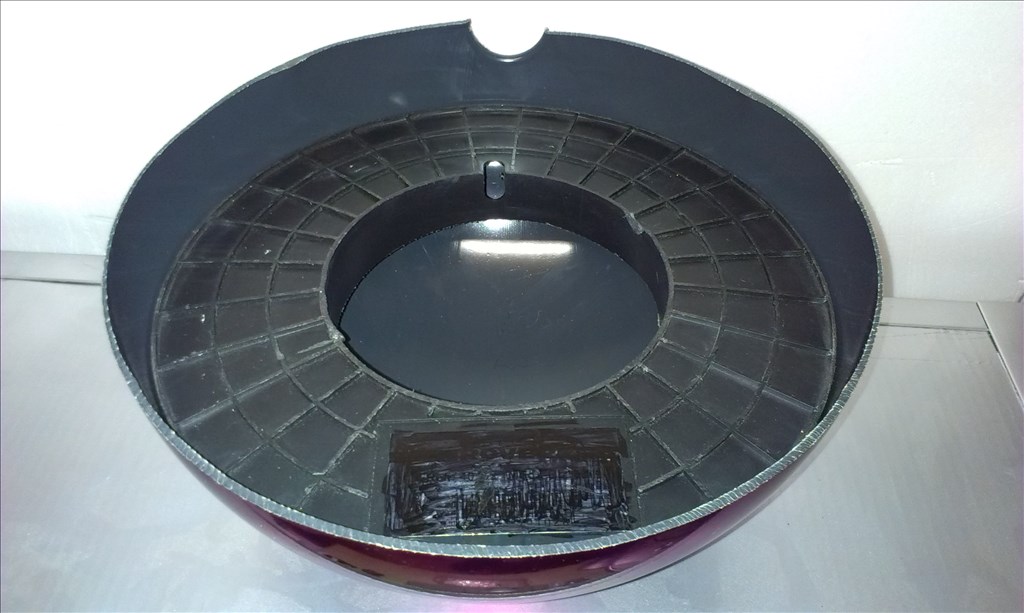

This is an area of 28 cm in diameter (11 inches) of PVC, is a large Christmas ball, once cut in half I've noticed that need structural refurzos to hold its shape once installed all the electronics and mechanics. So I will use sections of an empty roll of wire for reinforcement.

By R2D2

— Last update

Other robots from Synthiam community

Ezang's My Tracking Bot For You To View

Bot will find you, you can't hide anywhere, lol

DJ's Elastic Band Shooter

Elastic band shooter for hexapod in Synthiam ARC: servo uses a hexapod leg to raise/lower the body for vertical aiming....

Cardboardhacker's M2d2-The Diy Miniture R2d2 By...

Build an R2-D2 replica from a Lysol wipe container using cardboard, servos and a ping sensor, finished with paper-mâché...

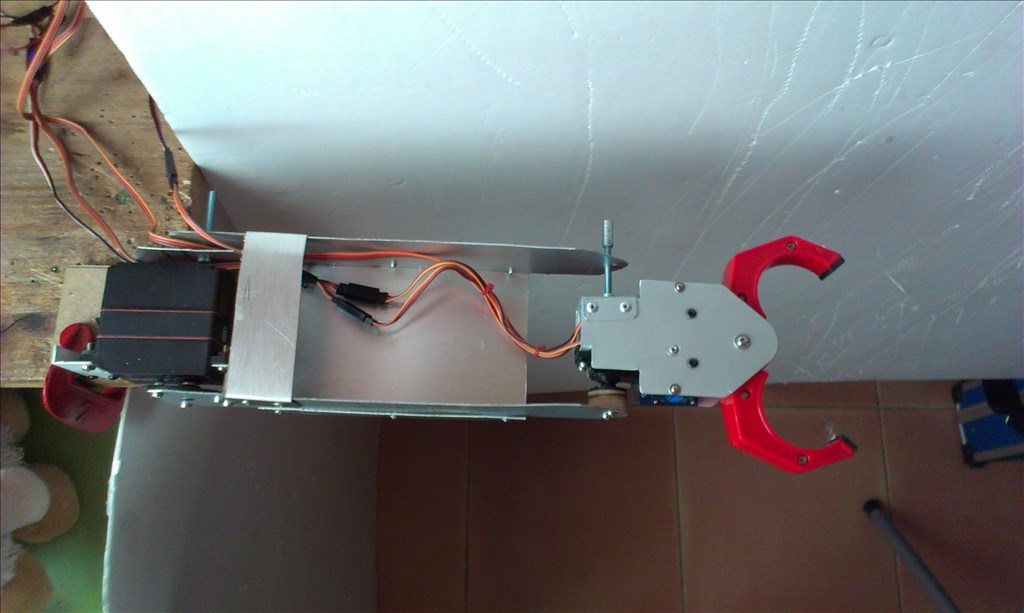

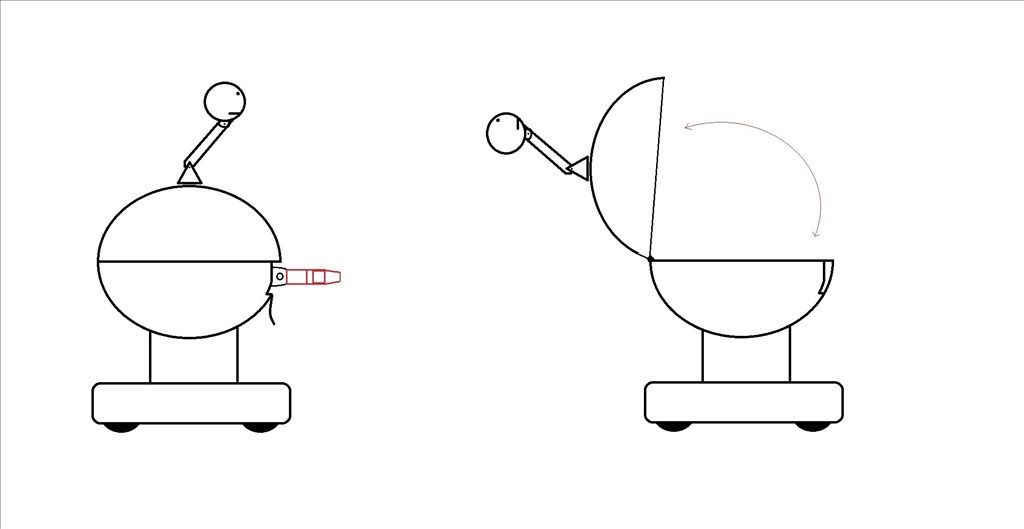

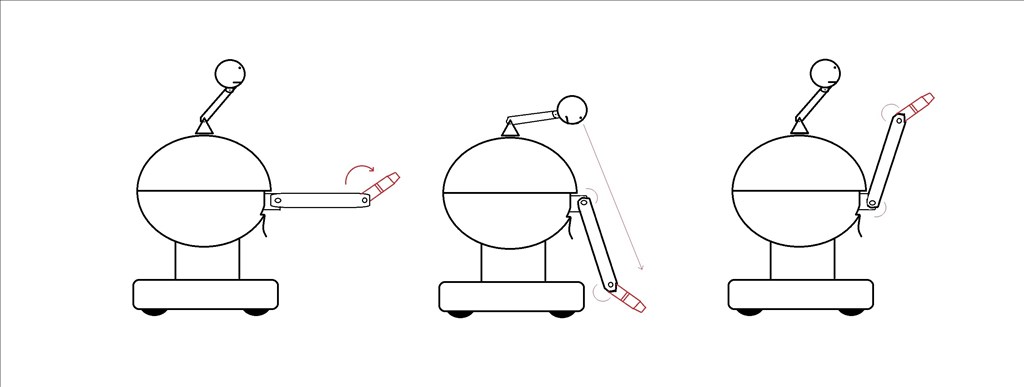

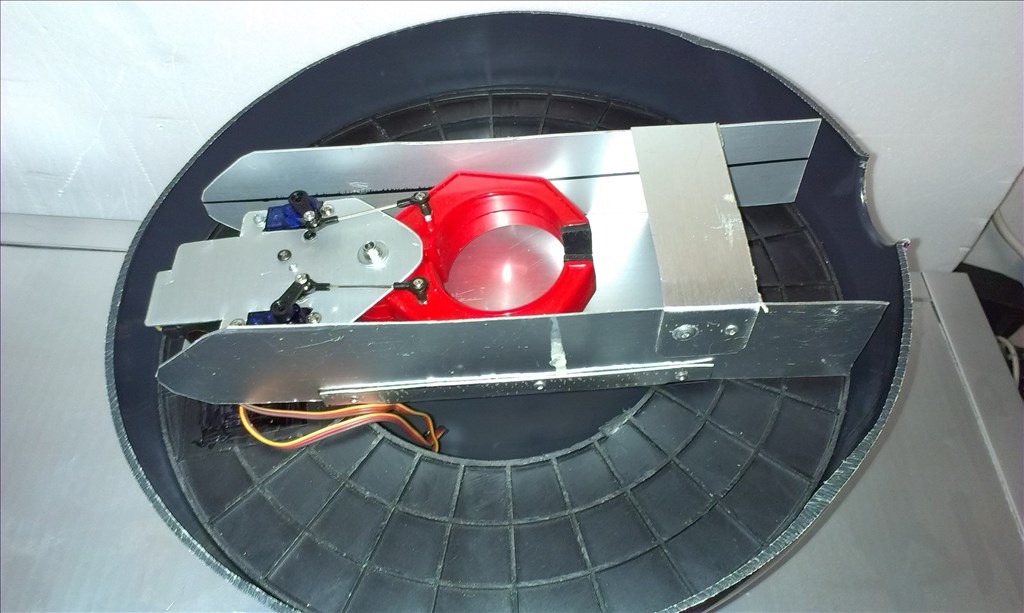

His appearance will approximate this when it's finished, although, I have not decided if his head is shaped like a sphere or other differently. The base of the robot, where the engines, wheels and battery, joins the sphere for 3 aluminum tubes. At the front door opens and out the arm by a rail system. The arm measured 25cm (about 10 inches) aprobechando almost the entire inner space of the sphere.

R2D2

Very cool. I'm a big fan of unconventional robot designs. I'll be following your progress.

Jim

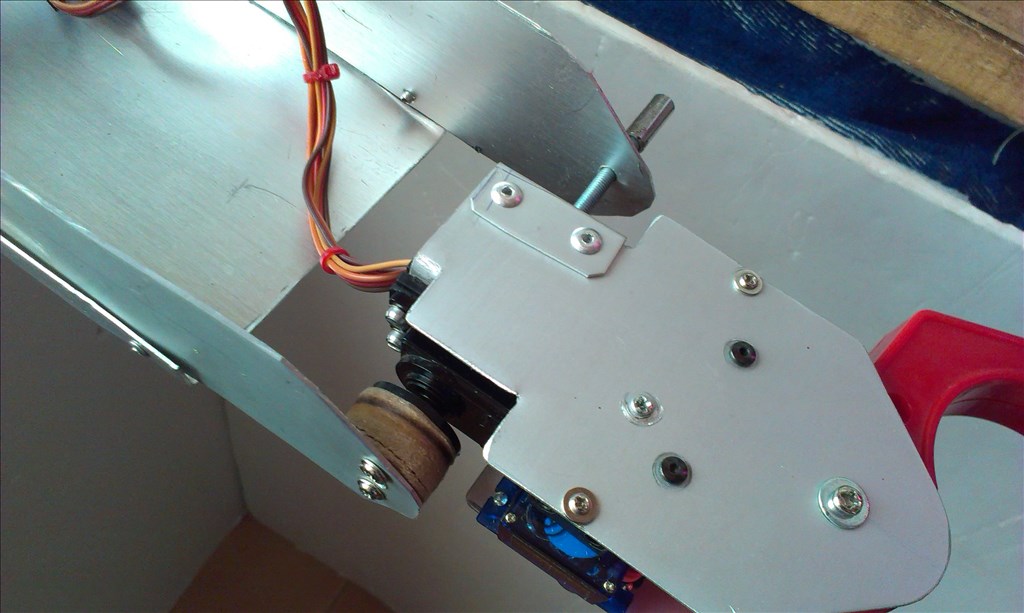

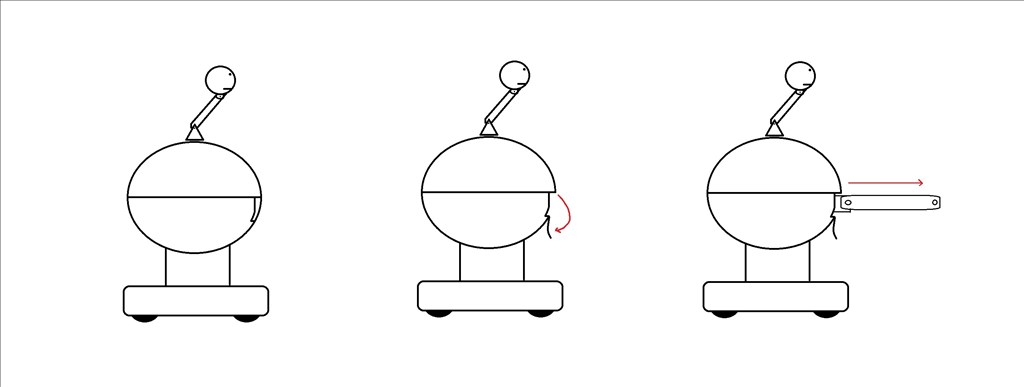

My goal is that his arm can handle objects from the floor to heights of 60 cm (23-24 inches) the table in my living room is inside that height, so you can pick up an object from the ground and leave it on the table or backwardO'nt as well as other tasks. The design, as well as the distance between the sphere and the floor and arm's height is based on object manipulation. The distance increases arm 15 cm (about 6 inches), to deploy the clamp with a rotation of 180 degrees from inside the hollow arm. (Although the maximum rotation servo wrist is 220-230 degrees ) This is ideal for deploy the clamp and reach other angles useful in handling. The head has three servos, one for turning left and right, and two to look up and down The pitch servos are at each end of the neck, and functions as an arm (let's say your big belly prevents him from seeing his low) With this system long neck always have visual contact with the gripper and object manipulation. I have some ideas with the color tracking multiple camera, your clip is red ...

You can also pick up your arm inward, leaving only the hand out of body, to take up less space if carrying something else. The sphere opens with hinges at the rear for access inside your body.

I love , love, love.round robots. I use to draw things I wanted to build as a kid. I like where your going with this - Josh S

- Josh S

Given the size of your robot a rover 5 tracked base would be ideal for your project... Or you could make your own and use 4 -6 continuous rotation servos with a couple casters and that would work very well too. The continuous servos are more quiet than the rover 5 if that's a concern. - Josh S

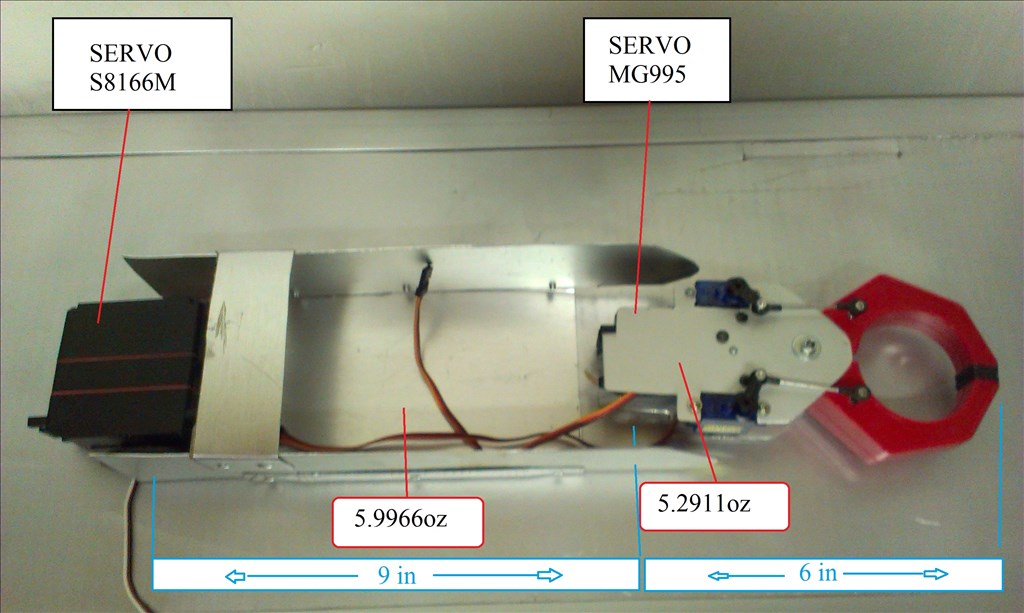

The base is a subject I have to polish, I want to be simple and try to avoid an excessive number of servos, necessarily have to be two, either servos or esc and motor and gearbox. If it would Turnigy servos s8166m that would have to be modified for continuous rotation, with a proper torque for the weight of the robot. And maybe if they opt for engines roomba base I've seen for $ 30 at a local shop secondhand.

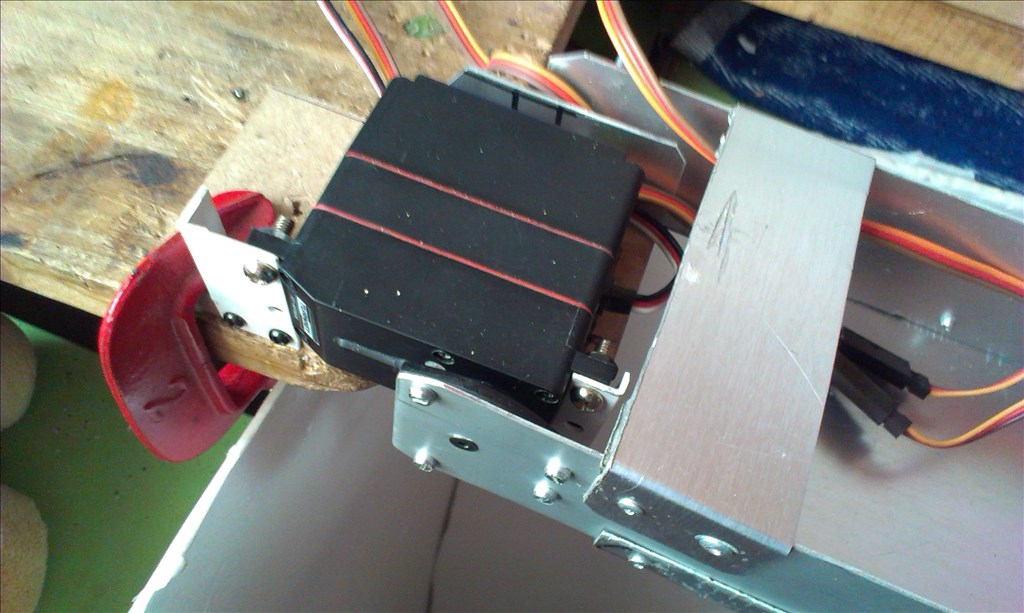

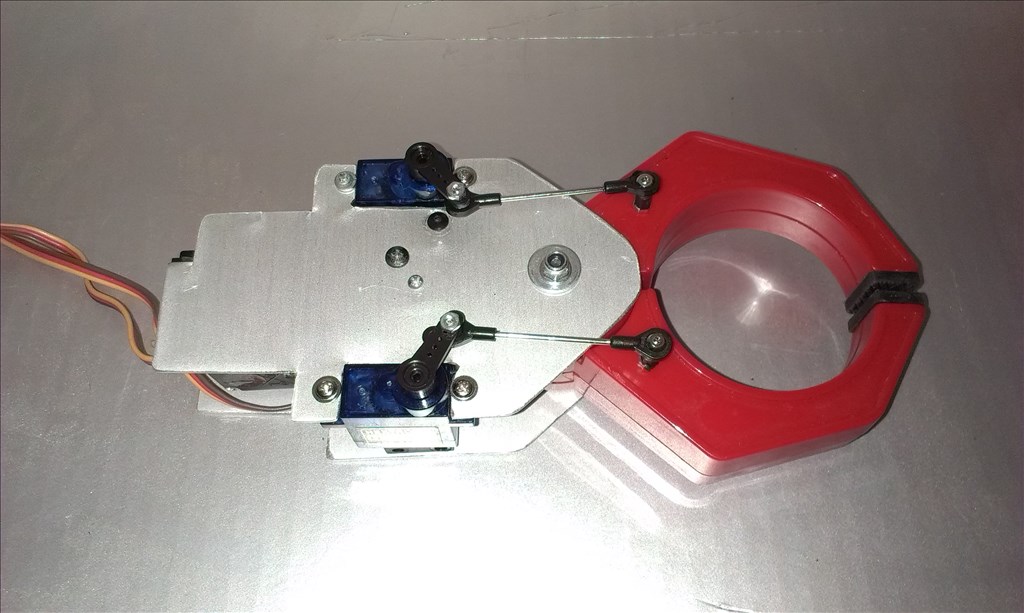

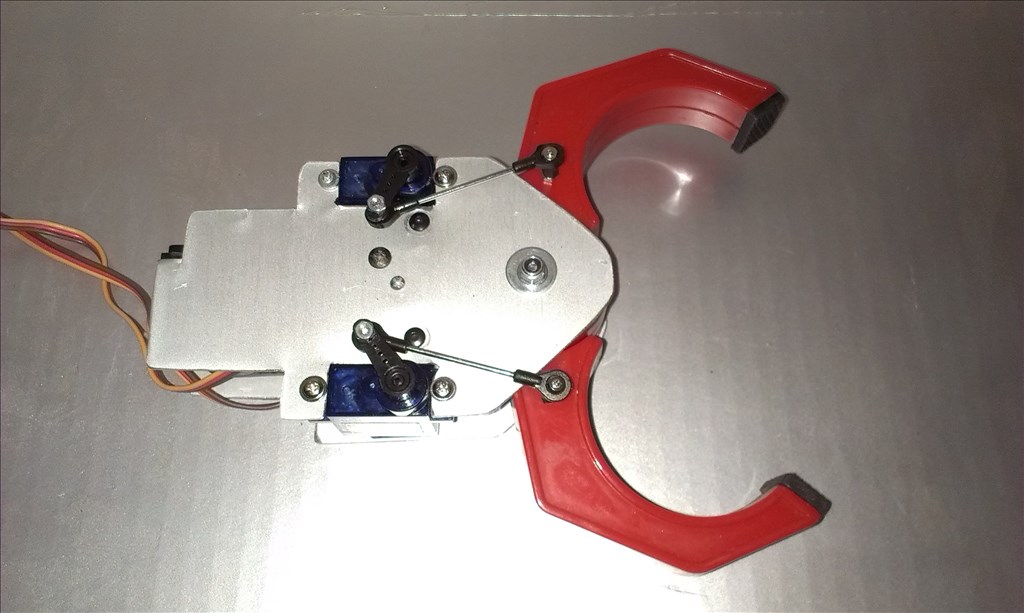

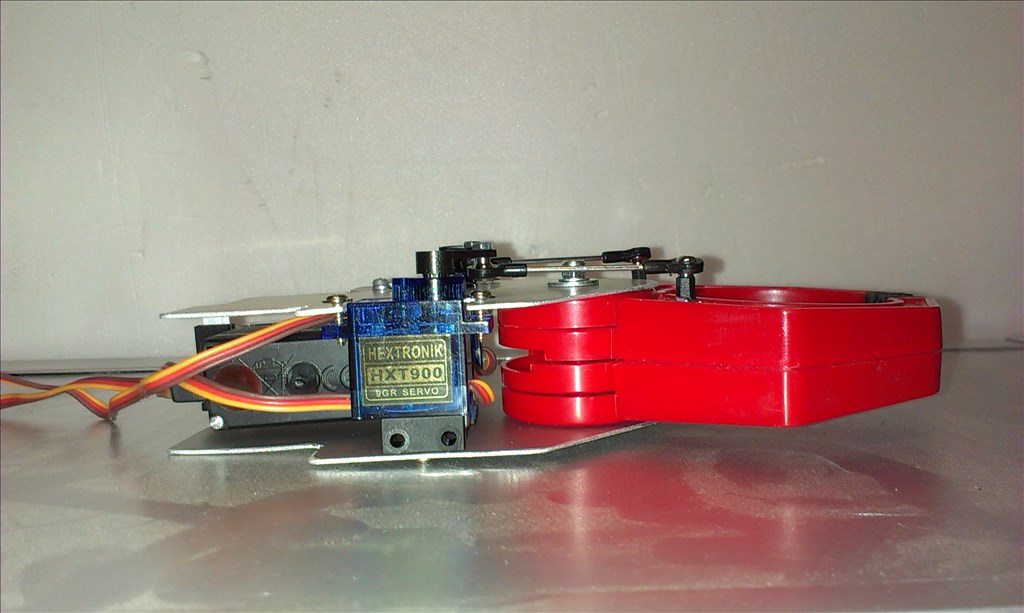

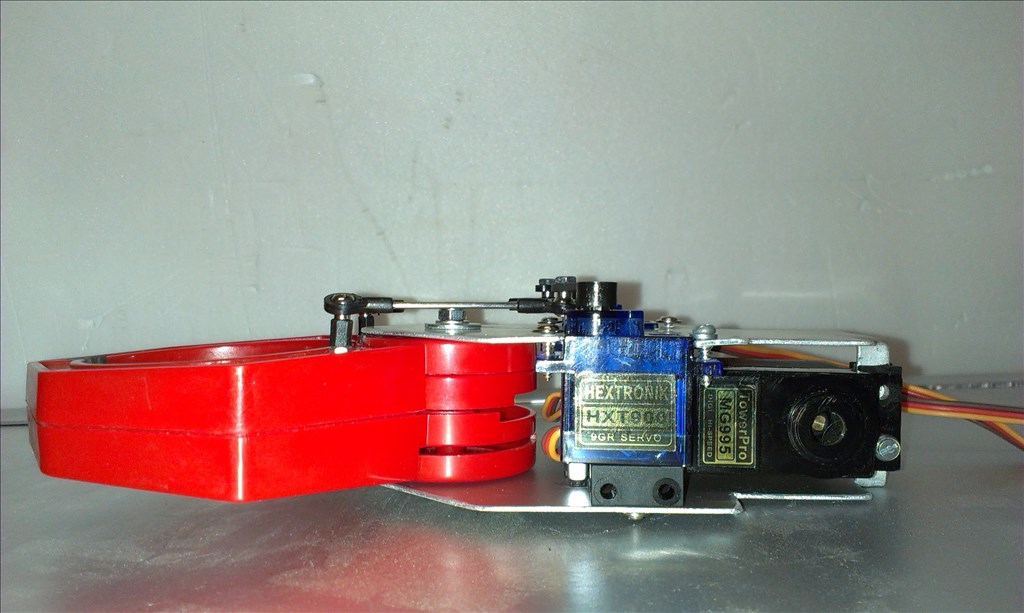

I used part of a toy hand to make the gripper. Consisting of 1 MG995 servo to deploy high wrist torque and rotation. And two servo Hextronik HXT900 for opening and closing of the clamp There are two reasons to choose two small servos instead of a standard: -The weight -The length of the hand With small servos could construct a shorter hand, and the two servos weight of 24 grams is small compared with standard servo 50 grams, half the weight bone. You use a rotation of 90 degrees in the sevo for a rotation of 45 degrees in each half of the gripper, and torque of each servo is doubled with respect to the gripper. The whole hand and their servos weighs 150 grams (5.29oz)

The whole hand and their servos weighs 150 grams (5.29oz)