There is no control yet in this robot. However with the upgrades I'm planning for this robot, Synthiam ARC and the EZB are going to be center stage.

I was asked by a fellow Lost In Space and B9 Robot fan to help him rebuild his B9 Robot. He bought it a few years ago and was a bit overwhelmed in getting this poor old robot put together and working. I agreed to try to help and give it a try. I couldn't bring myself to see an old B9 Robot left to exist in boxes and never see the light of day again.

Hopefully this is the first of many videos documenting my journey rebuilding an old friend and a hero of my childhood.

Hopefully in a few months I can have him blinking, flashing and rattling off sound clips. Please enjoy this first of many video to come where I first see what I have to work with as I unpack and discover. LOL.

Other robots from Synthiam community

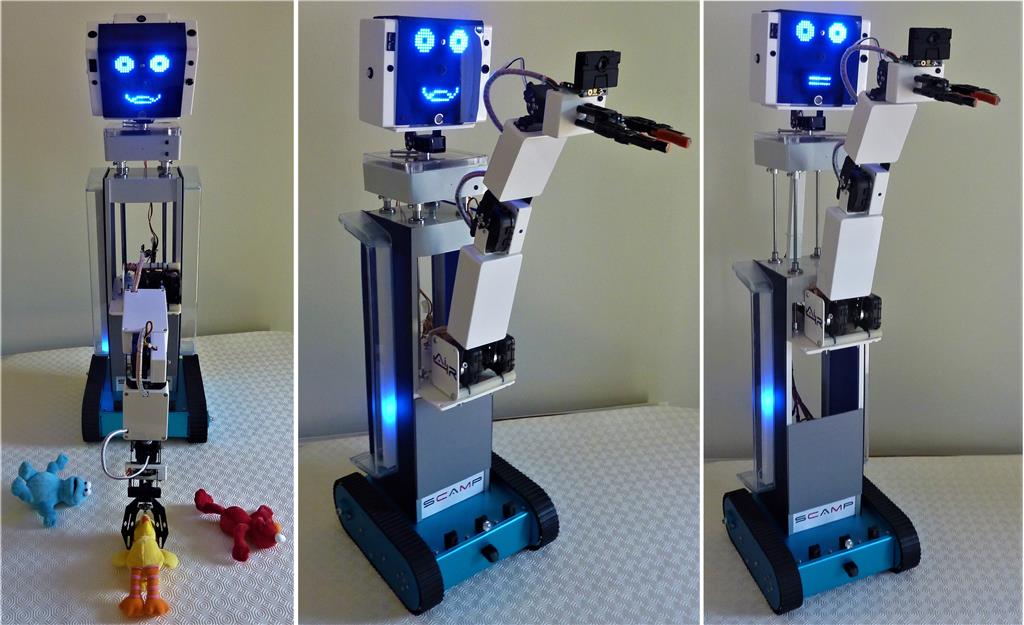

Toymaker's The Latest ALTAIR Robot - SCAMP

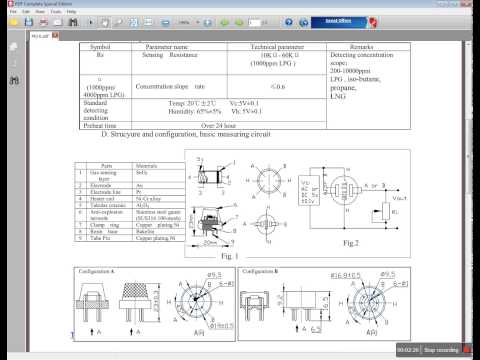

Luis's Using A Mq-? Sensor With The Ezb4 And ARC

Robo Rad, They are strong but crazy hard. Takes a lot to sand down any imperfections. Here they are in the raw:

I was rereading past posts. I saw in post #89 that I mentioned I was going to reuse the claws that came with this robot. After seeing their condition I'm glad I went with the kit that just came available! It's a much better end result.

That is why race cars like carbon fiber,lighter than metal and super strong! My 86 Fiero Gt is a mix of strange factory hard plastic and Fiber glass. Would love to reproduce some parts with carbon Fiber.

Dave, The claws look awesome, I didn't know you could print carbon fiber. Movement seems very smooth also. Enjoy your updates. Steve S

Always great work, my robot friend

Thanks guys! I appreciate the interest and nice words.

I know nothing about 3D printing and what can and can not be printed. All I know is it's as close to a Star Trek Replicator I've seen (quote from Will Huff. LOL). I'm so glad people are pushing the limits of this technology. One day when it's all plug and play and I can get a great print most of the time I'll probably get into it.

I've been working on this rebuild of a neglected B9 for a while now. I'm coming down to the finish line hopefully. There seems always to be more I notice needing to be done to this poor old guy.

One of the final items I have to complete are the arms.

These arms simply move straight in and out of the torso and are tipped and crowned off by B9 Robot Builders club vendors Robert Rossi's motorized and rotation claw kits and Craig Reinbrecht's light weight weight fiberglass wrists.

I've got one arm fully built and it's parts fully tested. It slides into place through the torso's arm holes and easily bolts down into place on a shelf attached to the CSS. Once I get this one arm complete to my satisfaction I'll be able to quickly build the second one.

What is different about my design from others I've seen is that it's driven by a finely machined lead screw and powered through a 90 degree gearbox that's powered by a Planetary Gear Motor with an encoder mounted on the rear shaft. It's a little slower then I would like but will do nicely. I love the arms to snap out quickly. This could easily be changed by swopping out a faster motor.

I have one more hurtle to jump with this design. That's cable management. I'm kind of scratching my head on this one. I need to run three servo cables out to the claw to control and power them. With the carriage sliding in and out in a linear motion I need to be able to feed about 12" of cable in and out along with the claws. I was thinking maybe bungee cord to keep things tight, Springs or maybe a drag chain. Space is a huge factor. A drag chain would be ideal but I don't think I can fit it in there.

I'll attach some pictures for your approval. Enjoy. A video may come later when I get this worked out. Thanks!!

I want to thank fellow B9 Builder Steve Neal from Down Under for his help in the early concepts on this design. The insight and skill he shared was invaluable.

I've made a big step on this arm build. I figured out how to manage the wiring issue. A drag chain was the answer to handle getting the wire in and out along with the claw. It's the same part used by 3D printers to handle their wires. With this solved I was able to pretty much complete the remainder of the build. After jumping a few other minor obstacles I've got my arm to the point of adding the control system. I plan to use a Sabertooth with a Kangaroo X2 to control it through ARC.

More to come on that part. In the mean time here's a video of where I am at now: