I have no clue yet to as what to name my bots, but I do know someone should probably ban me from EBay! I will end up with 3 total when it's all said and done.

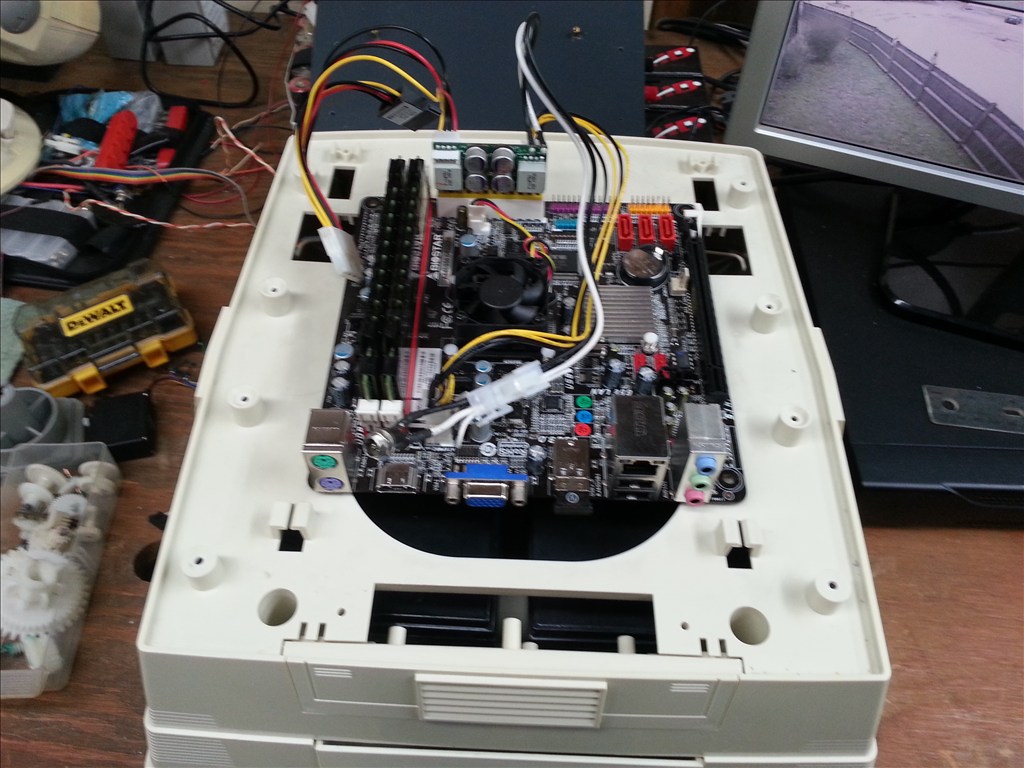

Okay so what I want to do with at least two of the bots is to add a Mini ITX setup, one I already have which runs windows 8, 8gb ram, and a 120gb ssd. I figured that the 3rd omnibot 2000 I can use for parts or whatever..

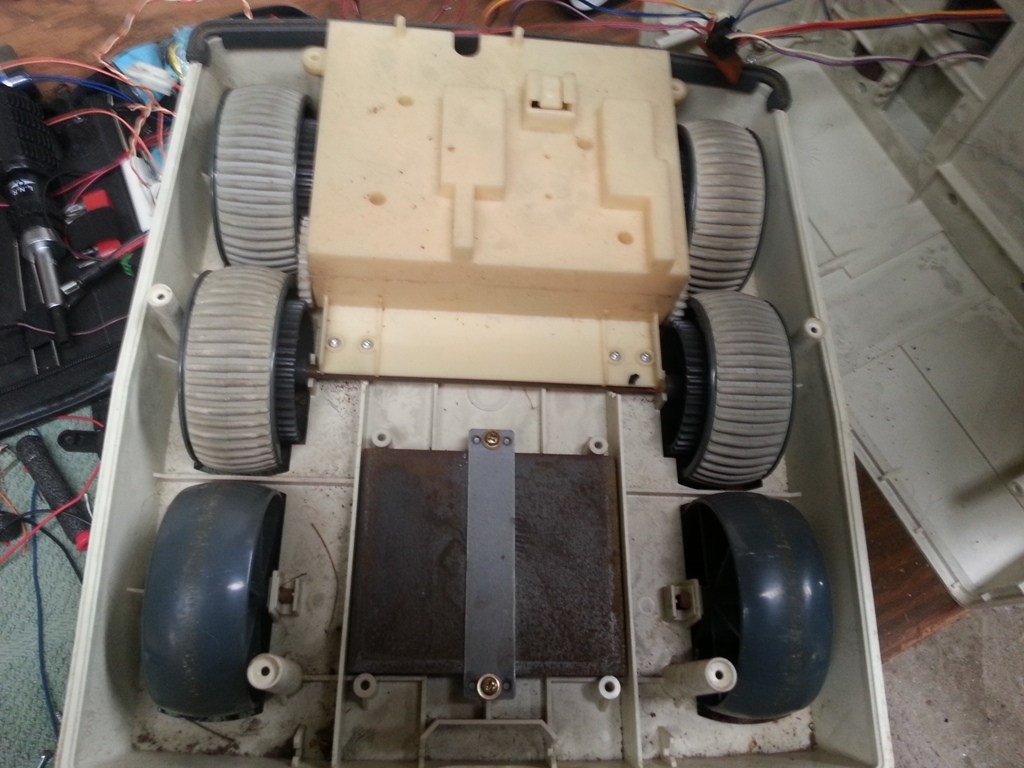

For powering the onboard pc's I figured that using a pair of 12vdc 7 amp batteries should be enough to run the pc for at least a couple hours? There will be another battery to run the EZ-B as well as other electronics. IS there enough room in the base for the batteries?

I would love to get some input on this project, as I mentioned in another post I also have a CNC Mill which I have recently started using again, and even though I am not that good with it(It's been a long time), I would think I can fabricate some parts if need be. I usually use either 1/8" or 1/4" think pvc plastic for milling.

Today I received my first Omnibot 2000, one of it's arms is broken and the first thing that happened is that it smelled so bad that it was taken completely apart and is currently in the dishwasher. I think it was living at a kennel with a bunch of dogs for the past few years, loaded with hair and all sorts of interesting things. I had to change after it was that bad.

A couple the things I want to do:

- Get rid of the gears and motors in the arms and replace them with decent servos, maybe something like the Power HD 1501MGs?

- Motor controller for each robot is going to be L298 based.

- Single Microsoft USB Lifecam HD camera on each robot - I found that the tracking on these is fantastic compared to the one that comes in the EZ kit, especially where lighting is an issue.

- Servo Pan/Tilt for the head, maybe using Lynxmotion servo brackets?

There's a bunch of stuff I am still working on but most of the items I mentioned above I already have on hand.

Here's a couple of pics of the 2000 I got today:

Other robots from Synthiam community

Tachyon's First Robot

Rich's The Testbot

@numba one check out my omnibot project for ideas

my omnibot 2000 project

and my friend JOSH'S OMNIBIT PROJECT

JOSH omnibot 2000 project

Alright, I was going to get one of the shoulders started yesterday, unfortunately my 8 year old dremel decided it wasn't going to happen and let out a little smoke and that was it, so I had to order one for today.

As much as I keep trying to keep this close to stock looking, I was looking at servoblocks from servocity, you could make a pretty decent arm(they can attach to the spg400a's), has anyone used these?

After I get the shoulder done, the next thing to figure out is the elbow, i've seen a few different ideas, I was thinking of mounting a servo inside the elbow, but I don't think it would be strong enough....

Got my new dremel setup in, damn they include all sorts of stuff now, also got some additional accys for it to make cutting a little easier. I've been trying to decide how to mount the Servocity SPG400A for one of the shoulders(even looked at Josh's idea), but I would rather mount them inside the body, which creates other issues, that and the fact I really don't want to cut this thing up. Anyone have some ideas?

If I could mount it inside the body, using standoffs and drilling out a couple mounts on the spg400a, it might work........

I think standoffs are the way to go. I tried several mods to my omnibot, but on my most recent rebuild I used stand offs and it is soooo much better. Is that a new battery you have in it, or is it the original? I would suggest a new battery, you can get one for about 10 bucks on line. Keep up the good modding. Can't wait to see pics.

Actually i'm not using the original battery with this one, I had to go with a pair of 12vdc 7 amp batteries since it's running a mini itx motherboard. The alumn standoffs should be plenty strong for mounting this to the body, just have to work out some details...

Standoff are great i use and have almost any size made,but becarefull you need to reinforce them depending on the max weight of the arm and what you want him to carry

I use a small aluminium plate and some like to use fiberglass resin,only its hard to work with and needs to work outdoors

Best about using aluminium plate,easy to work with,high strength,low cost and if standoff breaks like on fiberglass ,it can be easy to fix or change .on fiberglass it cant be fixed

That's what I gotta find, I have some aluminium plate/bars around here somewhere, somewhere around 2-3lbs max is what I am thinking for weight... Thanks

check mcmaster carr is cheap and fast shipping if you need other sizes also,just need a small piece near 1/16 to 1/8 thick is great,1/8 is what i use