This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

PJ's Robosapien ( R.A.I.D)

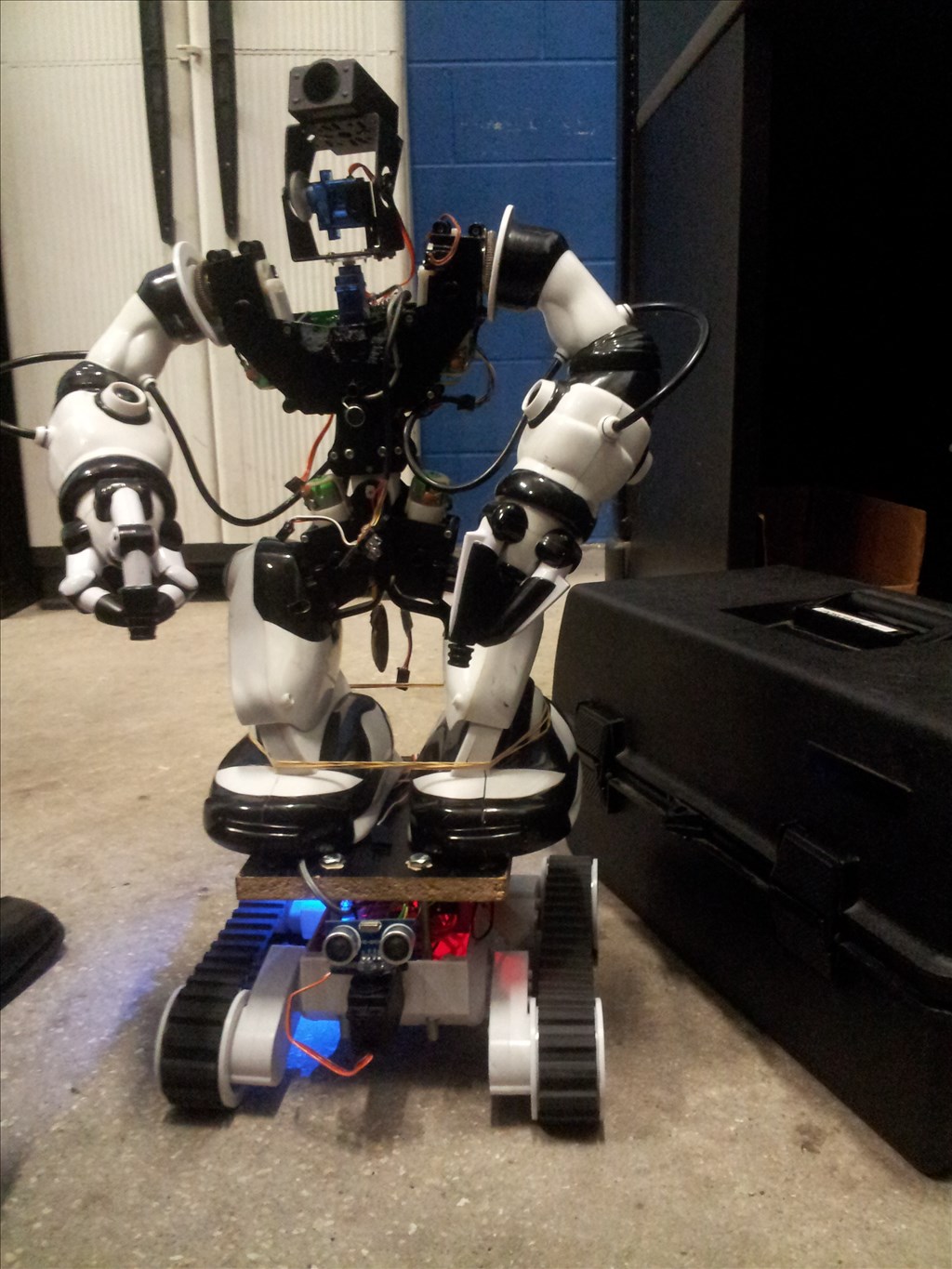

R.A.I.D robot test platform: heavy 4 D batteries, added Dagu Rover 5 tracks for grip; considering removing Robosapien...

Bhouston's New Eye Mechanism For Inmoov

I can’t access external sites. Please paste the webpage text or key content here and I’ll create the 150-character meta...

Xuven's Project Atlas 1.0

Project Gizmo robot with head and arm movement, MP3-triggered personality; future onboard computer, chest touchscreen,...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

the point of the hot glue was other projects,some like it because it cheap and easy but only good for prototyping,we use it at work alot and always breaks or comes off linear actuator i am using for my design,i found is the only way to move the claw in and out,besides using a leadscrew design tofill in screw holes i use liquid plastic,i bought a big can of it and works very very good heat up water then add the plastic power,and in a few minutes you can mold it and then it hardens very hard,then can sand it or drill it,if i mount anything to plastic,i have srew insets that press fit in to hole,just like thats done at a factory where they make stuff

@GLICKCLICK ,I thing everyone is doing excellect job of bringing vision to life on my design ,i look at as i want to be almost human,and last 24 hours,because i hate charging the design,second as a security robot,if beening charged it cant watch your house on lifting i want to lift alot more ,looking for 60lb ,but if can do 30 to 35 i be happy,when my design can do with my testing i done with weights not looking to have a computer for to use,only to control it and show emotions also bigger design to help me do cooking,(i was a chef for little while),there are a few made that can do cooking great to see JOSH using as a vacuum robot,ME I DONT NEED IT I HAVE MY GIRLFRIEND FOR THAT and it makes her happy to do it too,plus vacuum stuff on a robot gets in the way,plus i have tile floors BUT i might think latter of attaching it to his arms

THATS MOSTLY MY VISION,besides having a brain for ,math,spelling,answer the door bell,and a lot lot more,most of it i have already with the famous LEAF software

Lol thanks to.both of you , honestly your positive feedback , ideas and support give me the motivation to stay up those late night's , hearing back from you guys makes my day no kidding. I rather hear from you than a call from mom lol.

The.one.up! Here it goes - yup and my robots.gonna.eat.and poop , he can rescue me from a burning building with.a.firemans carry and make johnny.5.look.retarded. he.will.play.at least two musical instruments and also be my.personal trainer so.he.will go.jogging with.me. I.hate.dishes.so.he's doing that too , lastly he will will run a.full week between charges and NASA will offer to.buy.him because I design all his sensors so well. No hotglue all titanium.body. he won't have a computer.it will use a 15 yr olds brain because.they can go.without sleep.

Troy you know its funny

people might understand me,i think JOSH DOING A GOOD JOB,said it many times

some of my posts are to give JOSH better ideas since i been building robots for a very very long time plus in college i had somewhat of a course in it too,plus trade school on metal shop,(that was a fun time) building shopping cart with a motor,and a dune buggy with a fiberglass shell and lot more

@robotmaker: whats the name of that plastic stuff? Is that the same stuff that DJ uses in his howto-video of Omnibot 2000? Mike

its called instamorph And amazon sells it,very close to same plastic use to make the omnibot 2000 super strong ,sticks to anything,non toxic moldable plastic i like it much better then fiberglass,just as strong ,very easy to use

on the video's havent look at one yet,mostly dont need to,

Have you ever used that stuff? It melts at 140 degrees and has no adhesion , its the low temp plastic used to make dental dams and mouth guards for sports. That stuff is ridiculous exspensive and heavier than fiberglass and carbon fiber. Imagine if you drove your robot to the local convention center in the middle of summer and the little guy started to melt from the sunshine? I would never have the.money to trial and error with such a pricy material as low temp plastic , but you do have lots more money than me I hear lol

If you want a plastic that is tougher and moldable get liquid plastic or liquid Plexiglass polycarbonate

That would be pretty embarrassing...

@Josh, I cant wait to see your instructable!