This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

Klaatu's 1 M Hexapod (Autonomous Insect)

Autonomous 1m hexapod with EZ-B V4-2, 18 servos, LiPo power and Synthiam Blockly control for garden navigation,...

Gabbott's Quadruped Called Thumper

Quadruped robot nearing completion: installing servos for head motion and refining gait to improve walking performance.

Edison2's Spy Robot V2!!! Here It Is! The New Version!

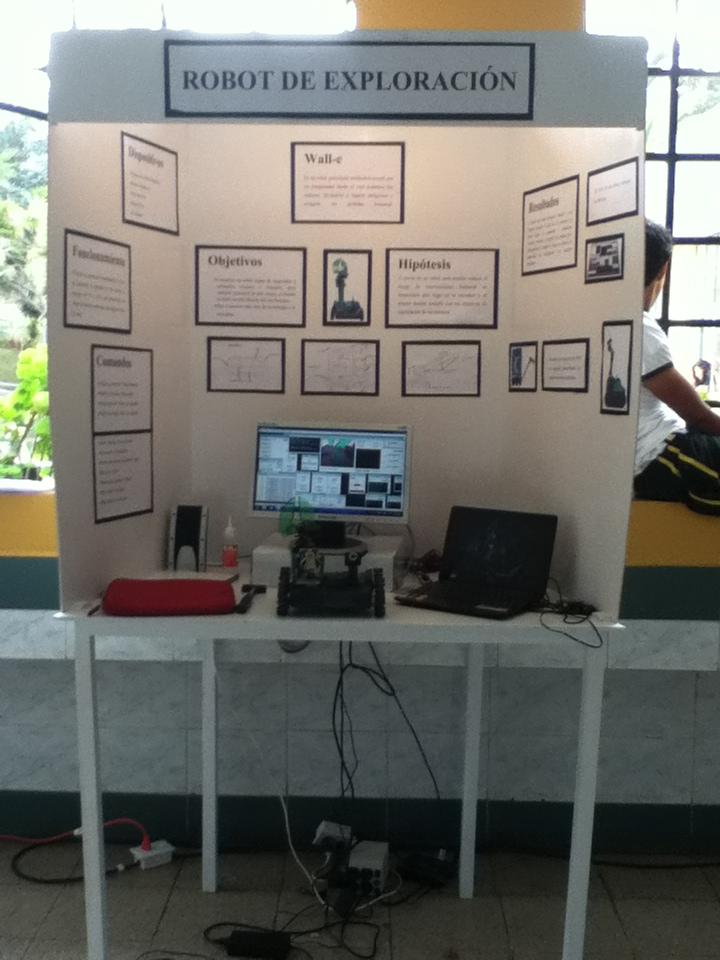

Spy Robot completed and showcased at a school science fair, credited to DJ Sures; photos and Spanish materials from...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

Looking real good Josh!

Right now I'm trying to think of a way to make the wrist rotation and claw opening and closing controlled by a servo. So far I have thought of an idea to have one servo actually in the fore arm only for wrist rotation , then use a bicycle cable ran from the claw up to the shoulder where a second high torque servo would be and try mounting it balanced on the pivot point of the shoulder so it doesn't add weight that the shoulder servo has to lift.

@sam - I.guessed your an aunt but if you rather be a different member of jarvis's family just let me know lol.

@troy + Brett thanks man , I'm trying to make him look good . I'm still kicking around buying the robotzone gearboxes for the shoulders.

. I'm still kicking around buying the robotzone gearboxes for the shoulders.

Update on arms , I finished wetsanding the areas that were fillwd , two large screw holes and two even larger holes that originally attatched to the torso.

I used babysoap in hot water to wetsand these parts , all four took about 30 minutes then I rinsed them off. Normally I would fill the couple of pinholes and repeat but servos and logo badges will cover them anyways so there will not be a visual or structural affect.

This shows the layers of filler , original plastic and fiberglass epoxyWow thats super smooth!

Fitting my S logos for Starnes customs , I cheated they are normally used on cars.

As I finish today's work I am trying to figure out which robotzone gearbox + gear ratio selection I would like to get. Take in mind I have two types of servos possibly to drive it , either 645mg 133 oz servo or the super hoss 5995tg 414 oz in. The three to one ratio gear would provide 1242 oz in. That would be the arm holding 3 to 4 pounds in the claw. The lowest ratio I can get which also upgrades me up to metal gear is 5 to 1 over 2000 oz in but I don't think I need that much , heaviest thing he would ever grab is a wine bottle. The 3 or 4 to one ratio is 59.99 for the gearbox and I would need to install and modify the servo accordingly.

ok I made the jump! I have two ROBOTZONE 5:1 ratio servo gearbox kits on the way which I could couple with my 5995tg titanium gear high torque servo. because all my other servos run 6 volts I will also run my shoulders on the same voltage, even then the shoulders will have over 1500 oz in torque thats 93 pounds / inch and after you add 16 inches arm length thats 5.8 Pounds lifting torque. the smalles surface mount unit is the one i went for.

I should be able to simply trim a knotch out of the torso to provide fitment otherwise its mostly low profile and this takes all the weight of the arm off the servo itself and all the servo would do is turn the output gear without all those lateral stresses servos arent made to handle. Now i will need help when they get here because I must modify them for continuous rotation and hook up there heavy duty pot for feedback that they supply in their kit. all together two kits were $126 shipped, completely worth it when you look at how much high torque servos cost. even one of the 645mg hitec servos I have would produce over 700 oz in torque with this gearbox! So i would recomend it to anyone really. Getting this robot to paint has clearly become an obsession. Now once the riser is done I only need to finish the arms , install these two gearboxes and finish the mods for the vacuum and im off to paint.

thats the one i am using only making my own gear box,if you look how its made i make all my own servo's like that,just a motor,gears and pot and a cheap servo board and if using a higher current motor then add bigger h-bridge,i get when i get the time will do a post with photos on how to make your own SERVO

hitec has a new servo out 600 oz