This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

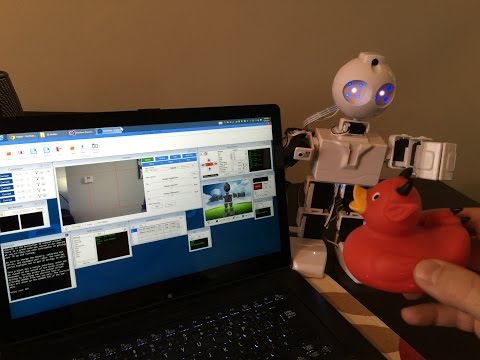

DJ's Jd Wants His Rubber Duck

Deciding whether to give it to him-lighthearted reflection on sharing, choice, and a playful "lol"

Bret's Roborad

RoboRAD combines a RAD 2.0 base and a Robosapien into a hybrid robot for hobbyist builders

Linux's Project Omega Status

Omega robot build 75% complete using Rad Bot 1.0 tracks and plexiglass; pending neck/head, wiring, motorized tracks, RGB...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

Nice Josh! It is really coming together and your improvements are fantastic. I only wish I had the money to do what you are doing. Can't wait to see the paint!

JOSH the omnibot i got from you ,when i took the hand apart all the gears are missing what happen to them

I like the logo for the arms, that is a nice touch. I really cannot wait to see him all put together. It is really hard to imagine this is your first bot. I forget all the time.

Is that regular car bondo that you use? What grit sand paper? That does look really smooth.

I have been thinking of adding a few lines etc to the bot body to give is a different look. I haven't decided on medium I want to use yet.

on sandpaper if you want a good finish start first with about 400 grit wet/dry and then use about 1000 grit ,if clear plastic you need a 2000 grit wet/dry (and they make up to 4000 grit and higher)

I believe I was using 120 grit , the soap and water prevents the sand paper from really biting in and gouging the surface but still sands reasonably fast. I hate sanding and this makes it soo much easier.

@robotmaker that bot I didn't fully disassemble I just cleaned it up best I could. I do have a hand gearset 4 sale because I'm pretty sure I'm just going to use servos in the claws because dc motors are slow and the plastic gears are kinda fragil I'm betting after 27 years.

i did noticed on the arms it has rubber paint ,like the kind you used for for the motors too ,any reason why you put that on there or does it come from the factory like that almost forgot it where the arm attaches to the body and where it turns (shoulder)

only gear i need is the one for the claw,so in case i want to match it and about dc motors ,they are used to make servos along with plastic gears plus a pot and control board,so really what you have in the arm is a servo,just no feedback pot i might need the gear to recast using a better plastic or metal or if i can buy a gear that matches it so only need the the one that matches the worm gear they using on the claw (may both sides )

120 grit wow. That is really smooth for the rough a grit. I sculpt so I use a 600 wet/dry paper for details. That would make it go faster. I normally have my kid come by the house and do my sanding.

i dont think they make 120 grit in wet/dry in paper yes ,but with soap it wont work 120 grit is very course