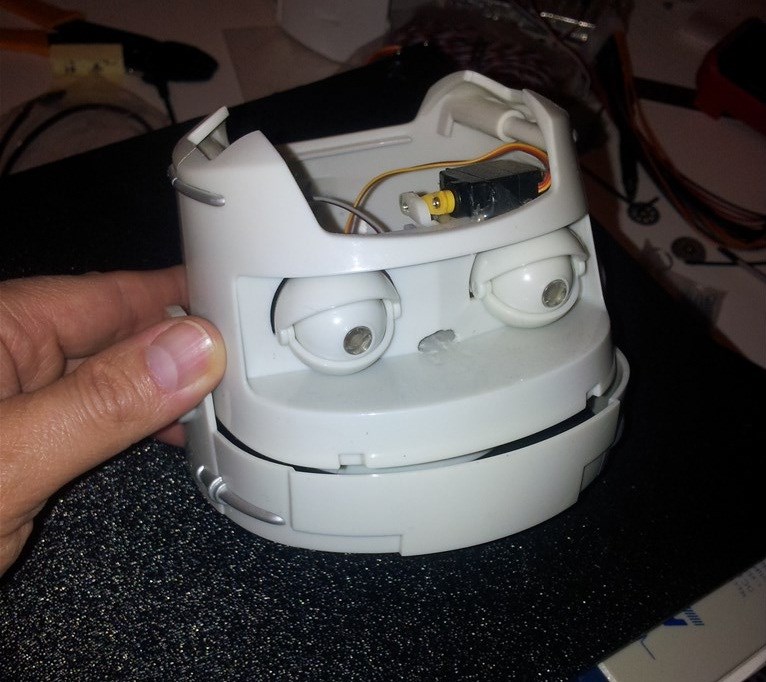

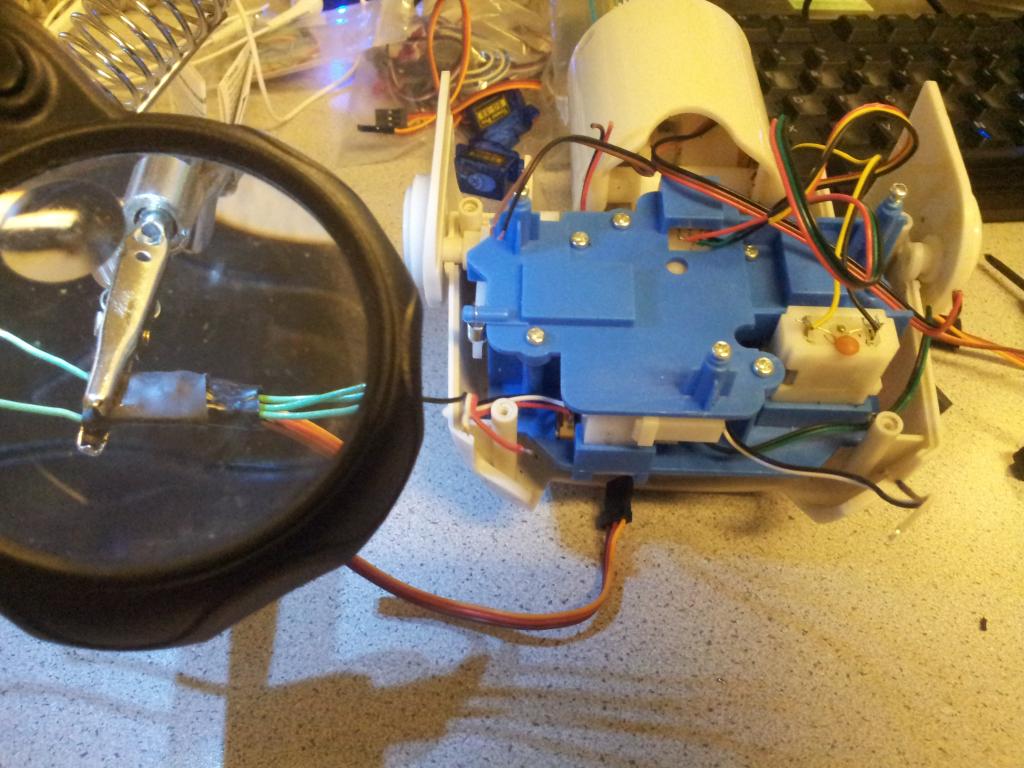

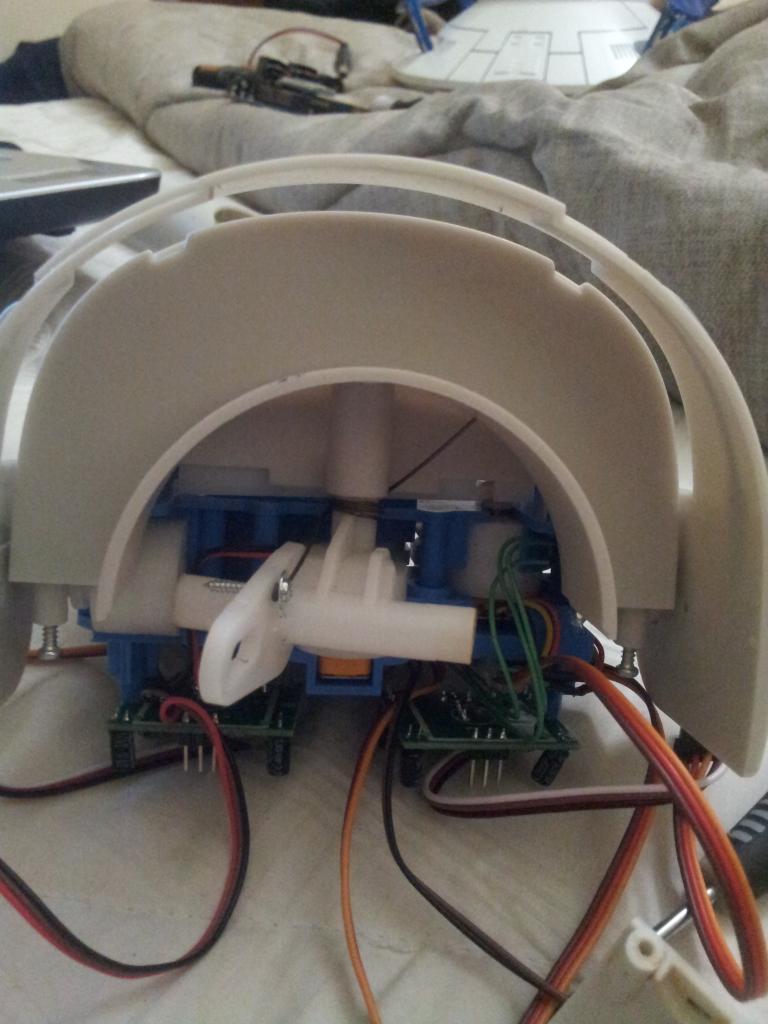

It's just a concept right now but I wanted others to see that the scale doesnt quite match. Right now its just stacked on there and neck is a little too long.

By Troy

— Last update

Other robots from Synthiam community

Steve's James, Commodore 64 Retro Robot That Learns And Uses...

Revived 35-year-old Retro Robot runs on 7.4V LiPo with buck converter; Commodore BASIC learns 3D motions via joystick...

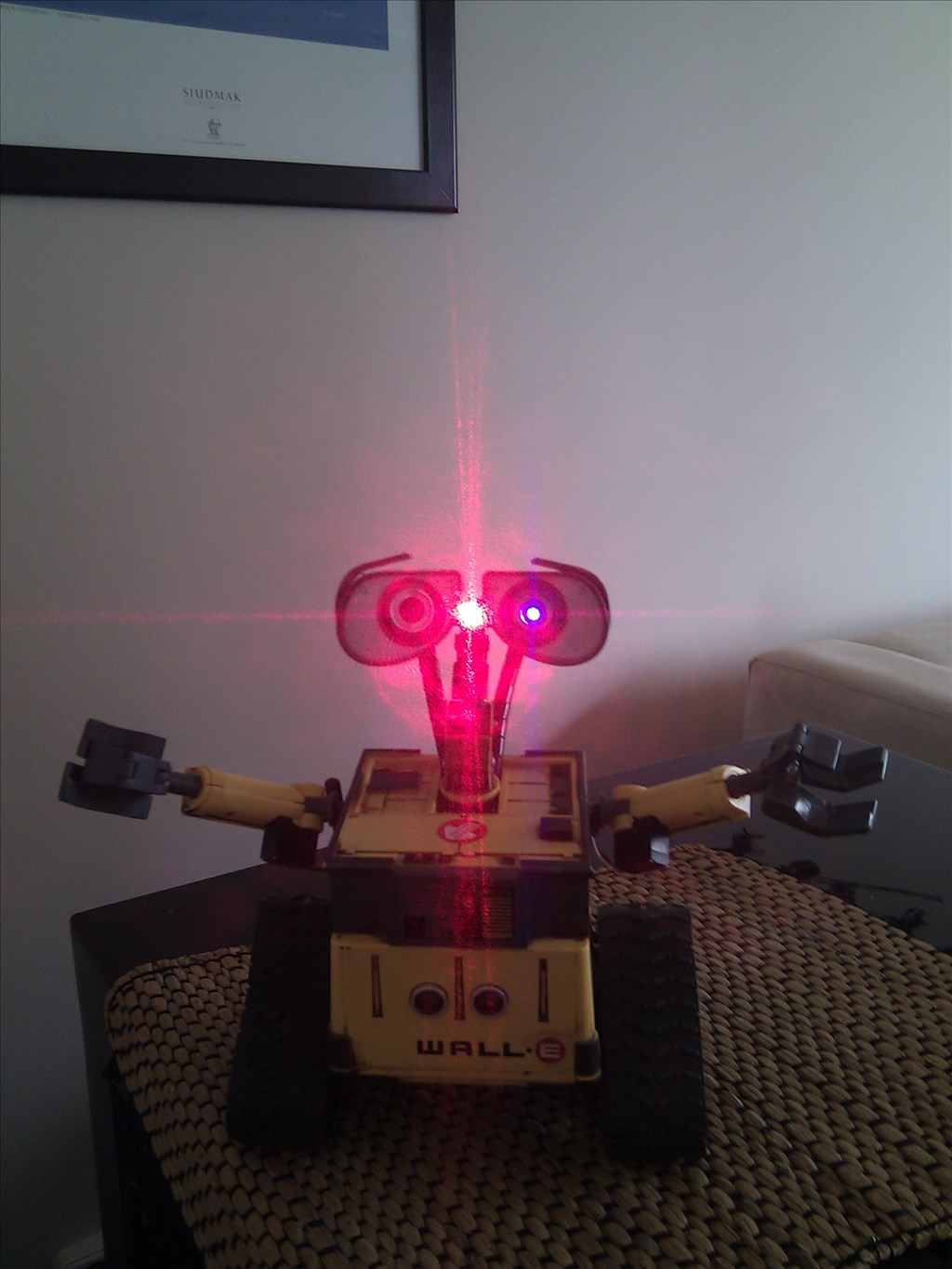

Fisha's Wall-E Wall-E From Poland - Tribute To My Newborn...

DIY Wall-E robot with 12-14 servos, camera, ultrasonic sensor, MP3 trigger, amplifier, laser diode, VU meter mouth and...

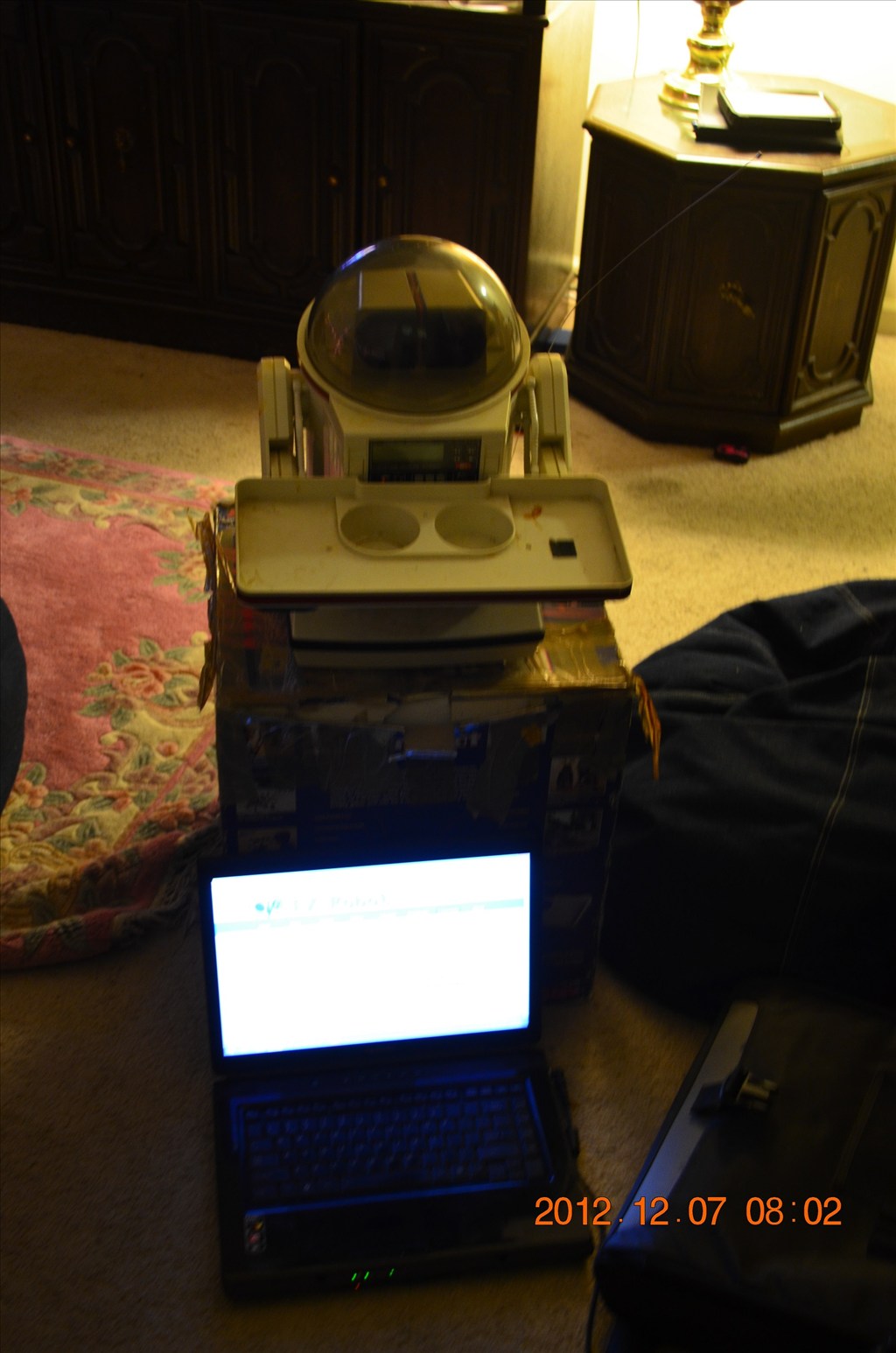

Herg62123's Omnibot 5402 Project - Code Name: Minion 8

Convert a 30-year OmniBot into Minion 8-integrate a laptop, keyboard tray, eye projector and ez-b kit for a Windows 8...

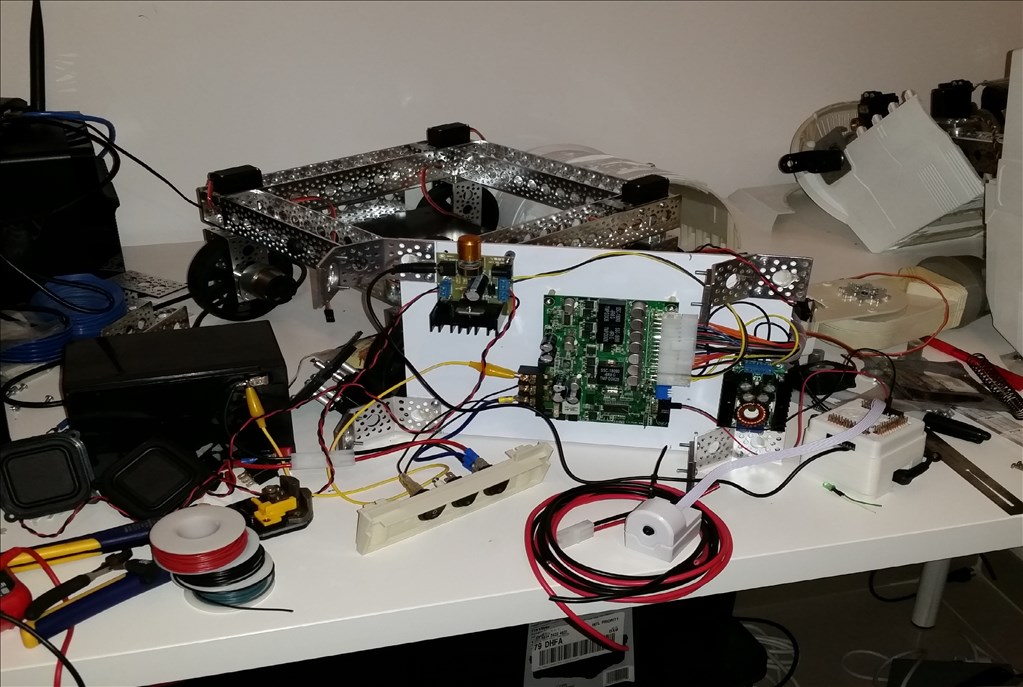

Thanks Bret and Irobot I actually didnt know that. I'm using a dremel with a cutting wheel. The dremel is a great all purpose tool for the "small" bots. I may need to buy some brackets instead of the stand-offs I originally was thinking of doing. They are too thin and will probably work loose with all the upper body weight. Im thinking of these to taper the top corner in.

Too bad you cant make your own brackets from thin sheet metal using cutting shears and a drill! Buy yourself tin snips and you will be making a lot more stuff! don't forget the file.

don't forget the file.

These are a bit stiffer than I could make.

In hindsight I should have posted a video of it before I took it apart.

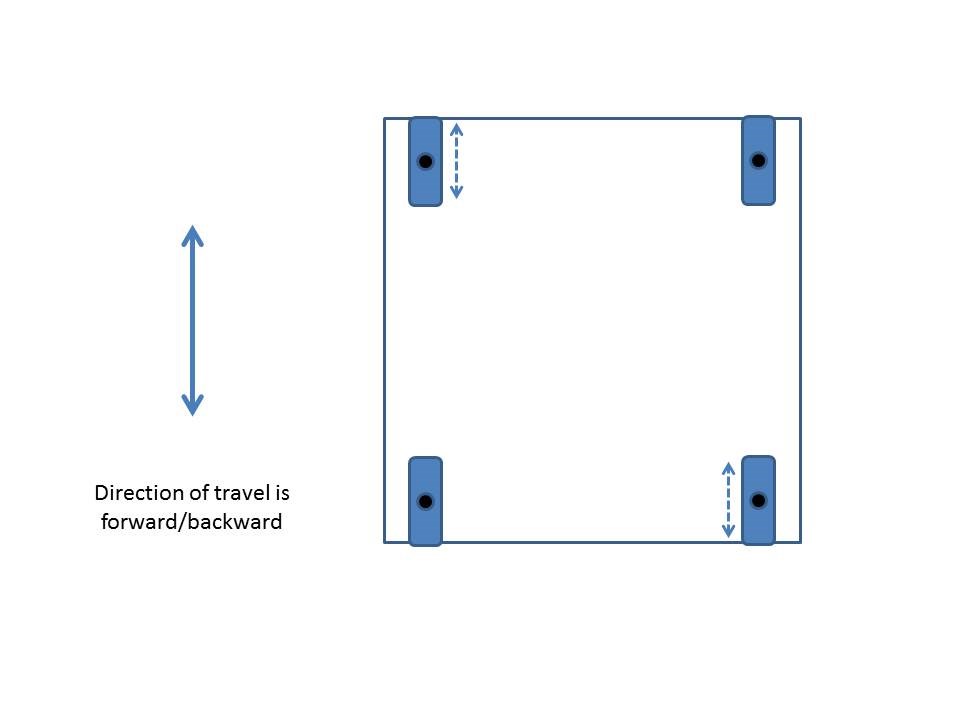

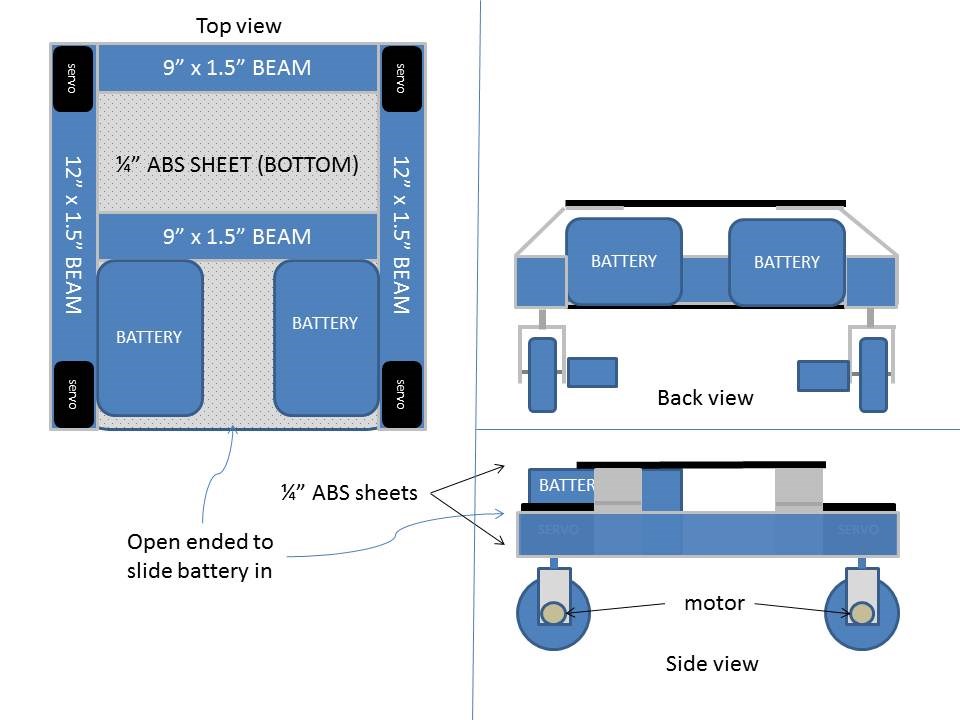

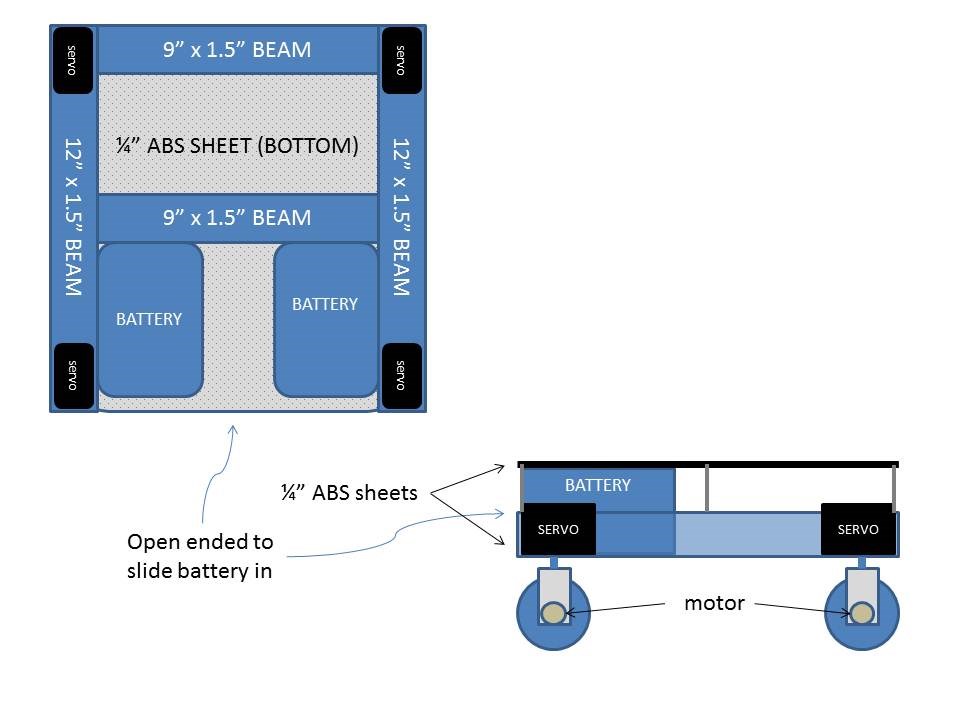

Small update to the frame plan.

Although this shows 2 batteries I won't add the second one until later. It's for additional amp hours in a 12 volt system.

Looks like a good plan.

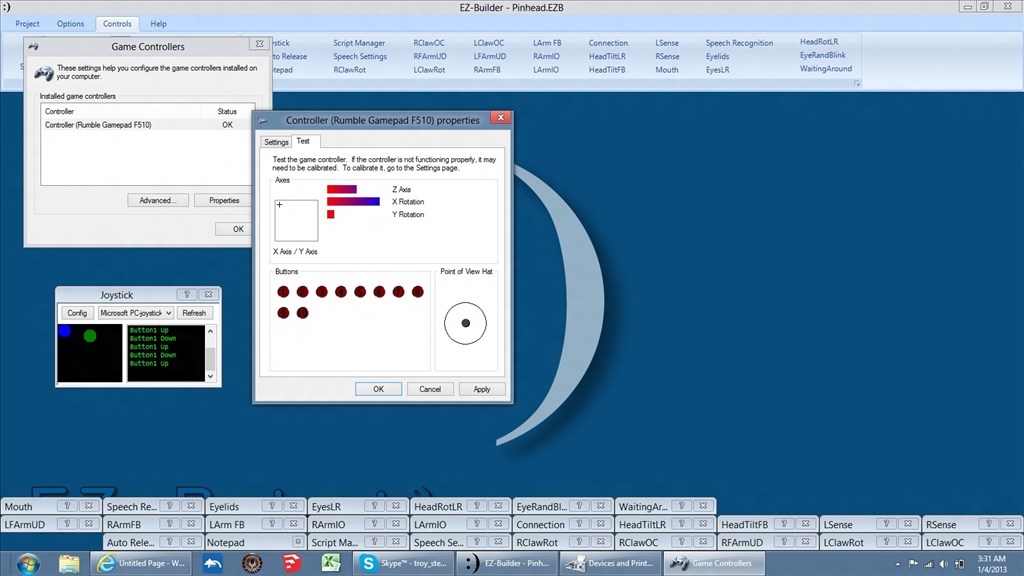

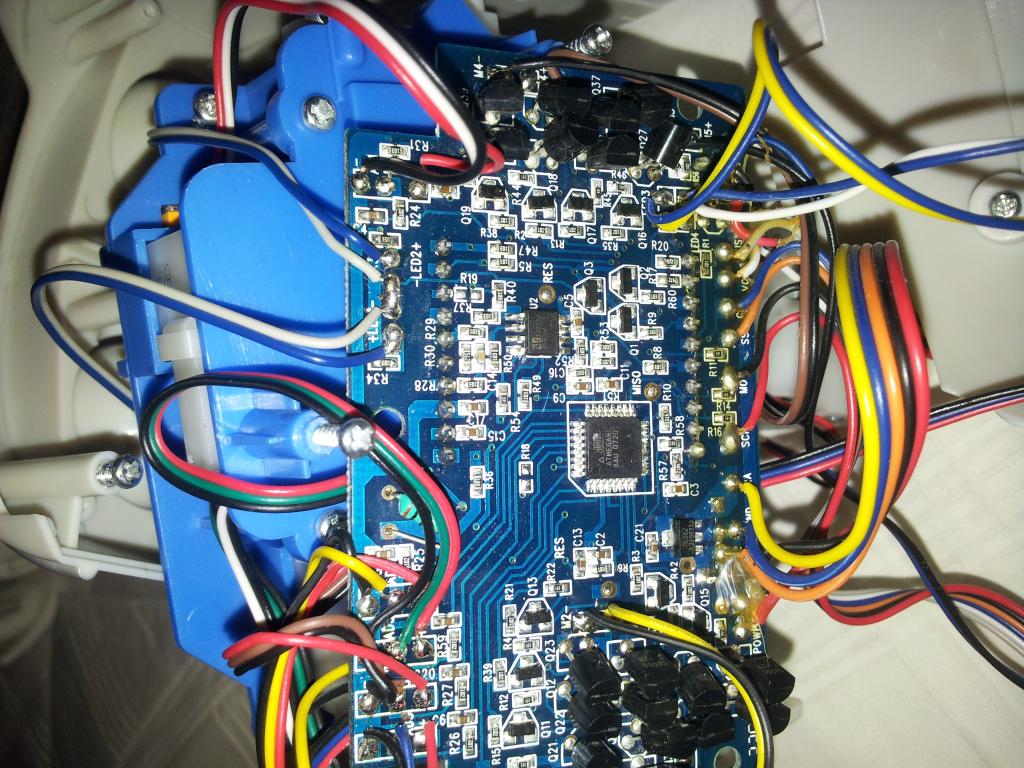

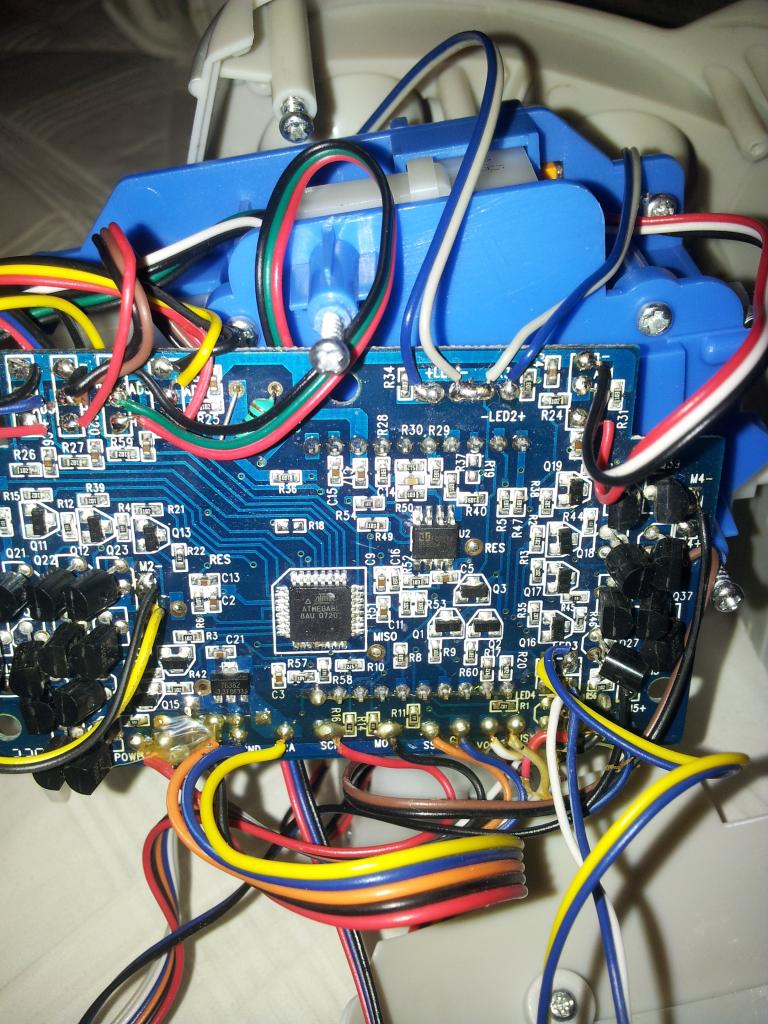

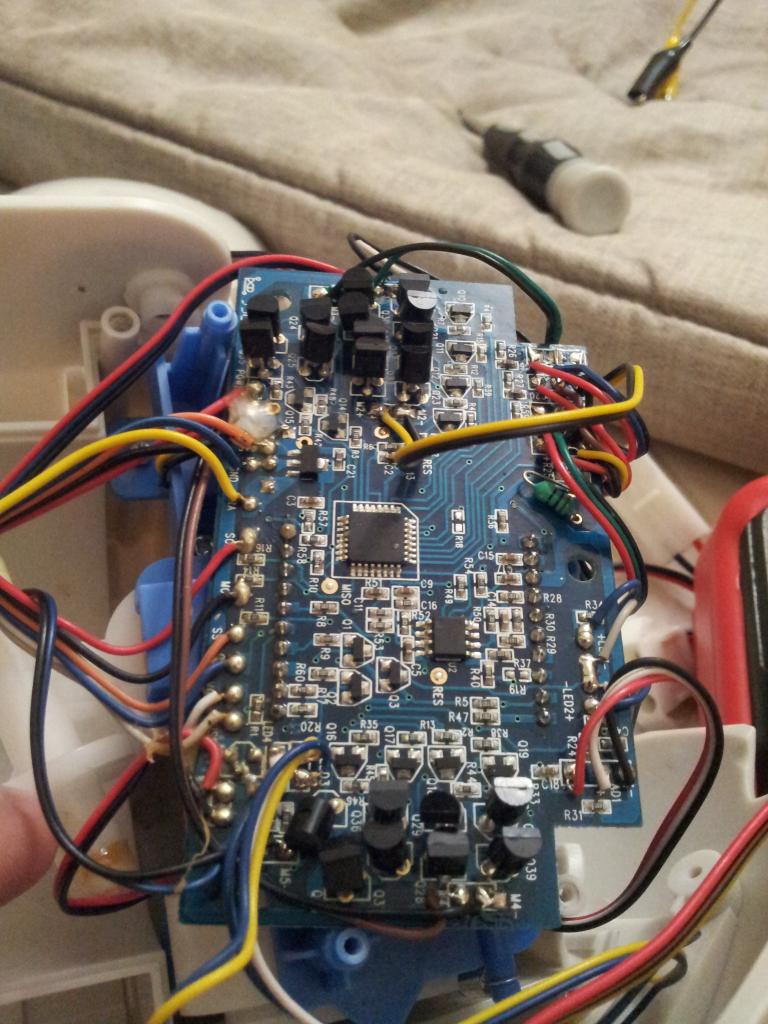

Thanks Dave. I'm waiting on more hardward fasteners, M4-ATX DC-DC power supply and a fuse block from the post office. The lower ABS sheet will hold the PS and charger. The upper will have the fuse block, power distribution block, an I2C bus, a couple small DC-DC converters, TrexJr motor controller and EZ-B. Maybe a signal terminal block though I'm not sure yet.

I'm waiting on more hardward fasteners, M4-ATX DC-DC power supply and a fuse block from the post office. The lower ABS sheet will hold the PS and charger. The upper will have the fuse block, power distribution block, an I2C bus, a couple small DC-DC converters, TrexJr motor controller and EZ-B. Maybe a signal terminal block though I'm not sure yet.

I have had a setback with my power supply I ordered. It didnt work and I sent it back. I should get it in the next 5 days.

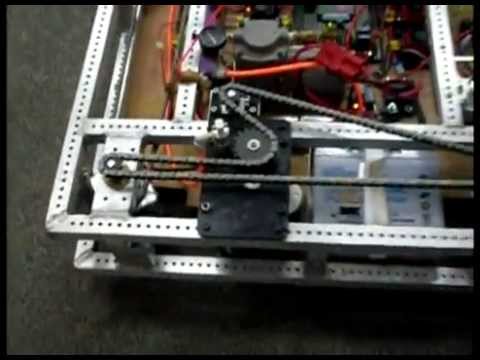

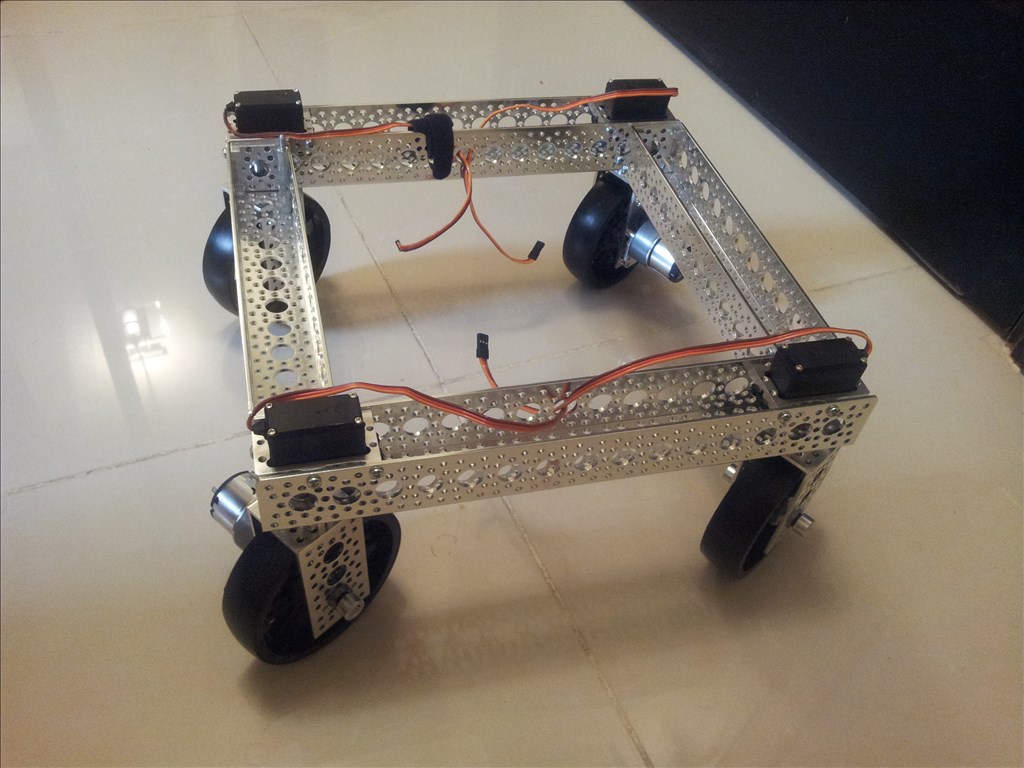

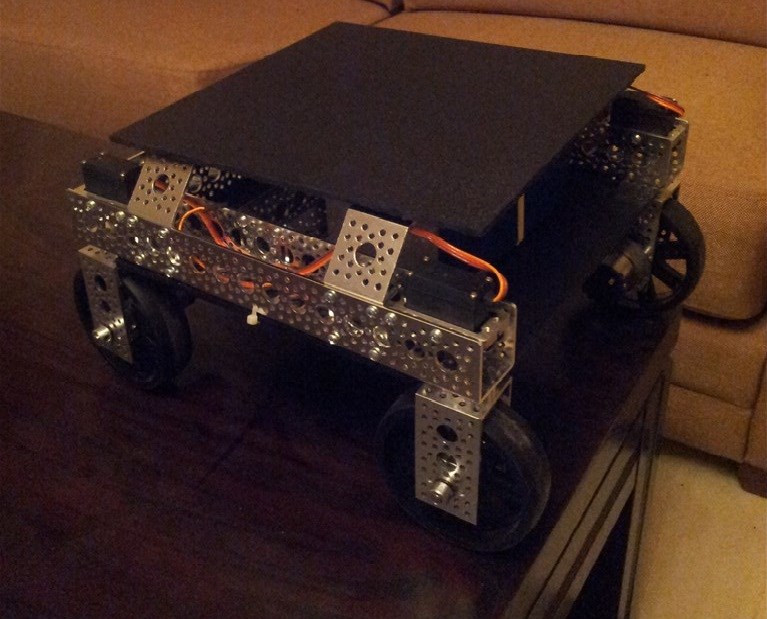

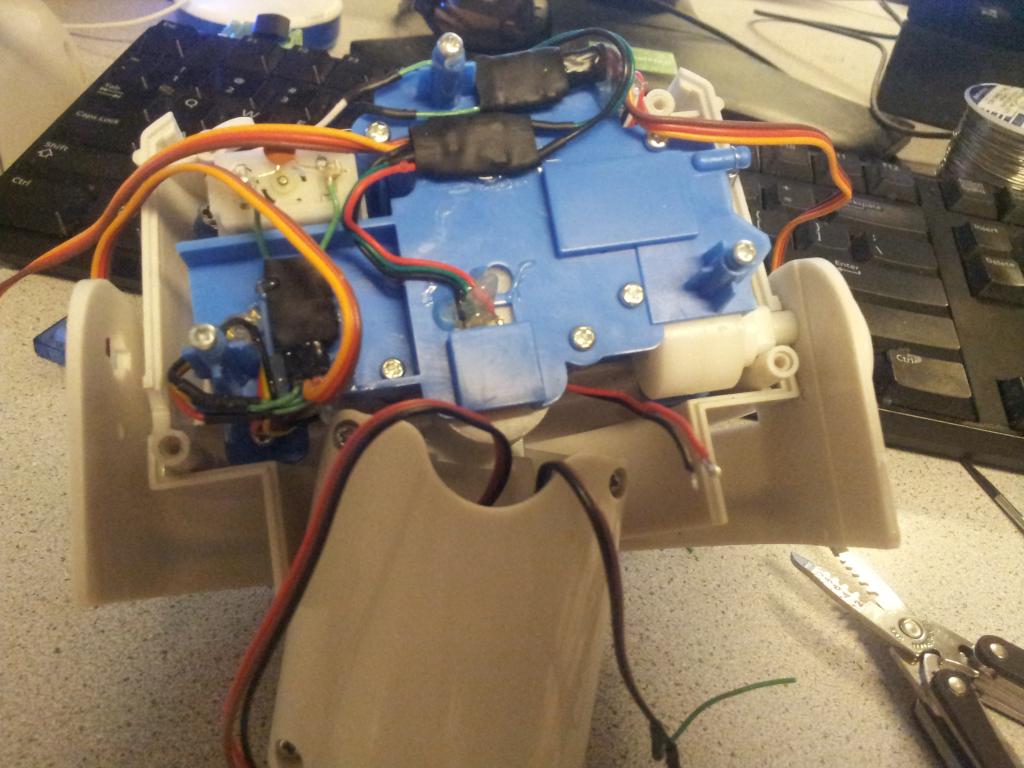

The base frame shown above is complete.

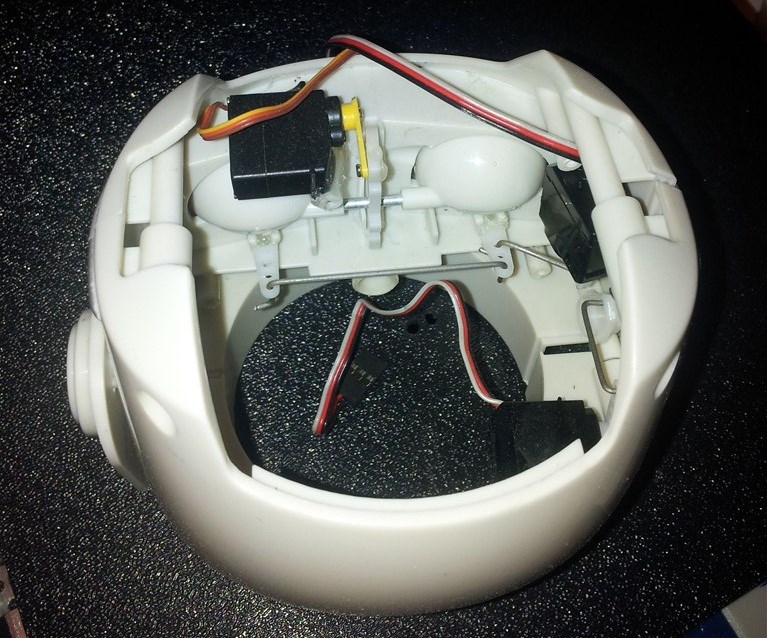

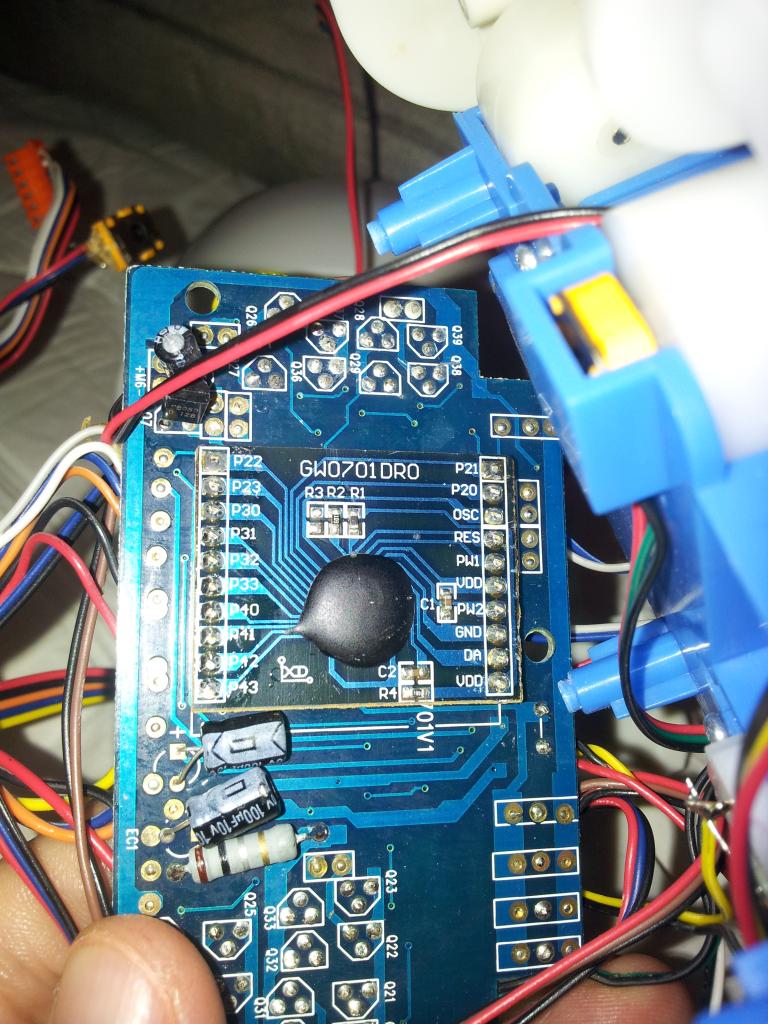

I re-did the head with micro servos so I can fit hardware to change the neck articulation. I'm not 100% sure how I will do it yet.

I also fixed the waist with a new lazy susan that was suggested in the forum previously. Works like a charm.

I'm also waiting on hardware to stiffen the elbow joint with the direct drive servo.

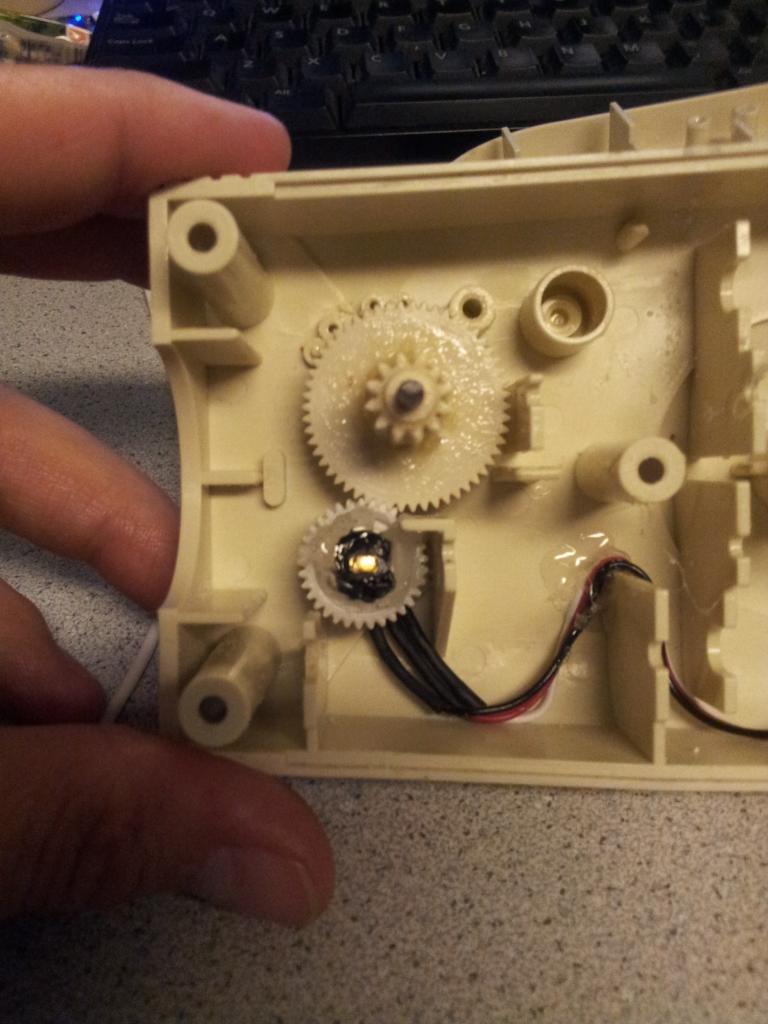

I was thinking of using a chain gear arrangement to increase power and reduce range from 180 to 90 degrees however it will mean more cutting into the plastic and I dont want that just yet.

I know it isn't much but that's where I'm at. I need to hurry up because I will be job hunting in 6 months! Not fun.

Well that sux about the power supply (think about using the human "by product" from your Robots in the news article! Sorry to hear about the job hunting, but there is an upside..all those extra hours to build Pinhead

Sorry to hear about the job hunting, but there is an upside..all those extra hours to build Pinhead  Thanks for the update

Thanks for the update