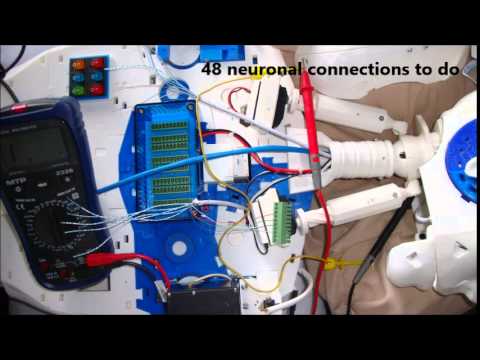

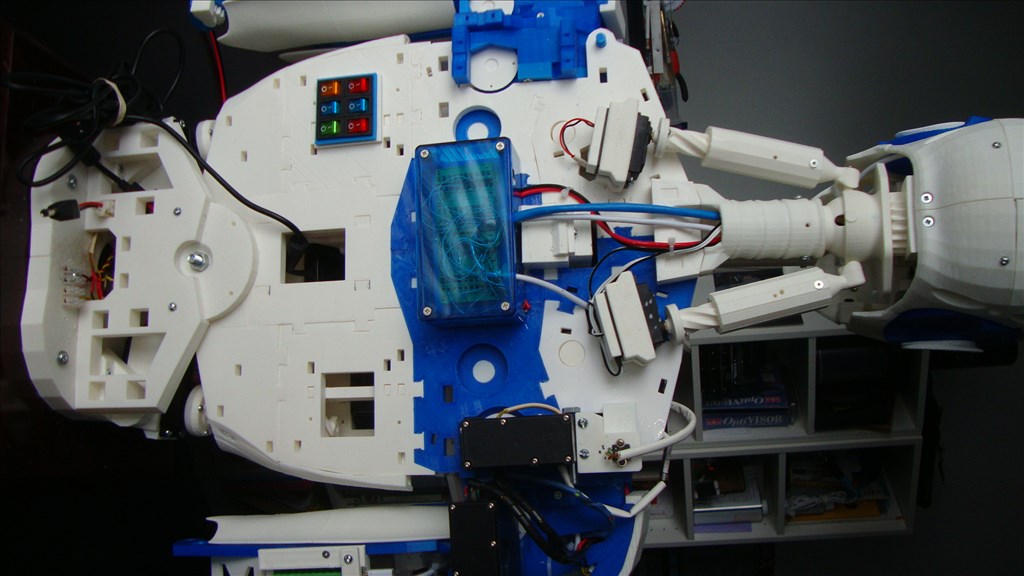

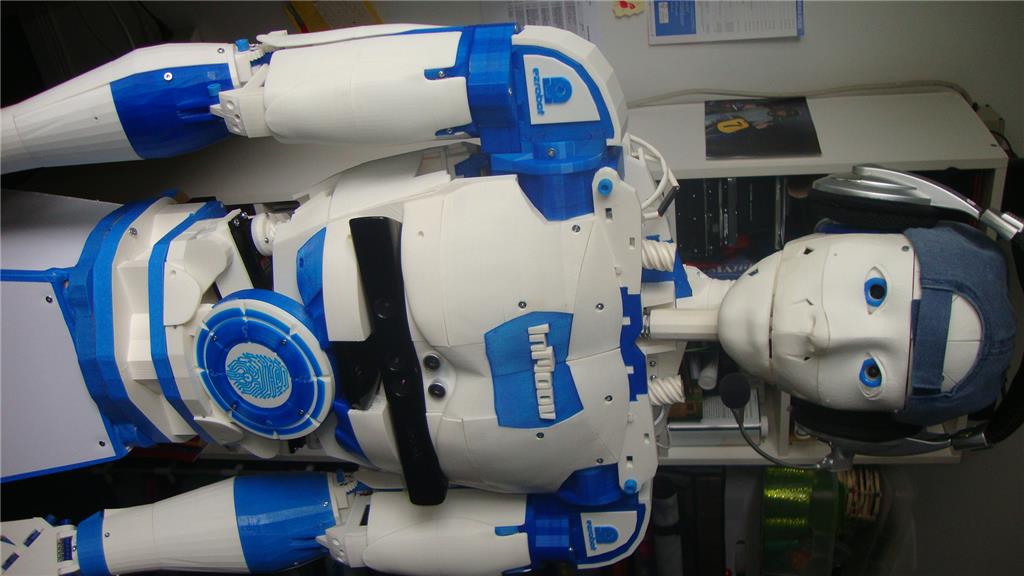

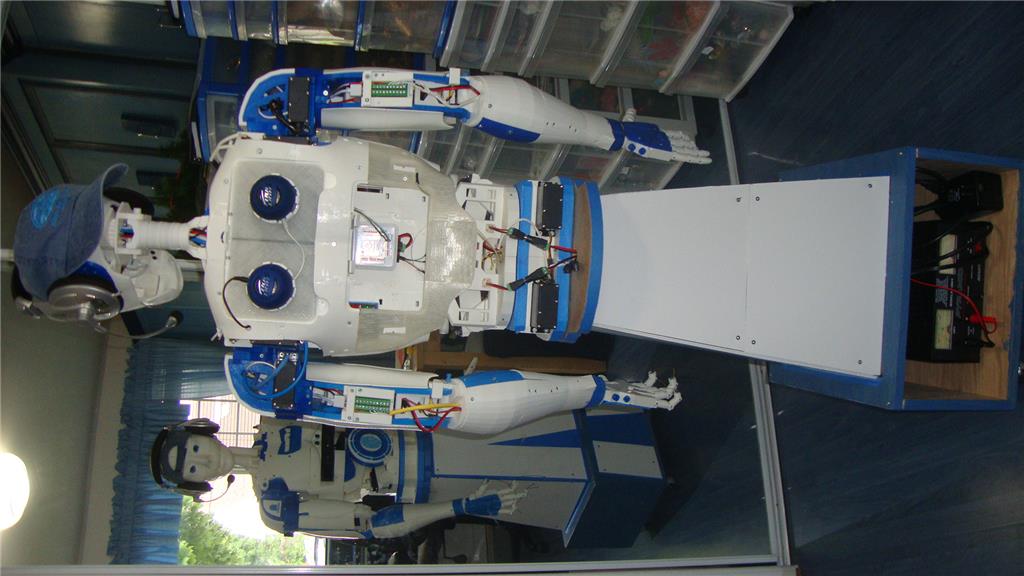

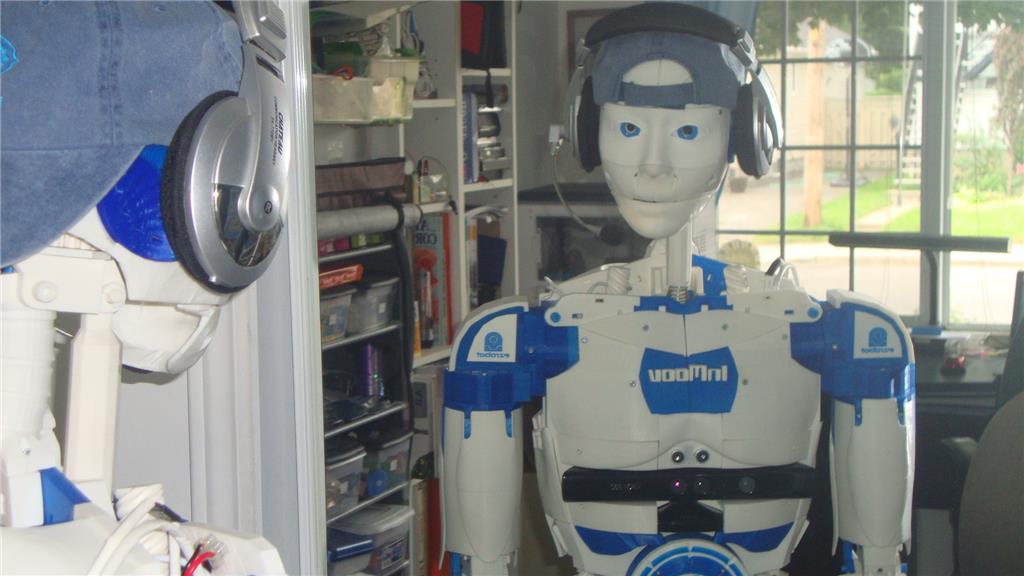

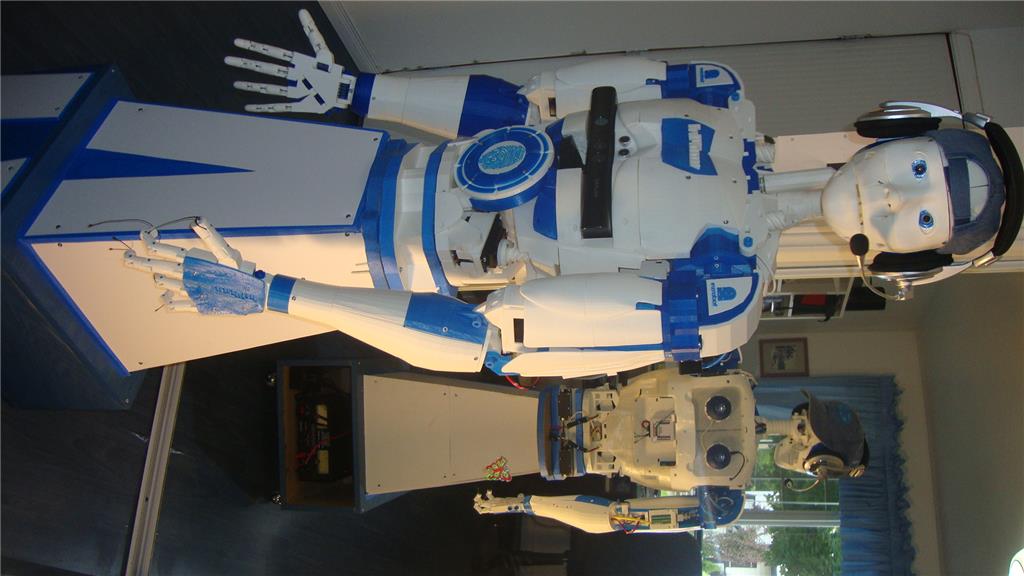

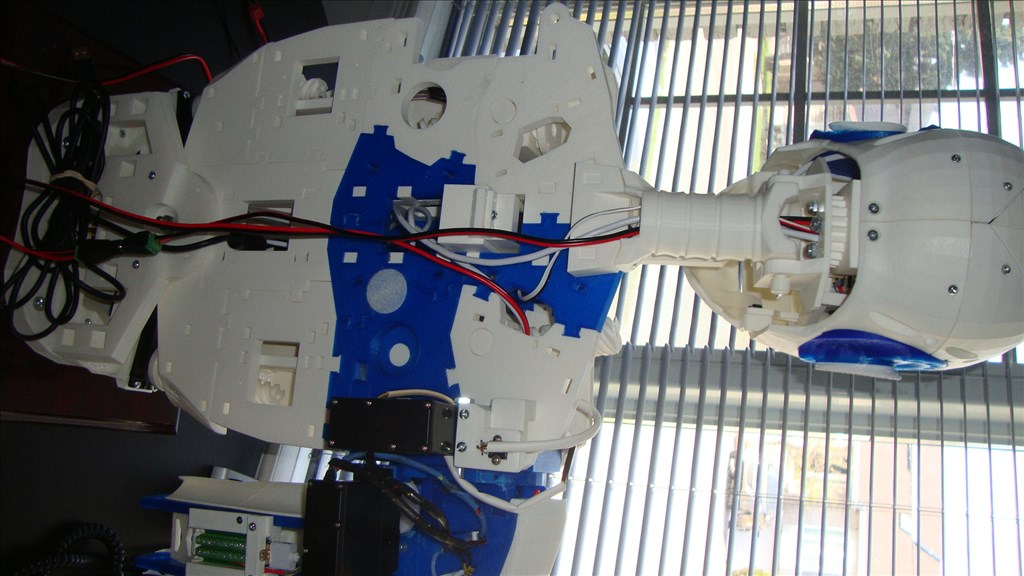

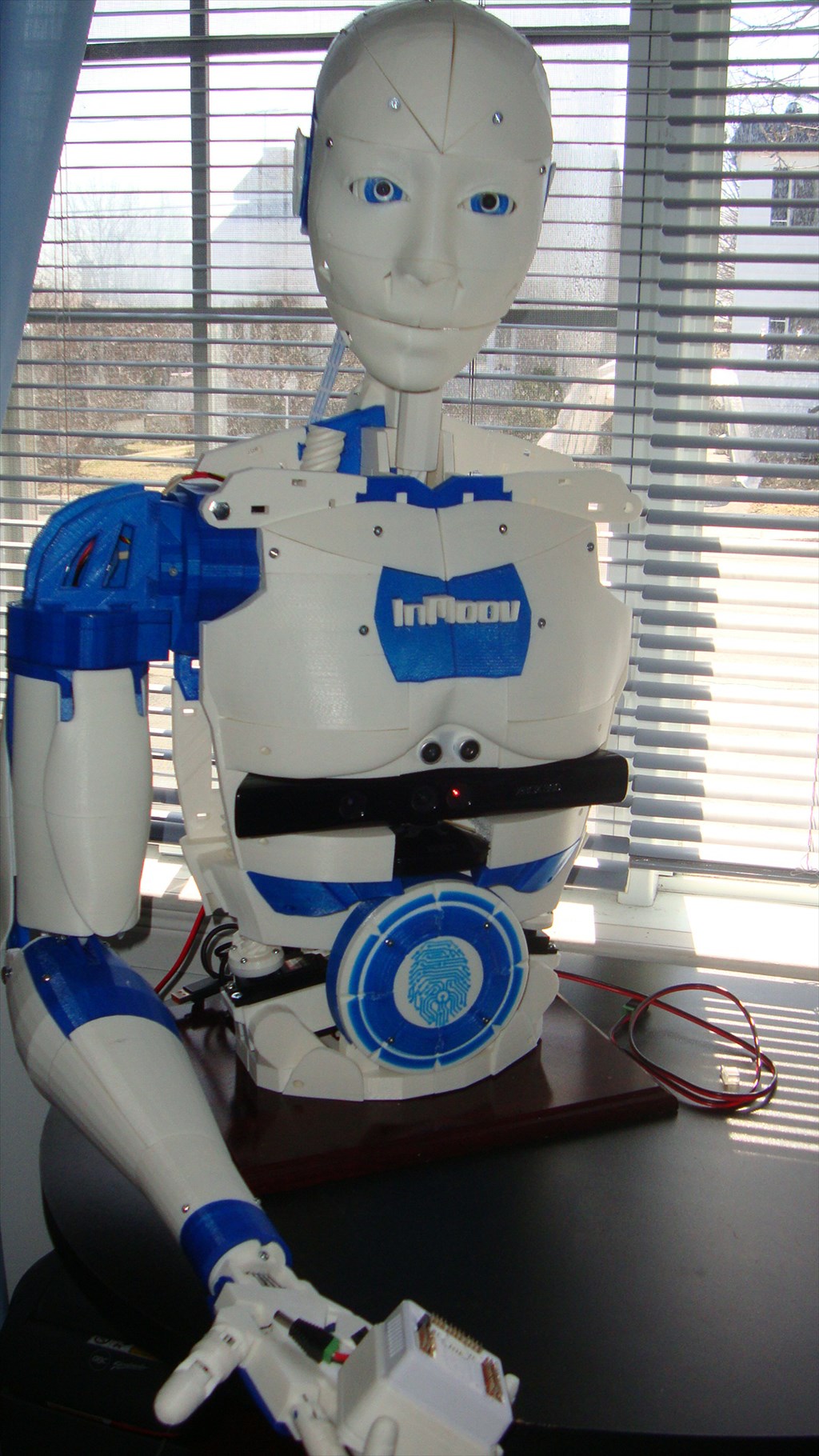

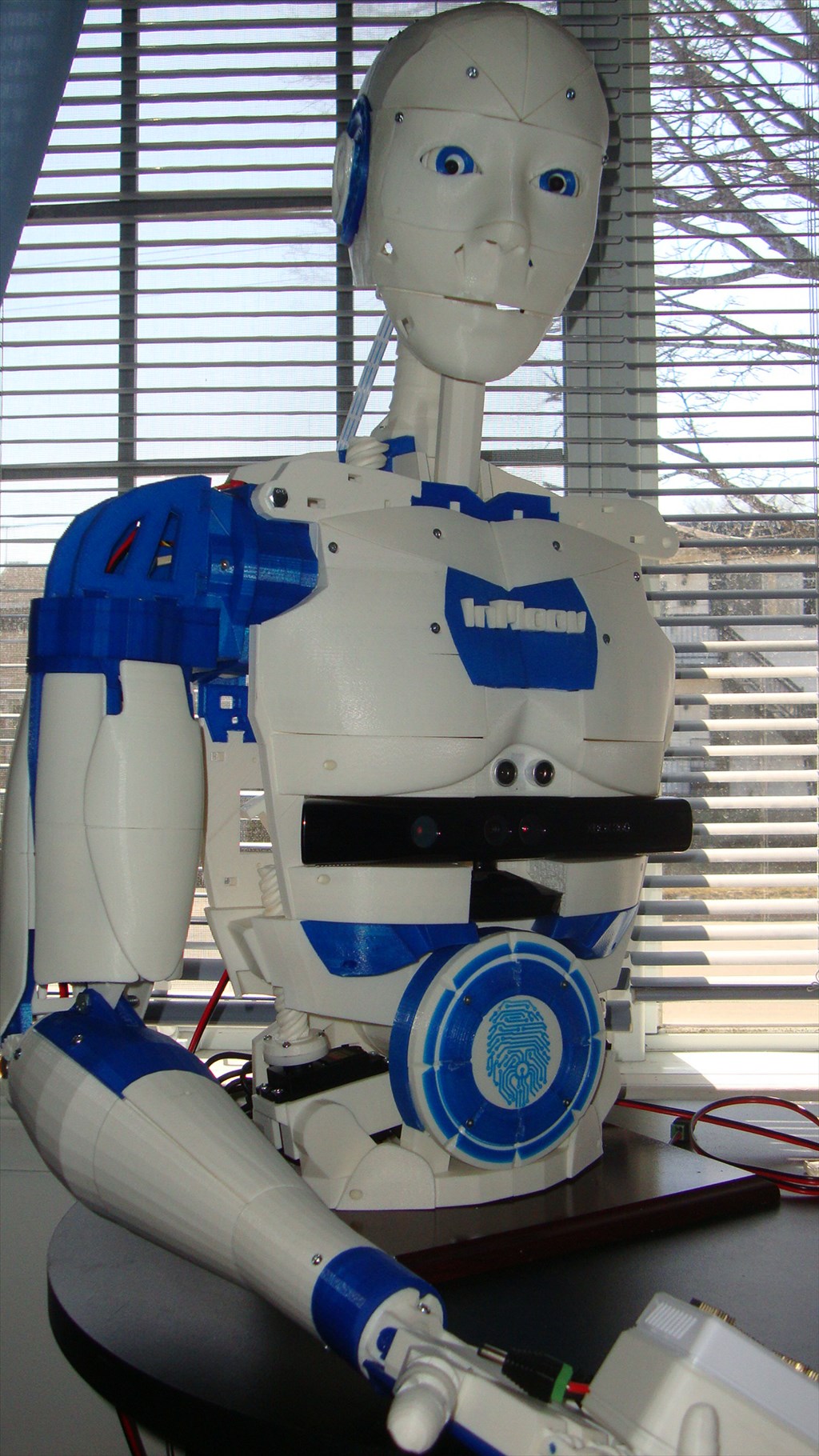

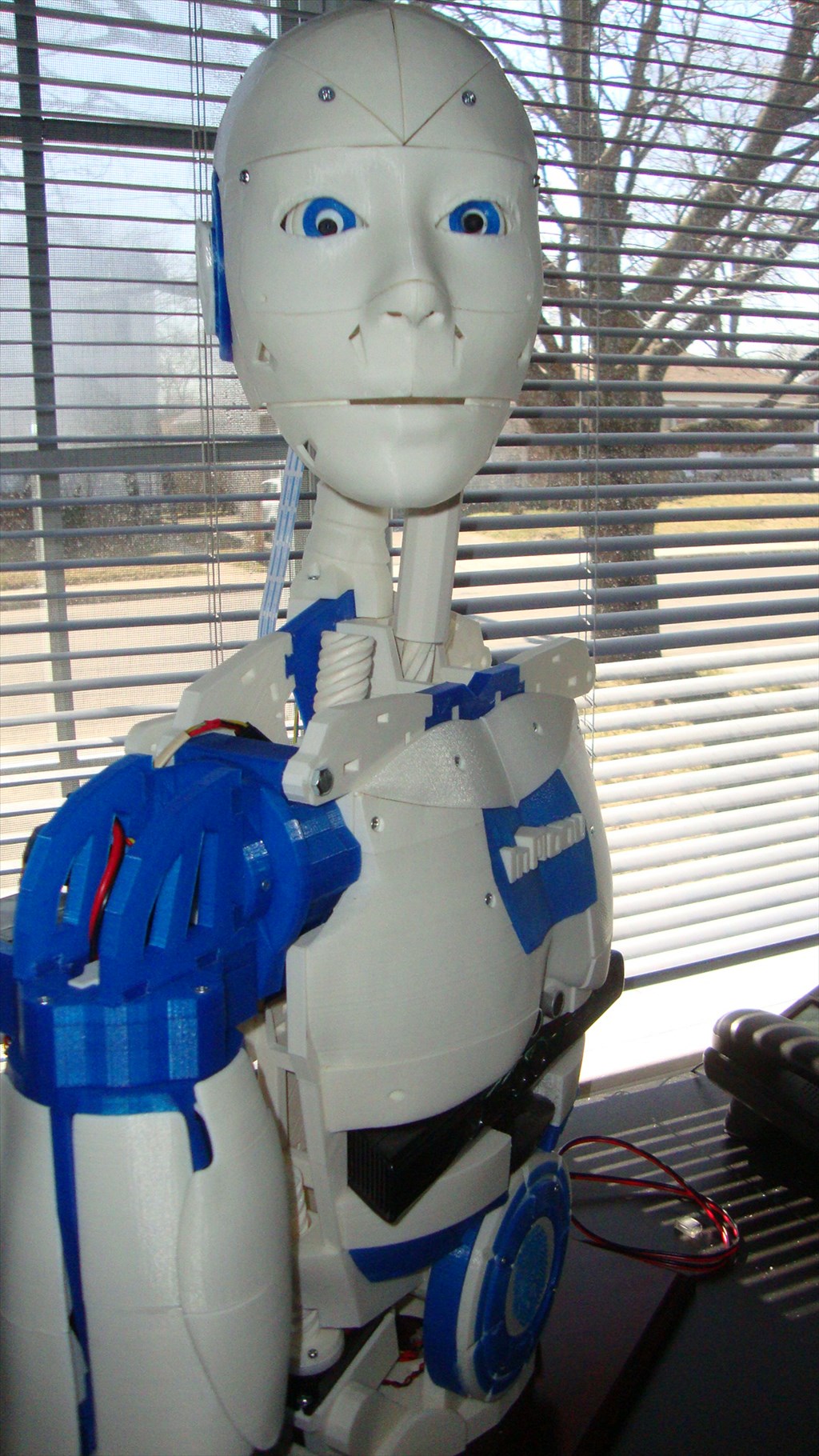

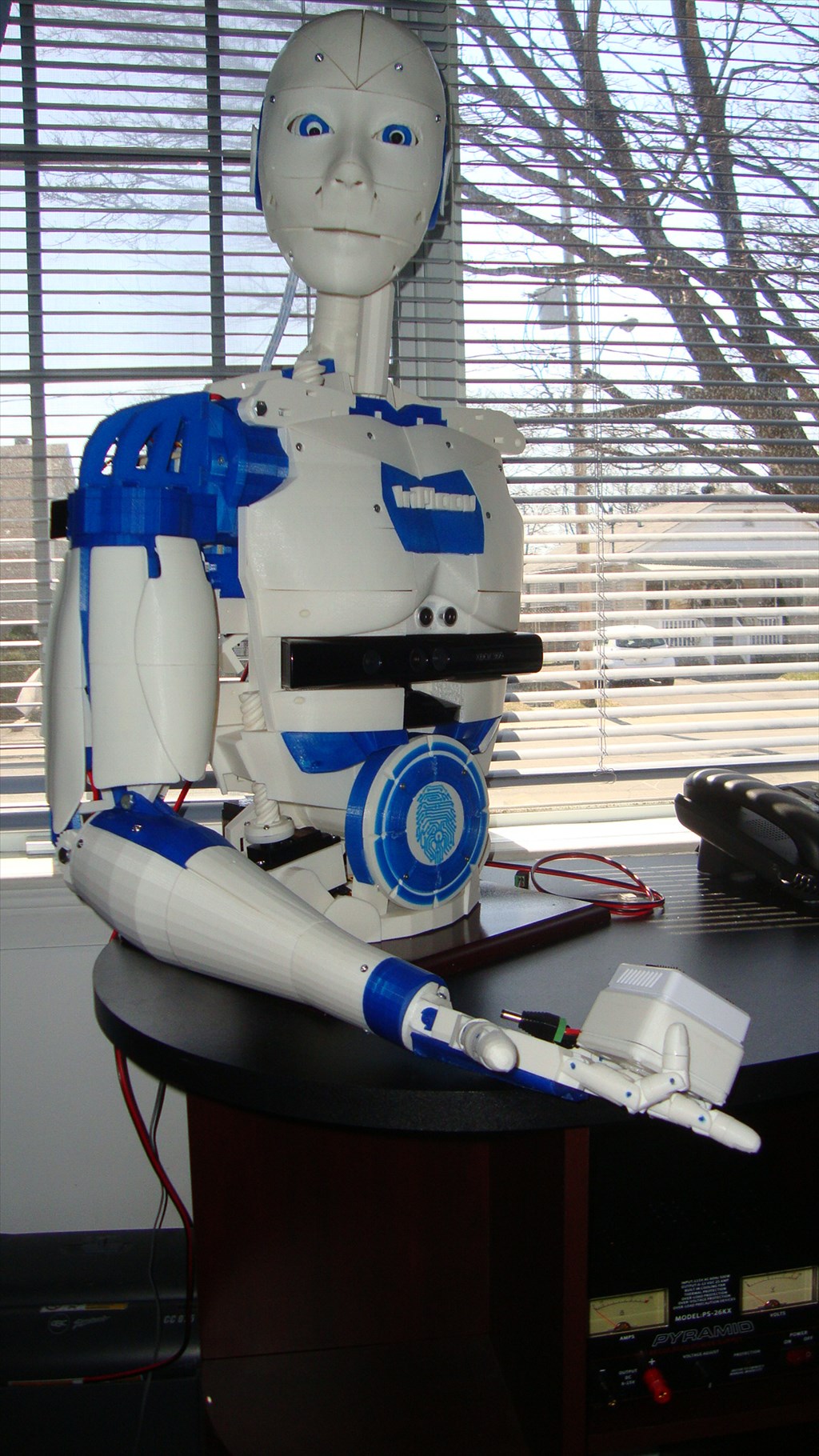

Let me introduce you my Inmoov version ,

(my 4 year grand daughter called it : ROBOTO)

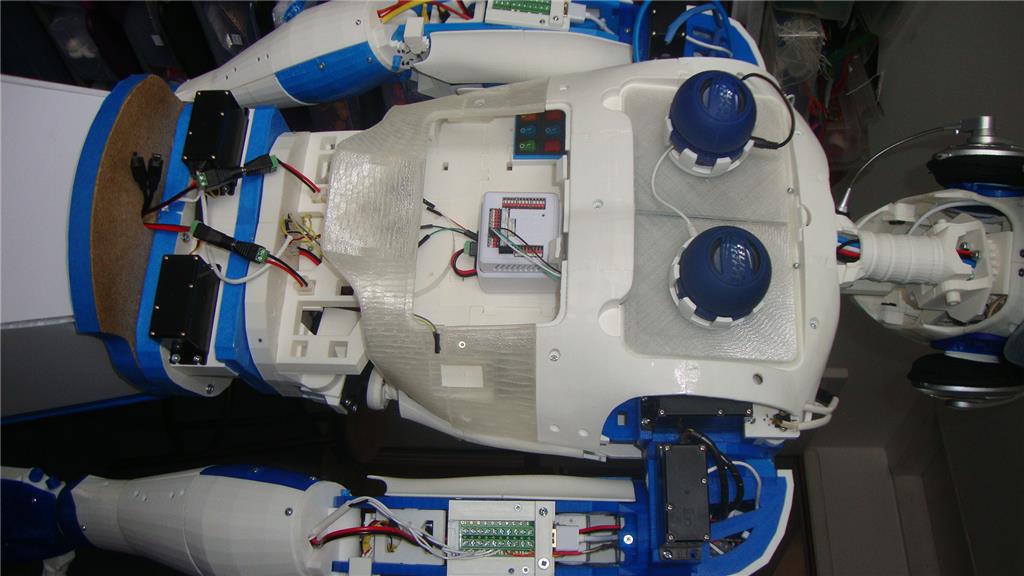

The work is not yet complete , but I think promising.

I intend to take a break during the summer and will get back to my project later.

Surely if it rains outside I will probably start writing scripts

(it is so easy to get addicted to this kind of project)

By Aerius

— Last update

Other robots from Synthiam community

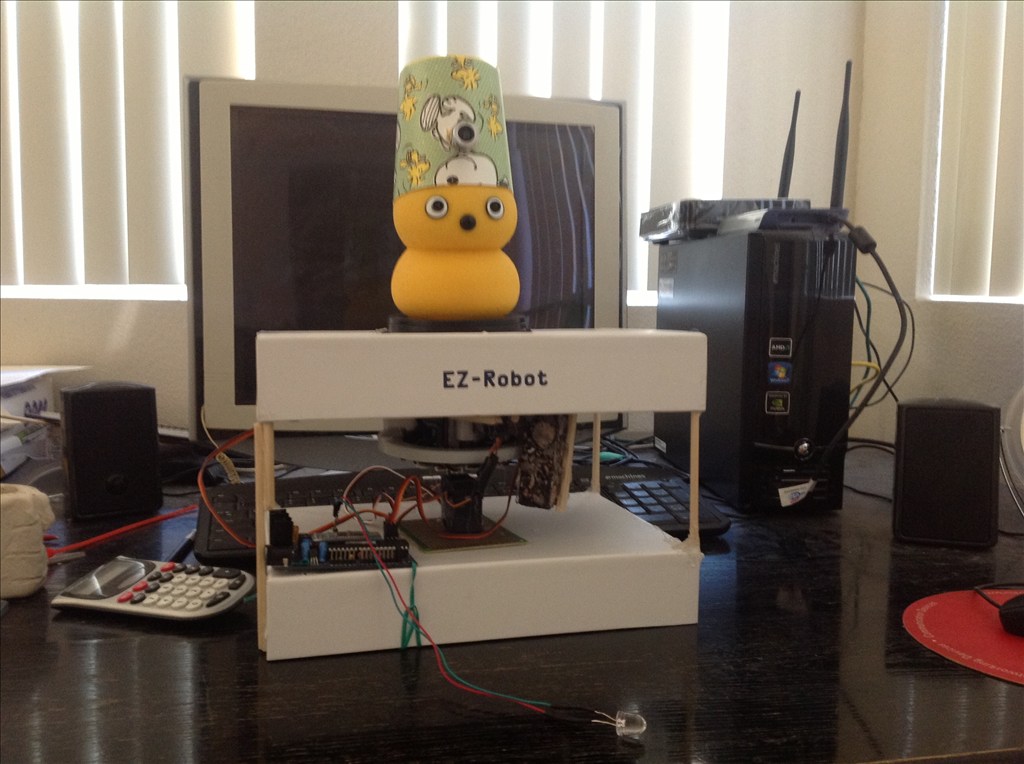

Techcrab101's My Robot Keepon

Keepon robotic friend customized from a dancing Keepon toy with a fez-mounted camera, voice interaction and reactive...

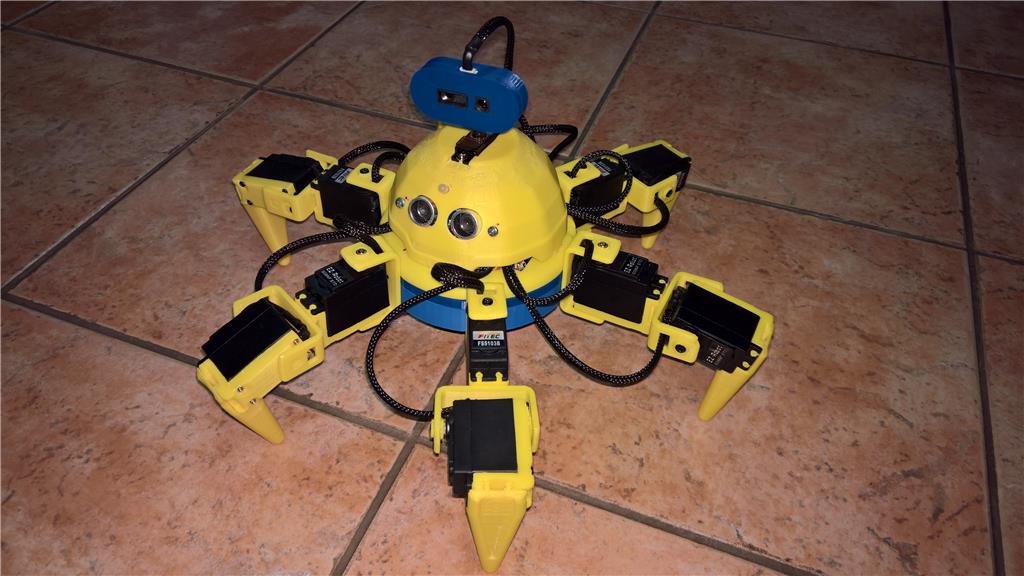

Donesvarc's Printed - Revolution Six

Synthiam ARC: reverse EZ-Robot servos with Auto Position Panel to fix inverted servos on EZ-V3/EZ-V4 Wall-E Six...

Ezang's Happy Crawler 5/18/2021 And New Combination Robot...

Metal-legged robot built with Servo City parts and 4 servos, IoTiny battery, using Synthiam ARC programming to achieve...

I love the look of him. I am about to start one myself. I have a few shelves worth of parts just waiting. Thanks for the photos!

I'll be glad to help If you have any question when you do the assembly

I am sure that I will come across something and just say "WHAT?" Thanks for the offer!

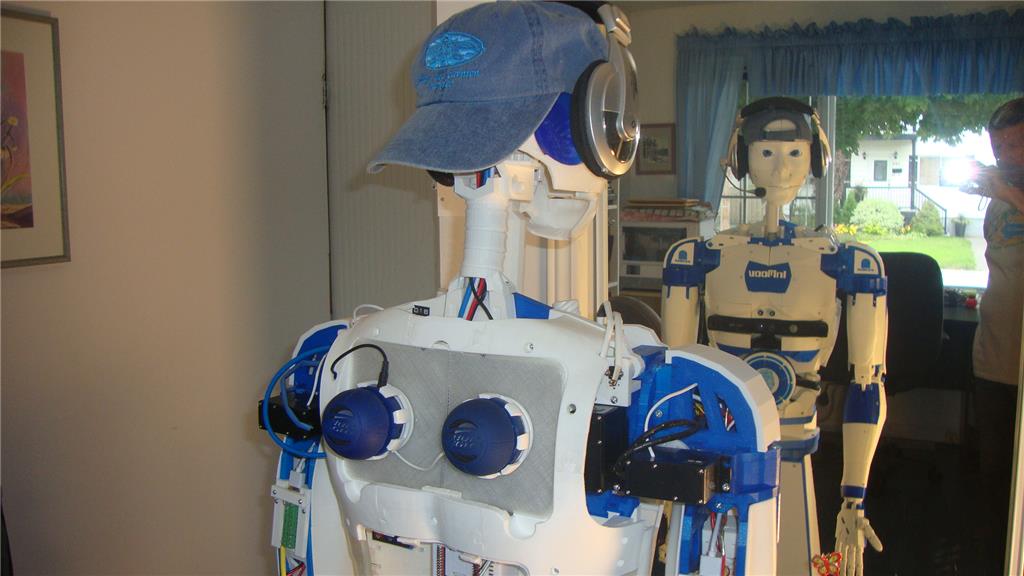

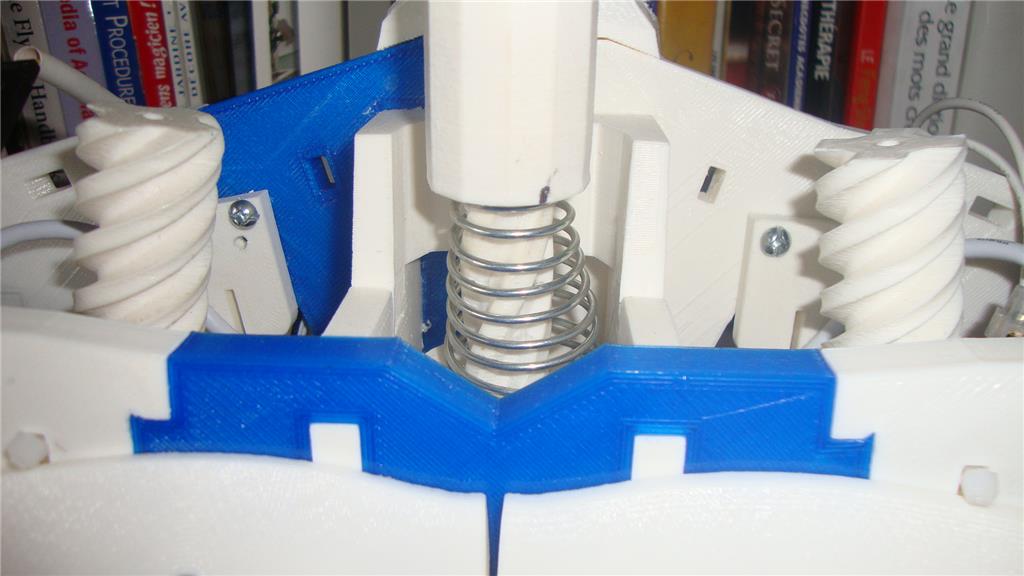

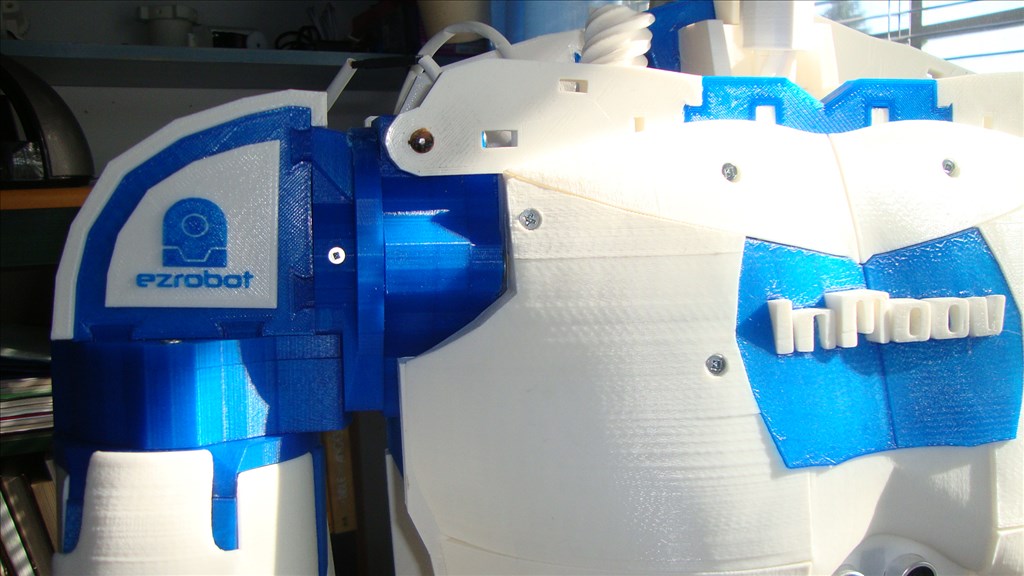

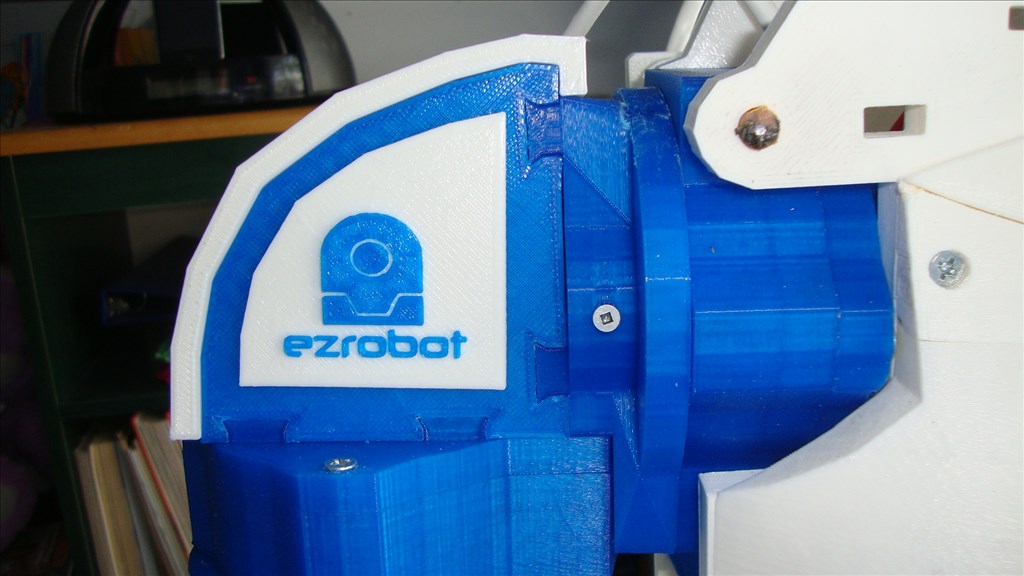

@Aerius. WOW! That looks fantastic. I like the colors. A two color printer really helps to add the accents. What printer do you have?

That is fantastic! I really dig the colors as well - man, all of you are getting me jealous.

Might have to create our own InMoov here at ez-robot

@ bhouston tanks! I am using a Flashforge Dreamer. When printing i can interrupt the job, unload the filament, load an other color and resume printing. That's the way i did print the stomach circle and the ears.

Guys your good words make me proud and help me to go foward. Tanks

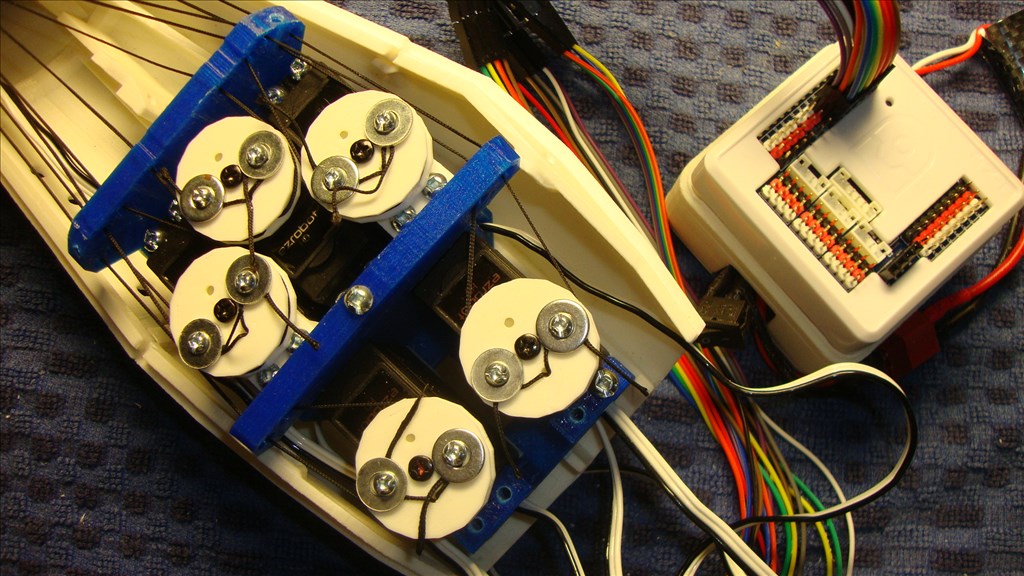

@ dj what my Inmoov is holding in is hand will make the real difference.

@Aerius Great work.... your parts fit nicely.... very clean build indeed ....