Hi Friends!. well I'm finally ready to put my full size R2 to roll... But I need a tip from you. What kind of H-Bridge or controller do I need (or can I use) to use with my ez-b ? I believe that the regular one will not be able to power this Scooter motors that i'm using.. am I wrong ?!

By tevans

— Last update

Other robots from Synthiam community

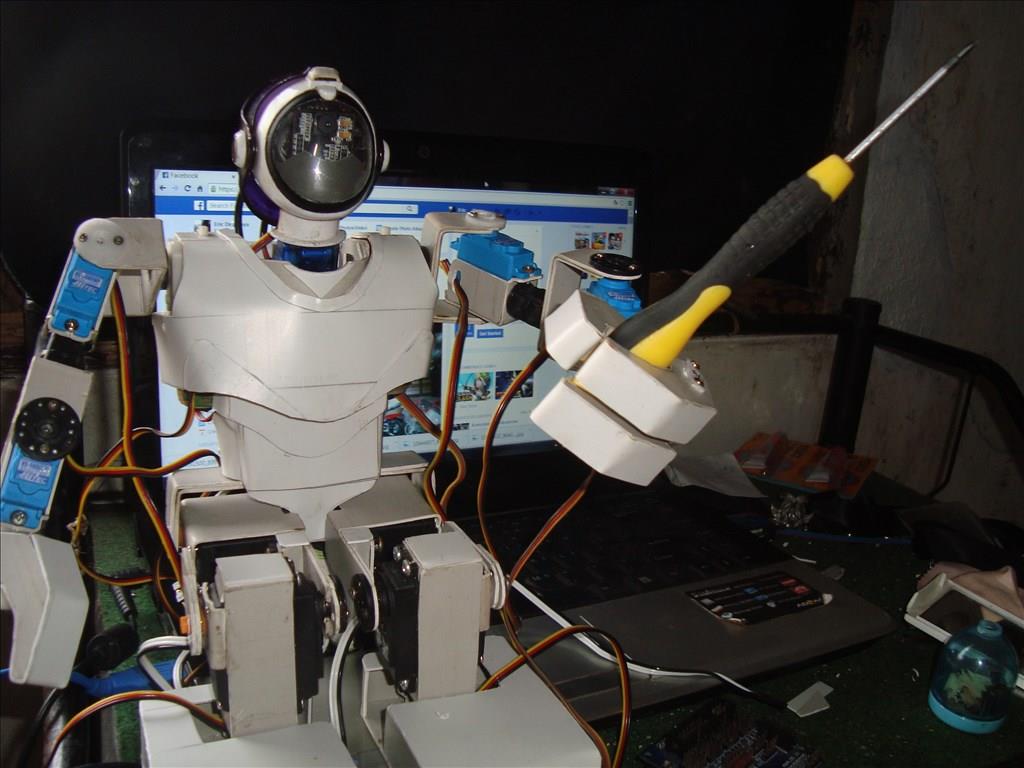

Ericez's New Friend For Jd, Lita My Humanoid Robot Made From...

Building a DIY humanoid JD robot with ez developer using PVC pipes and scrap parts while awaiting gearbox replacement on...

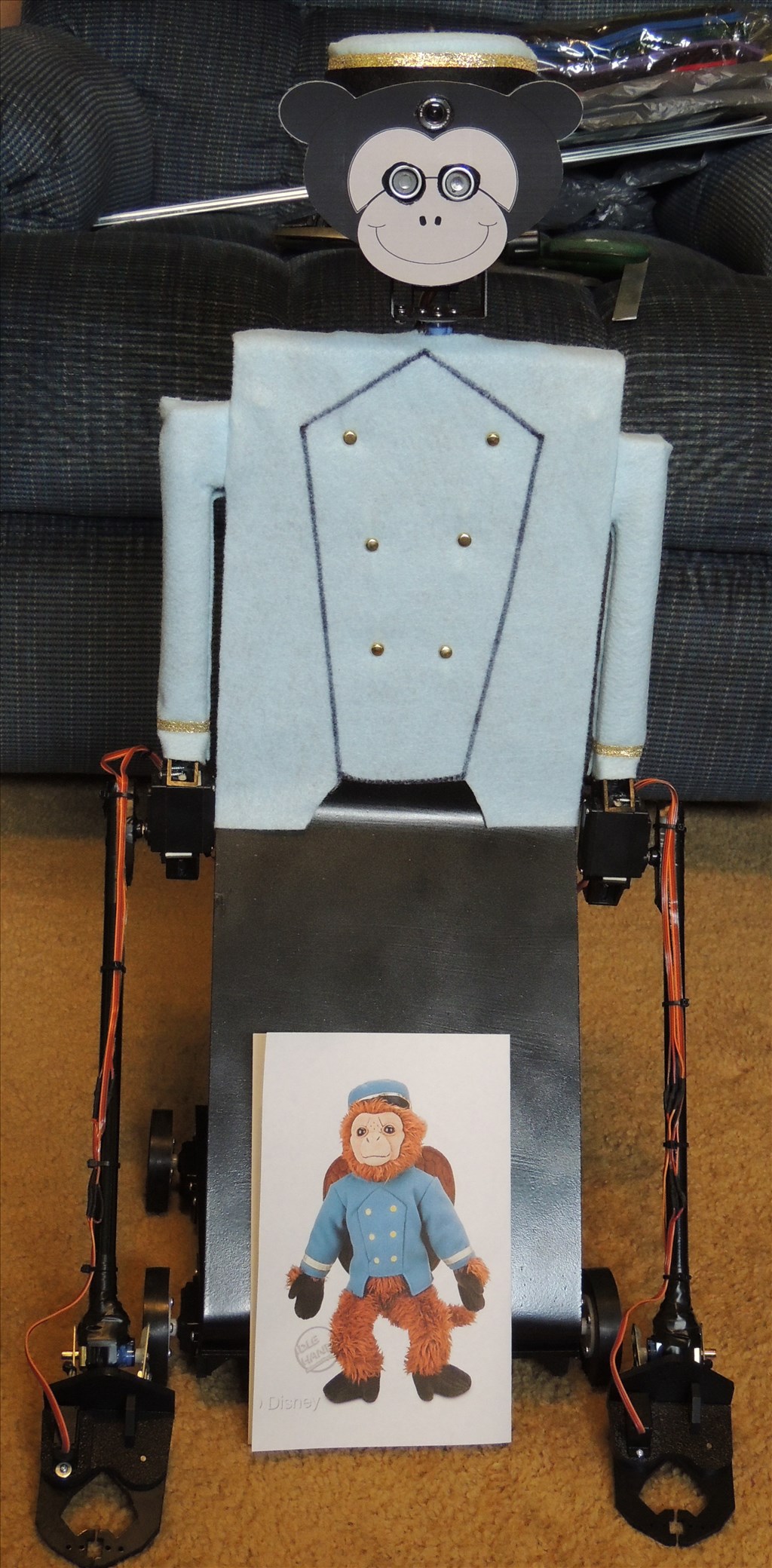

Justinratliff's Finley Themed Robot

Finley robot with EZ-B v3: 12 servos, PING sonar, camera, grippers, built to pick up objects and integrate with Synthiam...

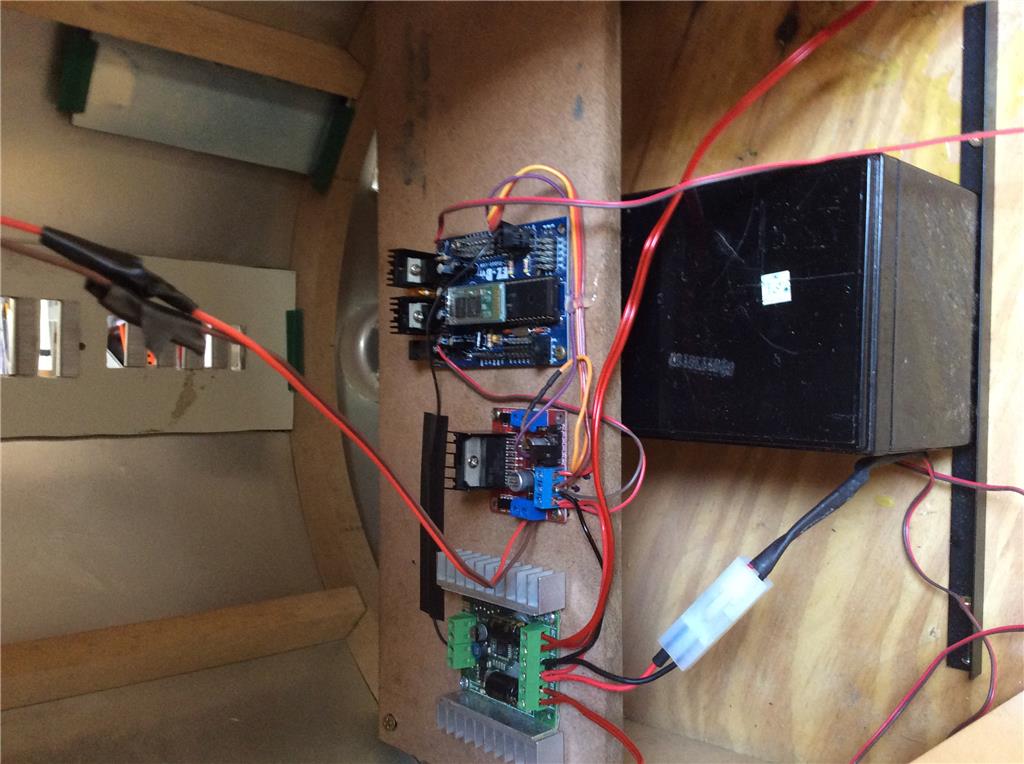

Hazbot's Bob Built On Bits

Bob, a 3 ft house robot built from an Ez-Robot kit and lightweight riveted angle-bead frame; plastic-bottle head; soon...

I'm getting very poor results here.. I guess the pot is not reading very accurately the values.. Maybe because of the friction install (instead of a sprocket)... Btw, I'm thinking about use a motor with encoder, or a stepping motor. What do you think ?

If you think using the pot is hard the other two ways will be even more of a challenge... If you switch to using a motor with an encoder you will need to buy the Kangaroo board to use with the sabertooth... That will require even more coding to get it up and running... Dave can help you with that... A stepper is even harder. Not too many people on here have really used a stepper in their projects to my knowledge... Pot values change very quickly as you noticed... it is very easy to overshoot your position... This may be the problem you are having, I don't know... What you need to do is proportionally slow the motor as it approaches it's position and reverse it if it overshoots it... So what will happen is the motor will gradually slow down the closer it gets to the position you set it for...

I have done this with a vex robot arm I built using dc motors (with pot feedback) instead of servos and it worked pretty good....

Can you send me an exemple of a code, or a panel configuration, so I can start from ? Thanks!

If overshooting your mark is the problem then increase the values in this statement :

if (($adcCurrent >($stop - 5) and $adcCurrent <($stop + 5))) goto(RotateStop) EndIf

The difficulty of useing a pot and scripting with math along with poor accuracy is the reason I switched all my motor control of DC motors over to a Sabertooth with a Kangaroo X2 daughter board. Once this combonation is set up properly and you understand how to send the simple serial commands through ezb's Uart port , it's very easy to write code for it. Accuracy of position and speed is great. I've found that useing an encoder with this combo gives me the best results. The Bata version I have of the software needed to make fine tune adjustments (use is optional but recommend ) also gives it speed ramping if enabled in the "All Controls" tab. Your milage may vary.

I have to warn that unless you have your system built in the way the kangaroo is expecting and everything is connected and working properly (power, feedback, connectivity ) this controller is a pain to get working. That's not necessarily a bad thing. You don't want to run your motors on a improper system. eek

Ok Friends, I get the Kangaroo and another sabertooth... Now.. I still need an encoder ?!?! Or a pot?! Because the motor I'm using does not have that.. Kinda of lost again ????????????????

If you are going to use the kangaroo you need a motor with an encoder built in...

Oh boy... Now I have to buy another motor... But, I'm confused.. if I use a motor with encoder I do not need the Kangaroo.. Am I right? Because if I get the feedback from the motor, I can just use that value to setup the limits.. Am I being stupid ?! What's the point about the kangaroo/sabertooth combination after all?

Sheesh ... you need to do some research dude LOL...The encoder which is attached to the motor plugs into the kangaroo. The kangaroo then plugs into the sabretooth... You need a kangaroo because you can't use a motor with an encoder with just a sabretooth... The (without the kangaroo) sabertooth by itself has no ability to read positional feedback from motor encoders....