This isn't a new robot but rather a remix of an old idea I had. It's based off of a robot that I built for a 555 timer design contest I entered years ago, I called it the Freedom555bot.

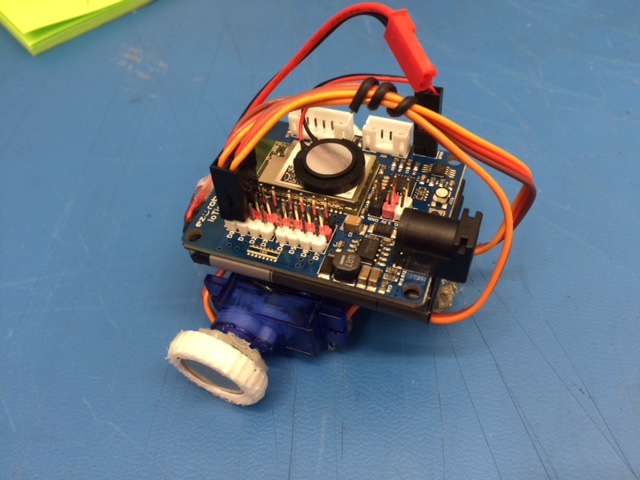

Fridgebot is a terrible name so I'm open to suggestions. I just named it that because I do most of my testing on the door of my fridge, lol. I've always liked the idea of a small robot that could cling to metal surfaces and I had it in mind when we were designing the IoTiny. I figured it would be the perfect solution to control such a small form factor robot. While mostly a novelty, I did have a few ideas on how this robot could be used practically:

- By adding a EZ-B camera the Fridgebot could climb up a lamp post and surveil urban environments from above, or take some nice pictures

- Place a brush on it and clean off magnetic white boards

- Clean ducting in your home

- Find an obstruction in a pipe

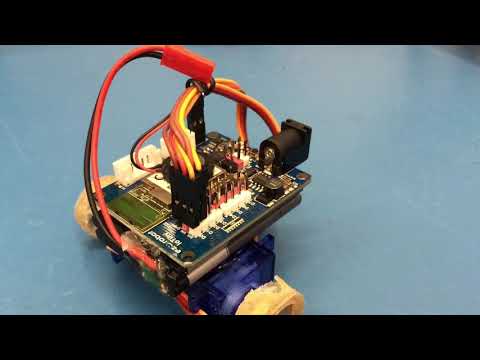

Materials I used to build the Fridgebot:

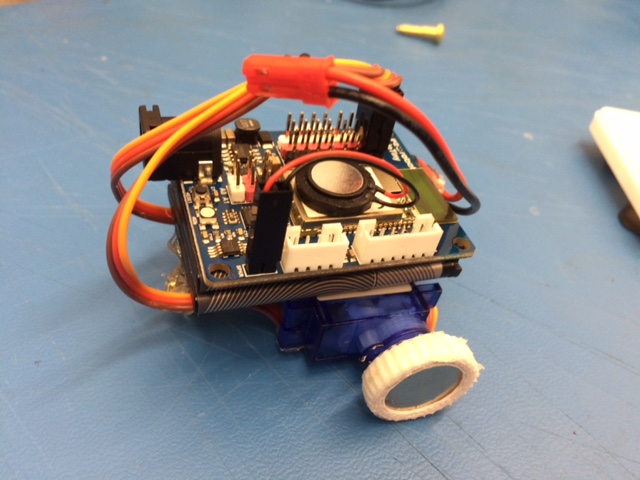

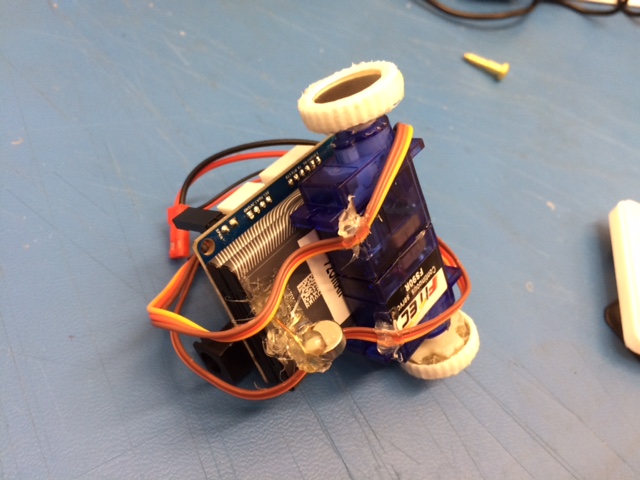

1 x IoTiny + Speaker 2 x 3.7V LiPo Cell phone batteries soldered in series (7.4V) 2 x 7.4V rated Feetech continuous rotation micro servos + servo horns 2 x 19mm Diameter Neodymium Magnets 1 x paper clip 1 x 8mm Diameter Neodymium Magnet as a caster Lots of Hot glue

Findings:

When traveling in a downward direction the magnet wheel cause the robot to tip all the way forward, which can cause it to fall off the ferrous surface it's traveling on, I found that using a magnetic caster kept the robot stuck to the surface at all times, no matter the direction

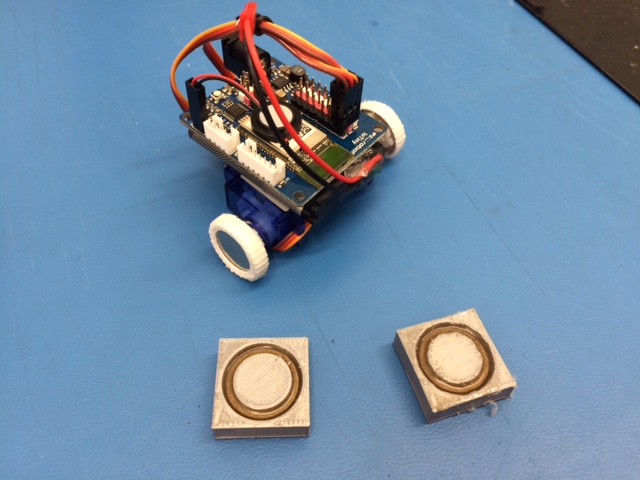

The magnet wheels need a thin grippy surface over them in order for the robot to climb upward on a ferrous surface. Otherwise the wheels just slip. The grippy surface also must not be too thick or the robot could lose magnetic adhesion

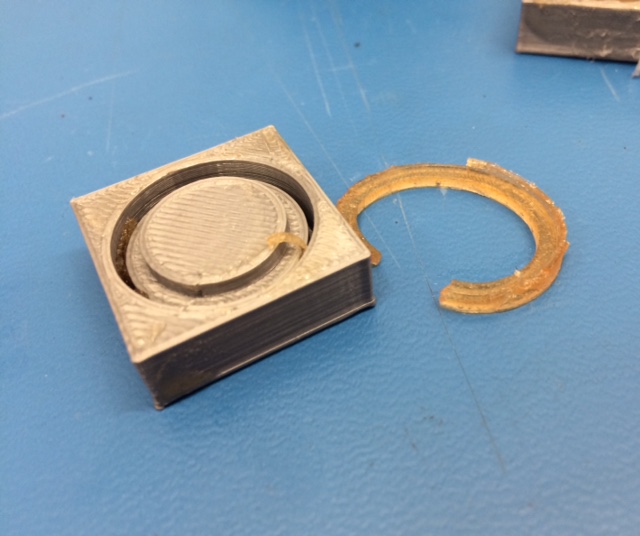

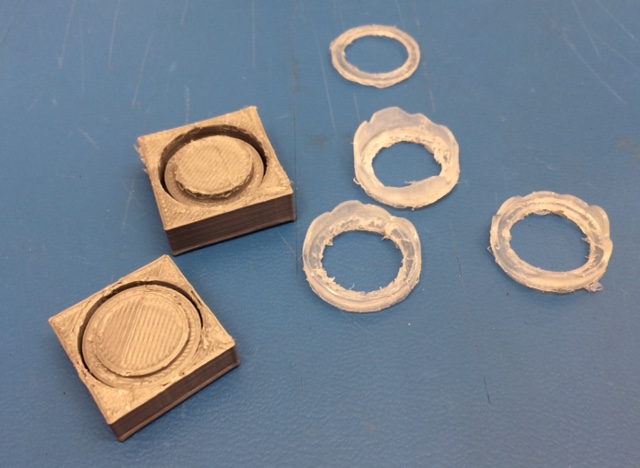

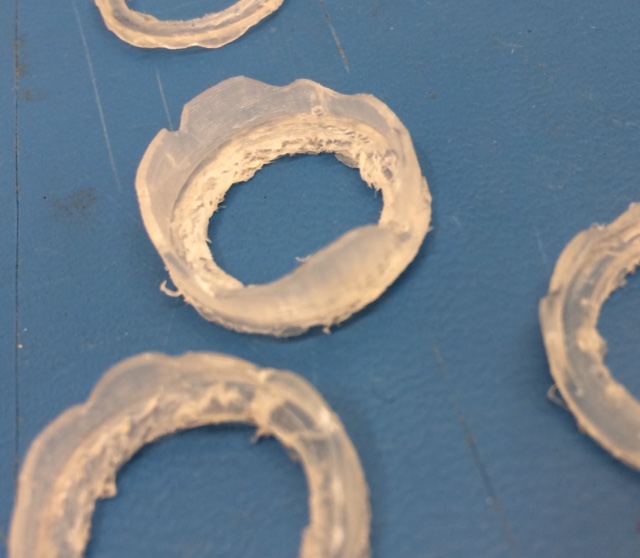

3D printing wheels with flexible filament works really well in terms of fit but unfortunately is too rigid to provide the grip needed. Making ridges in the wheel design doesn't work either. Spreading hot glue on the 3D printed wheels does work but it's difficult to spread evenly.The unevenness can cause the robot to suddenly lose magnetic adhesion

- When creating Hot glue wheels inside a 3D printed mold a 1mm opening isn't enough for the hot glue to push down into. A 2mm opening doesn't work so well either, it takes quite a bit of pressure to push hot glue into small openings

When using small elastics for grip on the magnets the elastics can twist off the wheels and they also get brittle over time (not a long term solution)

My next idea is to use 3D printed molds to cast some silicone wheels but I am open to other ideas

While making this remix design I did come across some new discoveries but it's definitely still a work in progress. I want to share it now so I could get some input from you guys/gals in the community. Thanks!

Other robots from Synthiam community

Bhouston's Robotic Arm

Fxrtst's Will Huff's Lost In Space B9 Robot Build

Any Star Trek Disco (Discovery) fans out there?....you could name the little guy "Spore Drive" or "Tardigrade"...or "Disco"

@JustinRatliff I like Tardigrade, as this robot is both small and insect-like

Update:

Well my first attempt at silicone tires didn't work out so well. I got impatient and removed the tire from the mold at 15 hrs (package says that it cures in 16 hrs). Looks like it's gonna take 24hrs or more because the silicone wasn't cured enough and I ripped the tire in half. Whoops!

Has anybody tried using magnets themselves as wheels. I know you could source magnets that have a hole in the middle. Maybe attaching similar sized wheels with thread to the side of each magnet wheel.

Hi @rb550f

Yep! That's exactly what this robot is doing Except you do need a grippy layer over the magnet or the magnets will just spin in place.

Except you do need a grippy layer over the magnet or the magnets will just spin in place.

I've researched magnets with holes in the center in the past but I couldn't find the perfect one for my application. I should look again as maybe some good progress has been made since then.

Let me know if you need any help sourcing silicones.. I know alot about them There are silicones that cure in just a few minutes and can be demolded shortly there after.

Some of my Lost in Space Robot parts....silicone..

There are silicones that cure in just a few minutes and can be demolded shortly there after.

Some of my Lost in Space Robot parts....silicone..

Will, I’ll take any advice you can give me! I’m a newb when it comes to casting. I need a silicone that can dry fast but is strong (flexible) and soft.

How about magnetic tape used a wheel tread with small grooves for traction.

OK I'll gather some options for you and post tomorrow!