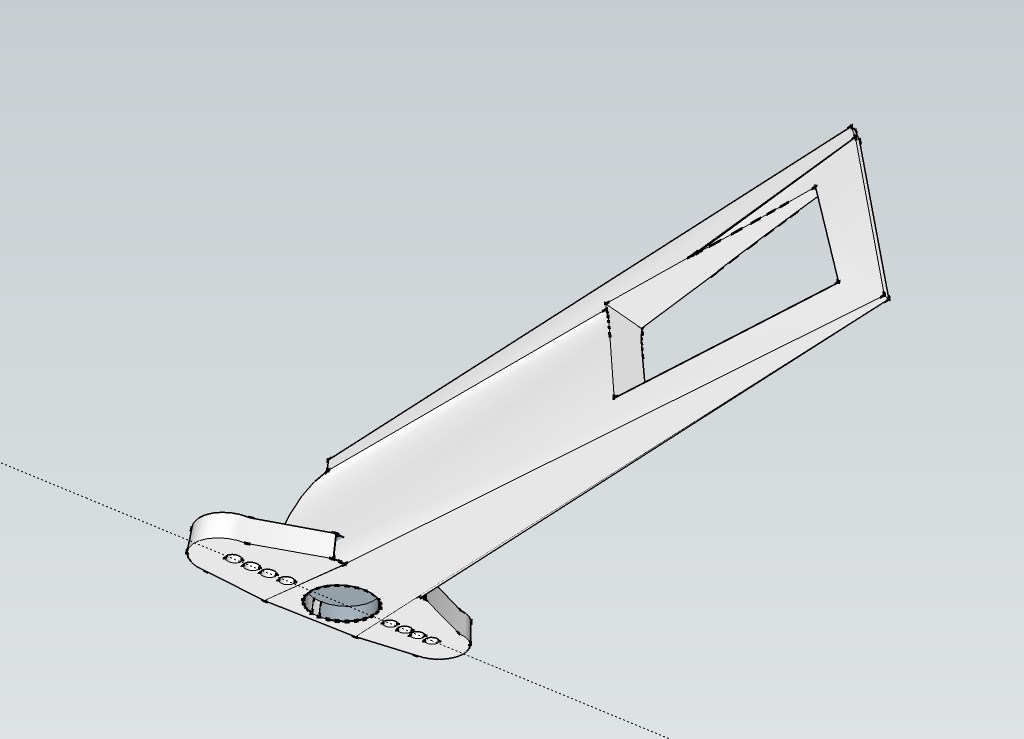

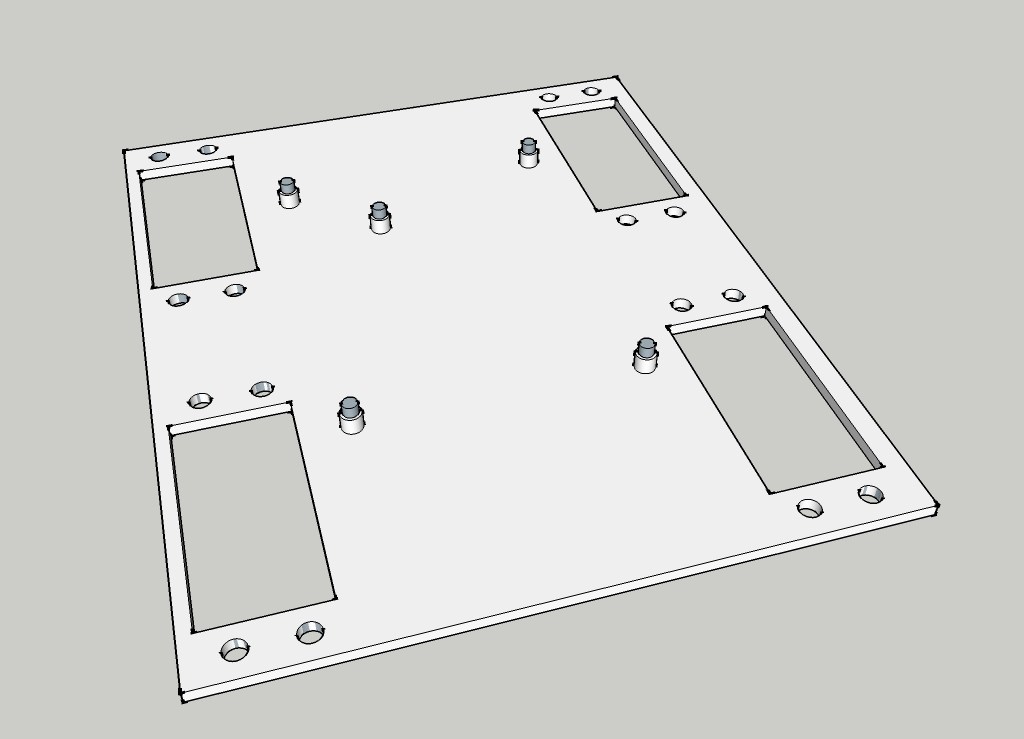

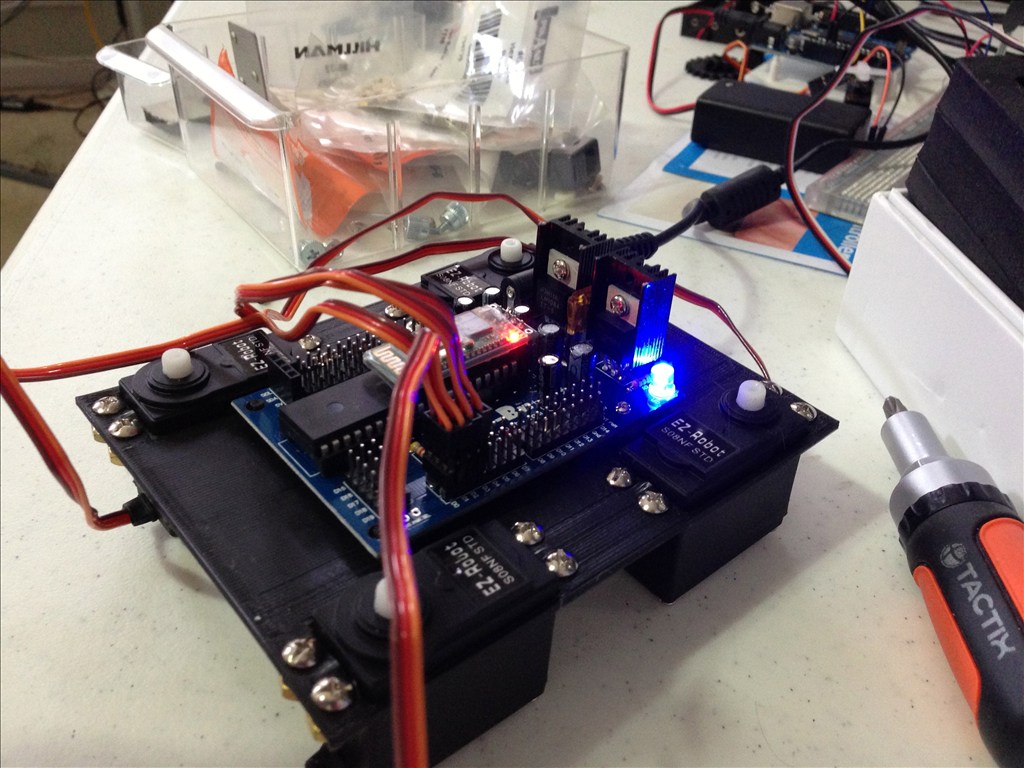

I am slowly designing and printing an 8 servo quadruped. I will integrate parts like the sensor and the camera after I build the base and get the walking figured out.

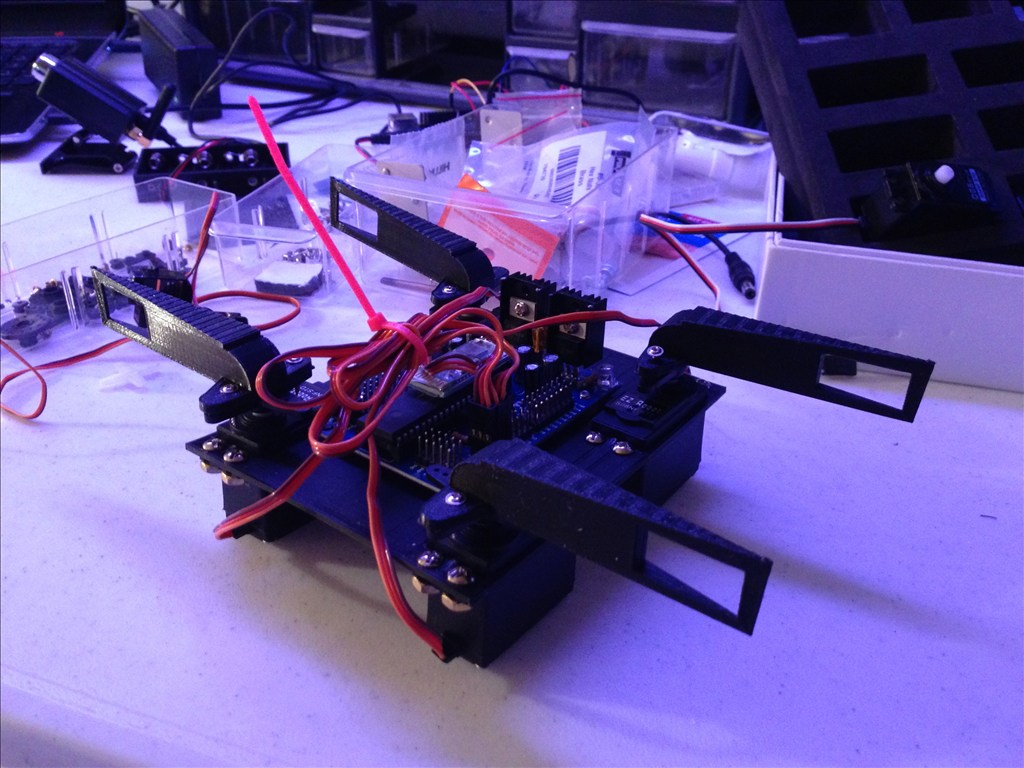

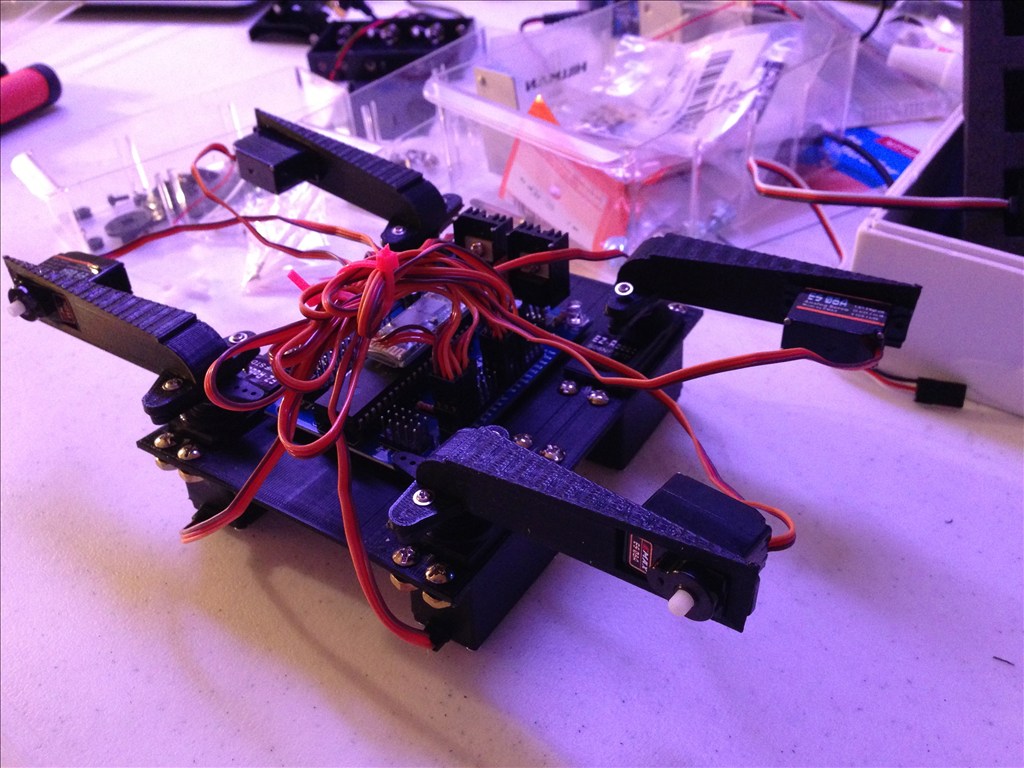

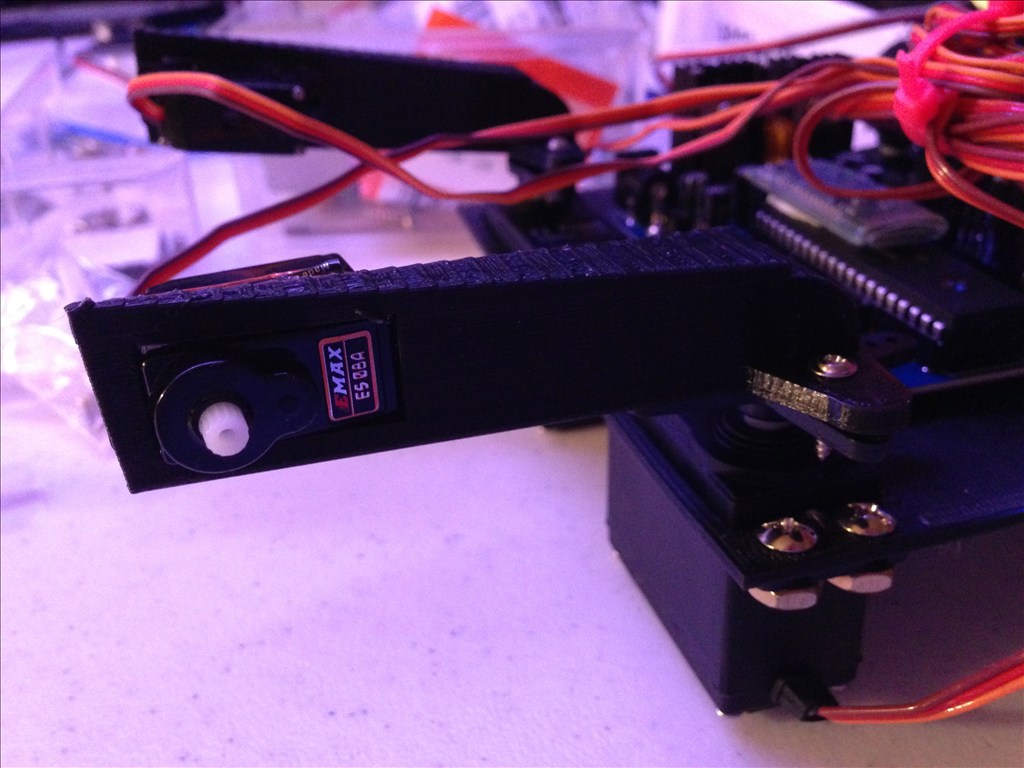

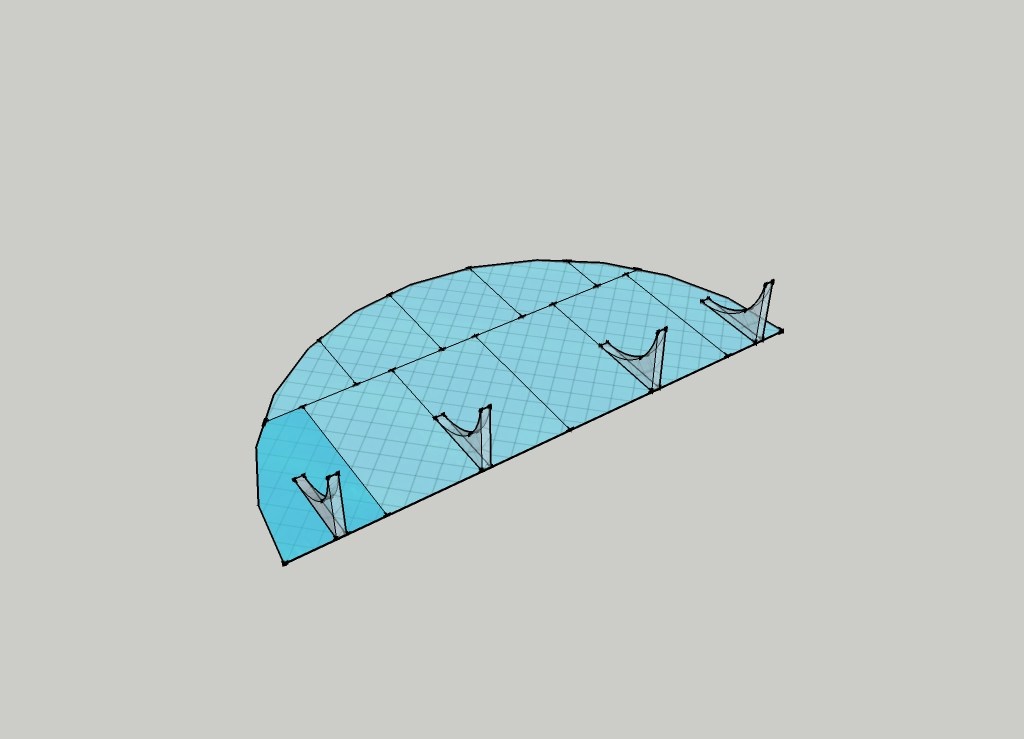

So far, here is the base design and the printed part:

March 13, 2013

March 14, 2013 - Testing the fit for the base.

I'll add as it grows.

By ElvisExMachina

— Last update

Other robots from Synthiam community

Mac's Irobot - Scuplture

Sculpture inspired by Asimov's I, Robot explores robots protecting humanity; face-tablet shows human faces and clips of...

Lizpoir's Video From My Omnibot 2000 An From My 3D-Printing...

Watch two videos showcasing my robots in action, have fun.

Hstud's Hunters1st Robot Sam

DIY robot S.A.M. built by 8-year-old Hunter using EZ-Robot v3 and simple parts, dollar-store body, PVC arms, LEDs and...

I so need a 3d printer

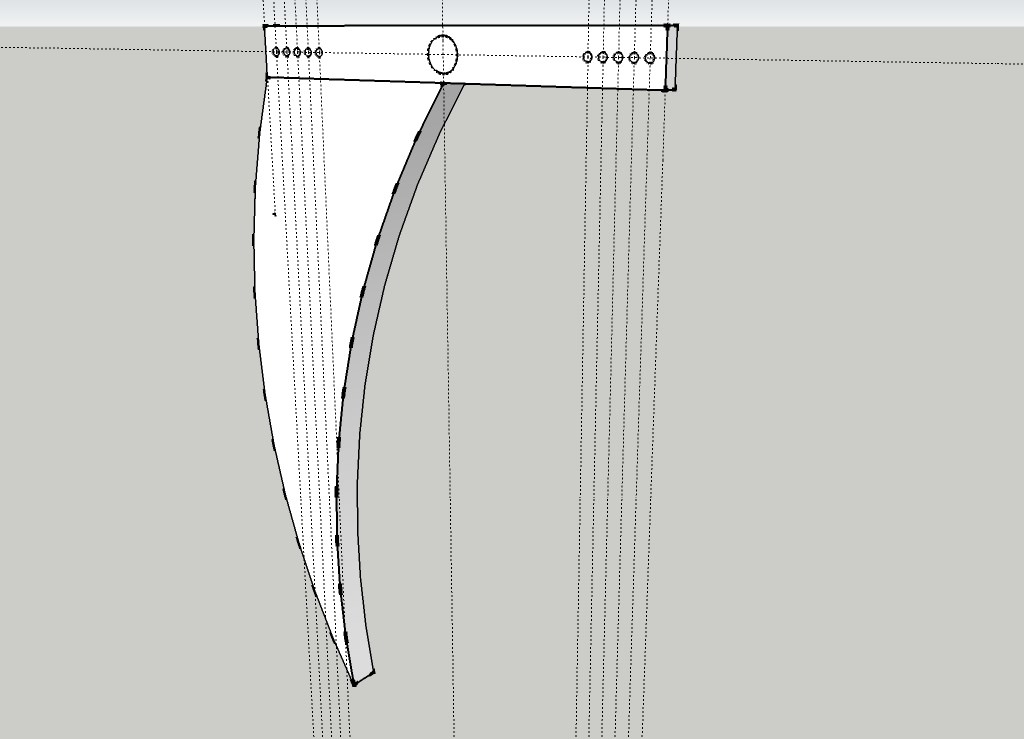

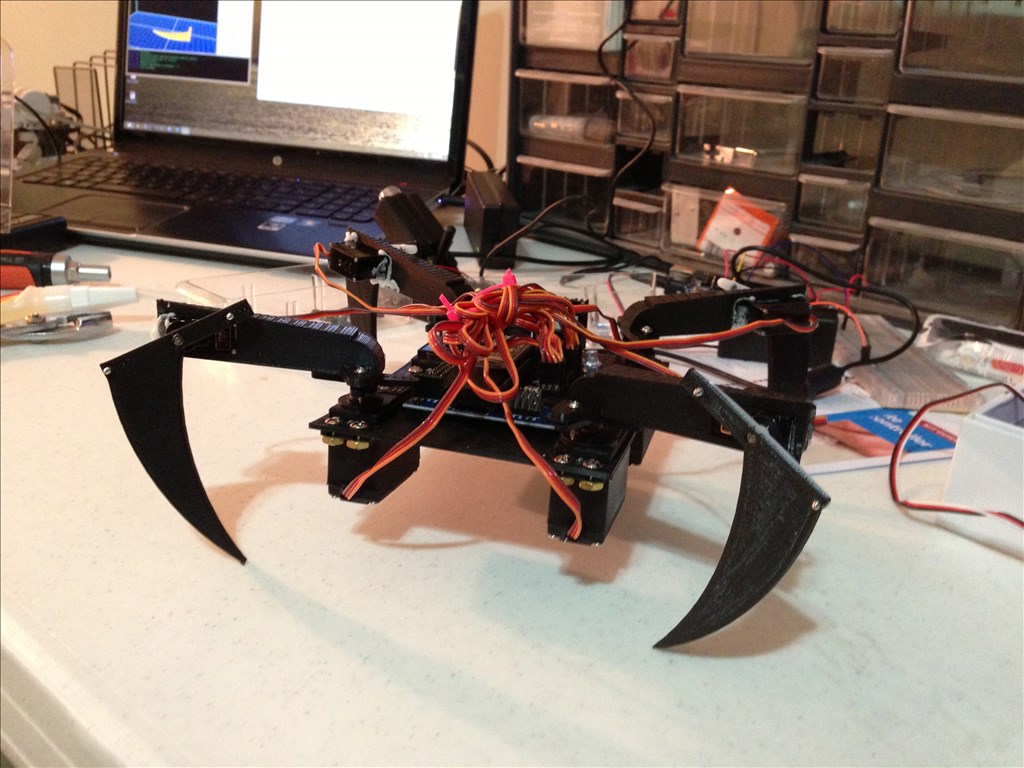

March 18th Update.

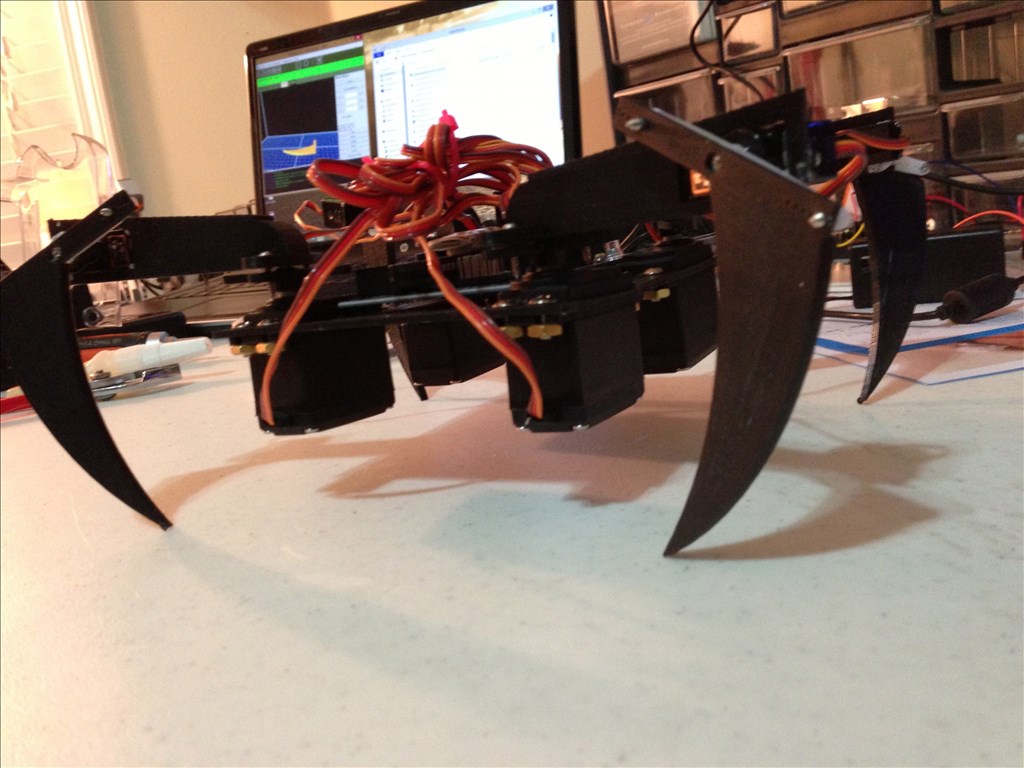

Slow progress due to work, but I modeled the top part of the leg and have it attached to the base. Here are some pictures and a really boring video.

Excellent! I am excited to see this project

I'm 3D printer are you using? Our new website will allow you to share and download EZ-Robot 3D printed items. It's going to be awesome! We're a few weeks away from launching that section. Ooops, did I say that outloud?!

I used your favorite printer...the Replicator 2

I'll have a good collection of STLs to share.

Sorry to hear that How does it work for you? Do you print at medium or high res? Ours is out of commission again... The heater stopped working now

How does it work for you? Do you print at medium or high res? Ours is out of commission again... The heater stopped working now

I had the whole thing replaced in January after struggling Nov - Dec with extruder issues. Now it works like a champ and after I made several modifications I love it. I can print .1mm but reserve that for final pieces or figures. I mostly print test pieces at .2mm.

I've made the plunger modification, use a glass plate instead of the plexiglass, oil the filament with canola oil and use 91% alcohol to prep the bed before each print (prevents curling).

The only bad prints I get now are design errors on my part. eek

They replaced the whole thing? I'm surprised they did it so quick for you. It has taken 4 months and they finally (as of today) told us they will replace it. They are replacing it with a RMA'd unit. This means it will be a unit that was once broken and now fixed. I'm not happy about it, but they're also offering a return.... for a price

Where did you get the glass plate? I'm interested in getting one for ours.

Does the Canola oil require a lot of maintenance for cleaning the extruder?

I was a pest about the problems, calling them everyday and emailing the president, Bre, when things were too slow. I filled out every customer survey I could about MakerBot complaining about the issues.

I had the glass plate cut locally and then I bought another two from the MakerBot Operators group on Google groups during a group buy. Now I can print, remove the plate, re-level and start printing immediately while I remove the printed item.

Canola oil requires wiping down the inside of the makerbot occasionally, you will see the oil splatter and know it is time. The extruder actually benefits from the oil build up. Though I still clean it every 50 hours of use with a very narrow pin. The oil evens out the flaws in the extruder and makes the flow of PLA smoother.