I just decided to redo one of my TIP122 Transistor Switching Circuits (mainly because I needed a break from working - there is nothing wrong with the 2 that are already in my Hearoid). So now's as good a time as any to do a small tutorial

This has become an evolving tutorial with additional information and options available being added. The change log at the end of this post explains changes made. Any additional information will be added as and when discovered.

Parts needed: 1 x TIP120 or TIP122 Darlington Transistor or IRL3103PBF Mosfet (see notes at the end) 1 x 1k ohm Resistor 1 x Small Piece of Strip Board (7x5 holes) 1 x Pin Header (1x2) 1 x servo Extension Solder Soldering Iron Cutters

Extra parts needed (if inductive load): 1 x 1n400x Diode as required

Search for part numbers in google or ebay or use your preferred supplier.

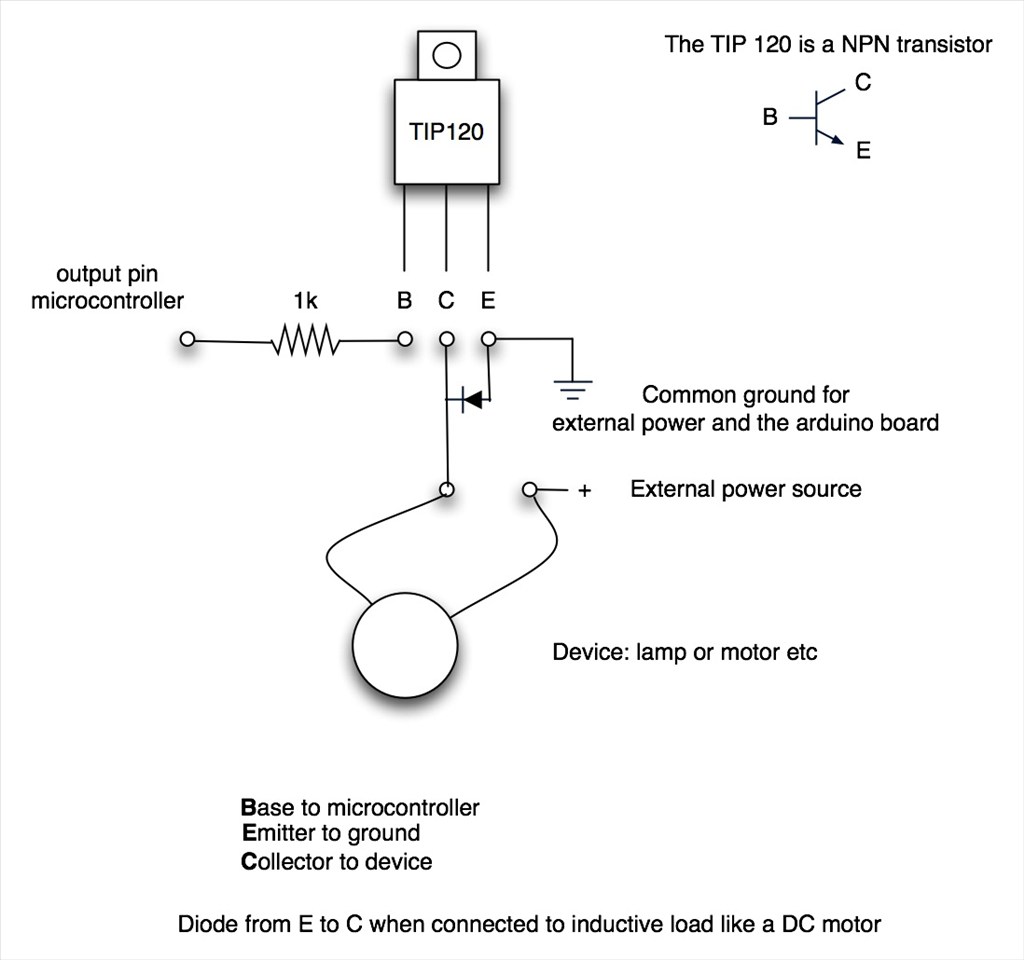

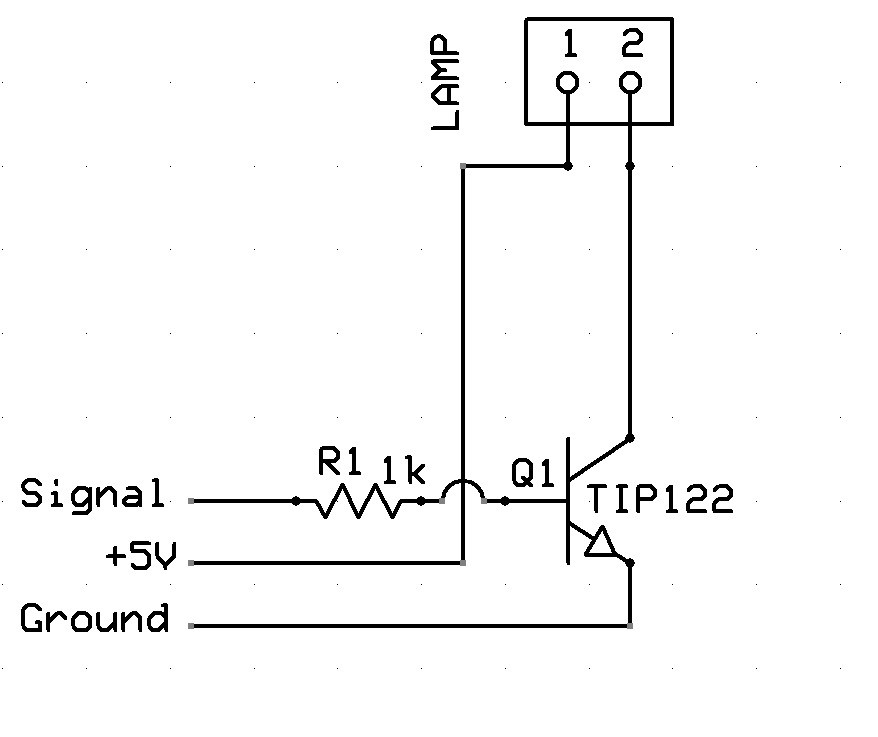

The Schematic:

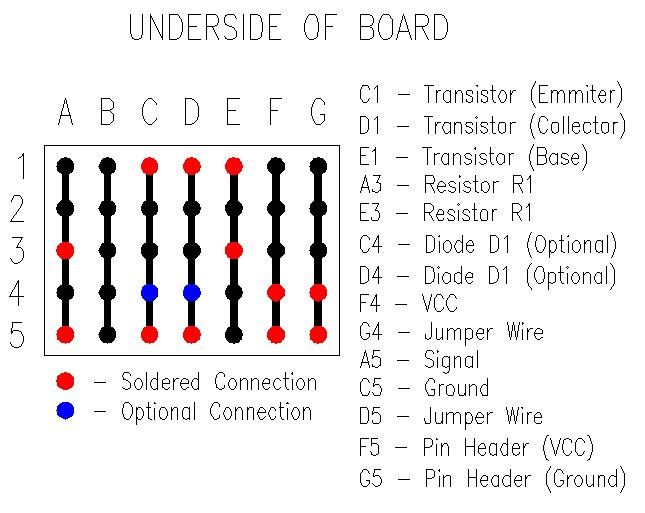

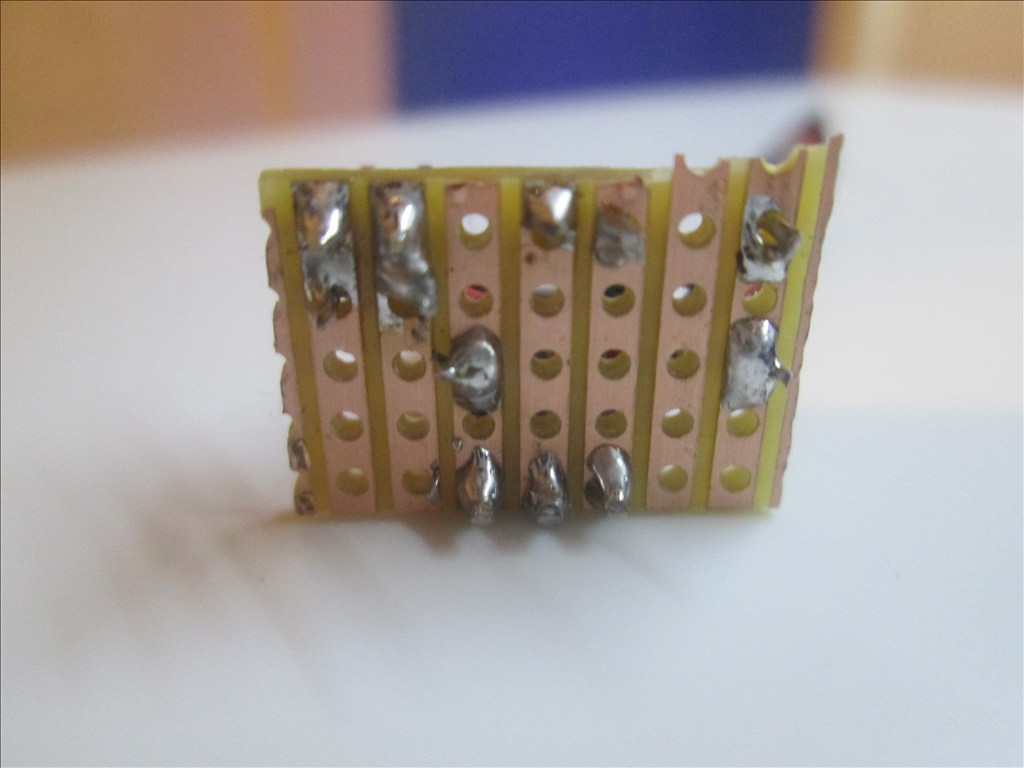

Underside of Board:

The optional connections are for Diode D1 covered at the end of this post.Method:

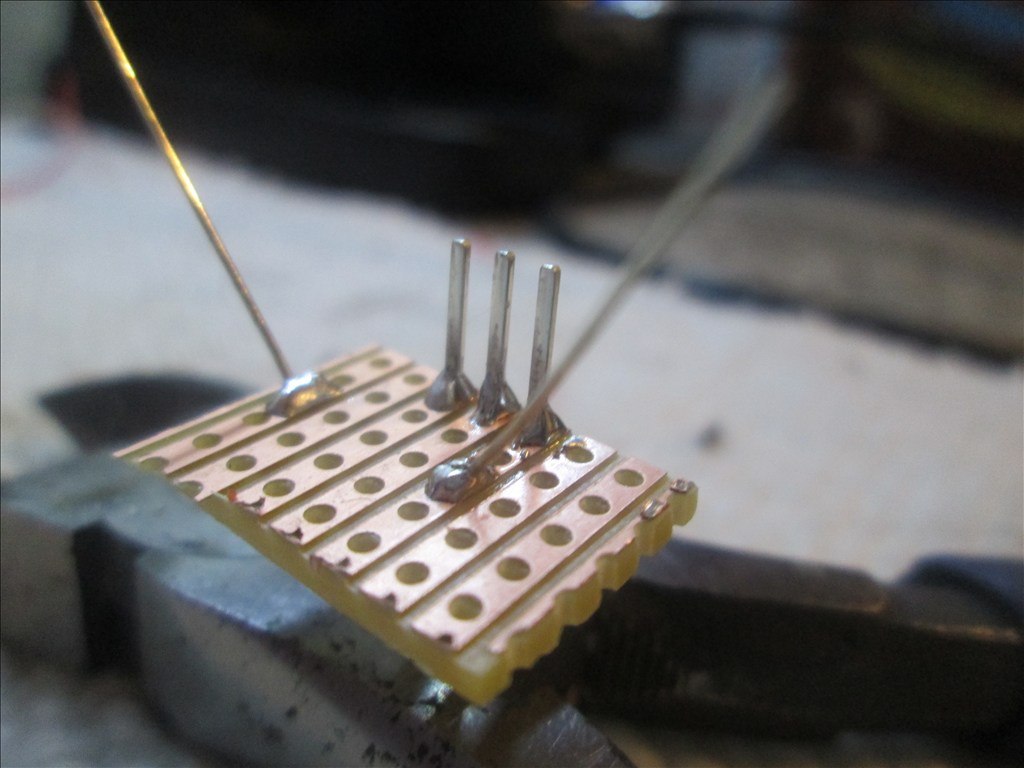

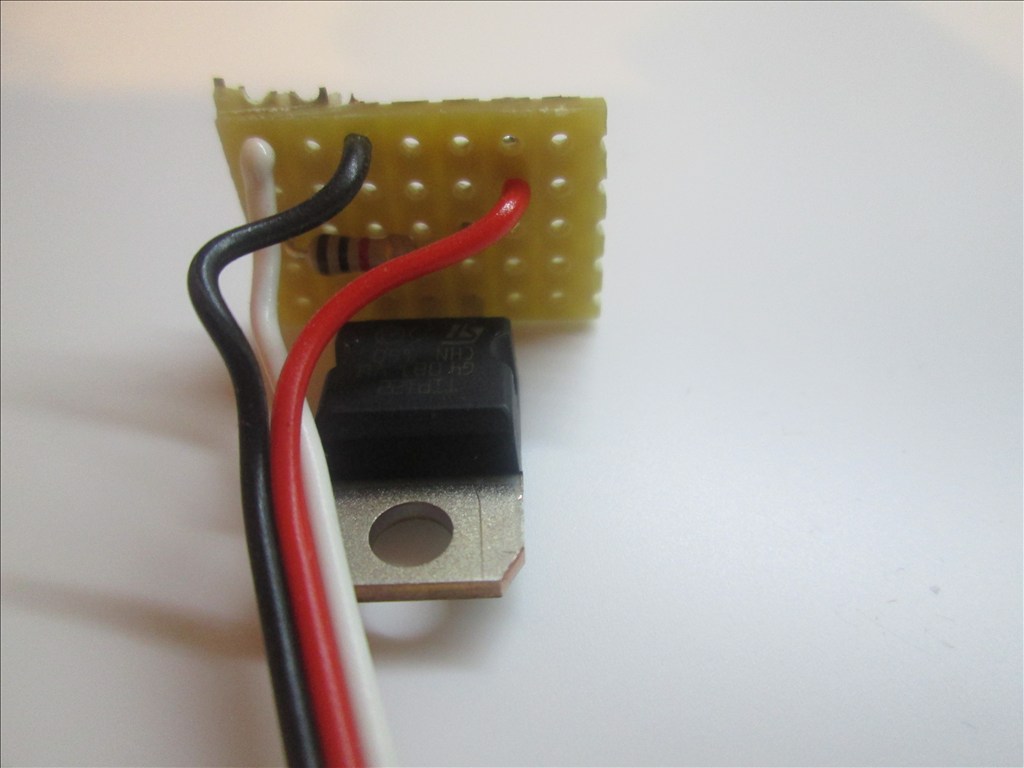

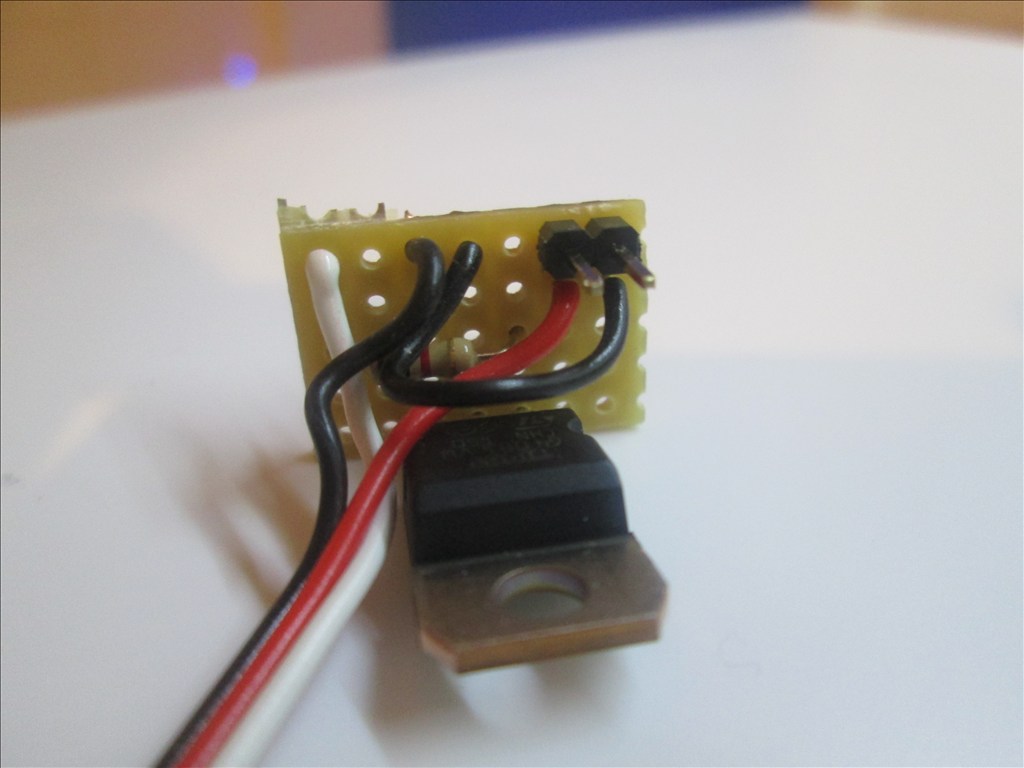

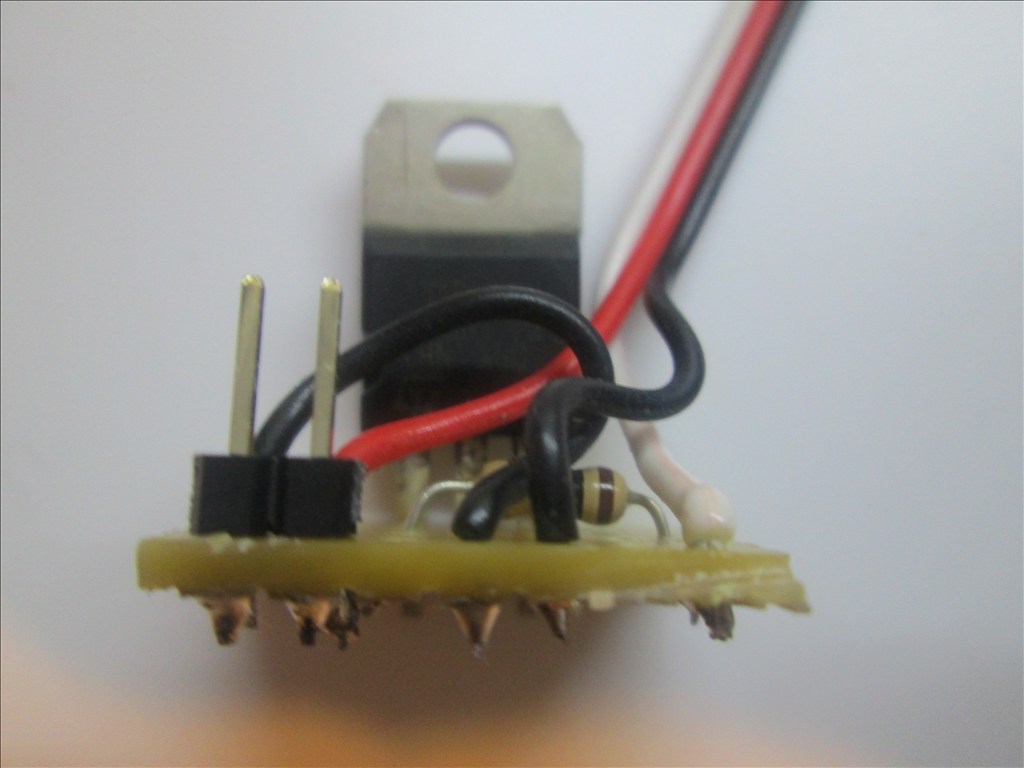

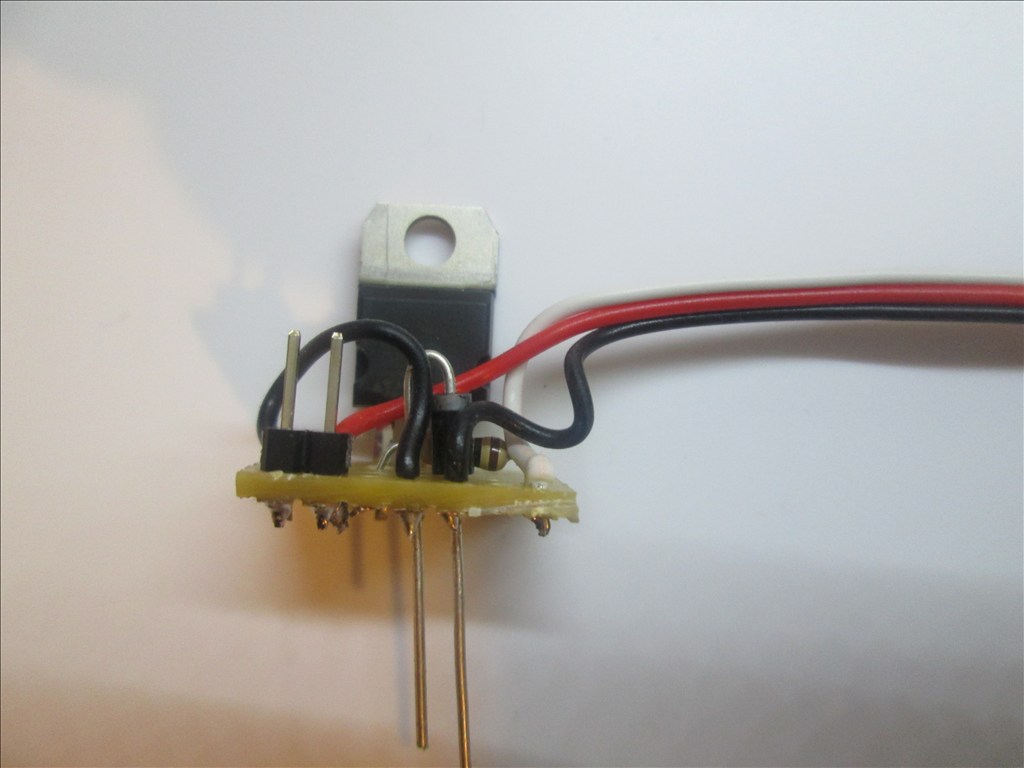

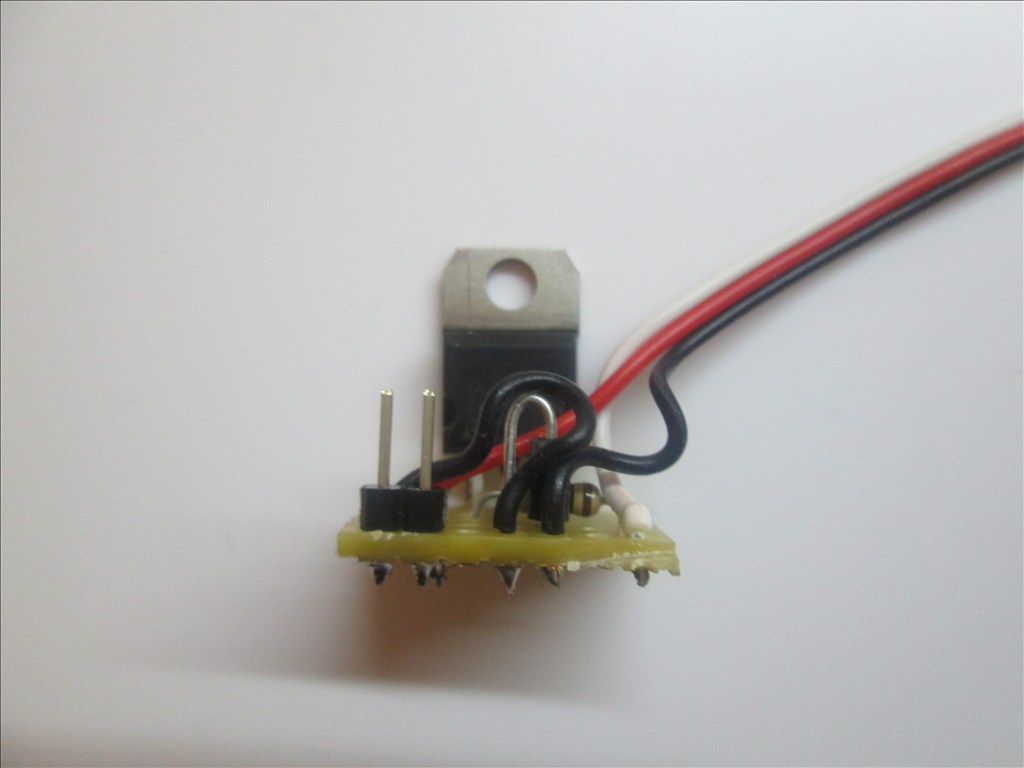

Solder the TIP transistor to the strip board so each pin is on a separate strip of copper

Solder the resistor from the Base of the transistor to a spare copper strip

Cut off the end of a servo Extension and strip back the wires

Solder the Black wire of the servo Extension to the strip connected to the Emitter of the transistor

Solder the White wire of the servo Extension to the strip connected to the end of the resistor (not the transistor end)

Solder the Red wire to a spare copper strip

Use a small off cut from the servo Extension and solder one end to the strip of the Collector of the transistor

Solder the other end of the off cut to a spare copper strip next to the Red wire.

Solder the Pin Header to the copper strips with the red and black wires soldered

Job done. Plug the servo Extension in to a Digital port on the EZB and connect the circuit that needs switching to the Pin Header, I do this with another servo Extension (as I have hundreds of them)

Or a JST connector works very well also

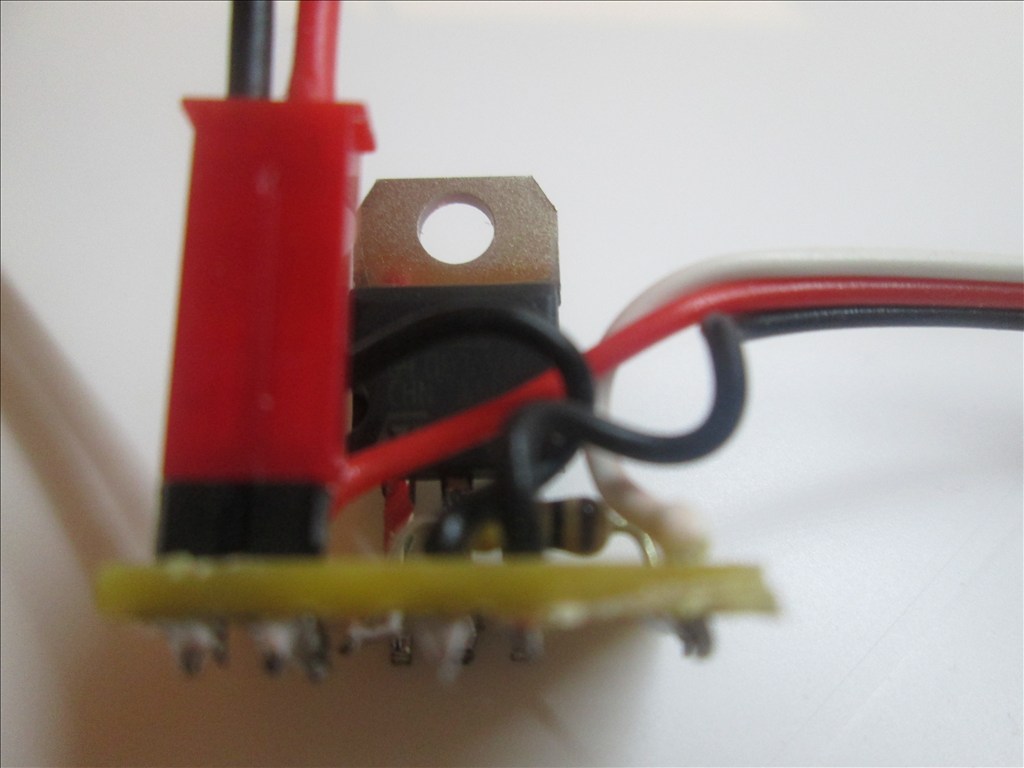

Adding the Diode If using the circuit for a motor or other inductive load a diode needs adding between the transistor Collector and Emitter. This is easily added in to the above circuit.

Bend the leg on the Diode so it will fit though 0.1" hole spacing

The band on the diode is to connect to the Collector and the other end to the Emitter. It will drop in to two spare holes.

Solder in place and cut off the excess legs.

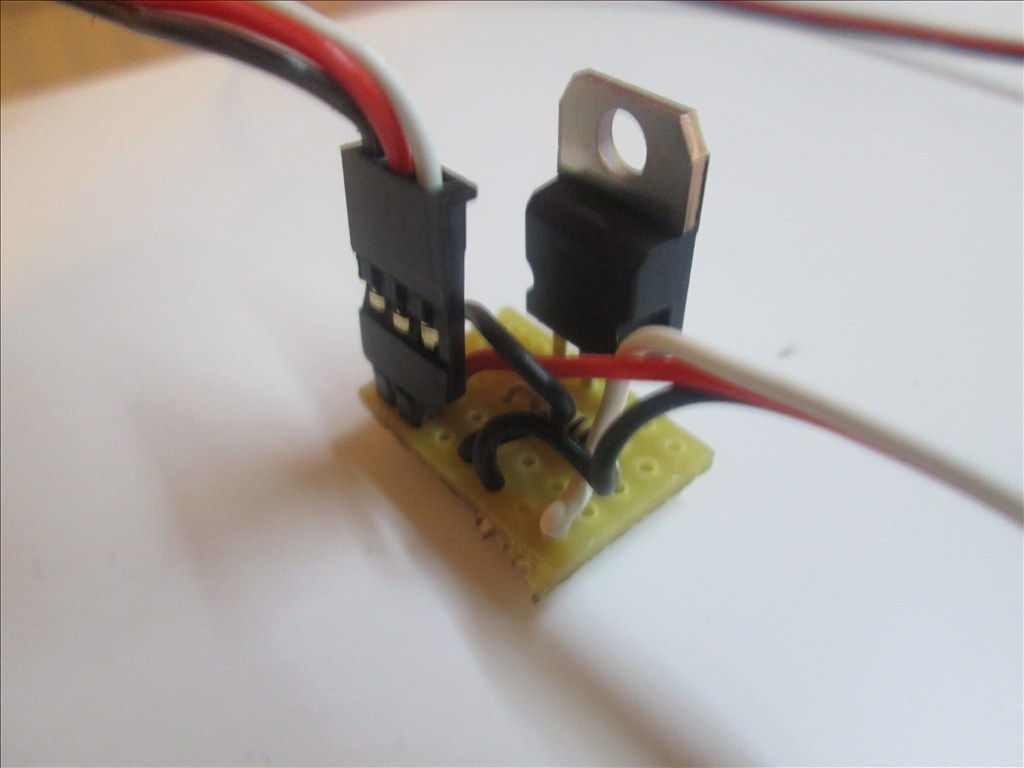

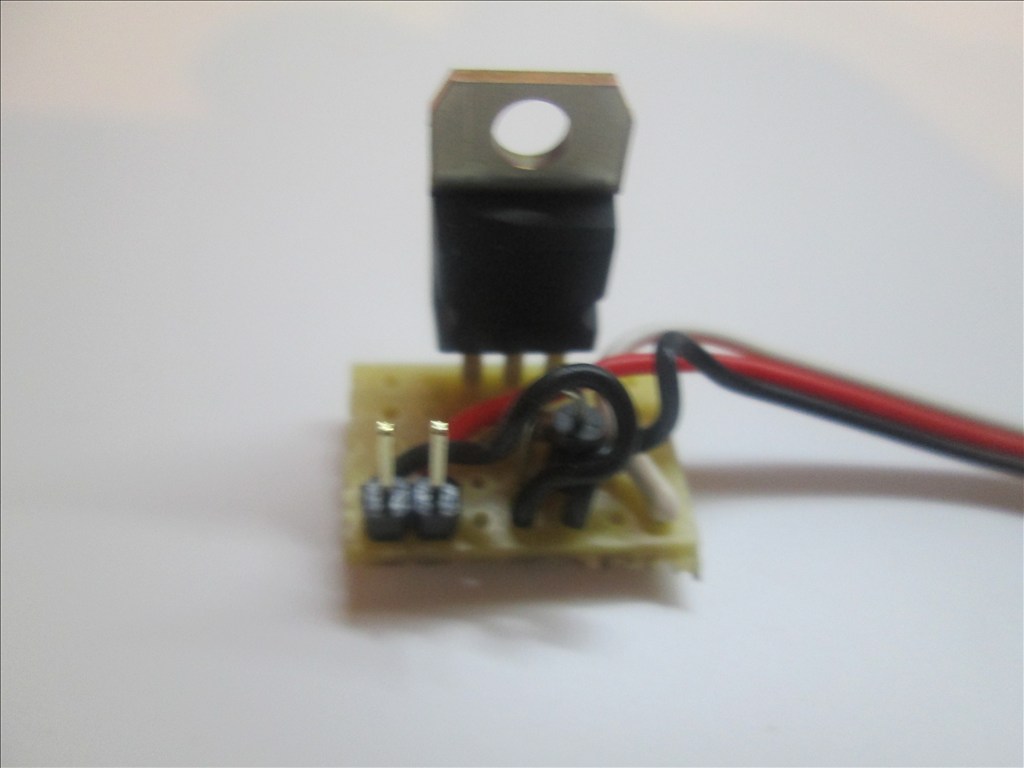

All done. You should have something like this.

Additional notes You may also use a Mosfet for this switching circuit. A IRL3103PBF mosfet can replace the TIP120/122 Darlington transistor. The circuit is the same however the pins on a Mosfet are named Gate, Drain and Source. The mosfet fits in the same place as the Darlington with the Gate to the left (replacing the Base of the Darlington).

Updates:

Edit 1 (2013.03.07): Underside of board diagram added.

Edit 2 (2013.03.07): For some circuits a diode is needed as shown in the first schematic. The board here does have space for a diode (C4 to D4 - would have to be with legs bent to accommodate 0.1" spacing) however I have not shown one - watch this space

Edit 3 (2013.03.07): Underside of board optional connections for D1 added.

Edit 4 (2013.03.07): Added diode information.

Edit 5 (2013.03.18): Added IRL3103 Mosfet information.

Very nice, Thanks Rich. I'll be making a few of these this weekend.

Updated it with the diode addition now too... 4 updates in one day ... I don't think I can do much more to it now but have added in the Diode if using motors etc.

... I don't think I can do much more to it now but have added in the Diode if using motors etc.

In case my photos aren't clear enough here are some rendered images of the step by step... Just like Lego

An alternative option using pin headers for the servo extension (although you would need male to male servo extensions)

this is the correct place to add a diode

IT DOES 2 types of protection not just one protection

it protects the rest of the circuit for spikes and surge and protect the darlington

here is the link to it

transistor switching circuits

Useless post, please ignore.

DIODE IS same you have in your circuit ,only need to place it across the coil.yours will work only it adds a extra protection for noises and spikes 1N4001 TO 1N4007 WILL WORK ,last digit after 1N400 is voltage RATING

Useless post, please ignore.

1N4001 foreword voltage is 50v and reverse is 35v 1N4004 foreword voltage is 1000v and reverse is 750vdc!

These and in between can handle up to 1 amp.