I just decided to redo one of my TIP122 Transistor Switching Circuits (mainly because I needed a break from working - there is nothing wrong with the 2 that are already in my Hearoid). So now's as good a time as any to do a small tutorial

This has become an evolving tutorial with additional information and options available being added. The change log at the end of this post explains changes made. Any additional information will be added as and when discovered.

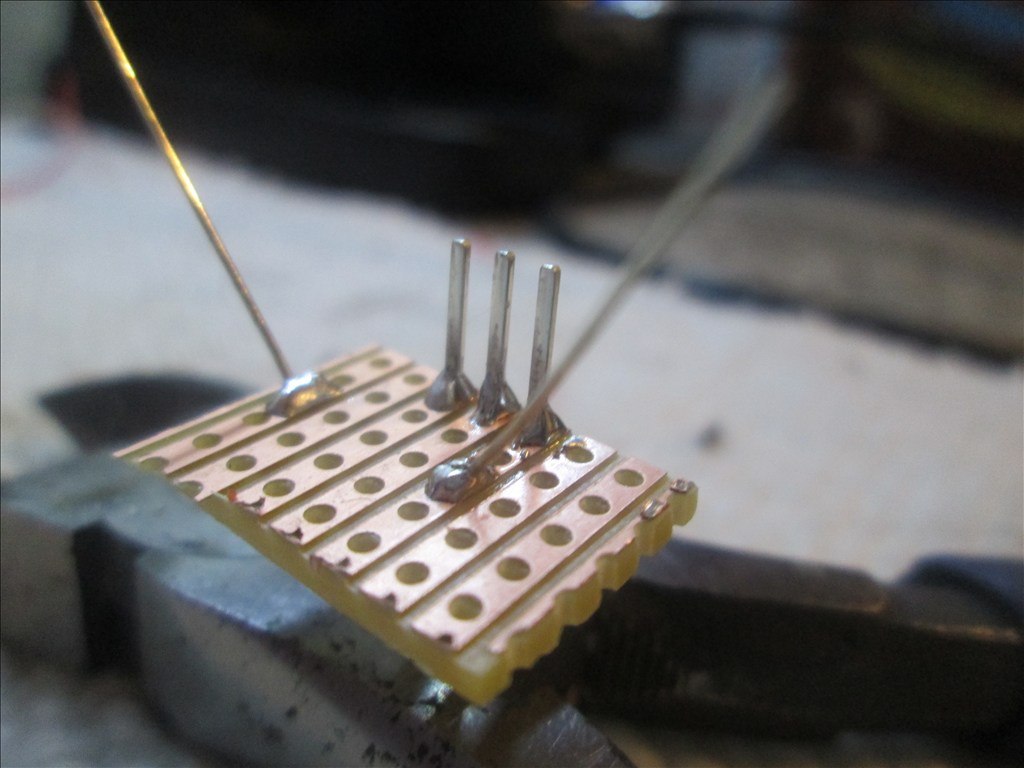

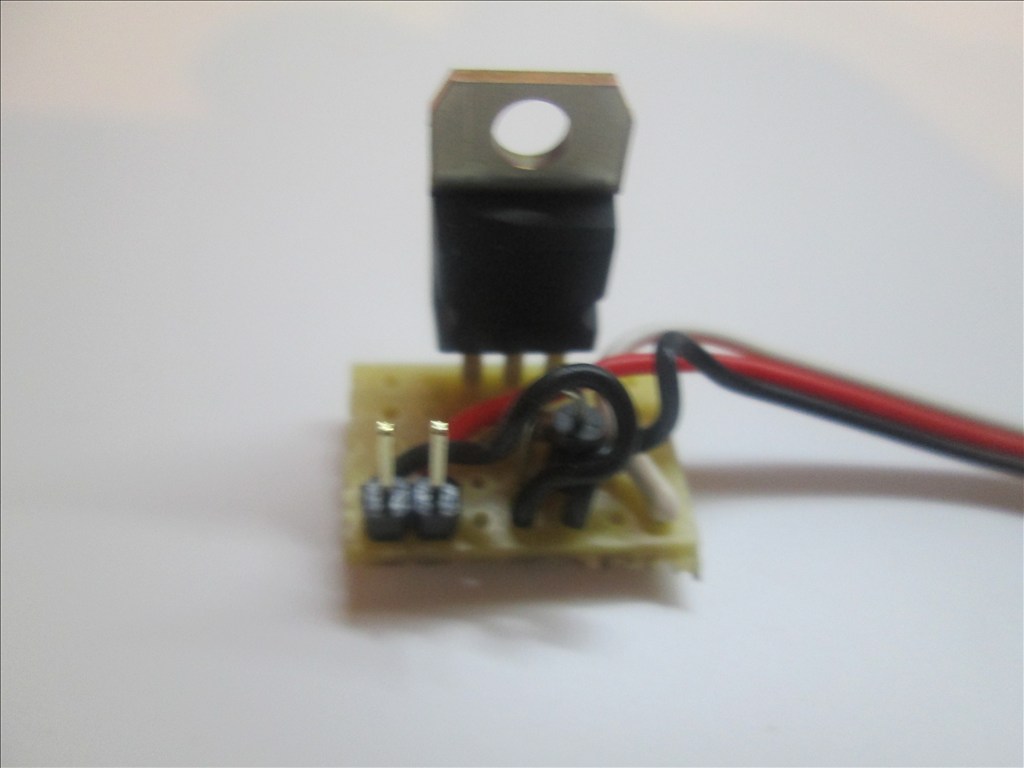

Parts needed: 1 x TIP120 or TIP122 Darlington Transistor or IRL3103PBF Mosfet (see notes at the end) 1 x 1k ohm Resistor 1 x Small Piece of Strip Board (7x5 holes) 1 x Pin Header (1x2) 1 x servo Extension Solder Soldering Iron Cutters

Extra parts needed (if inductive load): 1 x 1n400x Diode as required

Search for part numbers in google or ebay or use your preferred supplier.

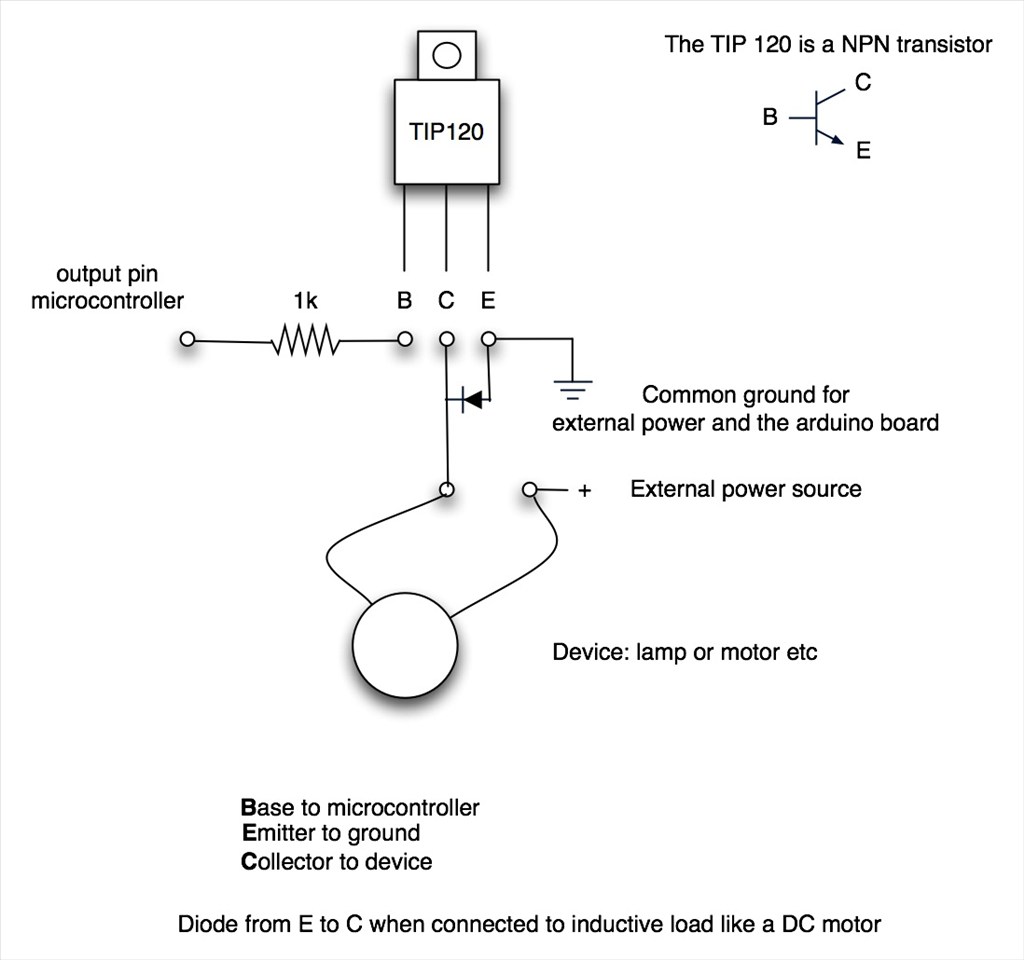

The Schematic:

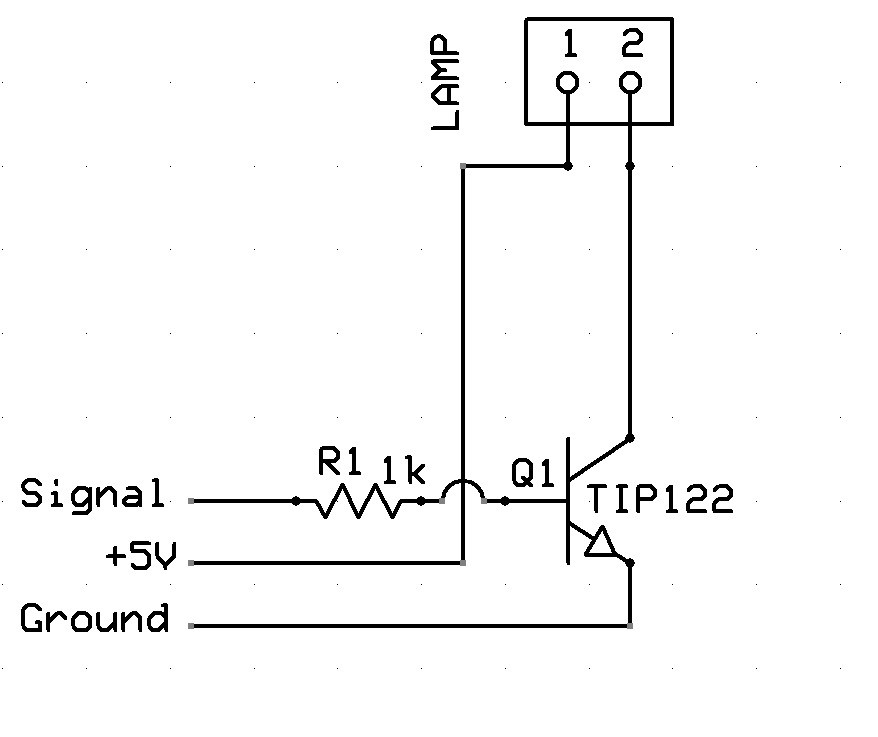

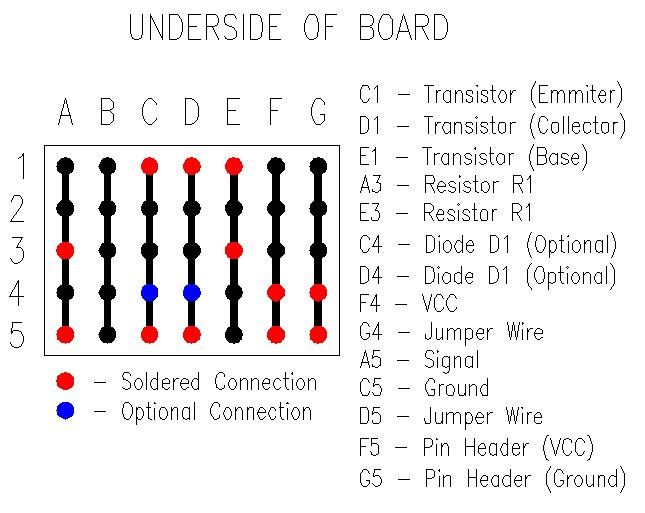

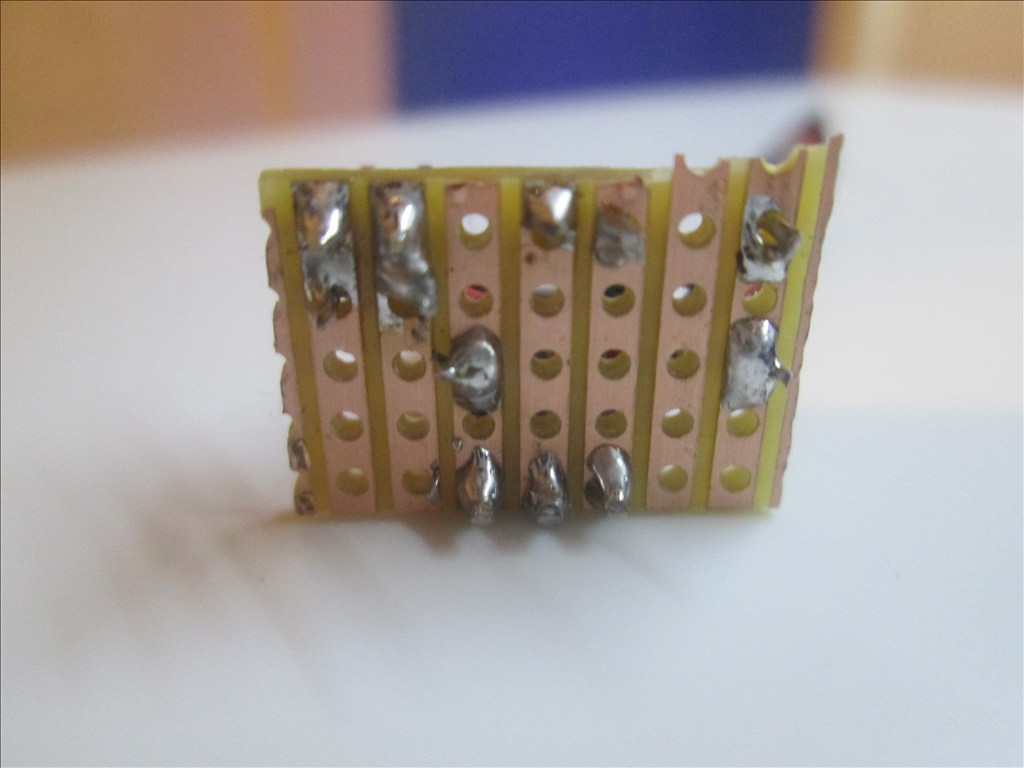

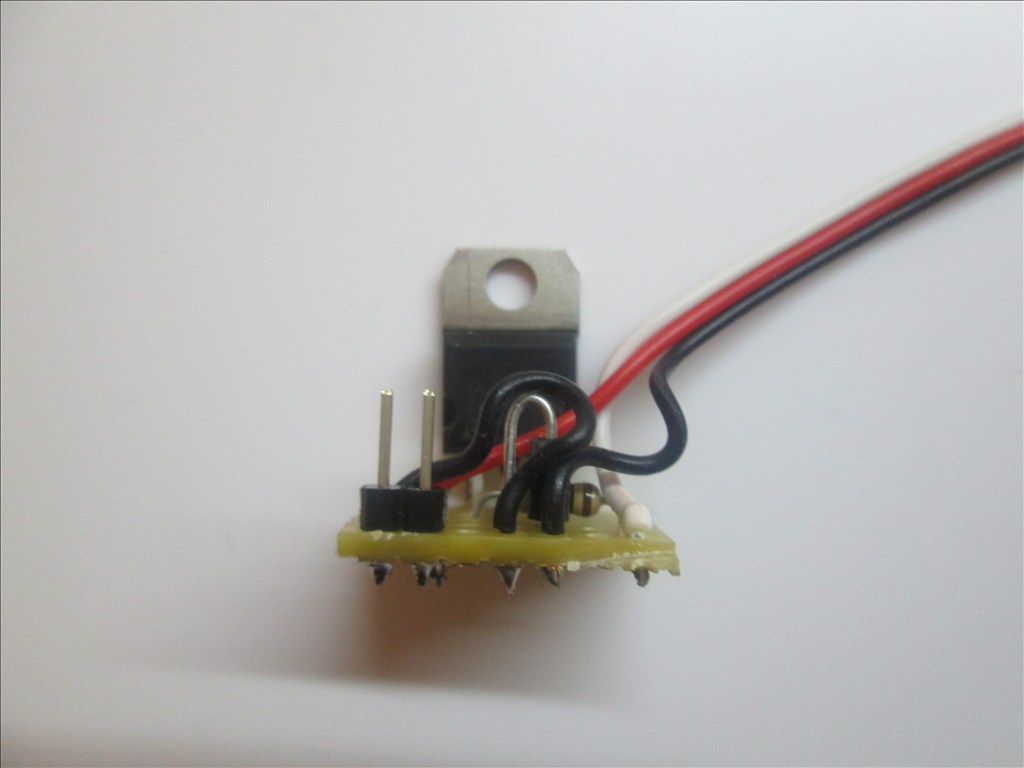

Underside of Board:

The optional connections are for Diode D1 covered at the end of this post.Method:

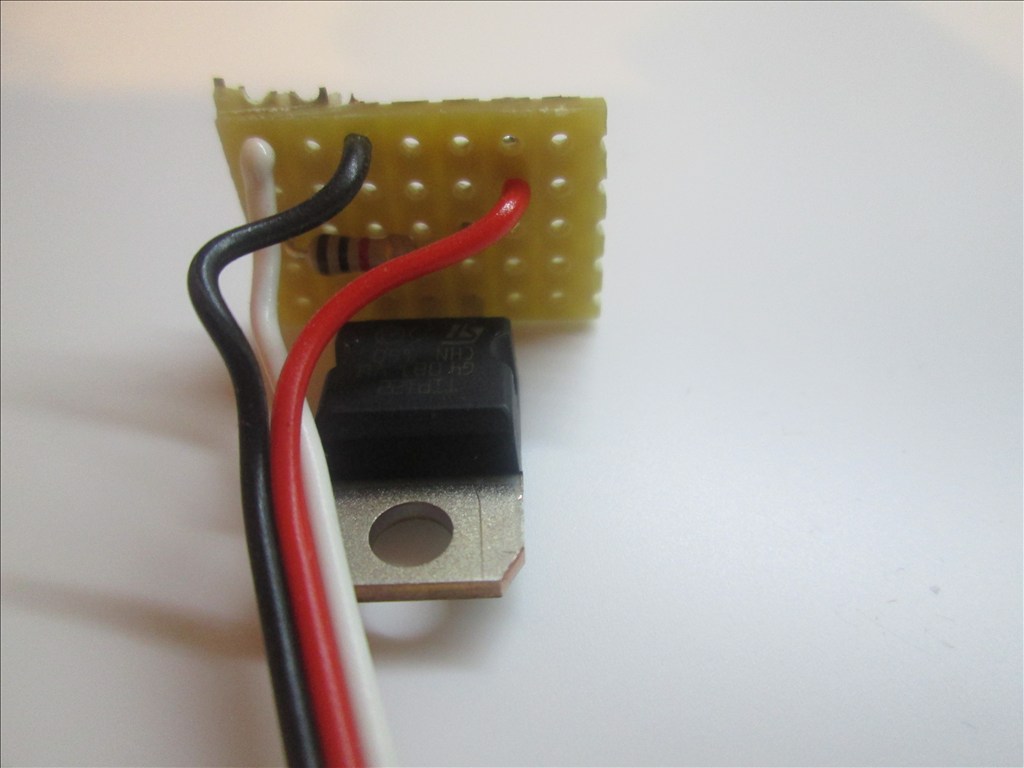

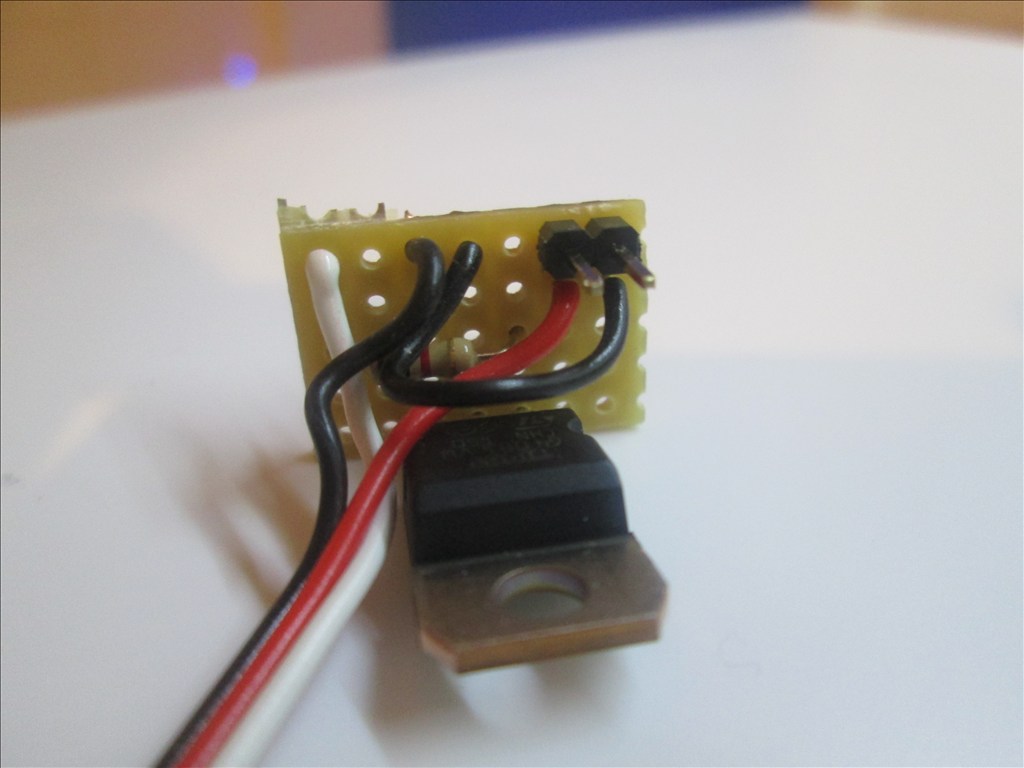

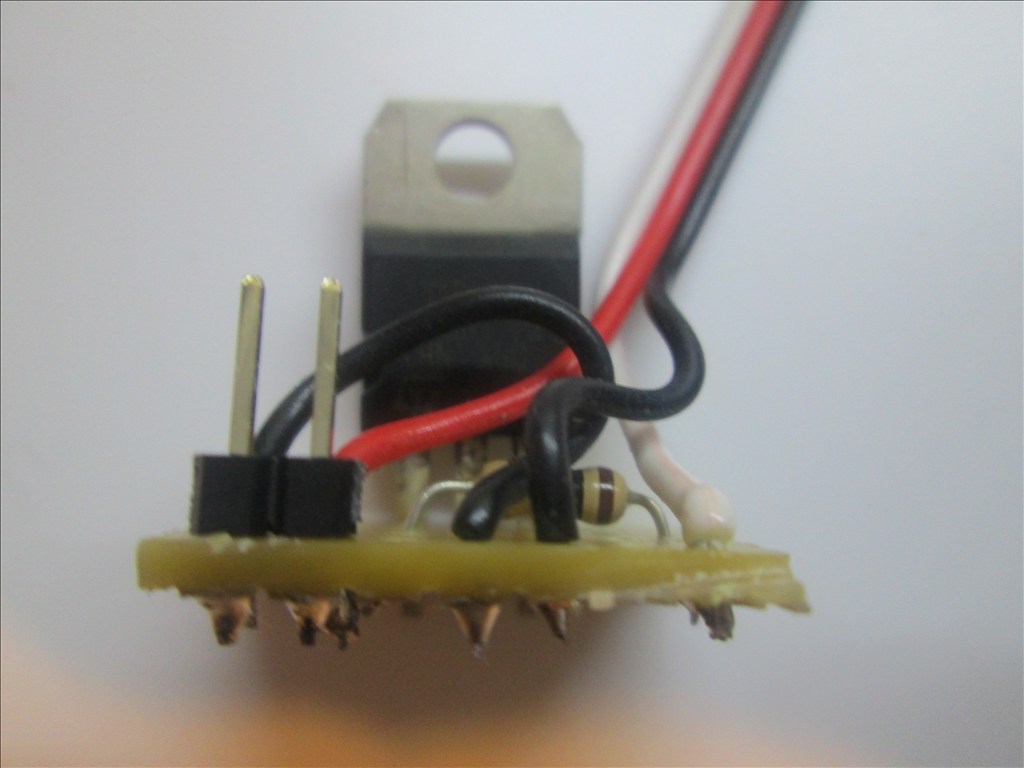

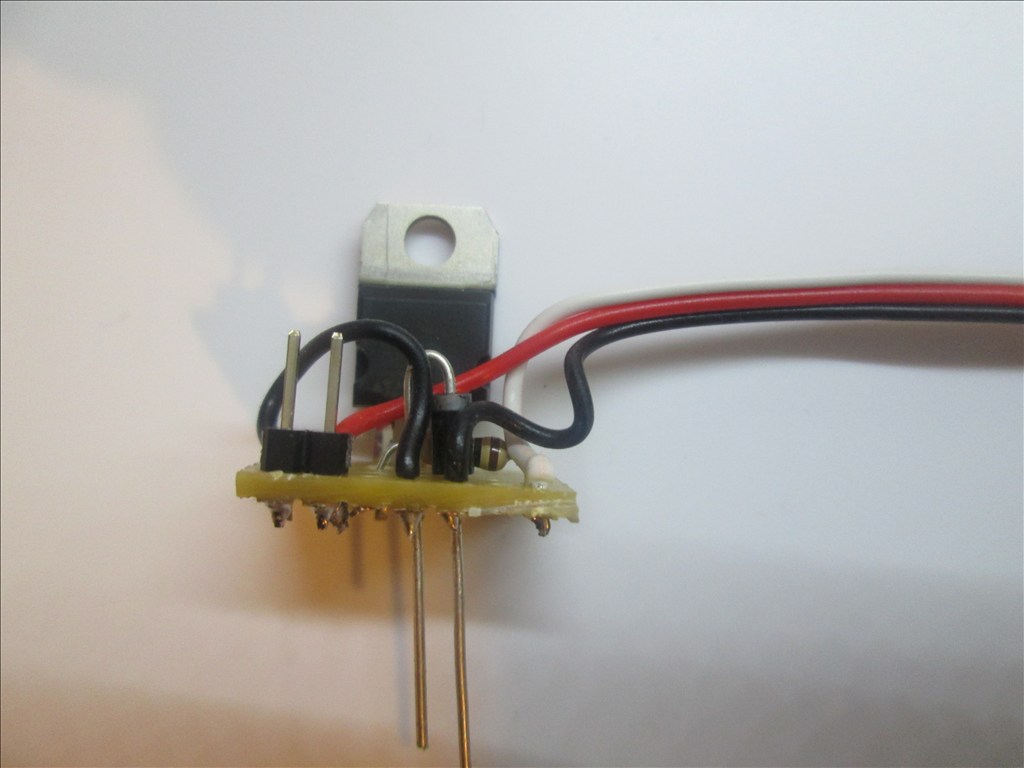

Solder the TIP transistor to the strip board so each pin is on a separate strip of copper

Solder the resistor from the Base of the transistor to a spare copper strip

Cut off the end of a servo Extension and strip back the wires

Solder the Black wire of the servo Extension to the strip connected to the Emitter of the transistor

Solder the White wire of the servo Extension to the strip connected to the end of the resistor (not the transistor end)

Solder the Red wire to a spare copper strip

Use a small off cut from the servo Extension and solder one end to the strip of the Collector of the transistor

Solder the other end of the off cut to a spare copper strip next to the Red wire.

Solder the Pin Header to the copper strips with the red and black wires soldered

Job done. Plug the servo Extension in to a Digital port on the EZB and connect the circuit that needs switching to the Pin Header, I do this with another servo Extension (as I have hundreds of them)

Or a JST connector works very well also

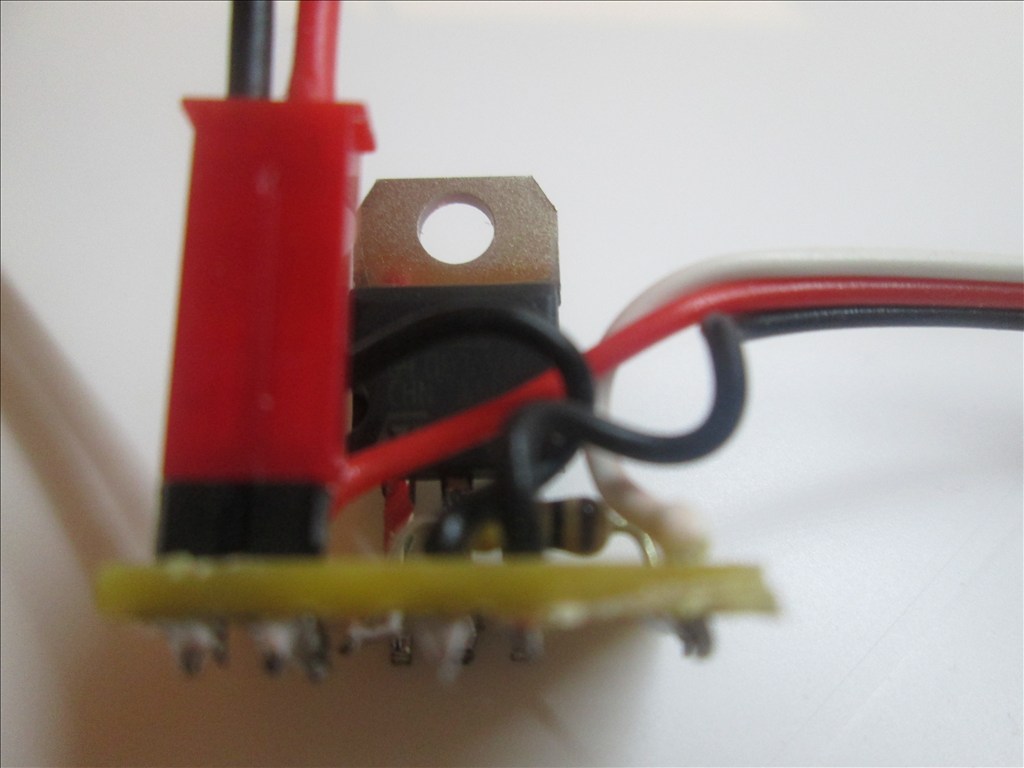

Adding the Diode If using the circuit for a motor or other inductive load a diode needs adding between the transistor Collector and Emitter. This is easily added in to the above circuit.

Bend the leg on the Diode so it will fit though 0.1" hole spacing

The band on the diode is to connect to the Collector and the other end to the Emitter. It will drop in to two spare holes.

Solder in place and cut off the excess legs.

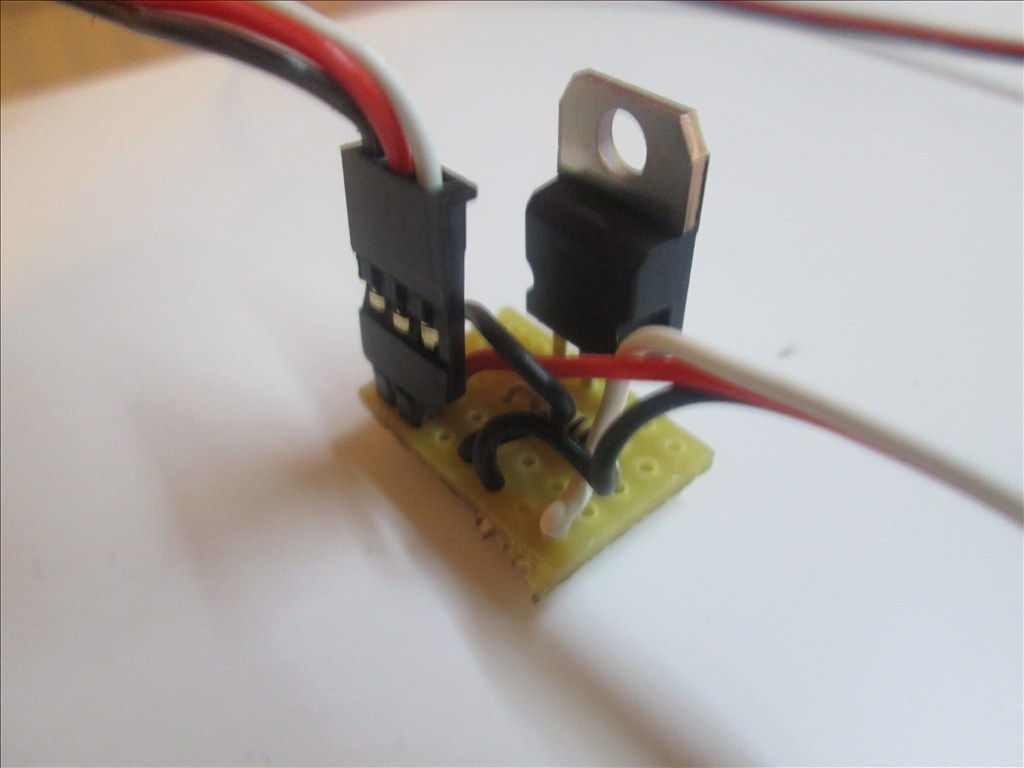

All done. You should have something like this.

Additional notes You may also use a Mosfet for this switching circuit. A IRL3103PBF mosfet can replace the TIP120/122 Darlington transistor. The circuit is the same however the pins on a Mosfet are named Gate, Drain and Source. The mosfet fits in the same place as the Darlington with the Gate to the left (replacing the Base of the Darlington).

Updates:

Edit 1 (2013.03.07): Underside of board diagram added.

Edit 2 (2013.03.07): For some circuits a diode is needed as shown in the first schematic. The board here does have space for a diode (C4 to D4 - would have to be with legs bent to accommodate 0.1" spacing) however I have not shown one - watch this space

Edit 3 (2013.03.07): Underside of board optional connections for D1 added.

Edit 4 (2013.03.07): Added diode information.

Edit 5 (2013.03.18): Added IRL3103 Mosfet information.

No, at least that's not what I was thinking.

What I was thinking is, using the board that drives a motor in a servo to drive a different motor, say the ones in the Omnibot drive system. 2 servo boards would drive both motors forwards and reverse with only 2 signal cables.

The board in the servo would govern how big a motor it could run, and it would need an external supply as with a HBridge but it would cut the signal wires needed down to 2 from 4 or 5.

Very clear! thanks so much Your idea is certainly worth pursing to reduce the number of signal wires!

Your idea is certainly worth pursing to reduce the number of signal wires!

GREAT servo to be hacked is futubu S3002 for the h-bridge,very low cost and the chip is easy to use cost is about $3.50 on ebay,and there is schematic on it also.

Ithink only one that there is a schematic for.

@Rich from what I read and my limited understnding of electronics in this post could this board be able to run a 7.2 DC motor like a servo, this would solve my vertical lift issues. P.S. great job on the drawing and the step by step assembly, SO what would you charge me to make me one and if I could run this board like a servo I would need 3.

Yes, just ensure you include the diode. There would be only 1 direction and no control other than on/off.

Think of it as if its a simple switch.

Edit: Just noticed the last part. If it wasn't for the shipping costs I'd send one over for free (it's about 1 worth of parts). If you really don't want to go through making it yourself I'll look at shipping costs, I'd guess it's about $5 or $10

This would be perfect Rich for my 1watt blue ray laser. Thanks again

@Rich: It is a very nice tutorial to make the switching circuit by using TIP122 transistor and the most important thing we don't need the relay but I am concerned about the position of diode whether it should be between base and collector to protect the microcontroller from the back current of load or it should be between the collector and emitter as you placed. Can you tell me the reason why you placed it between the emitter and collector?

electronic manufacturing services

That's the schematic that's floating around everywhere on the internet and the schematic I used to produce the perf board version, so that's the reason it's where it is.

An alternative position was mentioned in post 5. Personally I've never needed to use the diode as I have never used the circuit with an inductive load.