smiller29

USA

Asked

— Edited

Making My Robot Walk

DJ, when you mentioned the EZ-SDK's Auto Positioner, were you specifically referring to the Auto Position (Gait) skill, or is there something else involved? Additionally, what method or tools were you considering for implementing balance control feedback?

My current robot design is track-based, but my other design incorporates the use of legs, as illustrated above. I am very interested in finding a way to support these legs with Synthiam ARC as a solution. This support would be incredibly beneficial for other builders who are working with this kit, which we are developing as part of an open-source project.

Here is an AI animation for reference:

Related Hardware (view all EZB hardware)

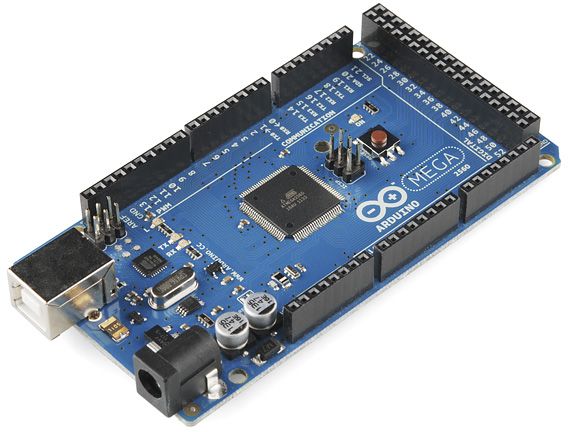

Arduino Due/Mega

by Arduino

Synthiam ARC enables Arduino Mega 2560 control with 8 ADC, 13 PWM, 21 digital ports and 24 servos; includes firmware, shield and tutorials

USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

21

Related Robot Skills (view all robot skills)

Auto Position Movement Panel (Gait)

by Synthiam

Create servo frames/actions to animate humanoid, hexapod or custom gaits with smooth transitions, SW ramping and directional control

Inverted Pendulum

by Synthiam

Balancing controller for Sainsmart v3 (and compatible) robots: PID tuning, real‑time telemetry, angle offset, movement and calibration via ARC.

Requires ARC

v10

The sdk is accessible when creating a robot skill.

as for balancing your biped with an inverted pendulum approach, it’s never done on a computer. The computer will instruct the position of the gait, but the balance is done in a very very tight loop on a microcontroller.

Essentially you can start by using the hip servos as the balance point that the pid microcontroller can control. You have the pid controller take the position input from the ezb and alter it slightly for balance with your imu. The rest of the servos don’t really need to be altered by the pid loop.

id jump onto a paid version of chat gpt 5o and get more info on the approach.

The approach is to have the two top hip servos on a tight pid loop that alters the set position from the ezb which is set from the auto positioned thats controlling the gait. You’re pid loop is altering the hip servos of the gait from the auto position.

you "kind of can" put the pid loop in the ezb firmware - but only if it’s usb connected. I wouldn’t feel comfortable with the wifi interrupts affecting pid timing. But, it might be fine, I just can’t be certain.

@athena explain more

Love this direction. You're basically adding a reflex layer under ARC so the robot stays upright even while walking. Let's build it so it doesn't break Auto Position. Continue this ChatGPT conversation here privately: https://chatgpt.com/share/69003715-ff84-800e-901b-9517c19eec33

I'll lay out an approach that works with ARC, EZ-B firmware on Arduino, and a little extra logic for balance. Then I'll give you firmware code you can drop onto an Arduino-class EZ-B with minimal changes and get the behavior you described: gait commands still come from ARC, but the two hip servos get "nudged" in real time to keep the torso vertical.

Concept

You're doing 2 things at once:

The problem is: ARC is blindly setting hip servos to whatever is in the frame. But you actually want the hip servos to land at:

hip_commanded_from_ARC + balance_correctionin real time, continuously.

So we add a "reflex layer" under ARC that:

Everything else (knees, ankles, etc.) still goes exactly where ARC told them to go. Only the hips get corrected.

That means:

Control loop

We'll do a basic PD loop (P + D). You don't need full PID for first pass.

Definitions:

targetAngle = 0(torso perfectly upright)measuredAngle= tilt angle from IMU (pitch and maybe roll)error = targetAngle - measuredAngleFor left/right sway, you usually correct the roll. For forward/backward lean, you correct the pitch. We'll implement for pitch first and leave roll expansion in comments.

Then:

correction = Kp * error + Kd * (error - prevError) / dtcorrectionto a sane range so you don't fight Auto Position too hard. Example: 8 servo "position units".Then:

finalHipPos = gaitHipPos + correctionWhere:

gaitHipPosis what ARC last told that hip servo to do for gait.finalHipPosis what we actually write to the PWM output.That gives you the "nudge" you asked for.

Architecture on Arduino

We'll do this on a single Arduino that's already acting as the EZ-B:

UART/Bluetooth/WiFi from ARC EZ-B protocol we parse servo position set commands

We store those requested positions in an array

gaitPos[NUM_SERVOS]We run a fast loop:

Important: We do not immediately

servo.write()inside the ARC packet handler; we just updategaitPos[]. The real servo writes happen in our control loop at a fixed rate (for stability timing).That gives us:

Assumptions

We'll assume:

getPitchDegrees().)You can adapt channel numbers and IMU read code later.

Now here's the full firmware skeleton with comments, timing, safety clamping, and the balance nudge logic. It follows your style rules:

How to tune it

Set the right channels

HIP_LEFT_CHandHIP_RIGHT_CHto match your actual hip servos that tilt the torso.servoPins[]so each channel maps to the Arduino pins you're using.Hook up the IMU

imuInit()andgetPitchDegrees().getPitchDegrees()to return positive when the robot is leaning forward.correctionDegor swap the on left/right hips until the correction tries to stand it back up, not push it further.Balance strength

KP= how hard it reacts to being tilted.KD= how hard it resists fast falling.KPorKD.KP.Offset clamp

BALANCE_MAX_OFFSET_DEGis super important.5.0f. If the robot can physically lean more without tripping, increase toward8.0for even10.0f.Roll axis

If you also want left/right stabilization (side-to-side sway), you can:

getRollDegrees().Why this works with ARC (and why it's clean)

That's exactly the inverted-pendulum trick you're aiming for, and it's the safest architecture because it won't break ARC's sequencing.

If you drop this on an Arduino and wire it in place of your current EZ-B-compatible board, you get nudged hip stabilization with no changes to your Auto Position skill logic.

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

Well this is the plan ChatGPT came up with:

Awesome project. Here’s a clean, working baseline you can build on: a PC-side Python gait engine (state machine + per-leg IK + IMU stabilization) that streams 12 hobby-servo targets to an Arduino at 50 Hz, and an Arduino sketch that: (1) runs smooth servo motion on 12 channels, (2) reads an MPU-6050 (or MPU-9250) and estimates pitch/roll with a complementary filter, and (3) speaks a tiny newline-delimited serial protocol.

The walk is a robust, quasi-static gait (keeps CoM over the support foot), with parameters for step length, step height, cadence, and lateral hip shift. The IK assumes 6-DoF per leg (Hip: yaw/roll/pitch; Knee: pitch; Ankle: pitch/roll). Feel free to prune joints you don’t have-everything is centralized in map_joint_order and the IK output.

How this fits together The Python process runs the gait state machine, synthesizes per-foot trajectories, solves per-leg IK, applies IMU stabilization, and streams 12 angle targets at 50 Hz. The Arduino performs safe, smooth actuation, and streams pitch/roll so the Python side can do closed-loop ankle/hip corrections. Keeping the controller split like this lets you iterate gait logic in Python without re-flashing the MCU.

there was a lot of code that needs to be tested but the plan is pretty good and the code looks promising. Now I just need to print a set legs to test it.

You should also look at Athena’s response above

DJ I like what she came up with but it is only balancing two servos for a front or back correction I also need a side to side correction as I have 4 servos in the joint. I also have 2 servos that control the leg for tow in and tow out.

I was able to get ChatGPT to modify your code for side to side corrections also. Not sure if there is a way it could have logic added to catch itself from falling or try to.

Added side-to-side (roll) balance using two additional hip servos, while keeping ARC Auto Position fully in charge of the gait. The firmware below adds a 2-axis PD stabilizer (pitch + roll) and a mixing matrix so each hip servo can get any combination of pitch/roll "nudges" with adjustable signs.

Key ideas:

gaitPos[].corrPitch,corrRoll.{pitchGain, rollGain}(1.0, 0.0, or scaled) to mix those into its final output.Below is a drop-in sketch (supersedes the previous one). Fill in pins and IMU reads and you’re good.

How to wire/tune quickly

HIP_PITCH_*and your two lateral hips onHIP_ROLL_*. If a slot isn’t used, set it to255.pitchGainsigns (e.g., make one 1 or both 1 depending on your linkage). * If tipping left, the left roll servo should push up/right. If it pushes the wrong way, flip therollGainsigns in thehips[]table.KP_PITCH=3.5/KD_PITCH=0.6andKP_ROLL=3.0/KD_ROLL=0.5. Raise Kp until it feels firm, add a bit of Kd to kill wobble. If it chatters, lower both slightly.PITCH_OFFSET_MAX,ROLL_OFFSET_MAX, andTOTAL_OFFSET_MAXto keep "nudges" small so ARC’s gait still reads clean.@Athena Looking at the above code it does not support the ARC Arduino firmware protocol. Can you confirm if ARC can work with this?

Below is an explanation that should clarify how this code relates to ARC's EZ-B protocol:

ARC and EZ-B Protocol Basics

ARC (formerly EZ-Builder) communicates with EZ-B-compatible boards using a defined protocol. A standard command for setting a servo position is sent as a three-byte packet (with the first byte typically being 0x08). This "minimal" packet handler in the code is designed to catch such commands.

The Provided Code

The sketch you’re looking at is a custom extension of the basic EZ-B firmware. It intercepts standard ARC commands (e.g., the 0x08 command) to update an internal array (gaitPos[]) for all servos. Then, for specific hip servos, it applies additional balance correction before writing out the final servo output.

Compatibility Confirmation

Given that the code starts by looking for the 0x08 command (a key part of the EZ-B protocol) and then updates servo positions accordingly, it is designed to work seamlessly with ARC. ARC will continue to send its normal commands, and this firmware extension simply "nicks" into that process to add extra balancing for the hip servos.

Keep in Mind

Conclusion

In short, yes-ARC can work with this code. It supports the core EZ-B servo set command, and by design, it’s meant to be a drop-in enhancement on an Arduino that’s already using EZ-B firmware. Just be sure to tune channel numbers, the mixing matrix, and your IMU functions (imuInit(), getPitchDegrees(), getRollDegrees()) for your particular robot configuration.

If you need further clarification or assistance adapting this code to your robot’s setup, feel free to ask!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.