rregister

Hi all, this is my first post, and so i apologize in advance for etiquette problems (and i will try to learn and improve rapidly.) I'm starting an ambitious project with mutliple EZ-robots (love this system!) and i would like to modify the standard JD head front-piece by adding a 'bell-bottom' as shown in the photo attached (i did try to follow the instructions posted in this forum for attaching a photo) for this character called 'Chime'.

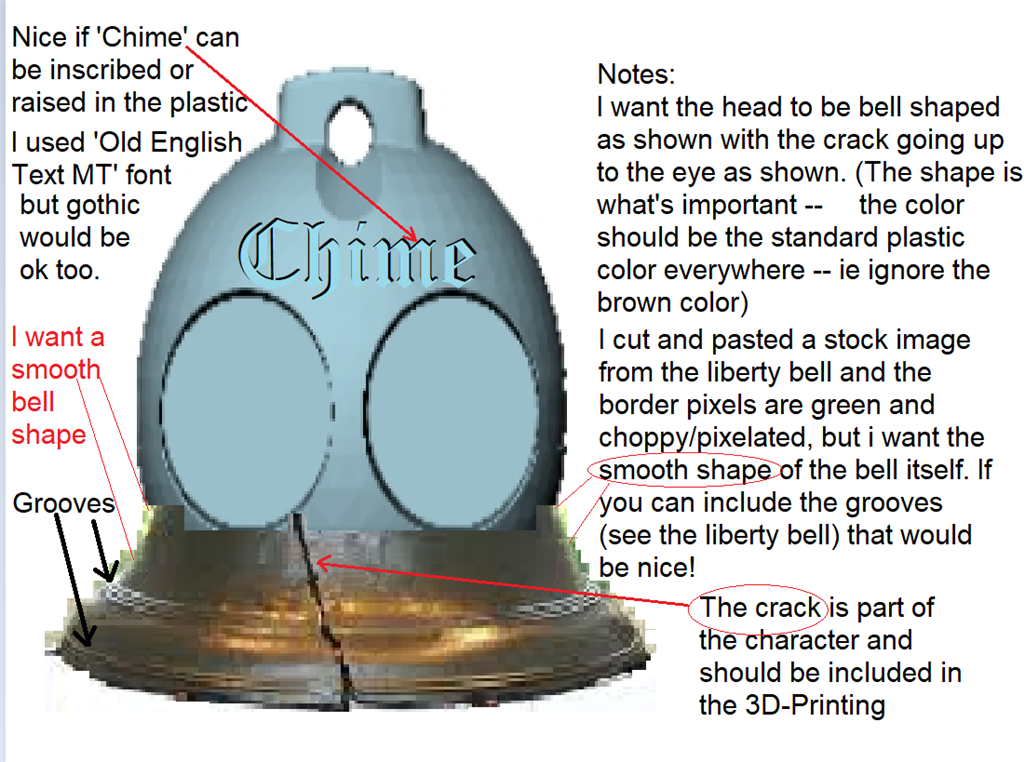

The idea is to keep everything the same and hopefully have no impact on JD's behaviors (e.g. head stands) but add some superficial plastic as shown to add character (so that his head looks like a bell), and it would be ideal if the 'Chime' name could appear centered on the forehead similar as shown. My problem is i have 1) no 3D printer and 2) no experience in this area (other than those 2 issues, i'm extremely well-positioned for a 3D project like this:). If anyone out there has a moment to point me in the right direction, i would be VERY grateful -- thank you! -Richard 'twitch' R.Notes: This character has a crack in his bell, like the liberty bell (this crack can be molded cosmetically in the bell-bottom and does not have to be an actual crack -- ie think of it as 'a scar'). I lifted/overlaid an image of the liberty bell to try to convey to you what i am hoping for, and the result shown in this photo is pixelated/blocky/blotchy/green-brown at the bell-shape perimeter, but i want a smooth bell-shaped perimeter. It would also be nice to have the beautiful concentric grooves at the bottom, which the liberty bell also has. (Note that i intend to use the standard head back-piece molding, because the front is the most important part (but if somebody felt it was no big deal to also add the bell bottom to the back piece somehow, that would be a nice addition).

Hi DJ I realize I'm being a pest, but is there any chance of making this solid works file available soon so Tony can help me with it? (or perhaps there are some proprietary issues involved and you simply can't do it? -- which would be totally understandable if that is the case -- if so can you clarify that?) Thanks!

Richard 'twitch' R.

Hi Tony, I guess that DJ @DJ has stopped following this thread, perhaps because i was too pushy about it (i didn’t mean to be -- maybe he will give me another chance at some point i hope so) or because he has some business-reasons for not wanting to make the solid works file available, or perhaps he is simply too busy to help out right now.

Whatever the reason, I wanted to get your opinion on how best to proceed from here? I am reluctant to keep pestering him because perhaps he is already mad at me and if so I don’t want to make it worse. Are you willing to try with the .STL file, or do you have any thoughts or suggestions?

Thanks for any ideas, -Richard 'twitch' R.

Hi Richard, I don't know why DJ has not responded to you, very out of character for him. Anyway, I'll mess around with the STL file and see what I can do. When imported into a CAD program they (STL files) are represented in (tens of)thousands of triangles so don't always play well with new geometry. I am involved with another project at the moment so can't give a definite date for completion.

BTW I changed my username to 3dPrinterGuy.

Hi Tony, (yes it seems unlike DJ based on what i've seen throughout the forum -- he's always so enthusiastic and helpful about people's projects, which is really great -- but I will respect his reasons, whatever they may be, and hope that he will clarify the matter for me eventually when he has time.)

ok -- so that is why the solid works file would be a better starting point -- makes sense.

ok i will be very patient! (and please let me know if i'm being otherwise). (and I like the new 3dPrinterGuy moniker) best regards and thanks again, -Richard 'twitch' R.

Hi Richard,

While you wait you could always try printing the JD head and the Bell as 2 separate pieces and then combine them with super glue, hot glue, acetone, etc. It might help with the designing process as you can mechanically see what works and what doesn't.

I'm not able to get the origin of the 3d printed STL for you. The origin of the stl's appear to have been misplaced. All we have are the injection mold origin files in solidworks, which are not the same thing.

I'd go with what Jeremie mentioned - for two reasons

i can't get u the original files

printing the head with the bell is gonna be a nitemare of support material anyway

I do agree with Jeremie and design a skirt for the existing head that converts it into a bell. And attach it with super glue

That way you maintain the integrity and strength of the original injection molded plastic

i found this 3d print of a bell.

bell

@rregister You can do what you want to do just in TinkerCad in about 15 minutes or so. Find a STL file of the liberty bell and import it to Tinkercad ...Cut off the part you don't want... Now import JD's head and merge the portion of the liberty bell (skirt) that you do want to JD's head to the position where you want it in... Combine the two parts then download them as one STL file... Done

However, I would do what Jeremie suggested (post #22) to do because of the amount of support material that is going to probably be needed if you print them as one big part...