Andy627

Germany

Asked

— Edited

Hello, I have a question .

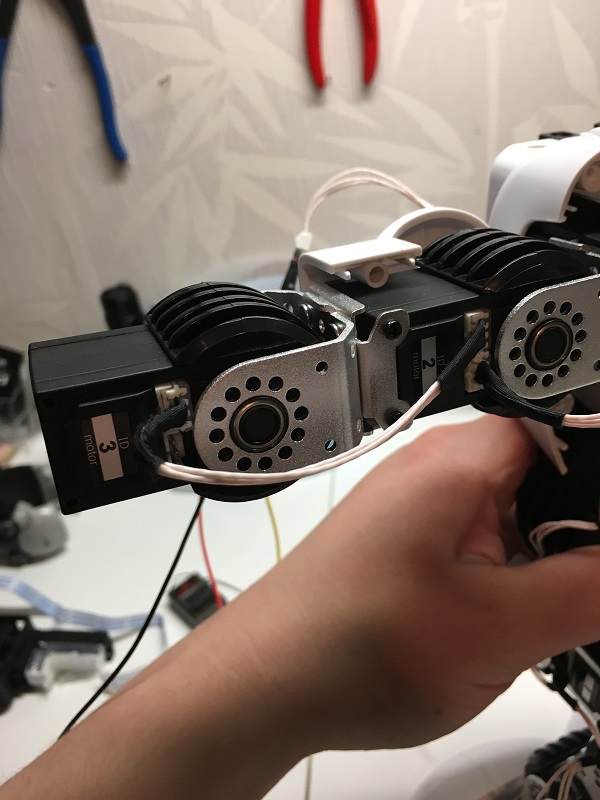

I have these servos in my robot and have now bought the EZ-B V4.

But if it does not get to work, can the Ez b control these servos?

The servos are all connected and the controller only has 1 cable

greetings

Can you post more details:

Servo brand and model ?

or

Product/Kit details ?

Hey, thanks for your answer.

It is the Ubtech Alpha s1

Data of the servo:

UBTECH Alpha 1S Robot Parts Digital servo UBT-12HC

description:

Model UBT-12HC Communications: Serial communication Speed: 6.5V: 0.238sec / 60 degrees 8.5V: 0.198sec / 60 degrees Torque: 6.5V: 8kg.cm 8.5V: 12kg.cm Gear: Copper alloy gear Bearing: Ball Bearings Angle range: 0-180 degrees, Adjustable Dimensions (mm): 44 * 22.5 * 29 Weight (g): 42 Amount of operating voltage (V): 7.4V Stable Current: 2.5A Operating temperature range: 0-55 ? Protection: Over Voltage, Over Current Dead bandwidth (no reaction zone): 0 Feedback: Position / angle feedback

If there's a data sheet for the serial communication protocol, then it would be an easy implementation as a plugin. Post the datasheet and I'll take a look.

I can't find the datasheet that contains communication protocol. Can anyone else find it? Maybe ubtech customer support has it

There is no contact to get with ubtech.there is not even a forum.

Can not find anything to unfortunately That's a shame I was so happy to test my ezb.

That's a shame I was so happy to test my ezb.

Is it possible to read the datasheet of the servo via the Ubtech Pc software?

not with the standard program from alpha1 and 2 this is the only link i can google.

ubtech