MovieMaker

USA

Asked

— Edited

I thought I would start a new page. I would like to completely delete the old stuff. I will have pictures soon. They are already taken. I have had my struggles, so i named her Botchy instead of Sunshine.

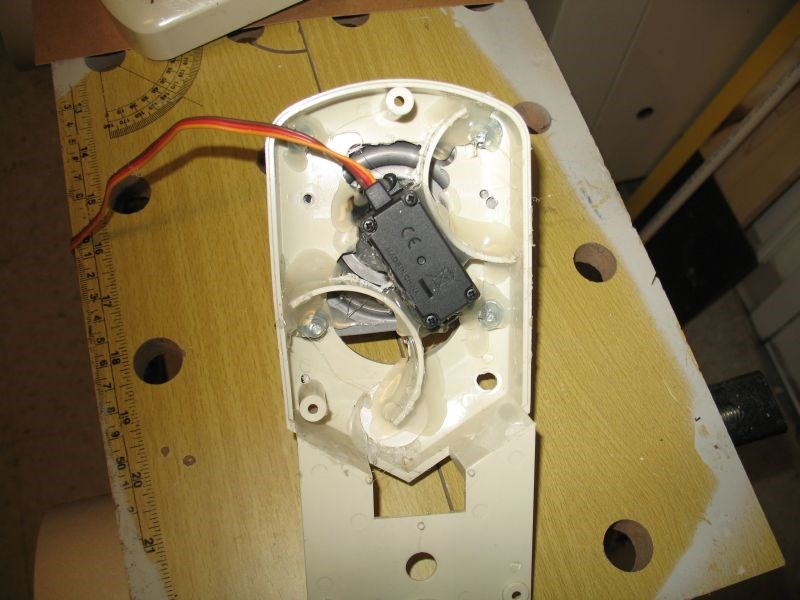

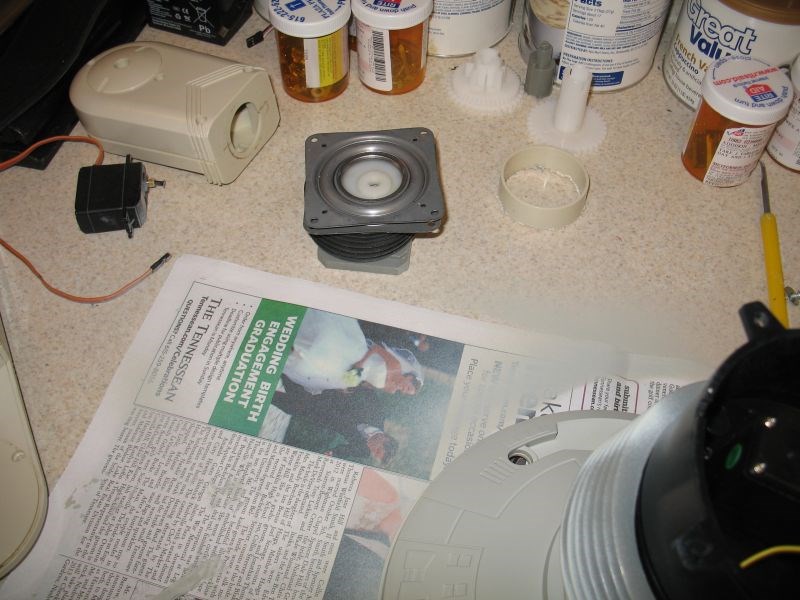

Here are some pix:

Thanks for your support!

:D

That is what I have so far.

That is possible. I am just letting her set until I can get my faculties back. It was such a blow. After I come to my senses, I may have to rewire everthing. But, the problem is, I can not get to everything. If I had to redesign this unit, I woulld build Modules and wire them separate and just hook them together. But, this unit has wires running from the head to toe.

I made a ground bus bar. And a twelve volt terminal strip, And a 7.2 volt terminal strip. I was thinking the batteries were low. But, when I hooked up the charger, it said they were fully charged. I have three twelve volt batteries in there.

I almost always figure these things out. But, I can not see very well what I am doing.

I will just pray for God to help me.

Thanks for your support.

Oh man Mel, I am sorry! I know how that feels.

Mel, try not to panic. It's probably something very simple. More then likely a broken wire, loose ground or a connection or switch mis-wired. You've done a lot of changes in the wireing by adding in the switches and then all the wires coming loose then having to reattach them all. You need to triple check all your wireing to see if it's properly connected and proper wire going to the proper place. If you cant follow the wires with your hands and eyes you need to disconnect one at a time and check continuity with a tester. You should probably do that anyway with all suspect wires just in case one came loose or broke. Testing for continuity is the best way to see if power is getting from one place to another or if there are shorts.

Most of my problems come from mis-wireing or bad connections. I dont think you broke your motor from a 3' fall. I know you didnt break all of them. So take a deep breath and get right in your head. Just resign yourself th the fact that you need to slowly recheck everything and it's going to take some time. Who knows, I bet you run across things that are not the problem but need to be fixed also.

Now, Start at the beginning. That's usually where the power starts. Make sure you have proper power to the effected areas. Also make sure all your grounds are properly connected. Pay special attention to the grounds. Then move to the signals and make sure your getting the proper voltages when that port is turned on and off.

One more thing and you may want to do this first; Test for proper power and signals coming out of the EZB and any outside power source (if your useing one) with everything disconnected. If you start getting weird readings or something does not seem right turn off power to the EZB for at least 30 seconds and then reboot it. I've had ports on the EZB lock up when testing them. Look for proper 5vdc on all power pins, Common ground between all the grounded pins and 5vdc on and off when you turn that signal pin on and off in ARC. Once you know your EZB is working properly you can feel confident in your test results as you move through testing the rest of your wireing in the robot.

This is the only way unless you want to use the scatter mathoid (just blindly checking this and that) and hope you get lucky and find something.

Good Luck, Dave Schulpius

Thanks , Dave. What you said means a lot to me. I have been doing this for over 40 years. I always wire, check, double-check. Then power up and it almost always works the first time. Of course I run into bluetooth problems and such that I have to get going. But, never a problem with the hardware.

So, that is where I started today. My configuration is as follows:

EZB1: in the upper body. It controls the arms and head and waist.

EZB0: in the lower base. It controls the motors, navigation and soundtrack and sensors.

I would have usually wired the batteries in PAR and then go to a regulator, etc.

But, what I did this time is run a ground BUS BAR. All grounds when there. Then, I ran a 12volt terminal strip. It took everything 12vdc.

Then I ran a 12v to 7.2 regulator to another terminal strip.

I was going to run another 12v to 7.2 regulator, but I decided not to.

so, I fed all of the 7.2 from the 7.2 terminal strip.

I also had to run a ground and red wire which was 12volts to the servo server. (you know, I don't know what it is called, but it is supposed to protect you from brownout.

From the servo thingy, I ran the ports to the EZB1.

I have two special testers that I made. One is to test servos and the other LEDs.

I put the LED tester on the wires coming down from the head. Most of them worked. A few did not. On the ones that did not, I put the servo tester. I got a bump out of the servo and that is all I needed to confirm where it was going.

I hooked it all up. Then it fell down. I took the fall for it because it fell on me. so, there should not have been that many gs of force on it.

Anyway, the first time I hooked it up, I could not hook up both ports on the netbook. I could hook one on the desktop and one on the netbook. I wrasseled with that for some time.

OK, here is where I am:

I am using Buck regulators. Out of the three I got in, only one seems to work well. I cannot adjust the voltage on it. so I just left it where it was. One did work and it was for the 7.2. (I was thinking. I may have hooked both sides of the 12volt Bus to the Buck regulator. That would have shorted it out and caused it not to work properly. that is a possiblity.)

All EZBs are getting 7.2 volts. All motors are getting 12volts.

Only a couple of Head wires are working. I need to fix the LowerRight eye D-15 the Upper Right eye D14,the waist D15-19,Upper Left eye D-11,Righteye D-0, and, Right shoulder.

When I give it directions from the direction pad, it goes forward, Backwards (really fast), and it turns Left, but when it is told to turn Right, it just sort of BUMPS in that direction.

The neck pan works fine, but the tilt is DEAD.

Most problems seem to be in the neck and Head which is the hardest for me to work on.

I haven't placed any sensors on it yet. I wanted to get everything else working. It really made me sad, because I have so much money invested in it. But, after a couple of days, I picked my feet up off the ground and I am taking my time working on it.

I have found one data cable connected to the ground on the digital pins. I found one cable not connected at all. So, I guess I will get those two working and it will be a start.

Thank You all so much for your support.

:)

Chin up Mel. My E2 project took a couple spills last night. Only damage was I striped the inner thread, the one where you would screw an arm or horn into. Gears and everything are fine so it's usable for something else just not a shoulder. I have a new servo coming.

Good luck. My thoughts are with you and Botchy.

Update** I found the vertical tilt wire. The servo is just to weak to lift the head. I have to completely redo the Head and Neck. I am concerned about the grunt when You turn it to the right. but, I haven't tried it with a script yet.

I will be waiting for parts to arrive.

Thanks for your support.

Mel, Glad your making progress! Take it slow and make sure everything is hooked up properly. I think once you've got that straightened out and the proper voltage being delivered your going to be OK. I cant help but repeat though that I think you should invest in a digital multi tester and use it to test for proper voltages and continuity. You can find them almost everywhere at affordable prices.

I'm concerned that your servo wont lift the load of your head. How heavy is the head and what type servo are you using? I'd think a standard servo would be OK for you here. Also the laboring sound you hear when the head turns to one side is troubling. Do the rotation and pivot points turn and lift freely? Make sure nothing is binding or sticking in there.

I have a multimeter and the voltages all measure fine.

I don't hear any sound on the servo, I just feel the magnetic field. If I help it, it works. But, unless I help it, it doesn't work. It is possible my neck is too tight, I mean the flex tubing part.

The Grunt I hear is when I try to turn to the right on the base. It goes forward,backward,left. But, when I tell it to go to the right it just grunts a little and goes to the right but only for a half of a second.

Thanks, Guys for your support.

:)