Asked

— Edited

3D Print Jd Head

hi

has anyone printed a jd head?my question is ,how do you print the head on the printbed?

thank you

Related Hardware (view all EZB hardware)

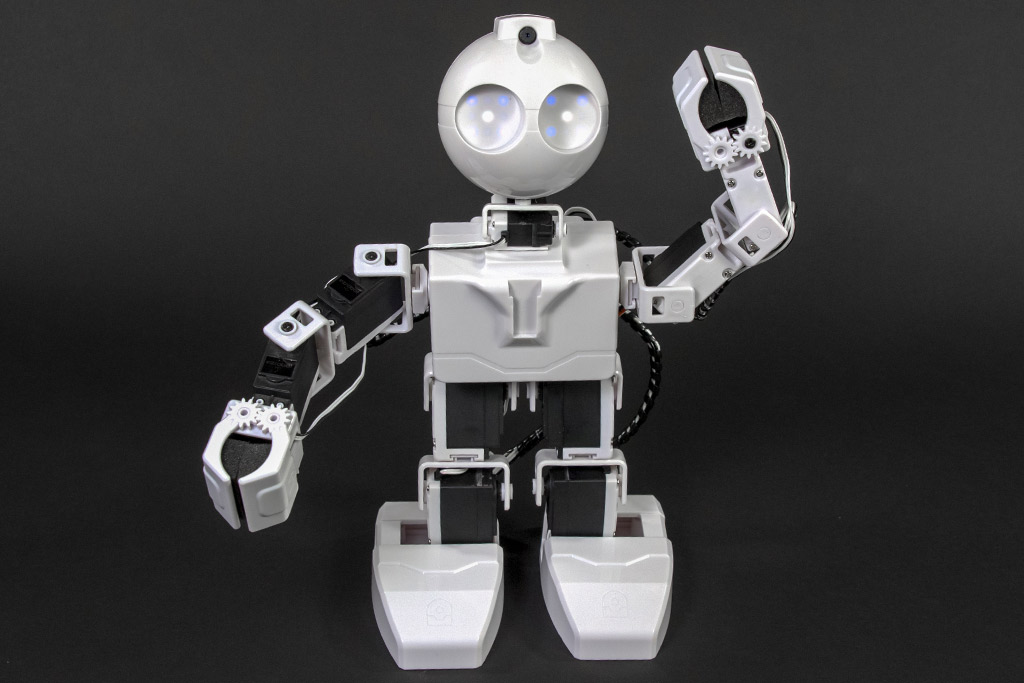

JD Humanoid

by EZ-Robot

JD humanoid robot kit - WiFi-enabled, 16 DOF with metal-gear servos; easy, fun, educational, available from the EZ-Robot online store.

Wi-Fi / USB

Servos

24

Camera

Audio

UART

3

I2C

ADC

8

Digital

24

Related Robot Skill (view all robot skills)

File Manager

by Synthiam

Displays files currently open for reading by scripts, shows only read-opened files, helps diagnose read/write locks and file access errors.

i ordered some wood to make an enclosure.i can print 3 parts in a row without cleaning the glas. then i scrape the glue off and clean with isopropyl.90%.good am using junk pla.

for me abs will be for much later.

pla.

for me abs will be for much later.

@nallycat no encloser, but i has been try printing inside the box, but is fail

EricEZ

do you have a picture of a failled print? that can be very helpfull.

@EricEZ A failed print usually means that object did not stick to the bed, it will release if it warps. if the bed is not prepared properly, the first layer is made to far from the bed and if the speed is to fast, and in the case of ABS cooling is to fast. check your print nozzle to bed spacing the bottom of the print should be as smooth as the glass it is printed on you should not see individual print lines. Make sure you print on glass use hairspray, check your nozzle height from bed one sheet of printing paper. in the slicing program slow down the first 2 layers. do not use a fan, cover the printer so it is warm inside the box or enclosure before printing. IF all of this fails I suggest you use PET G instead of ABS, PET G is stronger then ABS but is much easier to print you do not need an enclosure. bed only needs to be 60-65 deg C hot end temp is the hottest suggested temp listed on the filament roll. maybe 220c you must use retraction. as PET G is stringy and you will get lots of strings if you don't, but to much retraction will result in nozzle clogs. I use 3mm with my all metal hotend, you may need more retraction if you use a regular hotend. run a test print 2 test cubes on the build plate. there should be no strings between the cubes if there is then increase the retraction 1mm, test again until there are no strings. I have built two Inmoov robots using PET-G and never have a Print failure or strings. use weldon 3 to join PET G prints it is a solvent weld and is stronger then the print itself.

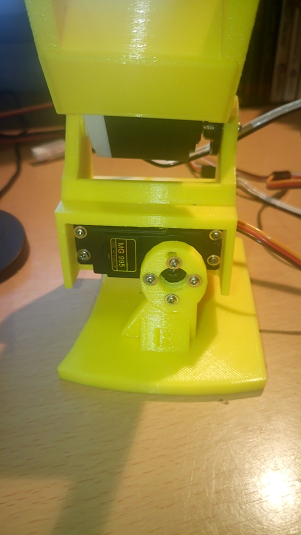

new colum .servo is less viseble.

new colum@Nomad6R very nice, and neat, I can see that servo is further in. good Job.

hey nallycat

the printer is awesome.i could use 10 off these.xD.and 50 rolls yellow.

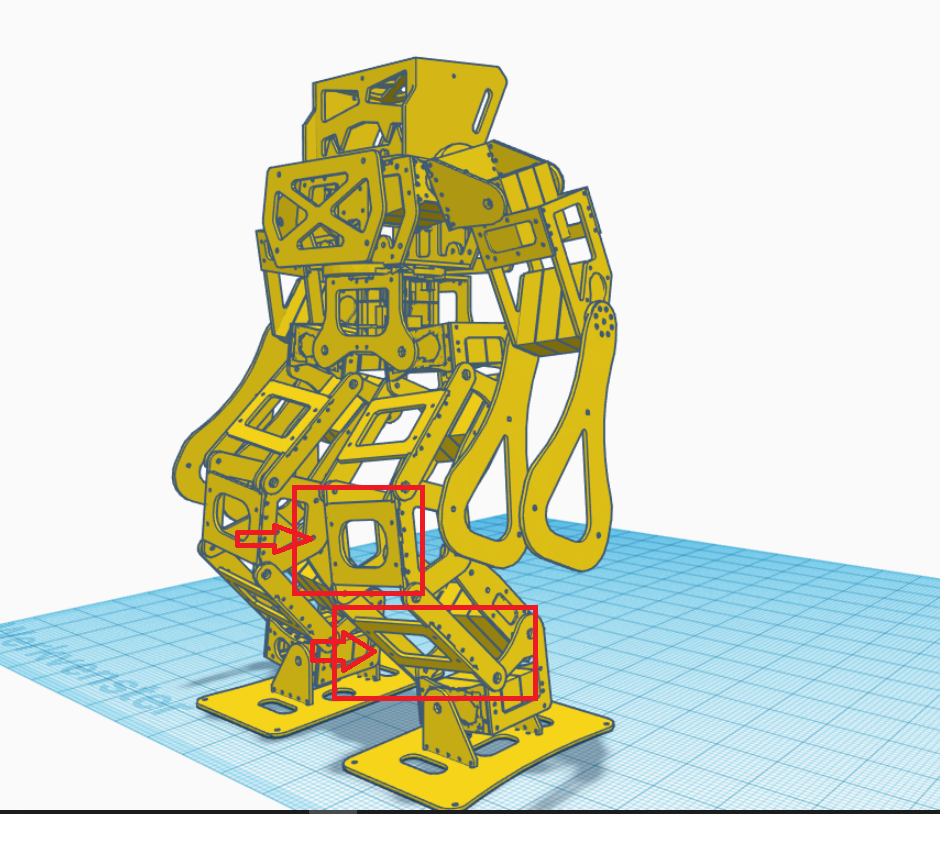

next to come is the front supports and knee.

thanksDid you build that one, its really cool!! Awesome robot design, you should make a seperate thread for this build!!