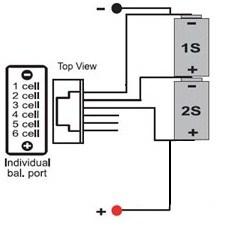

As also posted in my Hearoid showcase topic, but useful for anyone running LiPo batteries (could be adapted easily for 3S and 4S without too much of a problem).

Parts needed: 1 x Zener Diode 5.1v 500mA (Farnell ref 1861447) 3 x 100k ohm Resistors (Farnell ref 9339078) 1 x Small Piece of Strip Board (12 strips x 7 rows) - Maplin FL17T 3 x Pin Header (1x3) or 1 x Pin Header (1x3) and 1 x Pin Header (1x6) eBay Search 1 x servo Extensions (male to male) - made from 2 normal ones cut & soldered. Solder Soldering Iron Cutters

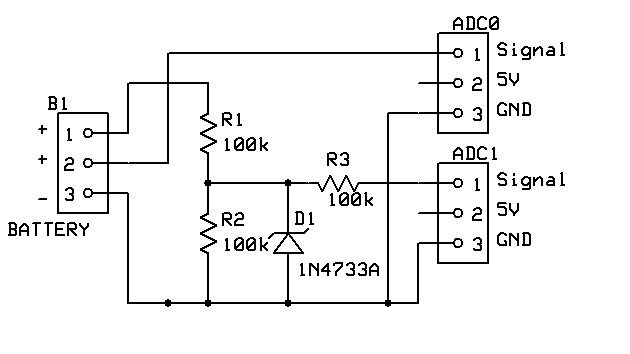

The Schematic:

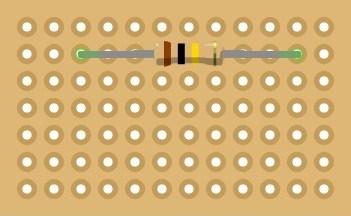

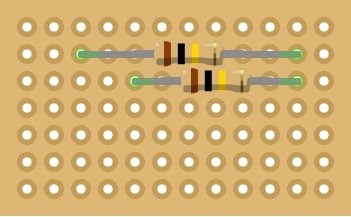

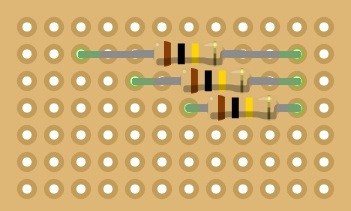

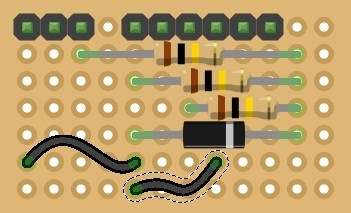

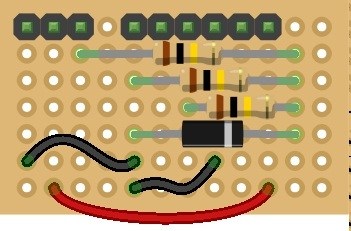

Method:

Solder R1 - 100k resistor from Row 2 Column 3 to Row 2 Column 11

Solder R2 - 100k resistor from Row 3 Column 5 to Row 3 Column 11

Solder R2 - 100k resistor from Row 4 Column 7 to Row 4 Column 11

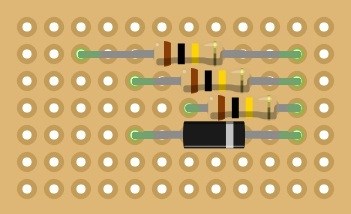

Solder D1 - Zener Diode from Row 5 Column 5 to Row 5 Column 11 (Band to the right)

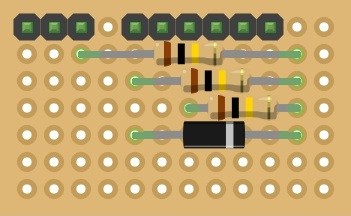

Solder the pin headers on Row 1 Columns 1, 2, 3, 5, 6, 7, 8, 9 & 10

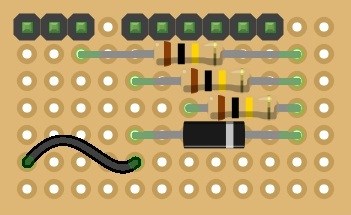

Solder some black off cuts of wire from Row 6 Column 1 to Row 6 Column 5 and from Row 7 Column 5 to Row 6 Column 8

Solder an off cut of red wire from Row 7 Column 2 to Row 7 Column 10

You're all done. Plug the balance port connector in to the 3 pin header on Row 1 Columns 1 to 3 (Ground to the left) and plug in some servo extensions (male to male) or 3 pin JST to servo on the two other headers (Ground on left on both), connect the other ends to ADC0 and ADC1 (or any other two ports if those are taken but you will need to adjust the script below if you do).

Now, to use the information in ARC...

The EZ Script

# Read voltage level of 2S LiPo battery and report to software.

# Set variables

# Change $vundervoltage to the under voltage of your specific battery (leave at 3v if unsure)

# Change $vcritical to your lowest voltage you wish for the battery to get before human intervention

# Change $vmin to low level alert value

# Change $vmax to battery full charge

# Change $multiplyer if using voltage divider

# Factor is 5/255 for adc value conversion to volts

$vundervoltage = 3

$vcritical = 3.5

$vmin = 3.7

$vmax = 4.5

$multiplier = 2

$factor = 0.019607843

:ReadCells

# Get ADC values

$vc1 = GetADC(ADC0)

$vc2 = GetADC(ADC1)

# Convert values to voltage

$cell2 = $vc1 * $factor

$cell1 = $vc2 * $factor * $multiplier

$cell1 = $cell1 - $cell2

$batteryv = $cell1 + $cell2

# Check for errors on circuit

IF ($cell1 > $vmax or $cell2 > $vmax)

Print("Battery Monitor Error")

Print("Check Monitor Circuits")

# Check for errors on battery connection

ELSEIF ($cell1 <= 0 or $cell2 <= 0)

Print ("Battery Connection Error")

Print("Check Battery Connection")

# Check for under voltage

ELSEIF ($cell1 <= $vundervoltage or $cell2 <= $undervoltage)

Print ("Battery Under Voltage")

Print("Check Or Replace Battery")

# Check if at critical levels

# Cell 1

ELSEIF ($cell1 <= $vcritical)

# Do sometihing if critical

Print("Cell 1 Critical")

# Shut down all power, switch to back up battery alarm?

# Cell 2

ELSEIF ($cell2 <= $vcritical)

# Do sometihing if critical

Print("Cell 2 Critical")

# Shut down all power, switch to back up battery alarm?

# Check if below recommended levels

# Cell 1

ELSEIF ($cell1 < $vmin)

# Do sometihing if voltage low

Print("Cell 1 Low")

# Cell 2

ELSEIF ($cell2 < $vmin)

# Do sometihing if voltage low

Print("Cell 2 Low")

ELSE

# Output voltages

Print("C1 Round($cell1,2)V")

Print("C2 Round($cell2,2)V")

Print("To Round($batteryv,2)V")

ENDIF

# Wait 5 seconds

Sleep(5000)

# Go back to the start

Goto(ReadCells)

Note: The should be just a normal closed bracket ) but the forums tend to think otherwise.

Update: Refer to page #2 post #18 for updated code taking in to account the updated syntax

I just read your post again @fredebec. This circuit doesn't shut down the power on low voltage and needs to be connected to the EZB with ARC running for it to warn.

I am thinking up a low voltage shut off circuit too, along with the possibility of adding in a low voltage alarm which is independent of the EZB (like those little lipo monitors that plug in to the balance port). I have a few ideas so far but nothing perfect yet... watch this space though

Although if you (or anyone else) have ideas on that please share.

@Rich, I understand that your circuit does not shut down power, but I think it is a very interresting power monitor. For now, I have a led connected to the Lipo with changing color when the battery go down. However, it do not reflect the balance between the two cells and moreover it is only a visual warning... I want to use your circuit (and script) to monitor the power and send me a message or a tweet if power is too low. Remotely shutting down the power is another story...

Just thinking outside the box.

I use cell monitors from E-Bay for all my LiPo batteries. Rather than re-invent the wheel, maybe we could mod these to give a warning to the EZ-B?

I really don't care about individual cells. The LiPo cell monitor start chirping as soon as one cell drops below 3.3v. Maybe tapping into the alarm leads would do the trick?

Might be an easier route than building the circuit? I buy these things for $2-$3 bucks each.

Just a thought. Back to hide under my rock.

It make sense. just an idea as i am not sure of what monitor type and feature you have . However , If you have simpe led indicators such as green and red LEDs on board, We can activate an electronic relay out of it to provide the supply to the EZB with the robot components. If both LEDs are off or simply only the green one. The relay can be deactivated and ultimately will cut the main circuit.

A good thought, and one I had but found it to be much easier to just build the circuit, the cost is minimal (3 resistors and a diode from memory).

If the alarm buzzer is less than 5v you could just feed the +v in to an adc, when it activates acd changes and ARC knows. I plan to do something similar with my lipo charger which has a green light that turns on/off when charging or finished.

This should be listed under tutorials. Nice.

I'm sure that eventually all tutorials etc. will get listed as appropriate. It's in the tutorial index I started, which is marked as a tutorial so it's halfway there

I had a few minutes spare so adjusted the script to suit a 12v Lead Acid battery (or any Lead Acid battery really)

This assumes a 1/4 voltage divider has been used to drop the 12v down to 3v which is suitable for the ADC port (5v max). If you use a 6V battery you can use a 1/2 voltage divider and adjust the values to suit.

Default voltage levels are based on 12v Lead Acid. Divide these by 2 for 6v Lead Acid. Multiply by 2 for 24v Lead Acid. Etc.

Hopefully it all makes enough sense to be usable and adaptable for anyone and any battery.

I plan to add in automatic calculations for different voltage levels and output to LCD display. I can also adjust it for any battery type, please request your specific battery type should it not be covered.