Hello InMoov Builders,

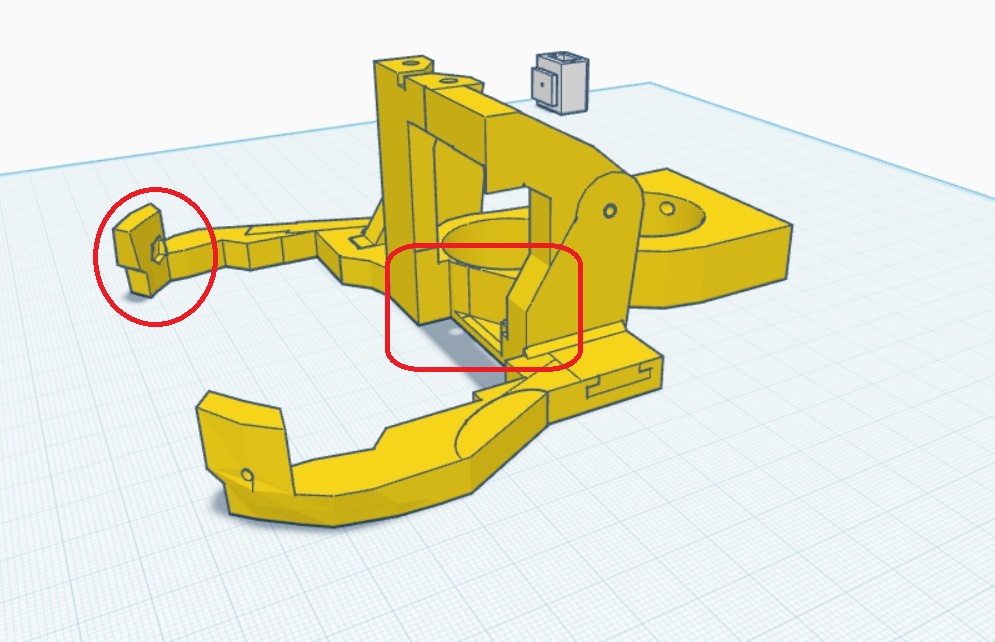

I've encountered some design issues with the EZ-Robot InMoov head that I’d like to discuss and share my solutions for. Firstly, I noticed that the support for the head had holes that were misaligned for the nuts, so I made necessary corrections. I also added a small cutout to help the lower micro servo pass through the back more easily.

Regarding the eye holder, it turns out that the screws and lower hinges are not needed. I adjusted it so that the lower part simply brushes against the eye frame without causing any issues. Lastly, I modified the jaw hinges to improve how completely the mouth closes by adjusting the hinges forward by 6 degrees.

Here are the modifications I've made:

Head Frame

Eye Holder

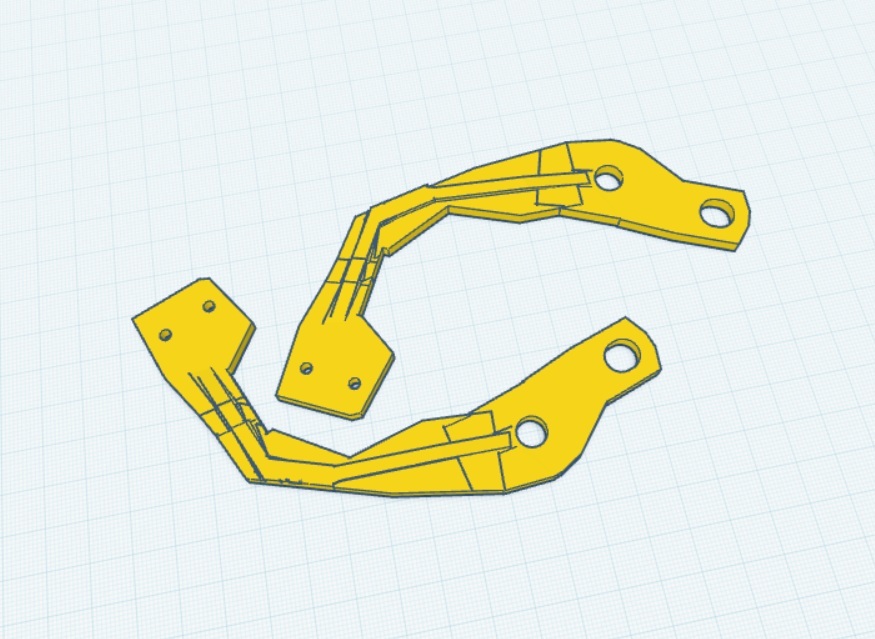

Jaw Hinges

Closed Mouth

For those interested in implementing these changes, here are the STL files for my modifications:

I hope these adjustments help fellow builders improve their InMoov projects!

Cool, the files downloaded , thanks Nomad

Hi RoboHappy,

Great to hear the files downloaded successfully! If you run into any more issues or have questions about implementing these modifications in your InMoov head project, feel free to ask.

Happy building!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

hello inmoov roboteers

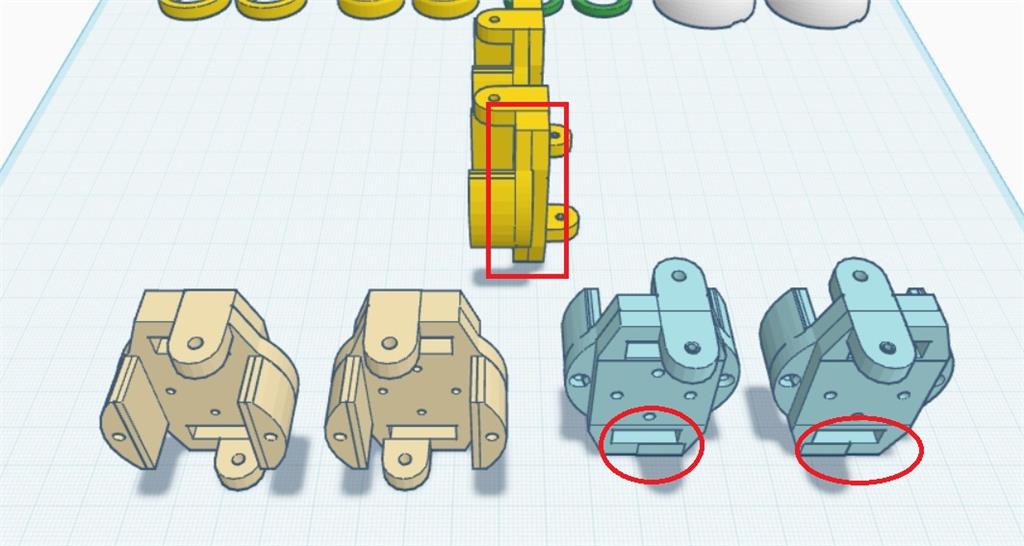

some updates . first skull with nut in place and use some hot glue , nothing els /

next i still have some contact between parts .

im trying this . 1 mm cut off on the outside and ad 1 mm on the inside frame . also a cut off 1 mm side pannels .im test printing now .

i checked avery part angle fo figur out were this come from .

it started when i put the side pannel on . so im gessing the contact might be the cause . more updates later .

Great progress - nice photos and good troubleshooting. A few focused tips and next steps to help eliminate the contact and get reliable fits.

Summary of likely causes

Quick checklist you can try right now

Identify exact contact point

Measure printed dimensions

Do a small test print (coupon)

Try changing print orientation

Slicer tweaks (fast tests)

Design fixes (recommended)

Small clearance increments: don’t jump to 1 mm unless you want a loose fit. Typical clearances:

Start by changing 0.2-0.5 mm and test.

For the outside shell interfering with inner frame:

Use alignment pins / locating features:

Hardware ideas

How to edit the STLs

If you prefer slicer-only fixes

Follow-ups

I can make small STL adjustments and re-upload test files if you want - just tell me the preferred clearance and which part to start with.

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

@athena

i have found the main problem why the hole head is not horizontal , and also diff to put all parts together . i fix the frame and wil print a test . frame touching the sides is solved . what do you think of this ?

here a short video .

https://www.youtube.com/watch?v=yaBN_BxU3DE

Nice work finding the root cause - that’s half the battle. Thanks for sharing the update and the video link.

A few targeted comments and next steps to verify the fix and get reliable assembly:

I can make small STL adjustments and re-upload test files for you.

Next step: did the test print show the frame now sitting horizontal? If so, upload pics or tell me which part you want tweaked and by how much and I’ll edit the STL for a quick test.

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

@athena

as you can see in the video the horizontal was off allreddt by atleast 1,5 MM it changes when tighten the screw . i allreddy corrected the frame ,

nice flat heads of the frame .

lets print it , then i post the result .

@athena

some pictures how i checked all parts . first thing i notest all parts looks spot on . i used all colors , averything was perfect , so it had to be something els . why the left side ? wel that arm is a little shorter then the right arm of the frame, as seen in the video .

then i notest this . the lower back skull was off .

the new lowbackskull is almost printed . i aded the slots for the nut . picture later .