Describe Your Robot Arm For Kinematic Robot Skill

We are in the process of developing a dynamic configuration system for robot arms, which will be compatible with a variety of robot arms and joint numbers. We kindly request your valuable input regarding your robot arm configurations to make this system as versatile and effective as possible.

One of the critical aspects of this project is understanding the layout and specifications of various robot arms. Your insights and contributions will significantly aid in developing this dynamic configuration system. Here's what we're interested in:

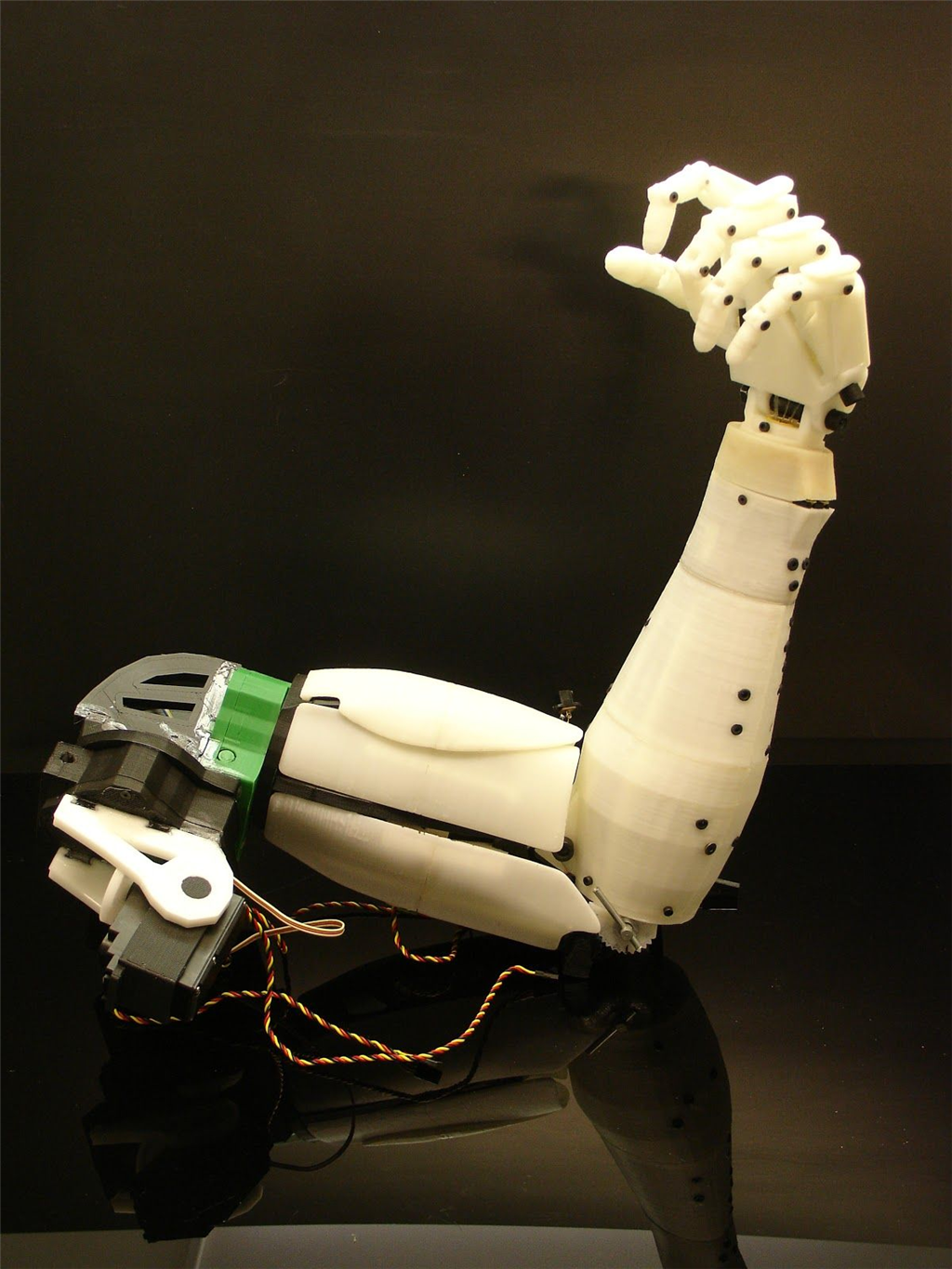

1. Configuration Description: Please describe or provide a picture of your robot arm's layout. Share details such as the number of joints and a brief overview of each joint's axis of motion. For example, does the base servo rotate the arms UP/DOWN, LEFT/RIGHT, or have any other specific functionalities?

2. Joint Axis Information: Provide specific details about each joint, including its range of motion, degrees of freedom, and any unique features or constraints.

By sharing these pictures or details about your robot arm (or plans), you can help us build a more inclusive and adaptable system, accommodating a wide range of robotic arms with different configurations. This system will open doors to numerous applications, including object manipulation through camera detection, remote control via hand tracking in VR, and many more.

Feel free to reply to this message with your robot arm details. Thank you for your time and expertise!

Not the best robot arm I have used and you have to slow servos down or it literally falls apart but hey took like 30 minutes to get a somewhat working robot arm. I think it needs someone smarter and with more patience than me to create a working control panel that doesn’t allow the servos to smash into each other or objects when moving. It was able to lift weight of a servo and manipulate an object.

but hey took like 30 minutes to get a somewhat working robot arm. I think it needs someone smarter and with more patience than me to create a working control panel that doesn’t allow the servos to smash into each other or objects when moving. It was able to lift weight of a servo and manipulate an object.

Do you think it could lift more if the rotation servo before the gripper was removed? I don’t see the use for that gripper as the arm can rotate from the base anyway

I honestly didn’t weight test it just picked up a servo cause it was on my desk. The rotation servo proved useful as I was trying to draw on my iPad with the pen.

Okay but there already is a rotation servo at the base. So it’s redundant. I don’t see how it would benefit a kinematic solution. I do it it would ever get used by the system because the base rotation servo would take priority as it moves the entire arm.

also that would make the gui designer super extra complicated for you to use. I think it’ll be best to leave it out as it’s extra weight that doesn’t have an advantage. Let me know if you think otherwise if I’m missing something

What do you think about developing a skill that could control an arm that has both DC gear motors with encoder feedback and servos? DC motors are strong and quick. They are good to use on big arms at the joints that need to move a lot of asymmetrical weight quickly, like the elbow or shoulder of a human arm. Servos are good for precise and careful movements like positioning and griping. like the wrist and fingers.

The arms on my full sized Lost In Space B9 Robot is built with both DC motors (at the elbows) and servos for the wrists and claws. They are strong and quick and work a lot like human arms (about the same size and weight). However it was a struggle in ARC to get the dc motors to work in unison with the servos to look like natural arm movement. I ended up using ARC's auto positioning skill for the servos and placed scripts in it to read encoders and move the DC motors. I had to place these DC motor scripts in the proper AP frames that moved the servos. I hope that makes since.

Good point and it was just an evolution as I was playing. Initially in top photo the gripper was mounted vertically under the rotation servo so I could rotate the gripper to pick up a pen from the table. I’m the second photo I just moved the gripper so I could write with the pen. Could you reach every point on a horizontal plane without the second rotation server if I just mounted the gripper sideways? I think you could but I don’t have inverse kinematics cool

You will soon nink haha

dave, the encoders will need to be connected with a robot skill that converts them into servos. That’s possible with kangaroo and saber tooth.

so I’m mocking up the designer. You’ll add each joint with parameters that define what axis it moves and the offset. I’m trying to make it easy friendly. It would be nice if it created a graphic as you did it. So I’ll work on that next.

The dimensions from joint centers is crucial so get your caliper out. No guessing or it won’t work. Has to be accurate to the mm

ok this probably won't work with EZ-Robot_Arm as there is lot of play in it. I think you will need something more rigid to calibrate this with screws and aluminum horns / brackets like the initial Arm you posted with EZ-Robot servo's.