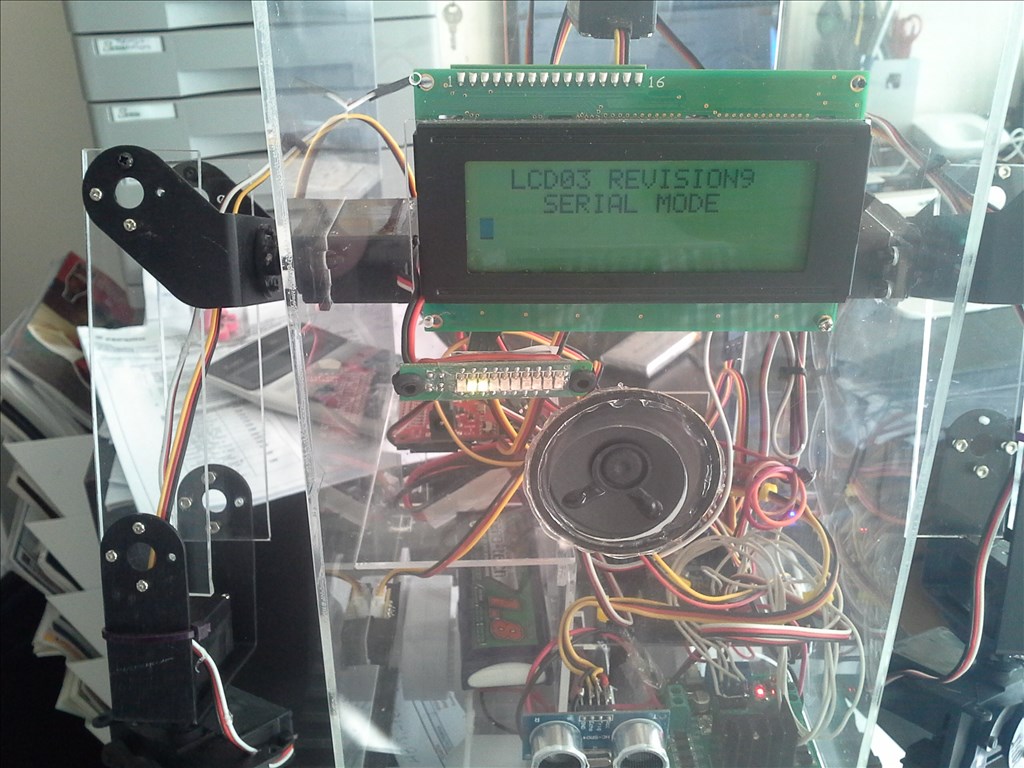

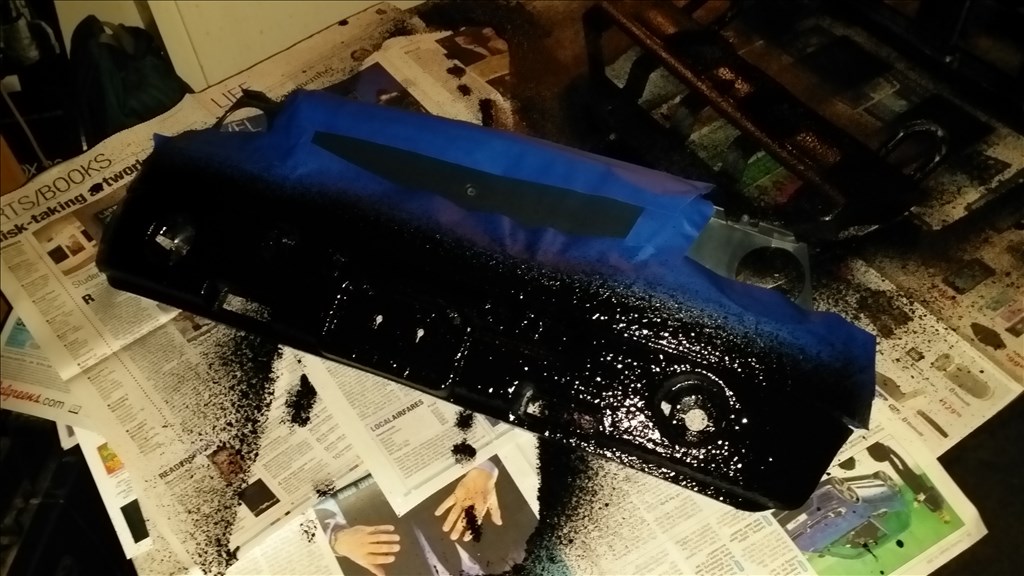

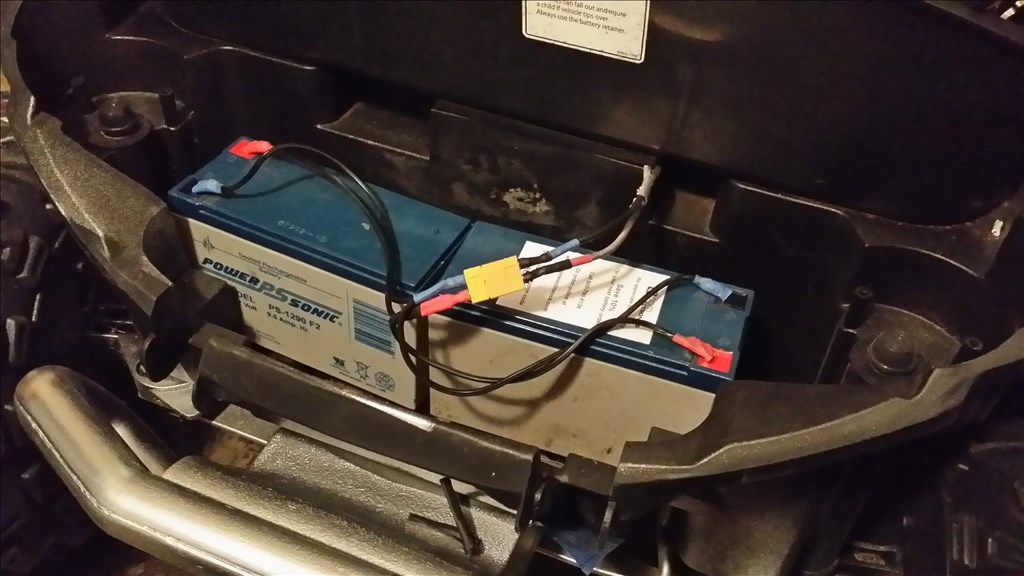

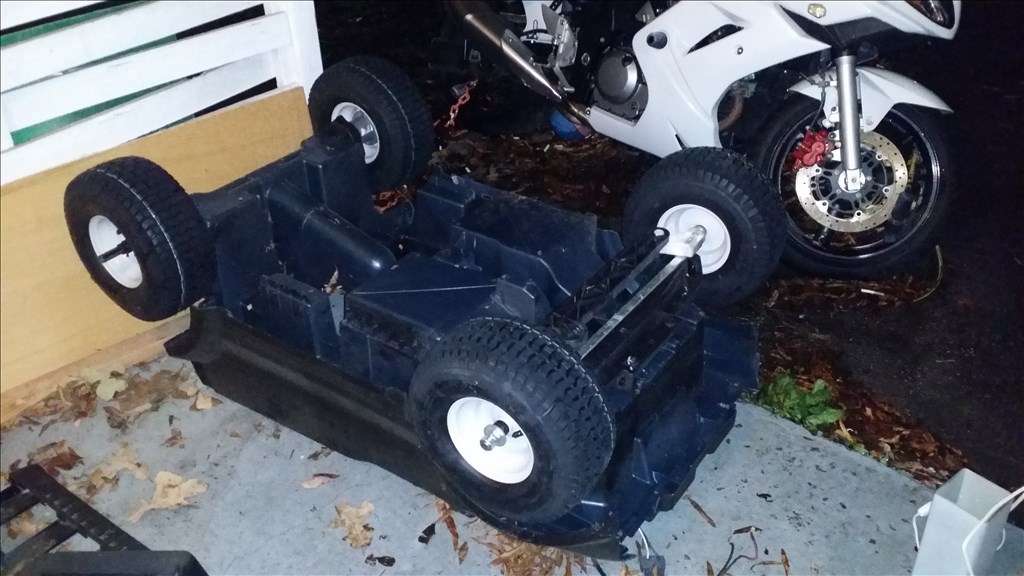

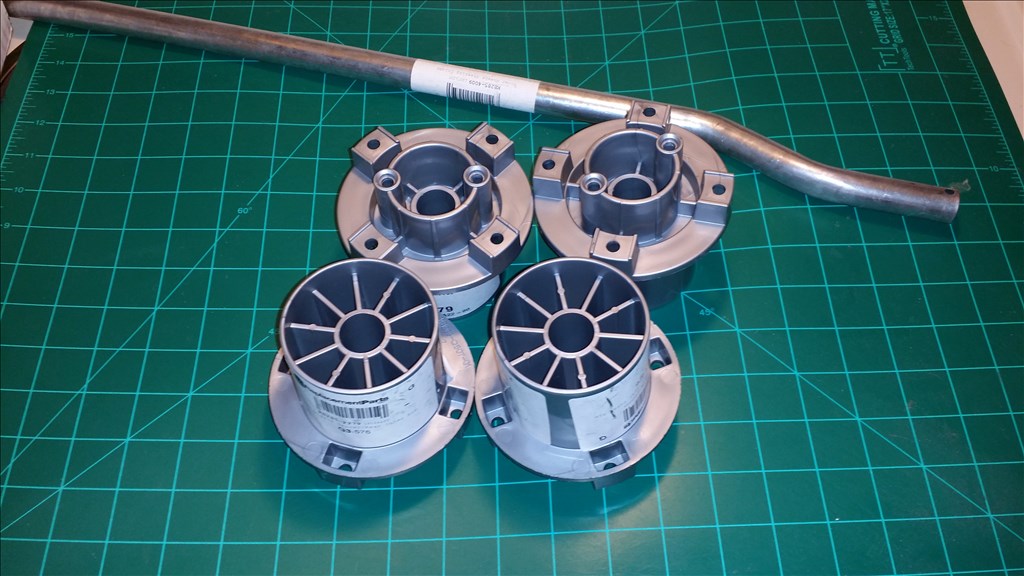

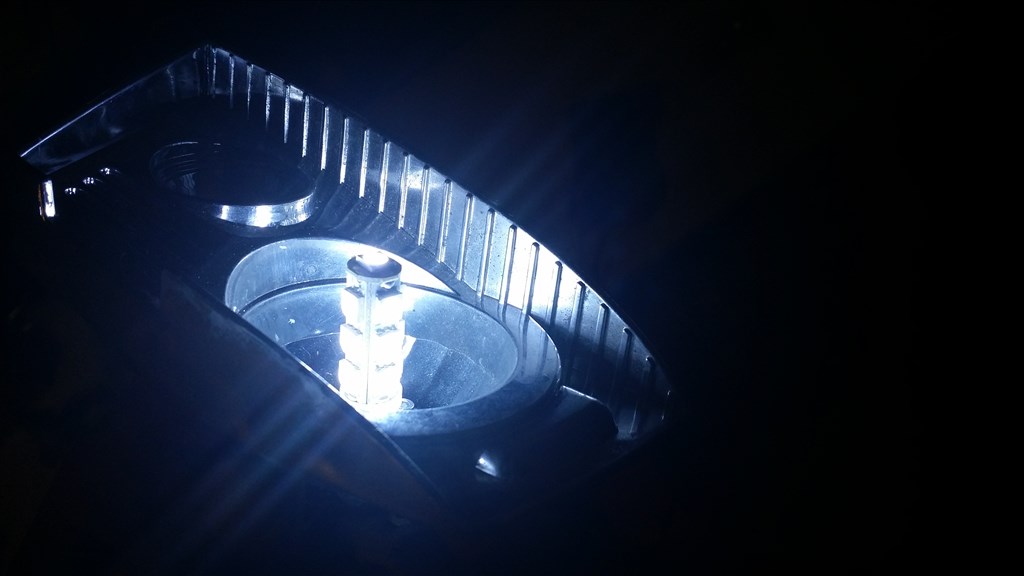

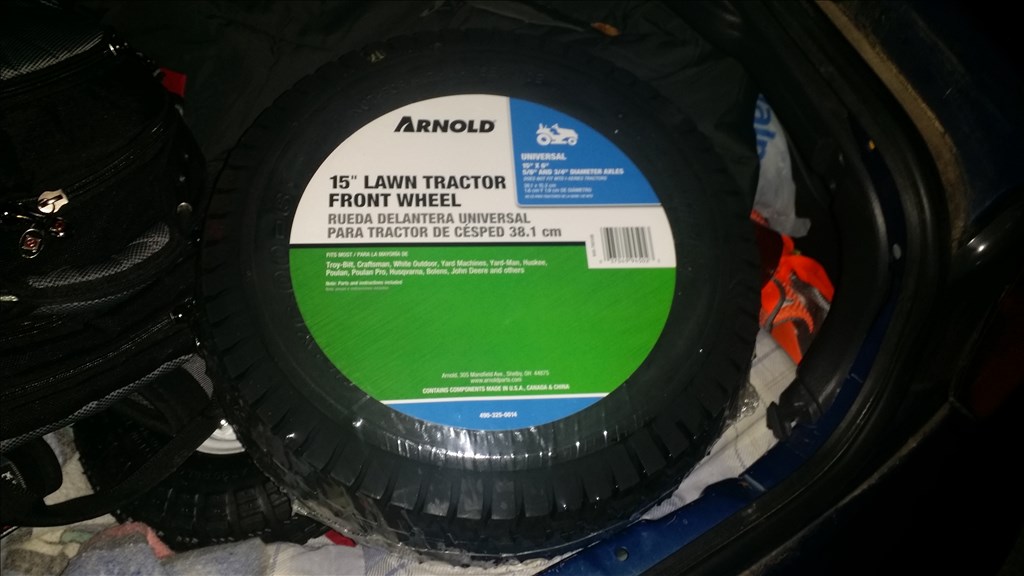

Hey Community , i really don't do enough fun projects. As you may notice many of my projects have a utility function. Squeegee mops, jarvis vacuums, smart marine fish tank is... well smart lol. So this is just for fun and I hope others enjoy it. I have already contemplated using it as a demonstration tool to get kids interested in technology. . Dang it! This is just for fun , ok I'll try not to get to serious with this. My friend Marty was talking about being able to drive the power wheels around while his kid was in it around the neighborhood. Or if his kid was driving and got to far he's just a button click away from stopping it. We found a free power wheels that had seen some rough years and we gave it a complete makeover. It looks better than new, new Gel cells from power sonic , smart charging and more. I gave it a cool high grass stripe camo.pattern and gave it to his son for his birthday. I'll post a couple pics. He's on the fence about doing the further mods so i searched craigslist.org for another power wheels that had been loved a little too hard. Searching for something with space and power I wanted I set my heart on a f150 , Toyota 4x or jeep 4x4. I didn't find a 4x4 model but f150 was the next best as it had dual gearboxes with rs585 motors. Also a good gel battery and charger was included. Here come some pics...

Other robots from Synthiam community

Nomad's Using Robosapien V2

Sakis33's Maria ,The Green Bot

Ok so I heard back from the metal Gearbox guy and he basically said that I am welcome to upgrade to a metal Gearbox from him which is aluminum gears verses plastic however he's pretty sure I will strip them anyways. He's under the impression I am going to be very hard on this robot lol.

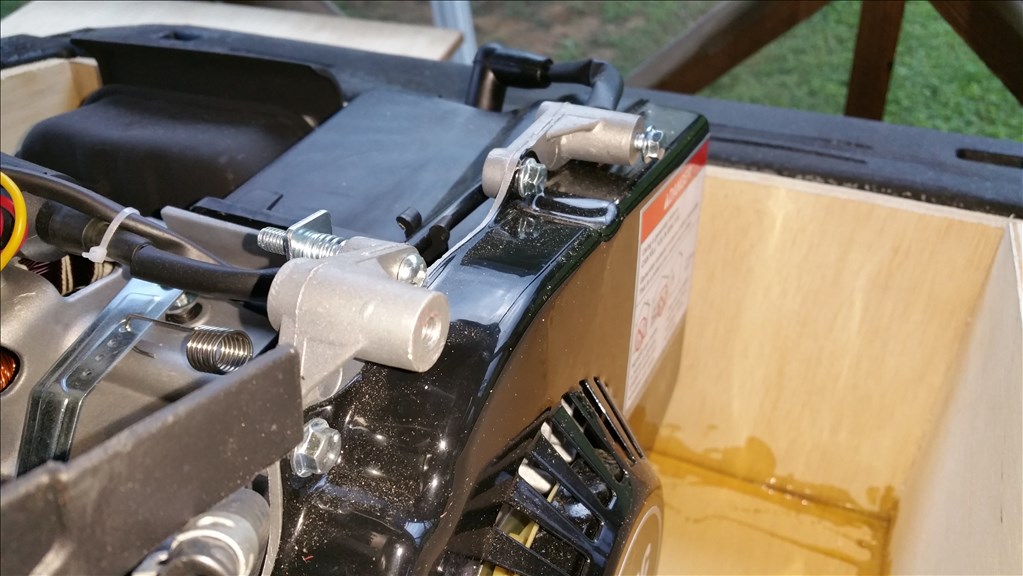

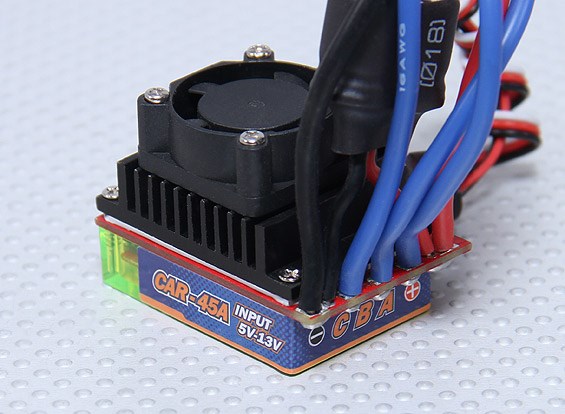

I assembled my Hitec 5995tg in the servo city 7:1 aluminum gearbox. I cannot physically turn this servo now! I am more confident that one servo can make the front wheels turn now. The bad news is I accidentally bike the tabs off a motor in the first servo. It might be repairable , I may send it in to Hitec.

Ok I made a couple short videos in between studying for finals. I found that the hitec 5995tg in the 7 to 1 ratio gearbox seems to be plenty fast for me. Now the next challenge is fabricating a mount the places the gearbox output servo horn as close to the center of the steering rack as possible. I want to try using the second hole for the steering and If possible the first hole on the horn. The closer to the center the more torque I have to move the front wheels.

Servo city 5995tg gearbox speed test. Its really fast for a 7 to 1 ratio gear! https://youtu.be/07YKk4fV7h4

Playing with a test fit servo gearbox and placement options on the power wheels: https://youtu.be/7qoSewF6iIk

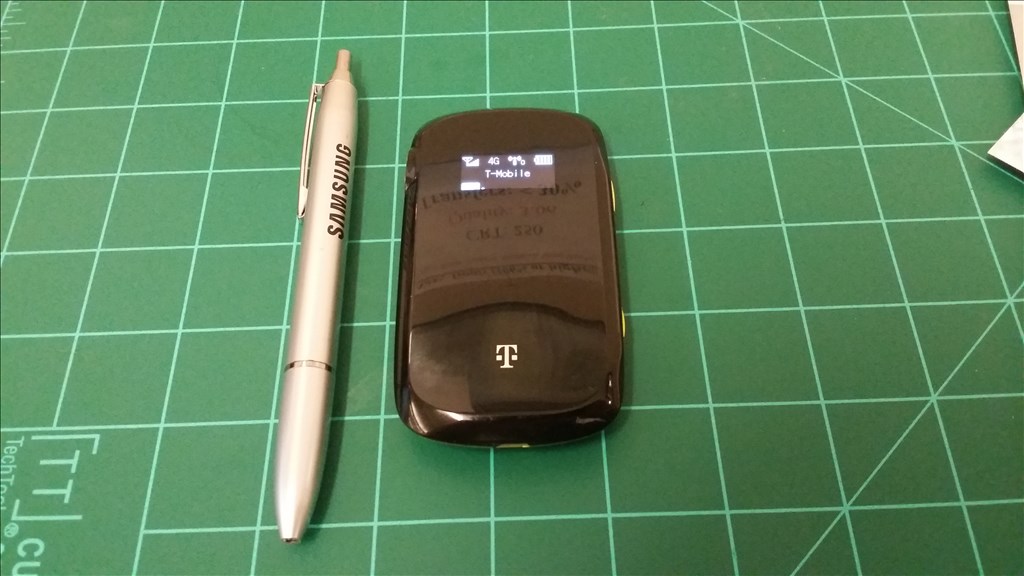

Tiny update: Per Jeremie B. suggestion I picked up Wireless Xbox controller with windows USB adapter. It advertises a guaranteed 30 ft range , but Jeremie suggested that it would work for 50 plus feet. I appropriately purchased the matt back one.... it's like I have a theme going here lol.

@Josh,

Looks like things are progressing well. I'm enjoying your vids. Even more so scene I'm using the 7-1 servo gearbox in my B9 arm. Looks like we have some of the same concerns and challenges. Here's a couple thing that pop up for me;

First it looks like the 5995tg servo is currently out of stock or unavailable at most places like servo City and others. It looks like a sweet and strong servo. Sadly the only comparable servo from HiTech that I've found the standard size HS-7950TH. This is what I'm using in my gearbox. Shockingly it cost almost $150 USD. It's as fast and strong as the 5995tg and can take voltage up to 7.4 VDC. More voltage, more torque and speed as you know.

I also was presently surprised at the speed and strength of the 7-1 gearbox with this servo installed. I have it vertically lifting an asymmetrical load of about 3 lbs at the length of about 7 inches or more from the shaft. The 7-1 works so effortlessly I may even be able to down size to a 5-1 gear ratio for more speed.

I did notice the set screw that hols the smaller gear on the main shaft of the servo installed in the gearbox tends to come loose under load. Again as you may know loctite may be needed if you use a metal geared servo. However Karbonite or plastic gears will become brittle and shatter.

I also am in need of some sort of cover or bonnet over the large and small gear set of the servo gearbox. I was thinking something like (as an example only) a plastic coffee can lid. This bonnet could screw right down onto the large gear and extend out over the end enough to also cover the smaller gear. It could also have edges that extend down towards the servo (like the coffee can lid example) enough to cover the gear teeth. In my case this would keep the inside of my rubber arm from wearing across the teeth and catching at that pinch point where the two gears come together. I was thinking of asking Anthony to design and 3D print me something like this. However I think you also may have a printer. If you decide to print something like this I would diffidently like a set of two or more for myself and would be willing to pay for your effort and material.

One question, How do you plan to take in account for the vertical movement of the attachment point at the end of the servo arm to the tie plate (between the wheels) when the servo arcs back and forth? Never mind. I see the extra pivot arm and the servo being off set in your pic. blush

I'll be posting videos of my set up soon. We can compare!

Well, thats about it. Keep up the grand work! Dave

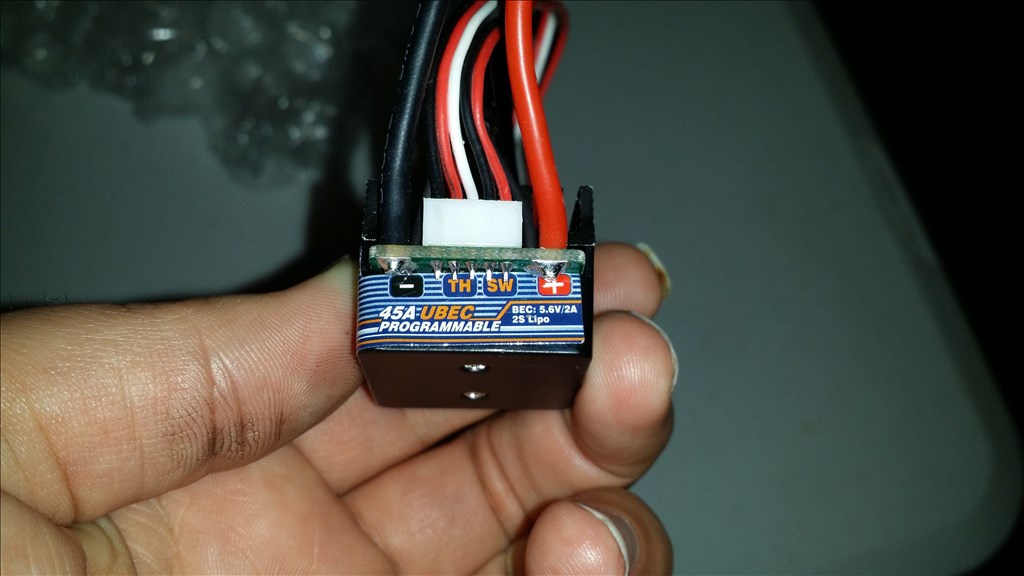

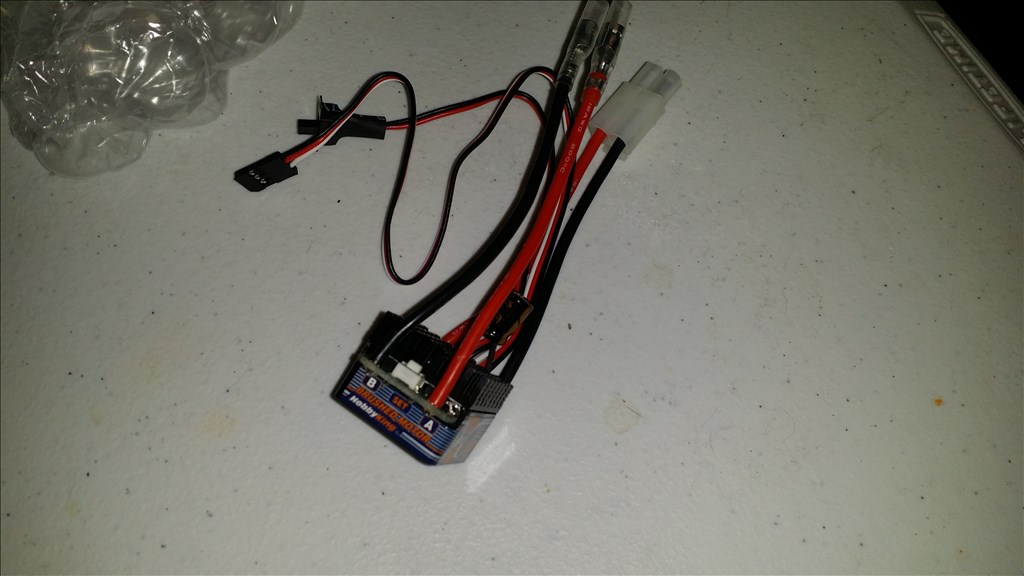

Ok , so I decided that I was not happy with the amount of torque with only a single servo. In some ways I predicted this , however I accidentally damaged the second Hitec 5995tg during modification, the power leads to the motor broke from the INSIDE of the motor. I searched ebay and with some patience found a guy selling some 5995tg servos and picked another one up. Also I ordered another 7 to 1 ratio gearbox kit from servo city. Now I will have twice the torque for steering!

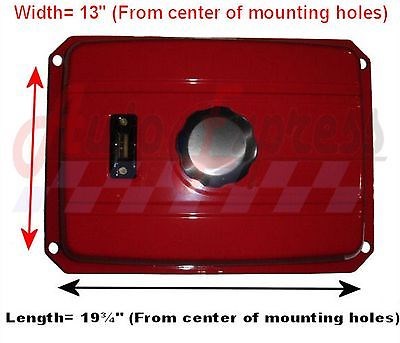

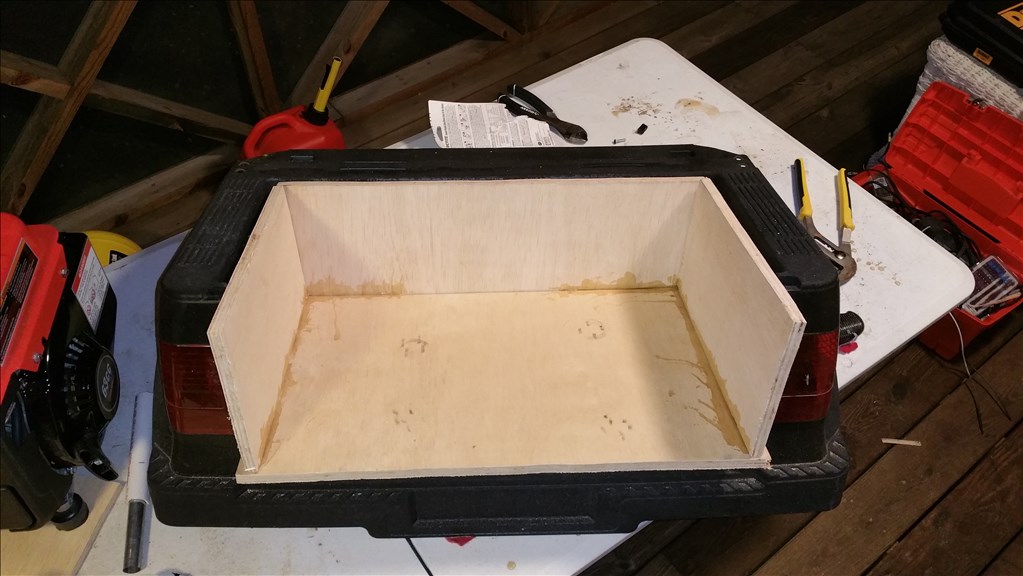

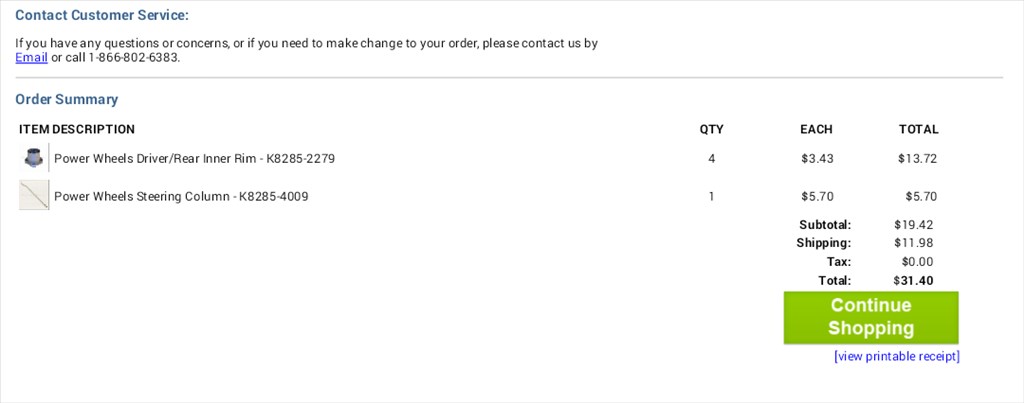

Ok , I finished up the semester and it's summertime. So I get to work on the website Redhatrobot.com (which will be a store where I sell custom accessories and bodies for ez robot products. I pulled the truck out of storage to do some work on it. I ordered the correct gear and pinion as I recieved the most recent one with a 5 to 1 gear. Today I recieved the 7 to 1 gear for the steering column. I attached fleece as a base and next I will saturate it with polyester resin. Once the resin hardens I can reinforce certain high stress areas with fiberglass to make sure this guy doesn't fall apart on the first drive out.