Hey Community , i really don't do enough fun projects. As you may notice many of my projects have a utility function. Squeegee mops, jarvis vacuums, smart marine fish tank is... well smart lol. So this is just for fun and I hope others enjoy it. I have already contemplated using it as a demonstration tool to get kids interested in technology. . Dang it! This is just for fun , ok I'll try not to get to serious with this. My friend Marty was talking about being able to drive the power wheels around while his kid was in it around the neighborhood. Or if his kid was driving and got to far he's just a button click away from stopping it. We found a free power wheels that had seen some rough years and we gave it a complete makeover. It looks better than new, new Gel cells from power sonic , smart charging and more. I gave it a cool high grass stripe camo.pattern and gave it to his son for his birthday. I'll post a couple pics. He's on the fence about doing the further mods so i searched craigslist.org for another power wheels that had been loved a little too hard. Searching for something with space and power I wanted I set my heart on a f150 , Toyota 4x or jeep 4x4. I didn't find a 4x4 model but f150 was the next best as it had dual gearboxes with rs585 motors. Also a good gel battery and charger was included. Here come some pics...

Other robots from Synthiam community

Kenny's Everybody, Meet Phil:)

Cardboardhacker's Raiko Personal Robot

Here is Marty's Power wheels , before and after. He's on the fence about doing the mods but I'm betting that doing the f150 will make him want to finish it. He he he.

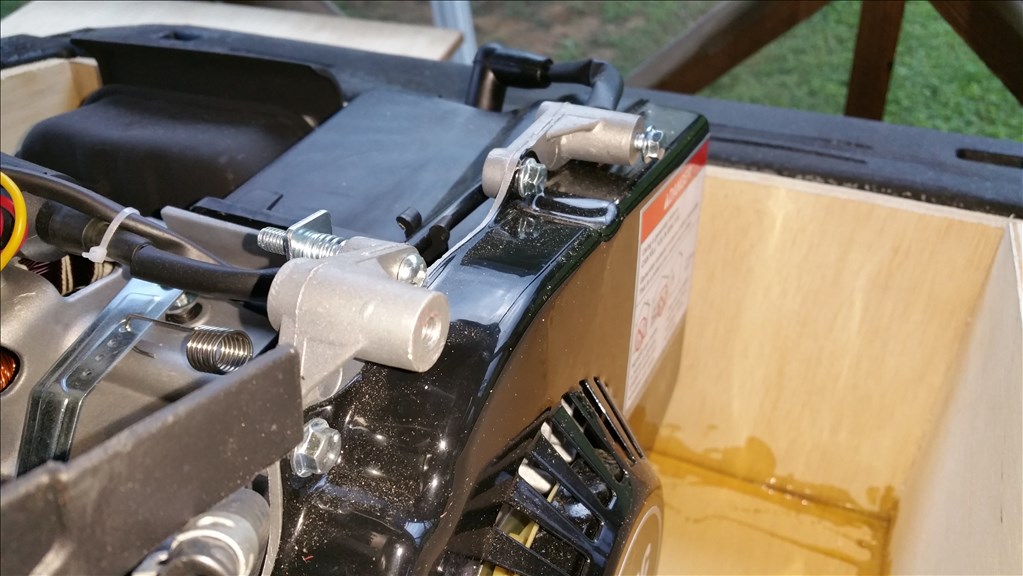

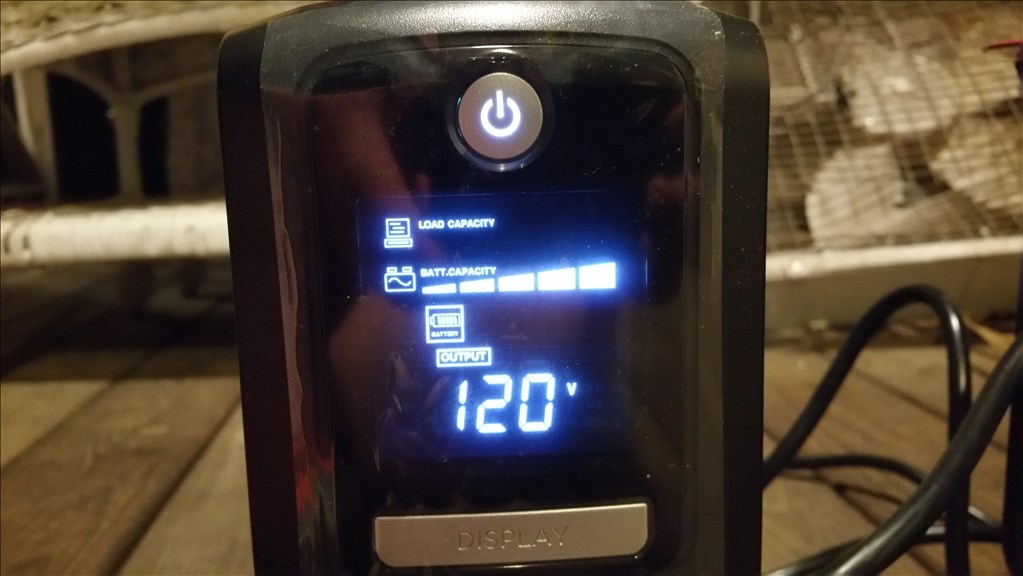

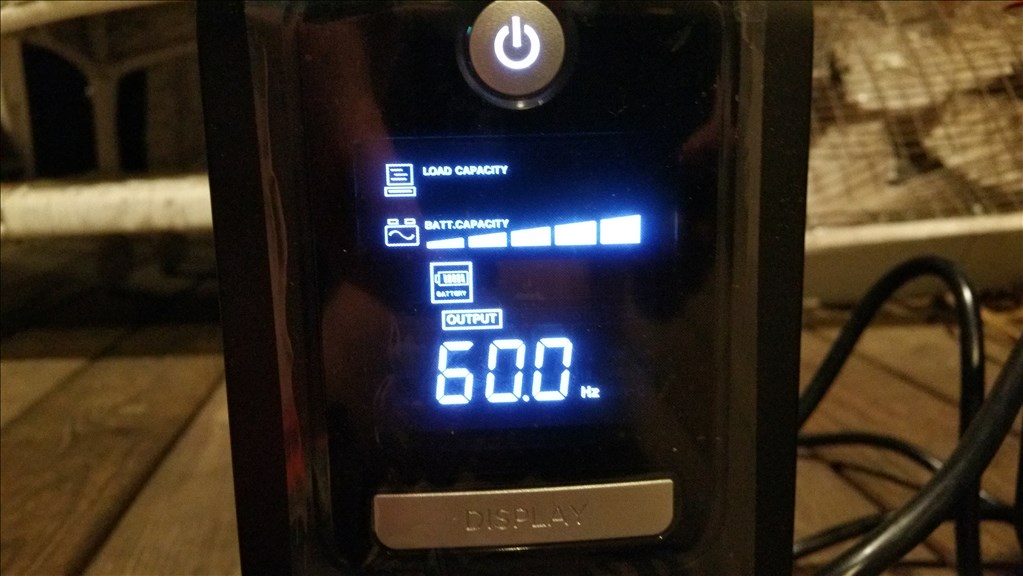

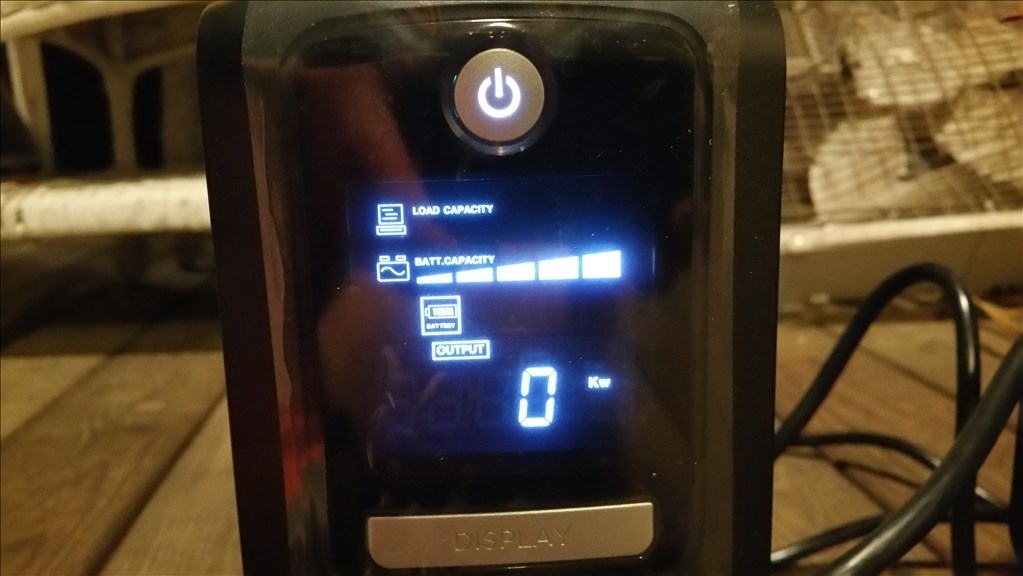

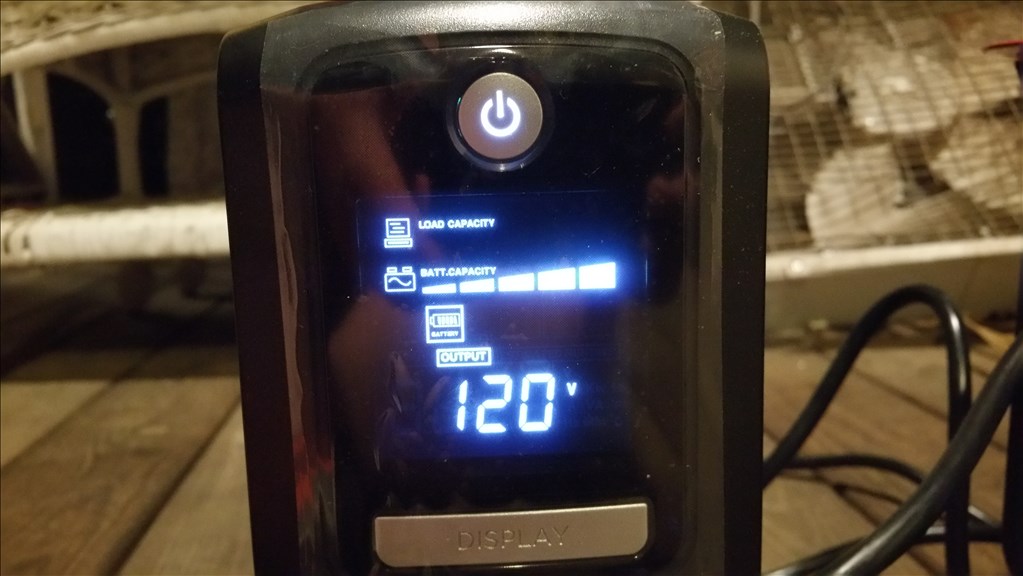

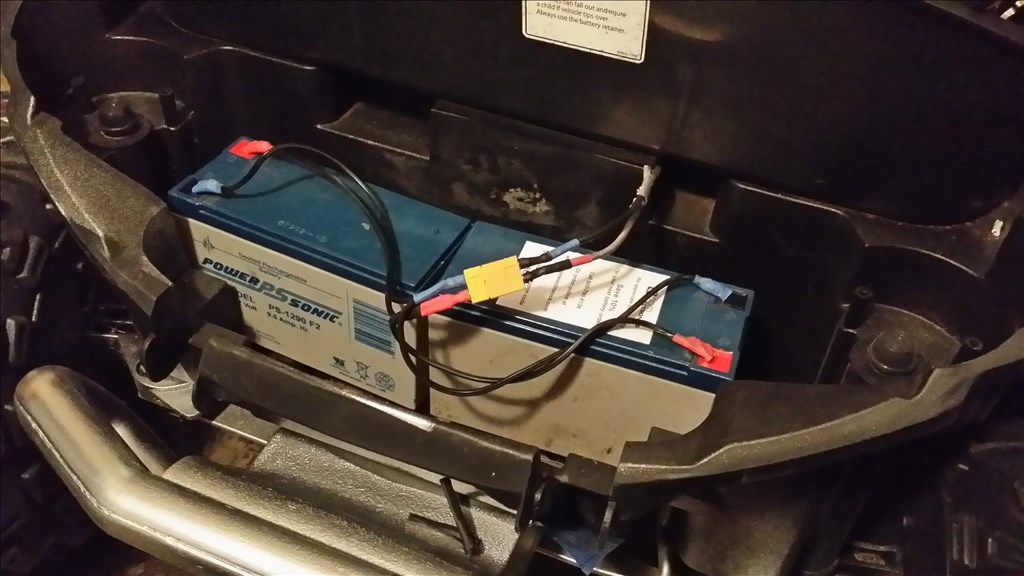

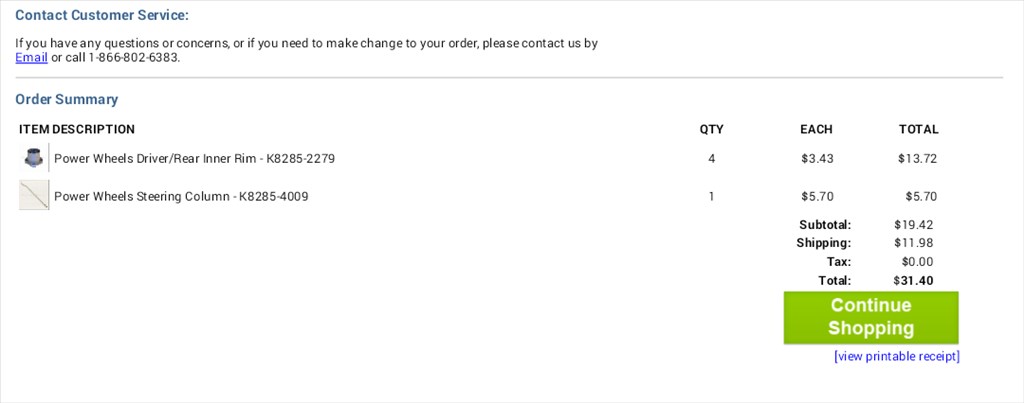

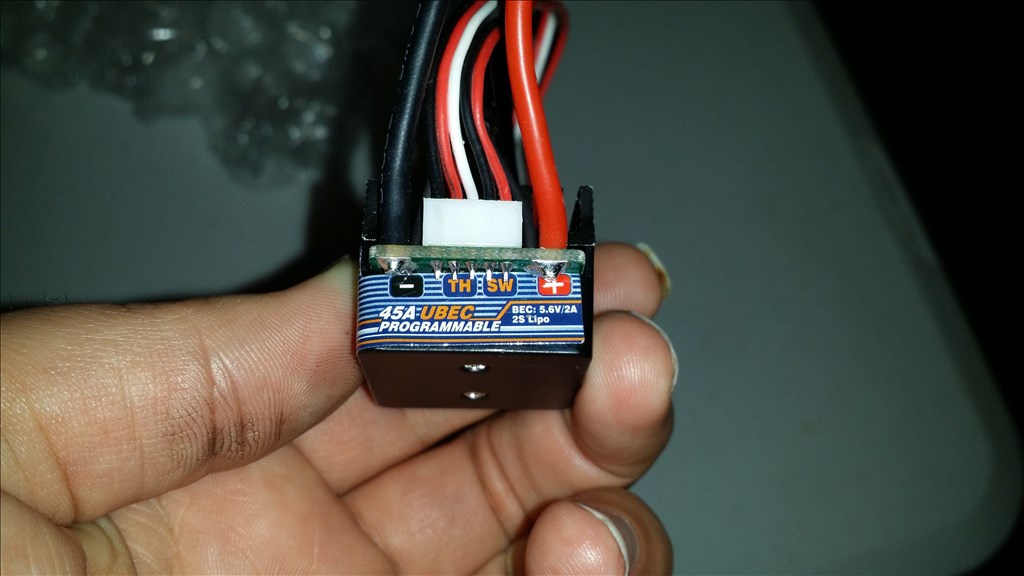

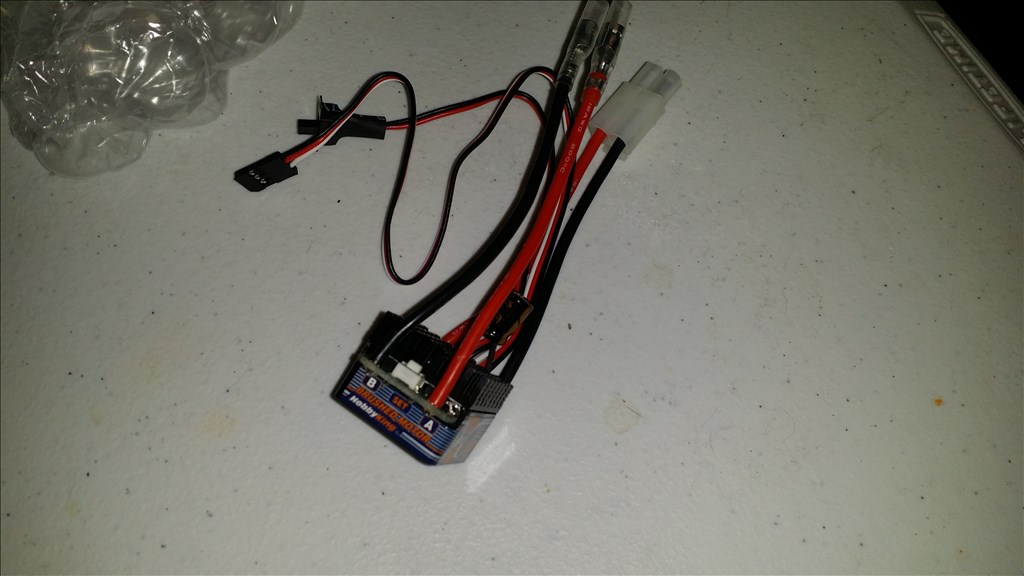

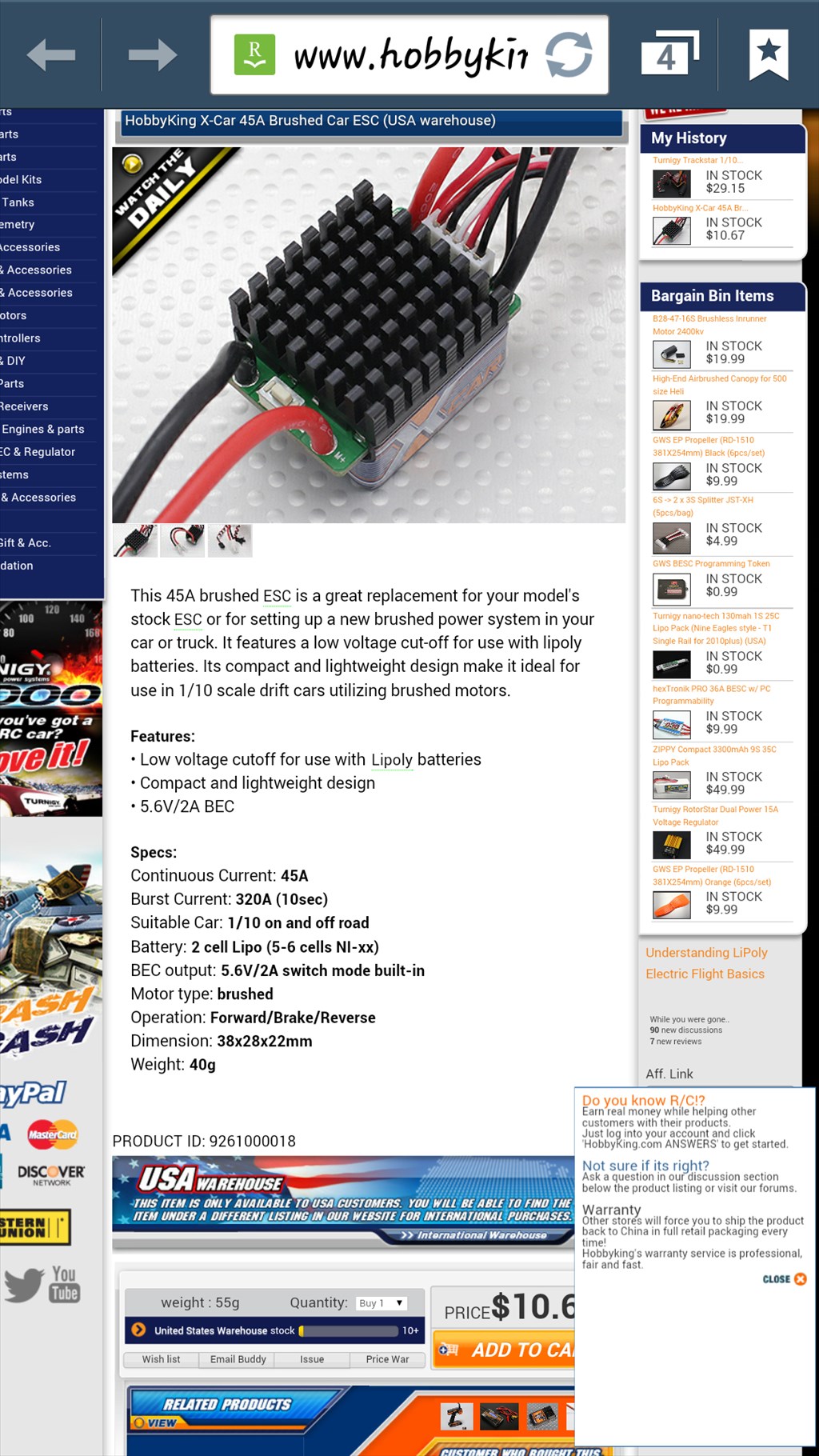

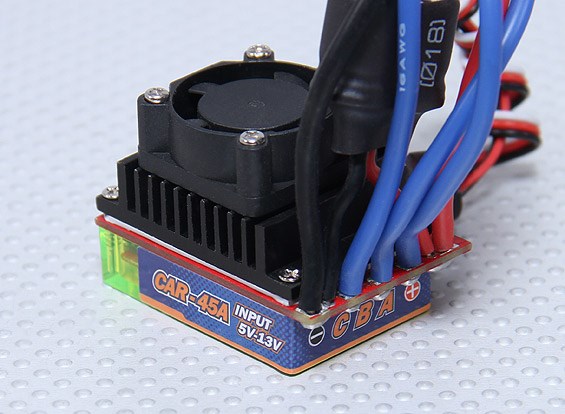

Electrical needed some love. Take it from 6 volt standard to dual 12 volt gel cell power sonic batteries. Turnigy XT 60 gold connectors were soldered onto 12 guage wire and covered in heatshrink.

Ok so here's a sneak at marty's machine, I will update this thread when we start adding electronic hardware like motors controllers ect.

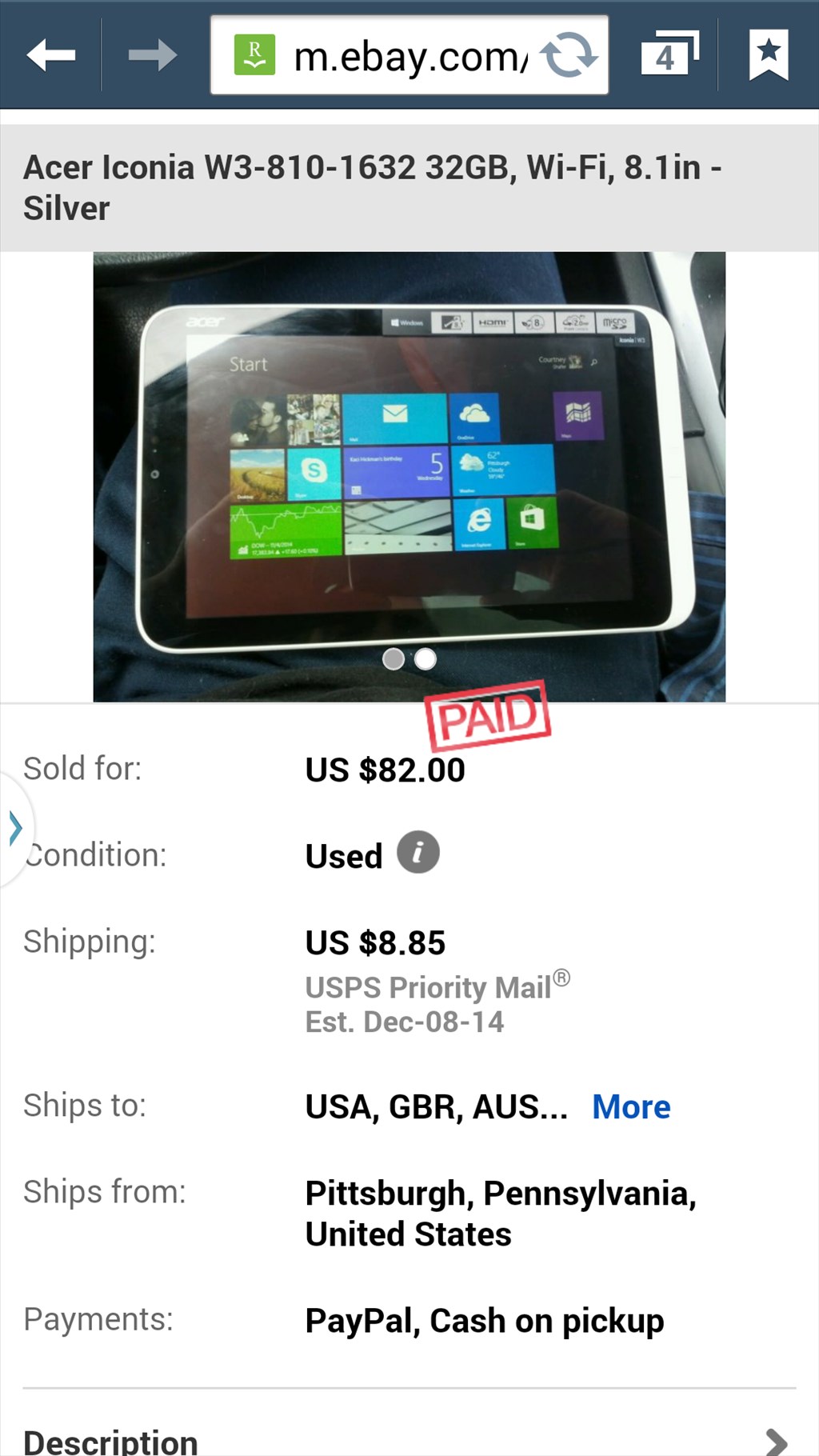

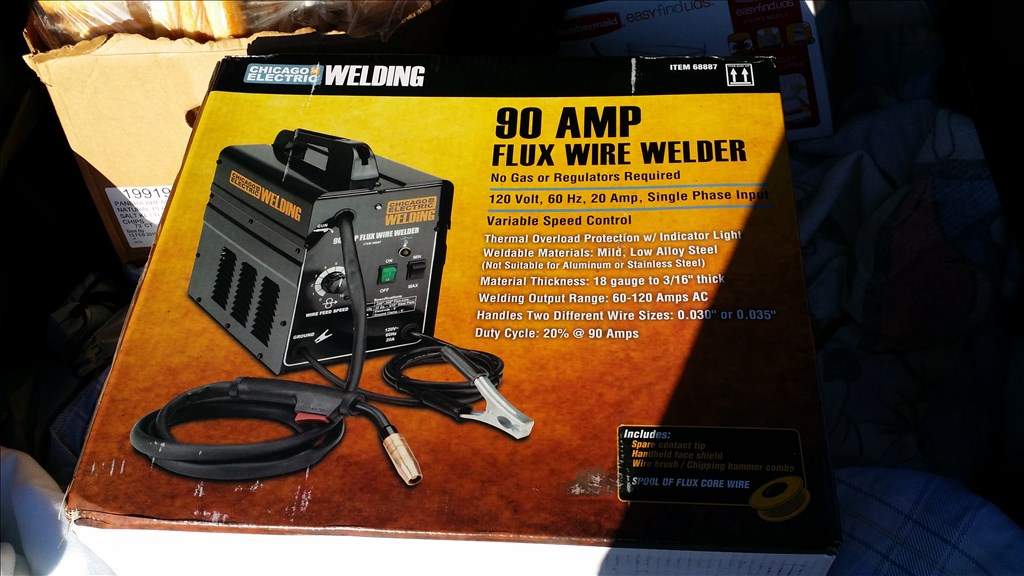

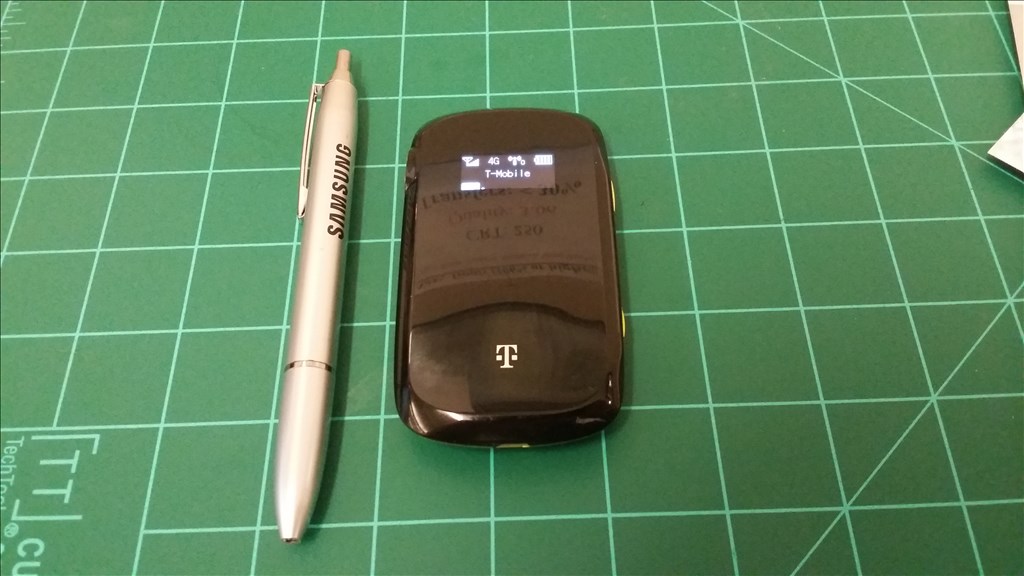

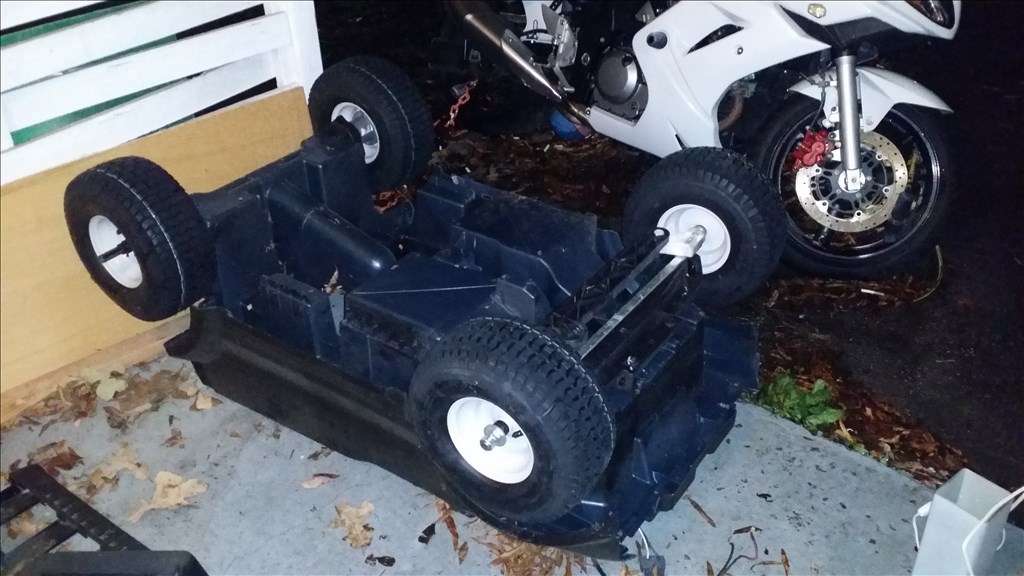

Ok here is mine, the Power wheels F150 series donor from Craigslist.org. I paid a hefty $40 and had to pick it up in my hatch back.

Yup I'm pretty sure we are gonna ignore that warning , safety first! .... well ok maybe second.

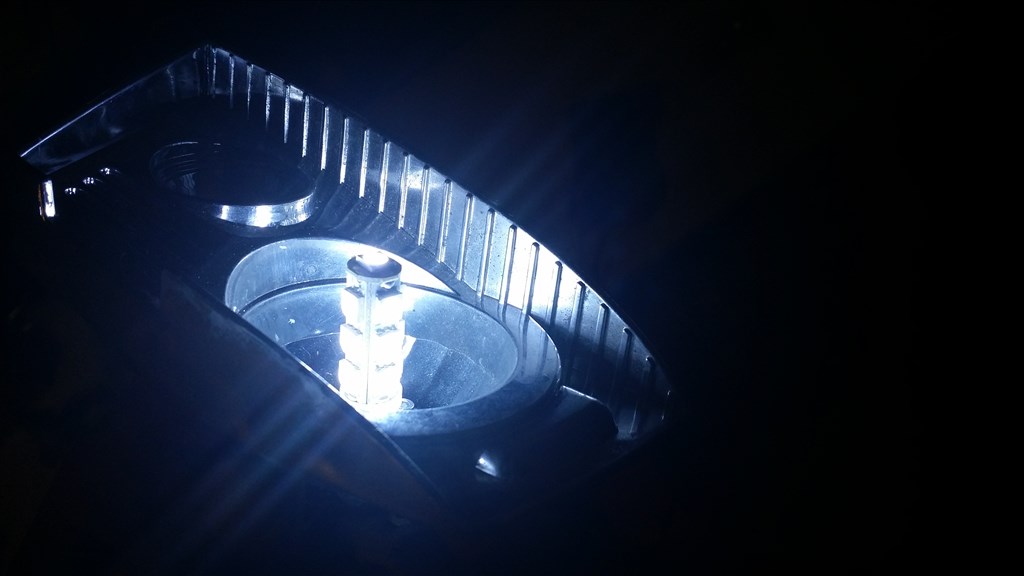

Something I realized is that the fake headlights and fog lights looked very convincing. I held a flashlight bulb in the reflector and found they worked pretty much like a standard round headlight. So while I had them out I'm drilling holes in all the reflectors so i can fit 300 lumen led. Led 1891 bannet socket bulbs. Just for testing I have some 25 lumen standard filament bulbs. Because I already know I can mod one of my cams to see excellent at night I am tempted to find a reasonable location for IR Illuminated strip or circle. So with one button press I can go dark and run around with very little light. This sounds like fun. The tail lights also look like they could be functional. It will never be a road vehicle but being able to turn the running lights on will make it easier to see if it gets out of sight or stuck and needs some manual assistance.

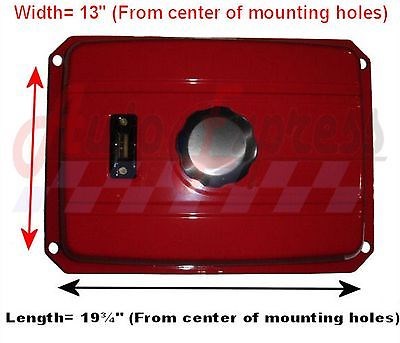

Here are some specs for the 1/4 scale F150

maximum recommended rider weight 130 pounds

1 Year manufacturer bumper to bumper warranty and box dimensions are: 35.875 x 29.875 x 51.5; weight: 92.1 lbs

The vehicle drives 2.5 and 5mph forward and 2.5 mph in reverse

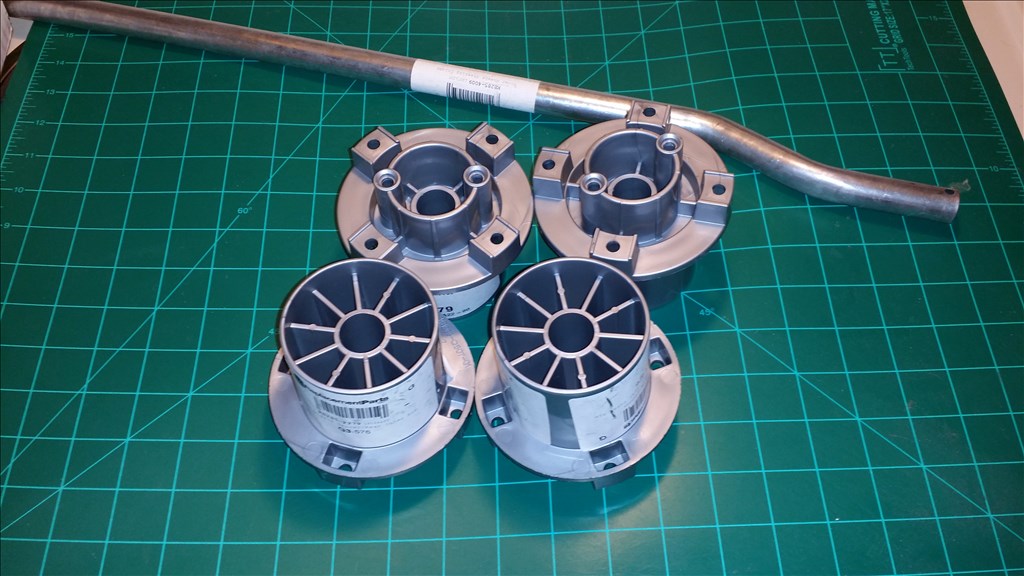

Dual Independent DC motors with gearbox on a solid galvanized steel axle in the rear

Front Rack style steering with galvanized steel spindles and steel tie rods.

Background of Power wheels modifications and competitions

I will also be posting the Power wheels awesomeness on a power wheels forum. Apparently its a lucrative hobby. Maybe people mods these things for competition, racing and even just for fun at car shows. I have seen many RC versions so EZ robot can bring a different angle to this "sport".

There are even clubs and competitions where power wheels are modded to be controlled from a computer and have a "gun" mounted on them to play a sort of laser tag with other competitors. Two man teams with one driver and a gunner portray a scenario of driving a HALO Warthog ATV. If anyone already didn't know HALO is a popular video game that has spanned more than 6 game releases for Xbox branded consoles worldwide.

Makerfaire Detroit has modified races https://makezine.com/2010/03/26/power-wheels-racing-competition-at/

Generator Stalwarts https://ithacagenerator.org/generator-stalwarts-to-compete-in-power-wheels-competition/

https://jalopnik.com/5601754/power-wheels-racing-fat-men-on-souped+up-toy-cars

https://ecomodder.com/forum/showthread.php/modified-powerwheels-racing-fun-12957.html (by the way there is a banner at the bottom of this website for Ez Robot, first ad i have seen)

https://mods-n-hacks.wonderhowto.com/inspiration/mod-your-power-wheels-into-wifi-halo-warthogs-0113812/

https://www.youtube.com/watch?v=sJDjQKR0kpg

PDC09 Makerspace coding for fun

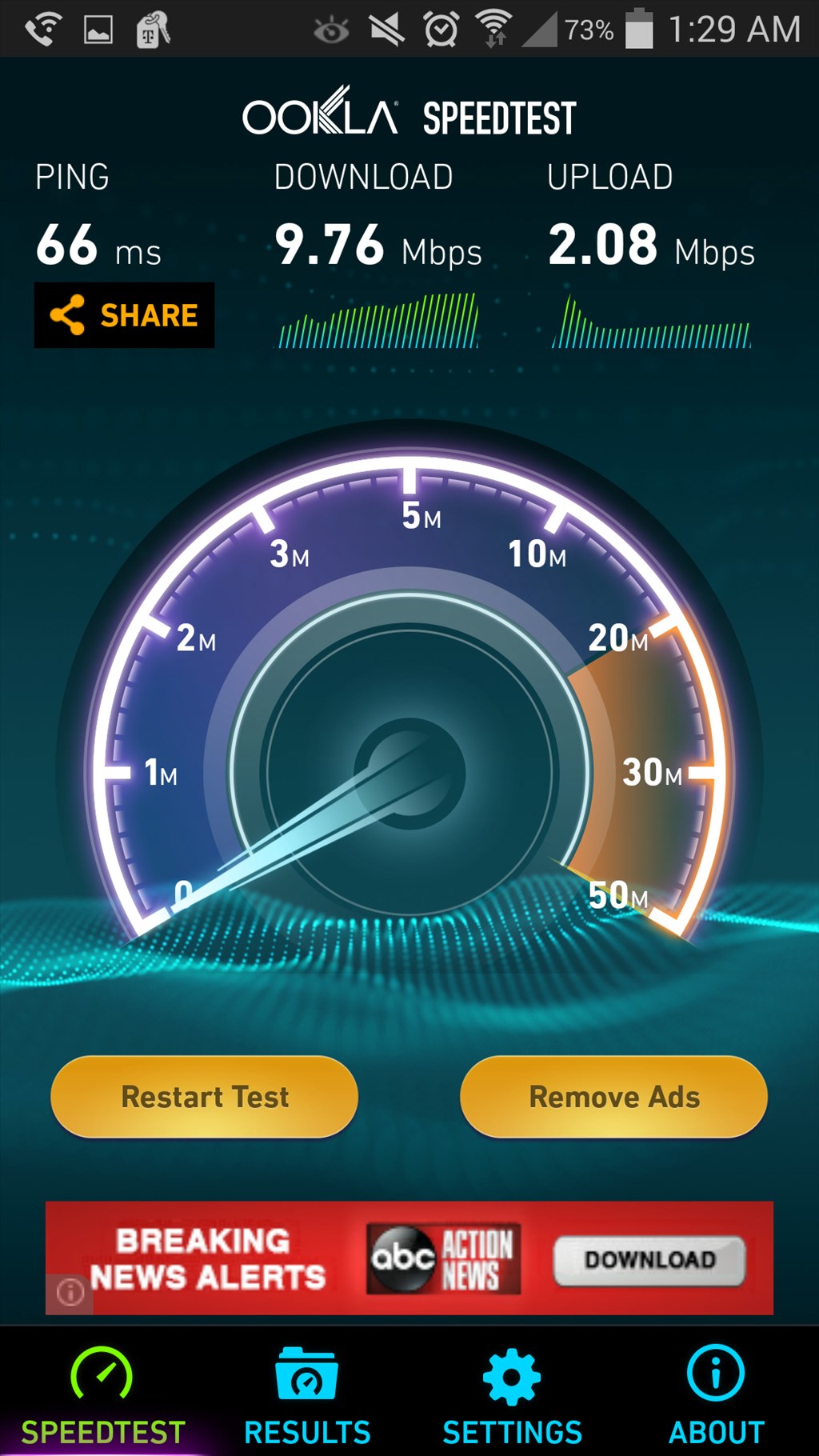

I thought this was cool, we already have two, now im wondering if there are any maker spaces or hacker spaces have modded Power wheels they can operate remotly. It also would be cool to try to do some point a to point b autonomy but lets get it manually controlled remotly though wifi and then we will go from there

I have Ba9s LED bulbs on the way to replace the temporary basic bulbs I picked up from radioshack. They are low current draw, and have high lumens for a small bulb. Since no one is really riding in my power wheels the lights are to illuminate the drive path so I can see well with a camera at night. Led bulbs always look much cleaner as well. Everyone knows I like my projects to look cool when possible.

So far I am thinking 4 headlights and 2 tail light bulbs.

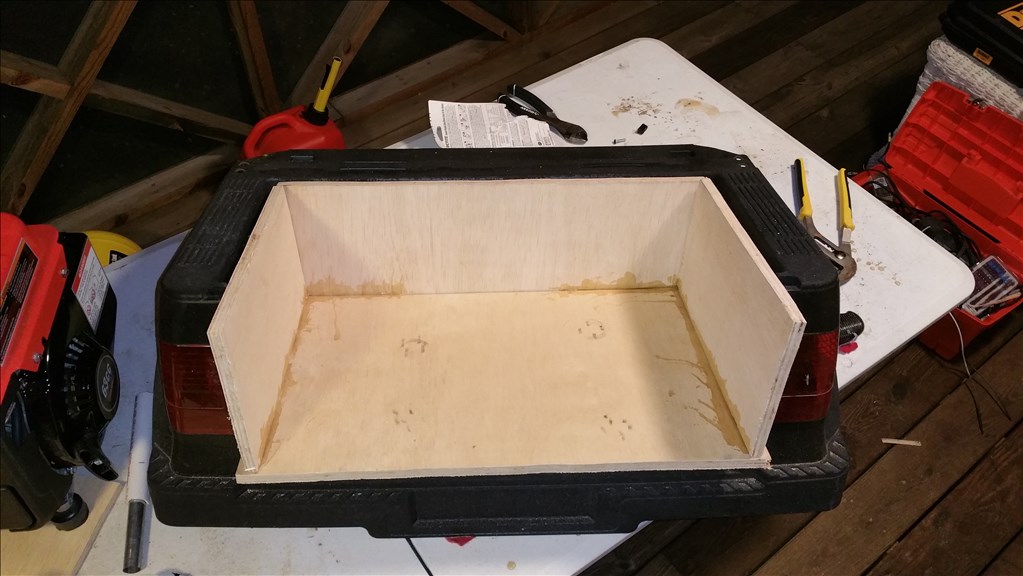

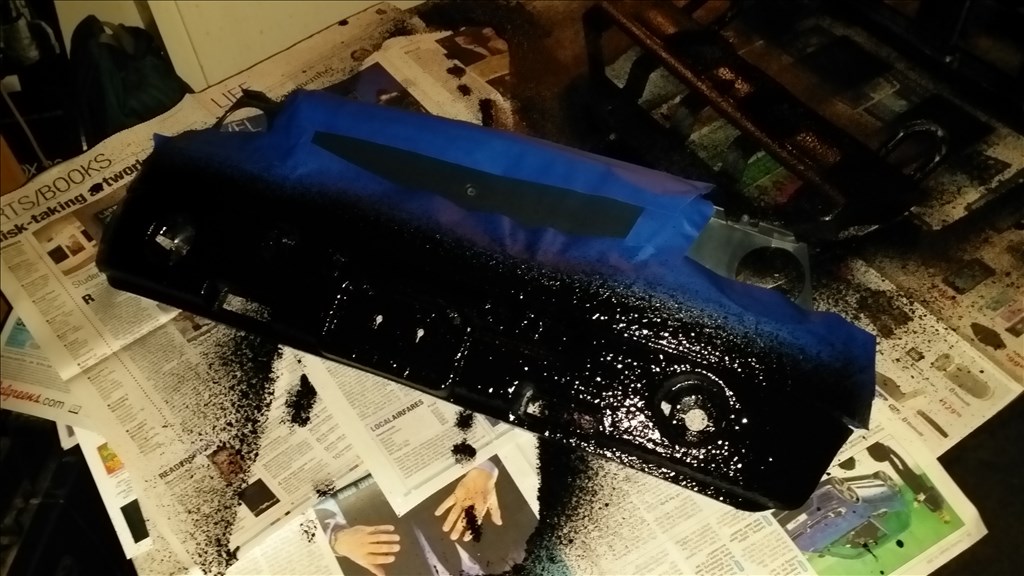

We tore down all the major parts last night and tonight I cleaned the brush guard , side guard / sliders , the front bumper and the truck bed portion. I sprayed them down with a liquid rubber sealer that looks similar to spray in truck bed liner.

Ok so this stuff goes on really thick and takes a long time to dry , if it is cold it can take more than 24 hours. We are in a garage and have a space heater going so hopefully we can get it up to 50 to 60 degrees so it will be dry tommorow. Basically the idea is lower edges of the truck will likely be scraped often whether it is from loading or unloading or just rock, sticks and things like that. So these high risk areas for scratches I'm coating. This is c all ed rubber flex seal.

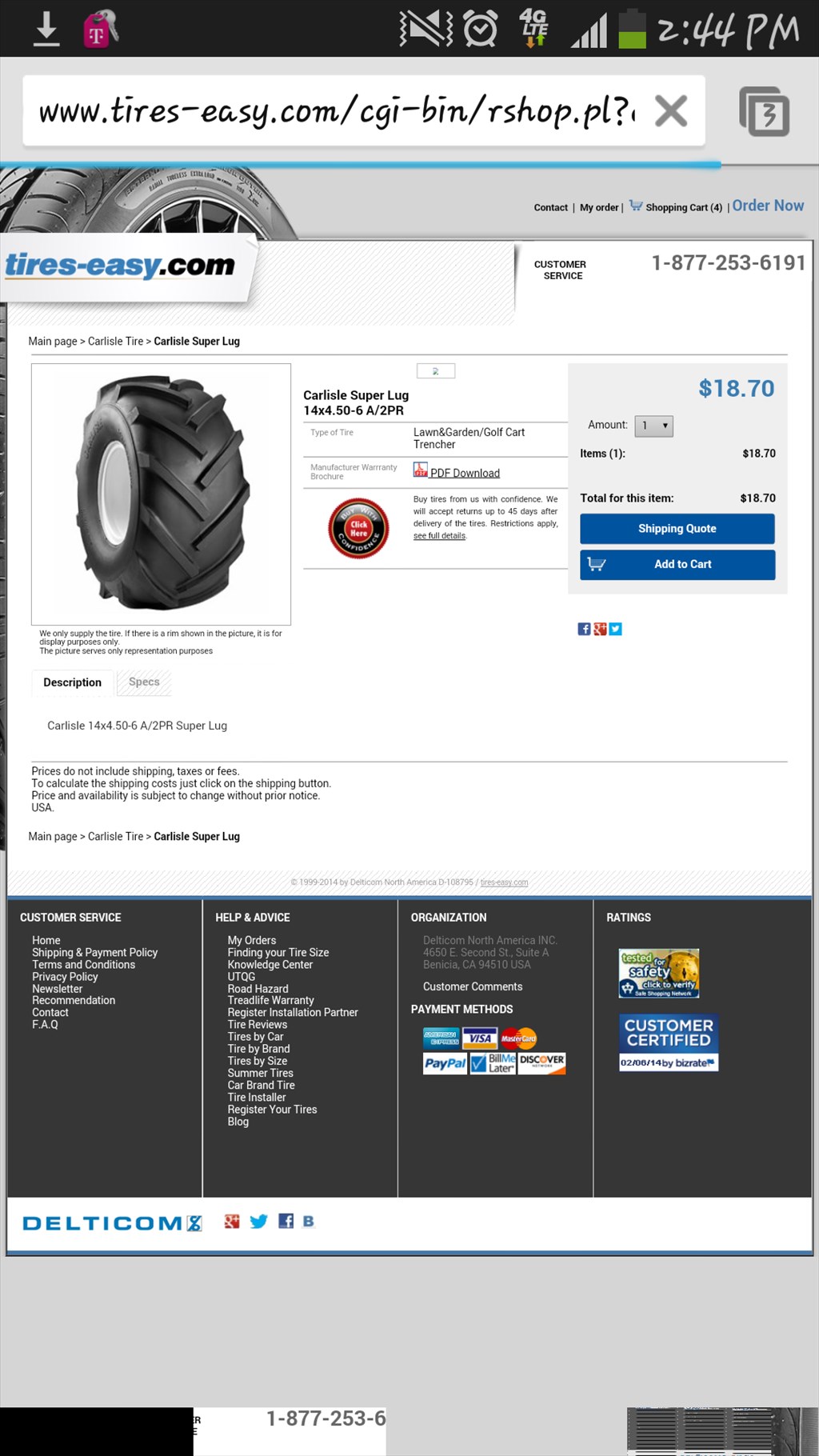

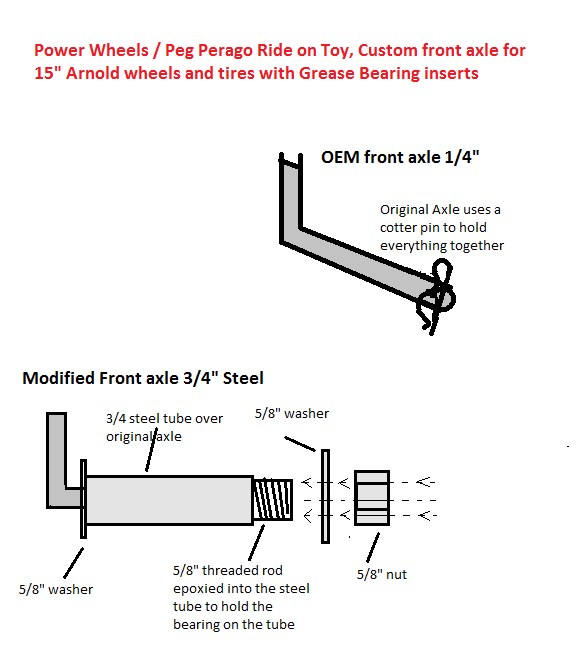

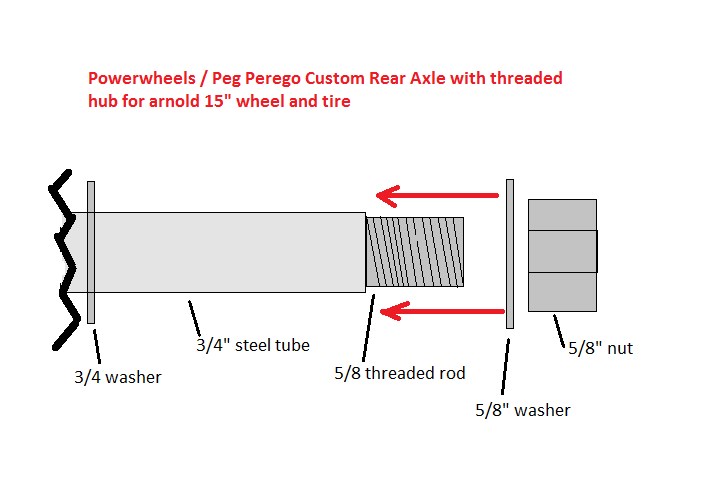

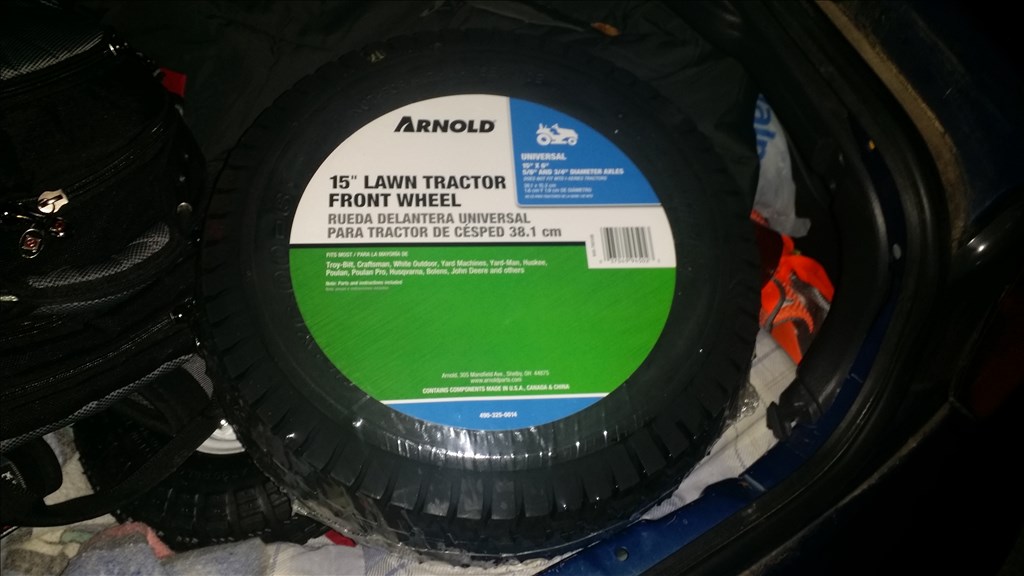

I'm looking at some real tire options as the truck has more torque than it does traction due to the hard plastic wheels. Looking at other projects using lawnmower designed wheels and tires work well.