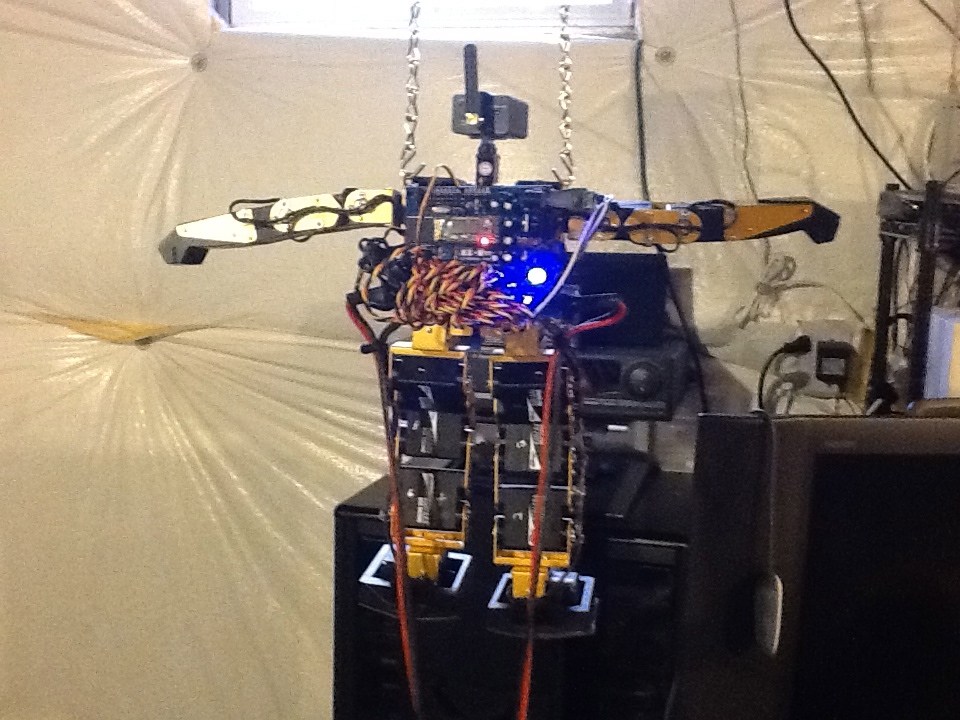

This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

Kleinjd's 17 Servo Biped (Formerly Robonova)

16 Hitec HSR-8498NB servos on dual external boards plus a 17th camera servo; 0.38A @6V draw, 1500mAh NiMH per foot and...

Fxrtst's Mecha Morphix Robot Platform

Build and program the Mecha Morphix robot head ALAN with hours of 3D printing, assembly, wiring and coding tutorials...

Ezang's Robot With Audio Voice Command And Audio Response

EzAng robot with audio voice command and audio response enables voice-controlled operation and spoken feedback

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

Yes i know its a data switch , But you didnot say that in the post , As i said just clarifying here .

As for programing i find it as hard as you do , but im learning too . May be we can comeup with somthing cool with multi banks of sesors and nav + security mode code.

Steve_C.

mostly working on building my omnibot project first,then work on the code ,and working on testing sensors ,like the compass in another post,and the dirt sensor for JOSH ,mostly know about every sensor made and how to use them,and how to mostly set them up for very good navigation sensors need to be placed on the robot correctly and horiz and vertical makes a big difference in good navigation

data switches are mostly digital,not really analog analog switches are what they are called ,mostly spst or spdt like cd4016 when more then 2 analog its called multiplexer chips

@Steve thanks man , I think 1200 max oz and 800 working ounces should be good. Basically the goal is 2.7 pounds lifting/ working weight @ the claw. Somehow doing that data switcher would be cool . IM not to that point yet but sounds useful.

hi josh

dont block the holes for the sensors just cover them ,then you could put them back in at a later date.

whats the weight of a beer ? i think thats the most important thing .

Steve_C.

i think he said before a wine bottle too,plus need to add the weight of both arm pieces with servo's ,plus hand

@Josh, will you have the upper shoulder hollow? Nevermind. It wouldnt help much at all.

@Steve yes a claborative effort to work on the programming end would be great!

I have several wine bottle a at home I could test with. IM super excited this is all coming together so well!

To do list

Sand Jarvis like a madman lol

Lots to do still but great progress

Iv been away for a month and in that time Jarvis has grown about 2 foot and got more sensors than cape canaveral.

Now summers over must work on Aegis.

I used to paint cars for a living . dont make your fingers bleed with the sanding