This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

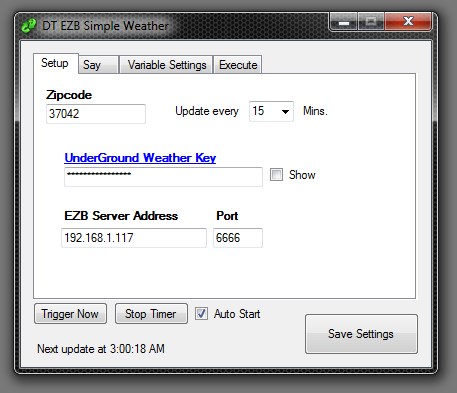

Luis's Dt Ezb Weather For Weather Underground Api

Control EZ-B robots with a Weather Underground API handler: fetch forecasts, speak templates, map variables, and run...

Rgordon's Project Questor

Questor: compact autonomous test robot with EZ-B control, camera 'nose', IR LEDs, remote-control option and...

Wmoecke's Yet Another Wall-E (U-Command Wall-E Teardown And...

Convert a Wall-E toy with EZ-Robot/EZ-B: disassembly, gearbox and linkage reuse, servo integration, audio options and...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

most likely its the most common grade acrylic,hardness level low and impact too but since JOSH is using fiberglass on inside it might hold up,just have to wait when is finished and tested ,another thing bad about TAP plastics no info much on the plastics i see

plastic i am using for mine you can hit it very hard with a hammer and notthing will happen to it,

Have you ever been to a tap plastic?

about 3 to 4 years ago portland oregon store

i did a simple test compare 1/8 thick clear acrylic 2 '' by 48 '' is $10 not icluding tax same size at mcmaster carr and type $5.49 no tax shipping very low

also what i did like about the store many types of picture frams and other stuff on display to buy,only found out prices very high was picking a fast order of plastics for the company i work for,we needed the same day not like mcmaster near 2 -3 days,company new is was going to be much higher,but like all companies they dont really care to much about money

With a couple layers of fiberglass the plastic holds great , just for fun I.put 80 pounds on the base , doesn't flex or.make creaking noises , its solid .

.

Update: I'm exhausted so I didn't work on the bot last night however I have the second ezrobot cam coming for junior any day now and the headrest monitor/ LCD kit came in today! I planned on putting the LCD in his chest. I will post lots of pics once I get rest.

couple of layers might work,makes it very heavy,not the greatest idea ,but at least it may acrylic is very weak plastic ,can tell by when it was shipped the first time it was cracked i see this type of plastic break out at work,so we use a different type

@robotmaker the plastic on the actual omnibot was cracked as well , its not a inferior material issue. Fiberglass backing worked great. I tried aluminum angle bar and there's No WAY in H%&l its lighter even using two rails in the center , and angles bar in the corners going straight up plus the nuts and bolts to hold it together you can only get in mild steel and stainless and just the nuts and bolts by themselves weighted as must as the fiberglass resins I used. I'm sure aluminum is stronger but it for SURE is not lighter once you weight the frame and fasteners to connect them together. A part reinforced with fiberglass only weights more based on the number of ounces you use in resin. If you use 8 ounces of resin plus cloth it only adds about 10 ounces to the parts. Pound for pound it is second only to dry layup carbon fiber.

i found it does,because you need to add the plasstic,then fiberglass,depend on the aluminium its super light ,i use aluminium rivets,you need to try it then you will see the results most people think it weight alot without trying second makes super easy to mount and remove parts,not using any bolts i use 1/6 inch aluminium angle not bar also with fiberglass resin you need to cover the whole surface , with aluminium you dont less then 1/4

i think it was 4 ounces for both aluminium bracket on the bottom deck 2 layer would be double but once i get home will finish my double shelf bracket and weigh it

Incredible. If only there were an Omnibot with an aluminum frame to see as an example.