This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

Danbachmann's Dandroid 20Xx

EZ-B v4 Cybot robot uses IR and ultrasonic sensors for obstacle avoidance, wireless monitoring and human/animal activity...

Foamtastic's Working On A Baby Dragon.

Build an animatronic dragon with EZ Robot using plastic garbage cans and wood; wing tests, build photos and YouTube...

Jeremie's Optimus Prime

Optimus Prime bipedal robot build using EZ-B, Arduino sound shield, LiPo battery and Gundam parts for aesthetics and...

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

Josh,

So when I was mentioning spacer thingies, these are the ones I am ordering to help lift my bot. These will go where the normal screws would go to give it extra support. So far it hols but I'd rather have extra support.

https://www.mcmaster.com/#catalog/118/3267/=i8ep3d

I am getting the 3" male/female hex

Samantha

@sfoy ,i bought another SPYKEE WIFI robot,got it low cost,going to restore it and add to my collection on the one i got from you going to use the EZB,so far is all apart,to see what i need

@josh on the schematic,since not good at drawing it,might have a to use my schematic making program i have,like i did for my h-bridge design

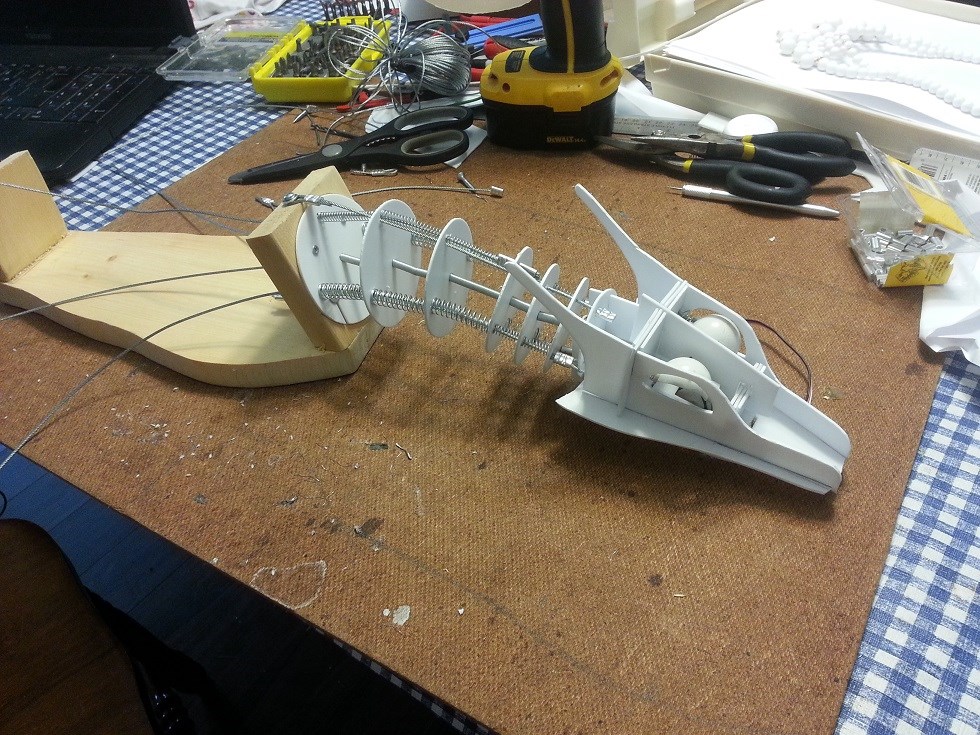

Two servos flushed in the arm , in the under arm area , red lines are servo push rods linkages , I will screw in ball links on the elbow to keep the operation smooth and discrete.

Josh, kudos on thinking outside the box! Be sure to get attachments on lower arm that spread the force on the plastic. I know you are already going to reinforce the back of it but I can see over time it might wiggle free from the top outer skin since it is softer. Maybe a small circle of the fiber matting on the outside to sandwich it. Also it would be best if you could get the pushrods to push through the middle of the arm as well to lessen the twist force under the heaviest load. Otherwise I think its great as is.

Wow this high torque servo can draw up to 5 amps! I am close to being sold on getting a robot specific gearbox for the shoulder to load this servo in to double the torque.Using the smallest metal gear box , 59.99 with for example the new high torque 416 oz servo I would have 2080 oz in of stall torque and around 1500 oz working torque. @ 16 in arm length that's 5.8 pounds of lift , that's a wine bottle and more

that what i been saying for a long time,high torque motors draw much much current 5-1 gives yout 2000oz stall torque from a 400 oz servo,i design and made so many of them

i see you bought the hacking a roomba book,its a great book with many idea's i got mine a about a year ago

Looks like you will have to factor 2.5 revolutions of the servo for 180 degree movement with that one.