By jstarne1

— Last update

Other robots from Synthiam community

Ezang's Mr. Metal Robot 2020

Synthiam ARC controlled Talking Mr. Metal robot with EZ-B4, 2 IO Tinys, RGB eyes, ServoCity gears and DFRobot hex base...

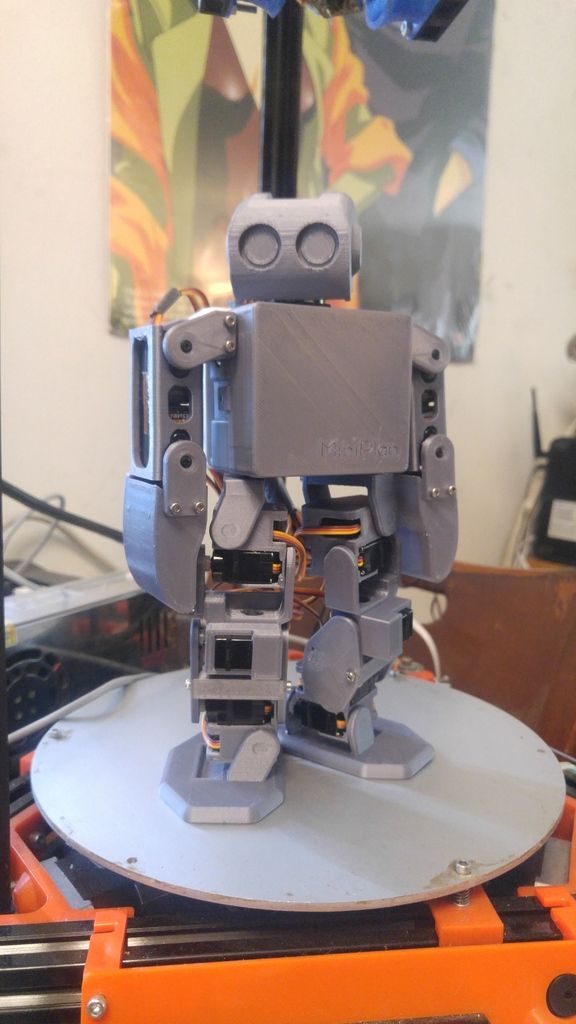

Kenny's Humanoid #3, The Miniplan

3D-printed humanoid built on a FLSun Kossel Mini Delta from Thingiverse, photo build progression and upcoming motion...

Lars1989's Omnibot 2020 - The Next Generation

Revive Omnibot 2000 with an ez-robot kit and L298N motor controller; add small servos for arms and test a 6V 5Ah gel...

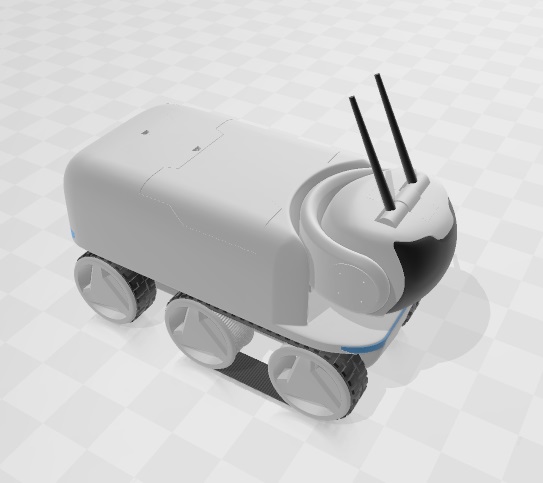

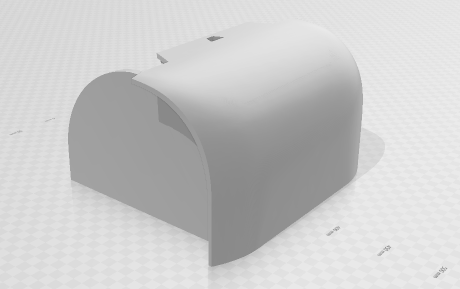

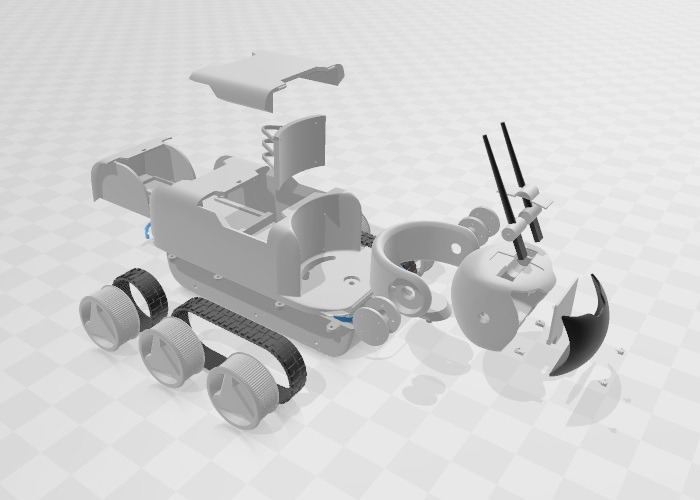

These are not all the sketches just bits a pieces. I have gone through 3 versions of the concept making it a little better, more practical and functional each time. Of course, anyone is welcome to weigh in with suggestions. The general idea with this concept is to have accessories that can be printed and attached , like for example a weed eating attachment and lawn mower. That is just an initial use , but I would like to come up with even more attachable accessories for this guy. Once I have several accessories available, I will also develop a similar but possibly smaller version dedicated to education. My idea is to put these up for sale and for every full sized kit, giving a special educational package to a local school.

Ideas for play and educational attachments are welcome.

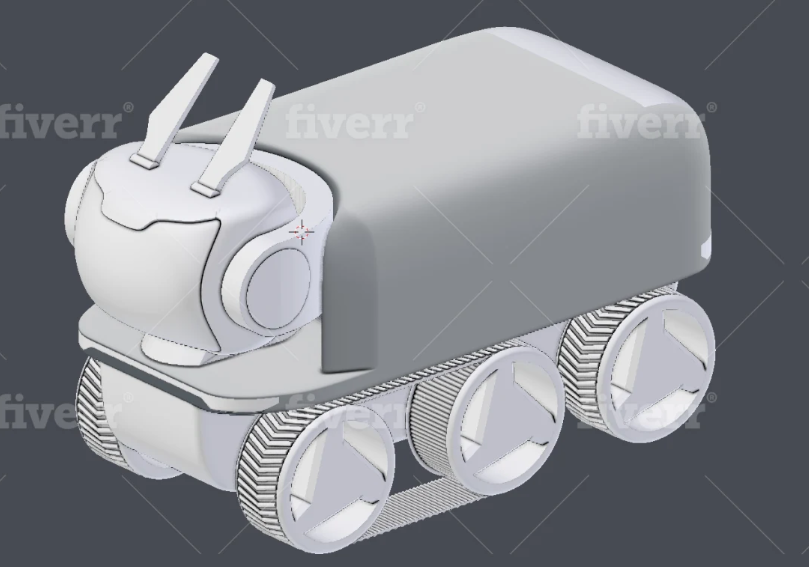

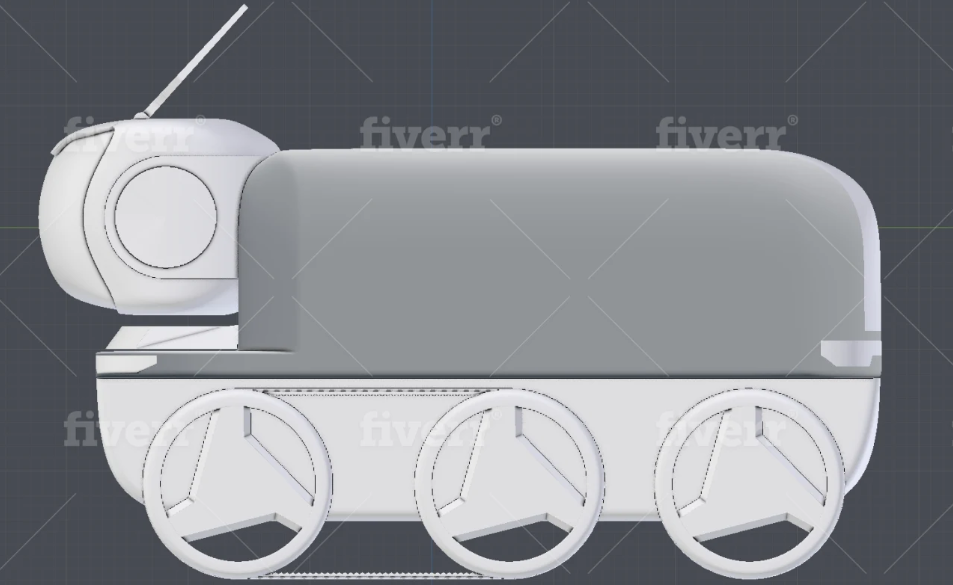

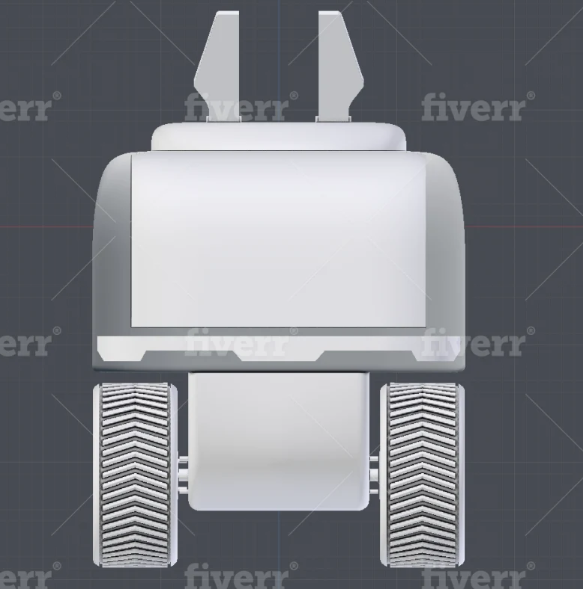

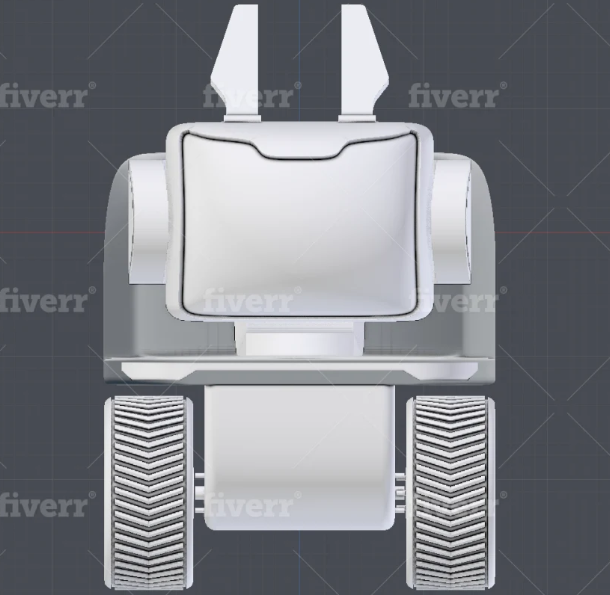

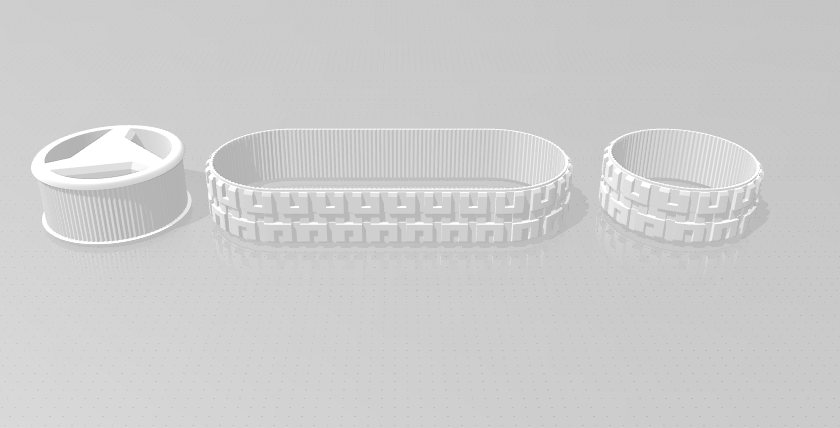

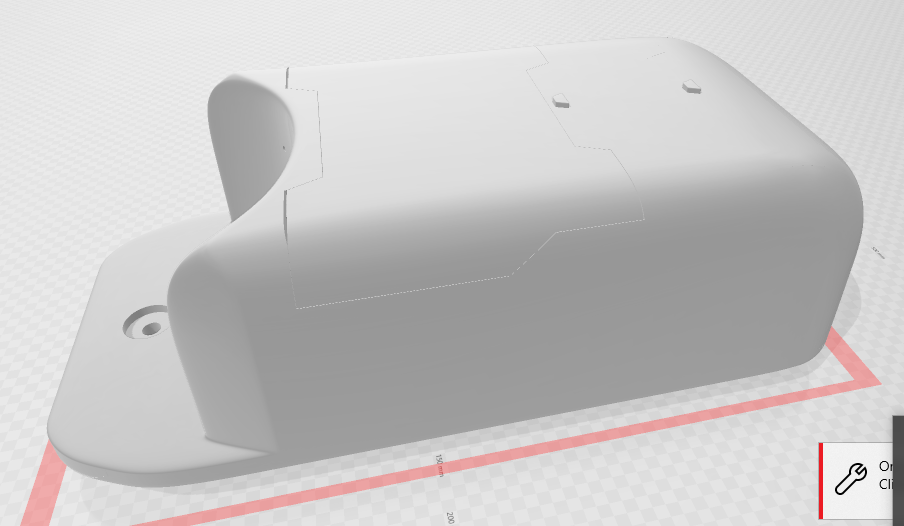

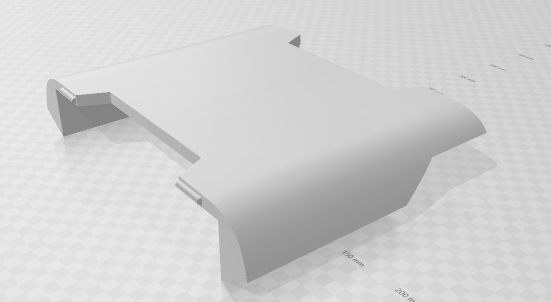

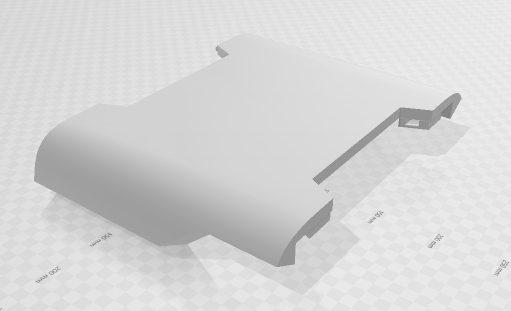

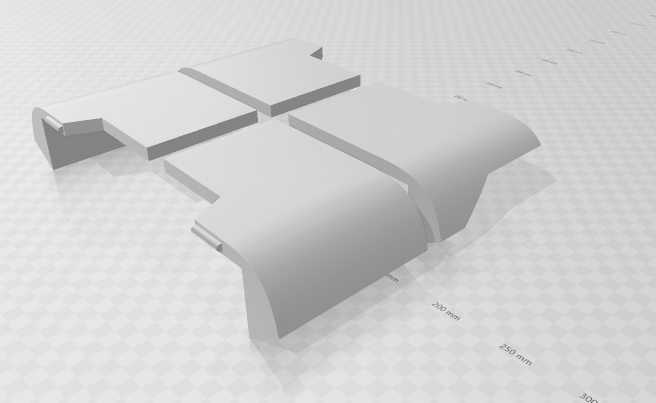

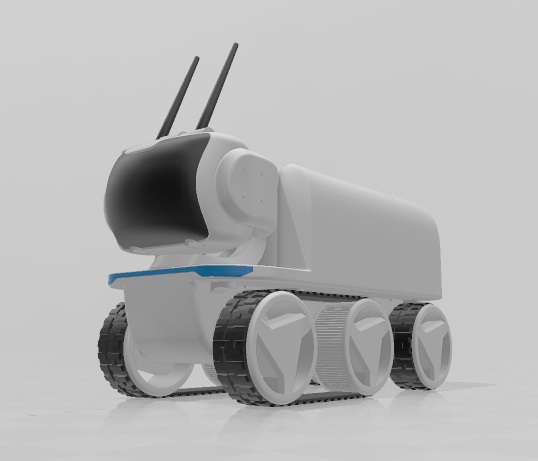

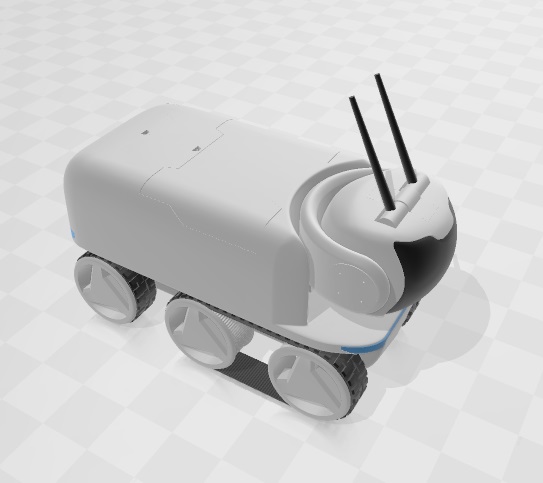

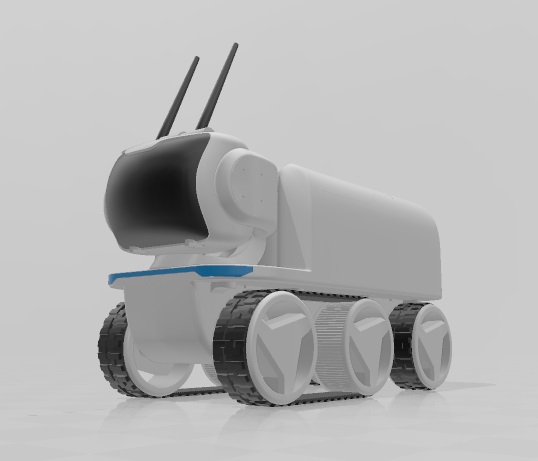

Original POST: Here are some updated renders, I have a talented 3D artist working on options for single piece tracks and tires at this time. I don't like this version of the tracks and tire because it is so thin. I feel it needs to be at least twice as thick so we are back to the drawing board on those. , but I was able to get some different views of the 3d model progress.

This is really sweet!! Cannot wait for further updates!!

Will that guy on Fiverr model you the real thing from your sketches? So you can print it and the servos will fit in? Amazing!!!

Hi Mickey666Maus, Thank you for your feedback!

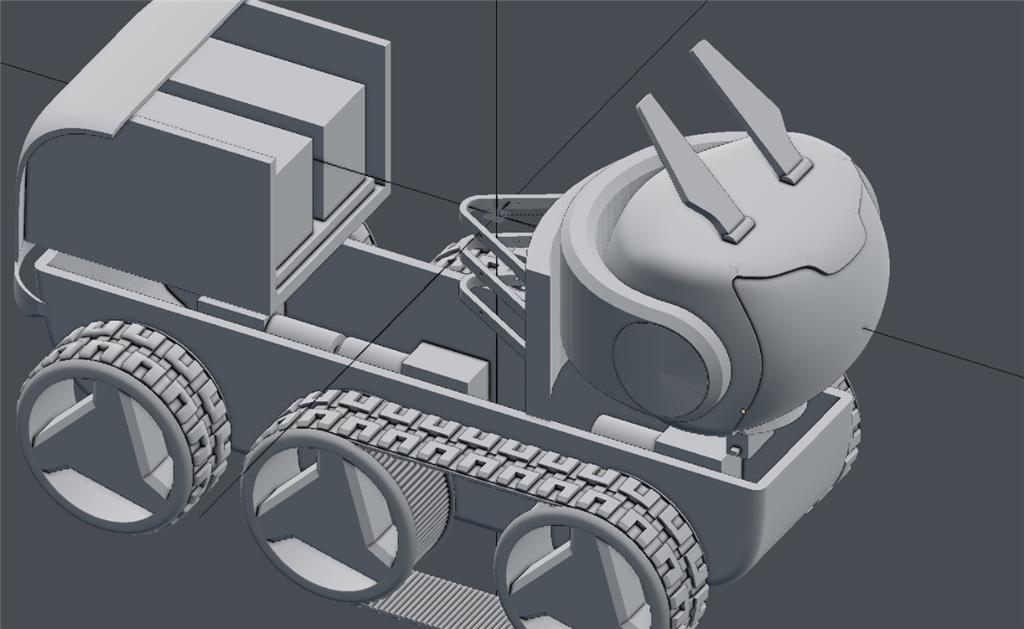

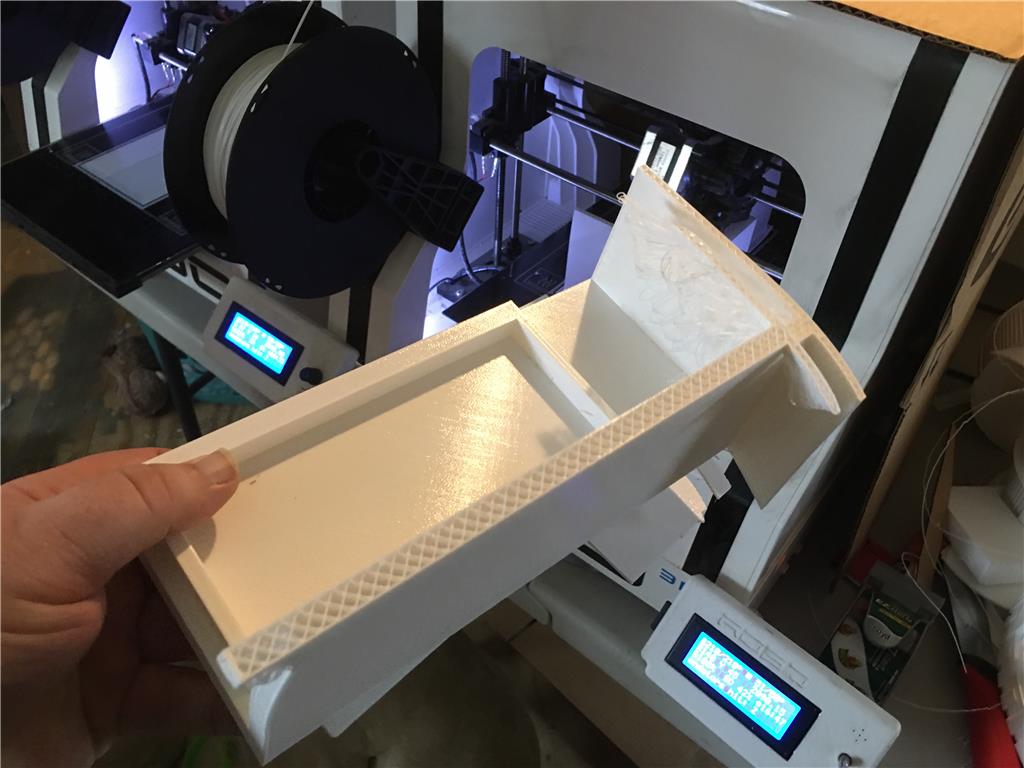

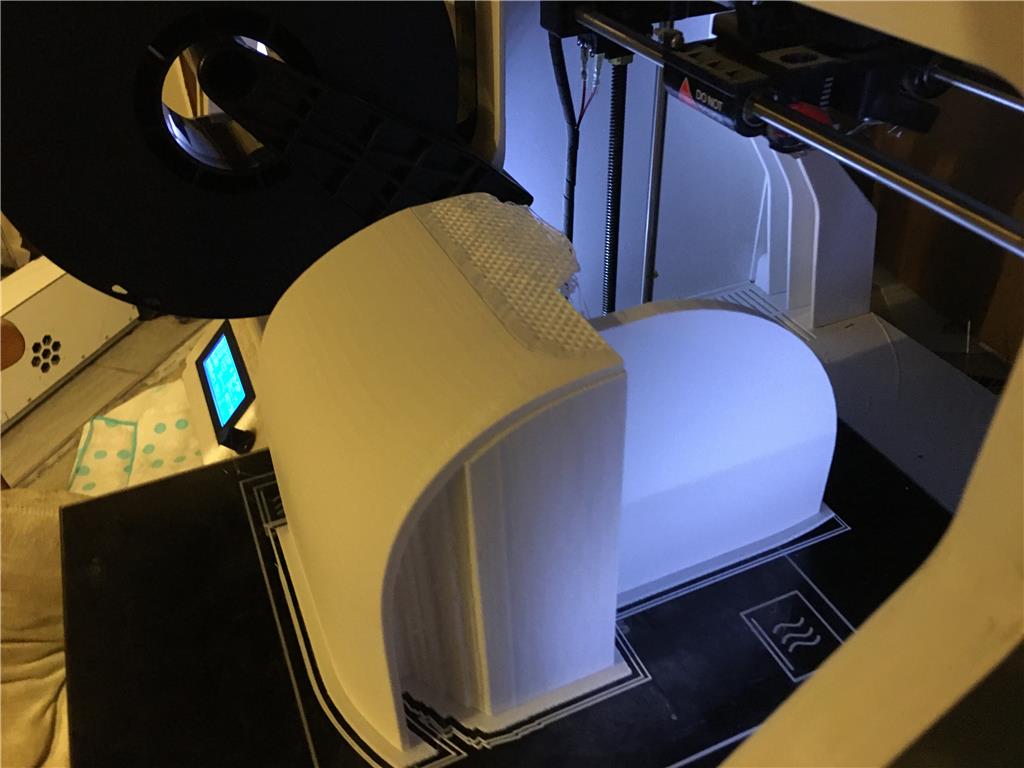

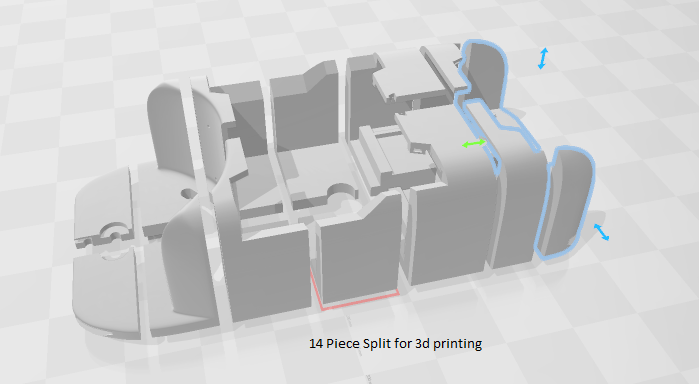

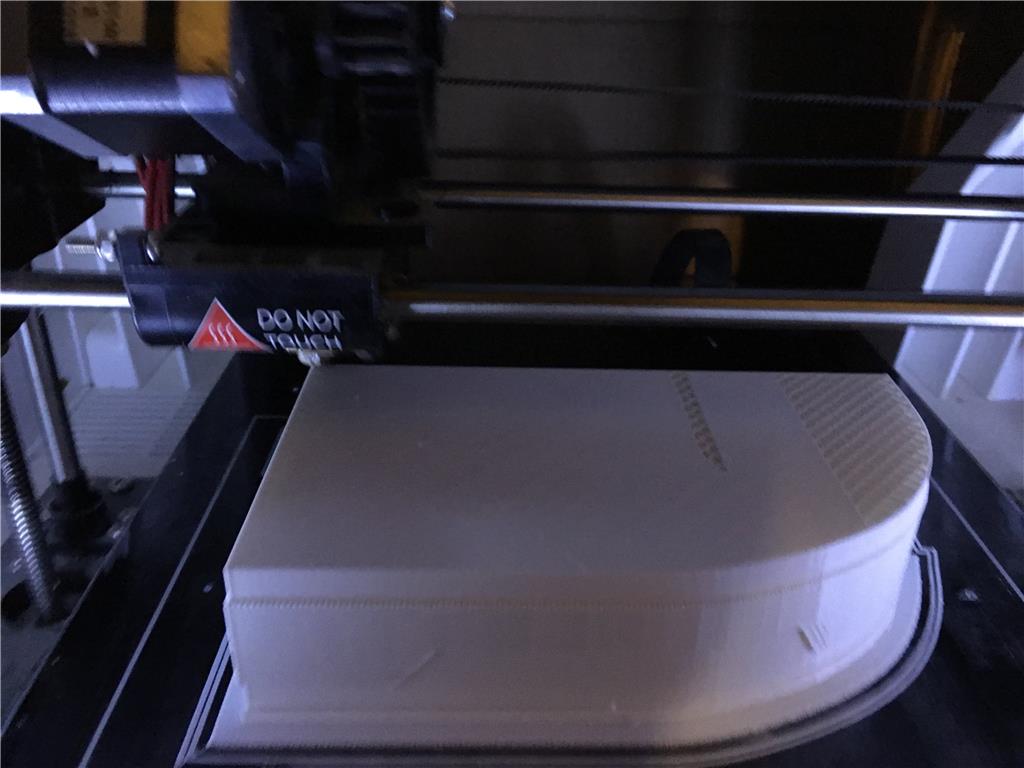

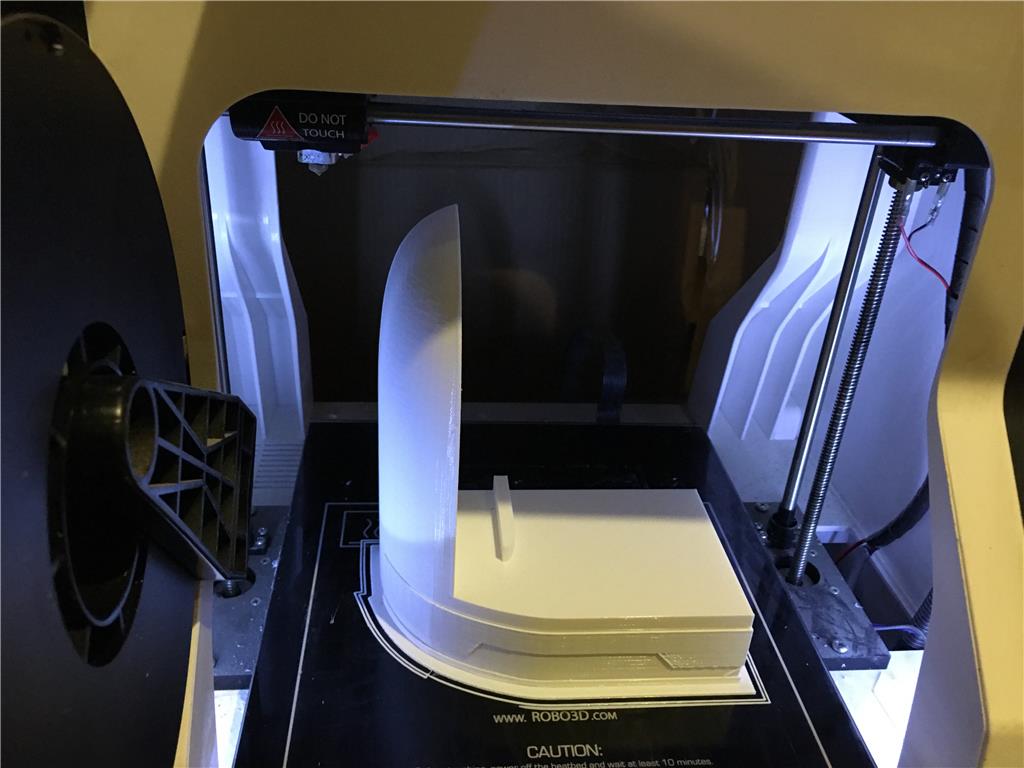

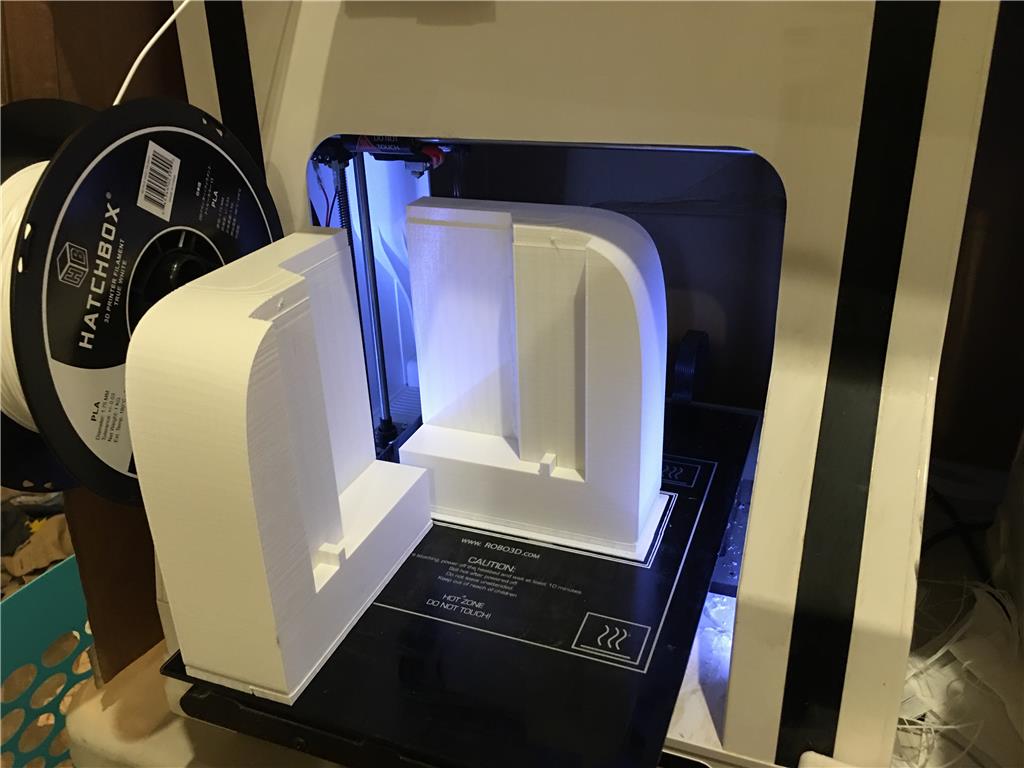

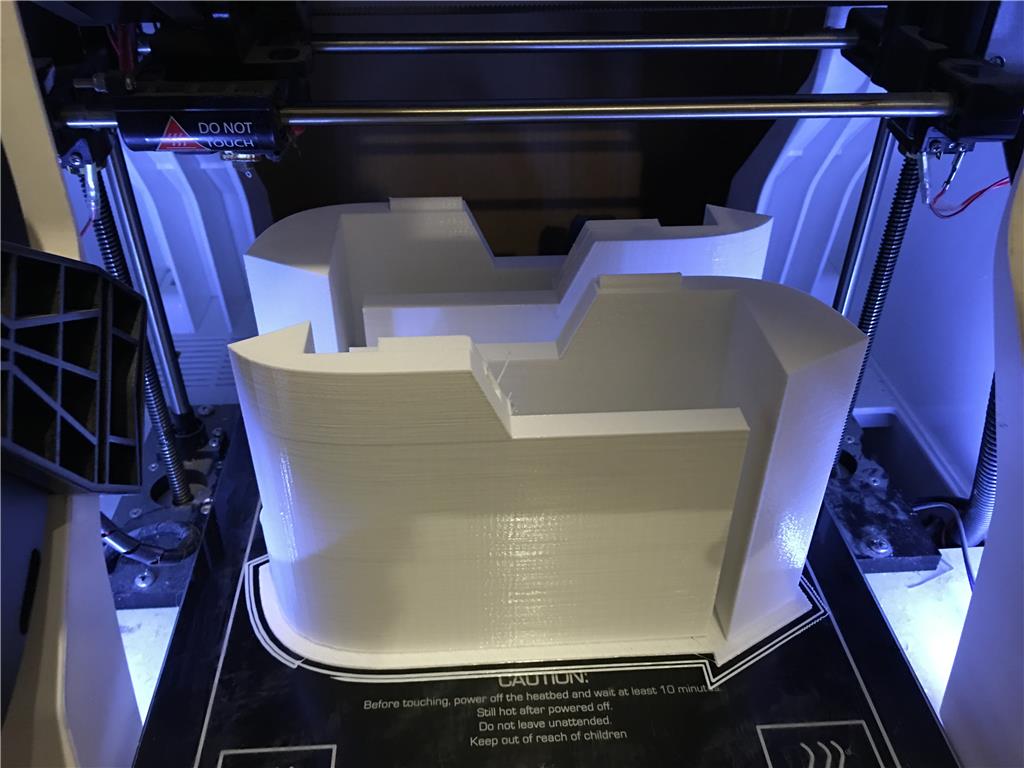

Yes the Idea is that there will be a "mini" model that uses Continuous RC servos. As it is being developed it is full sized with 6 worm gear drive 160 rpm motors attached to each wheel. The model is much too large to print in one go, so I am getting help from this modeler to break it into manageable pieces with tabs and key marks for alignment as well.Once I have the three robots I am designing printed and working in the real world I plan to launch a campaign to raise money and build 100 of the models. For every fully built model give a development kit and robot to a local school. There are 79 schools in our county. Hamilton County, Chattanooga TN.

Cool project!! Keep us updated...this looks really awesome!!

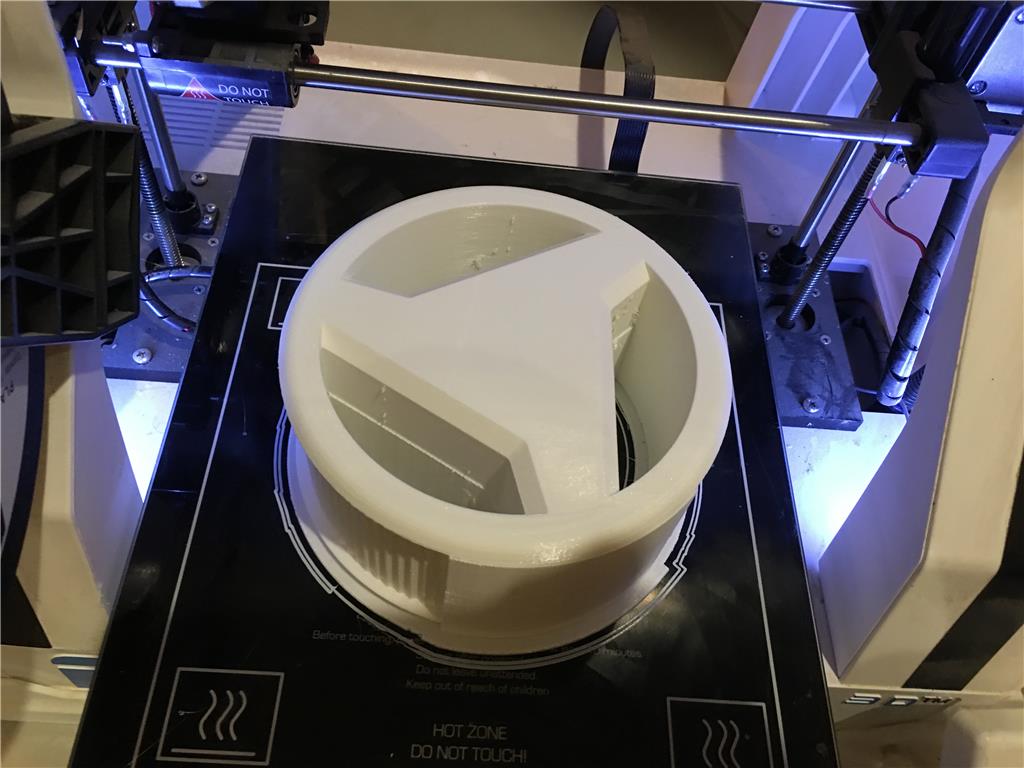

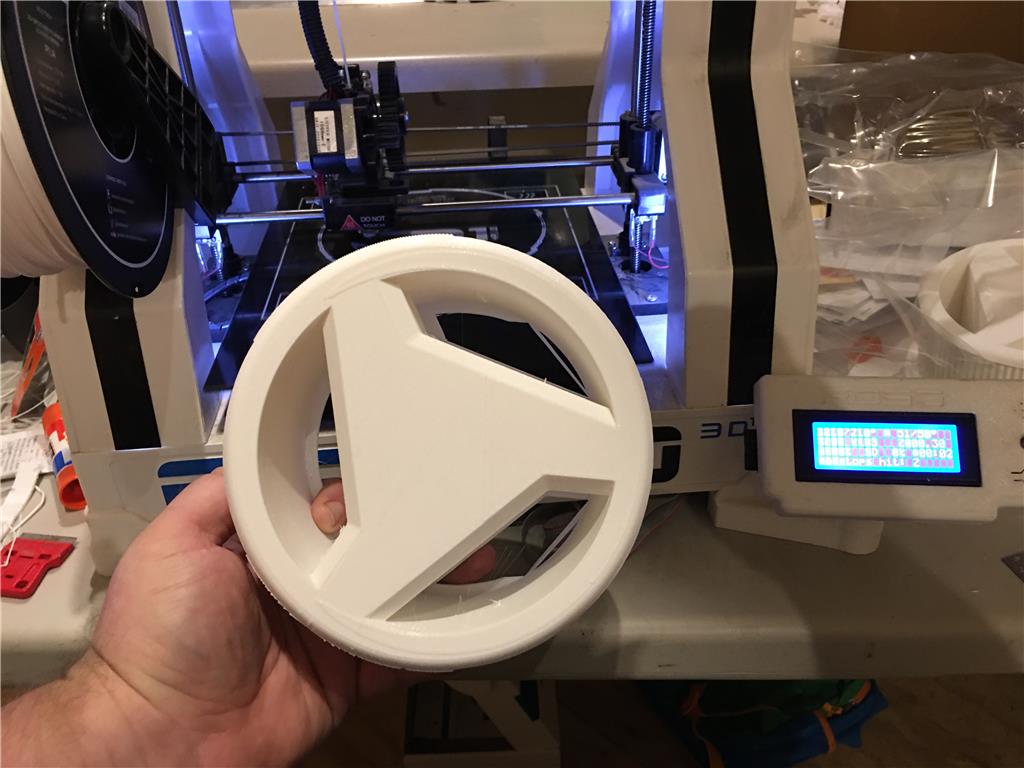

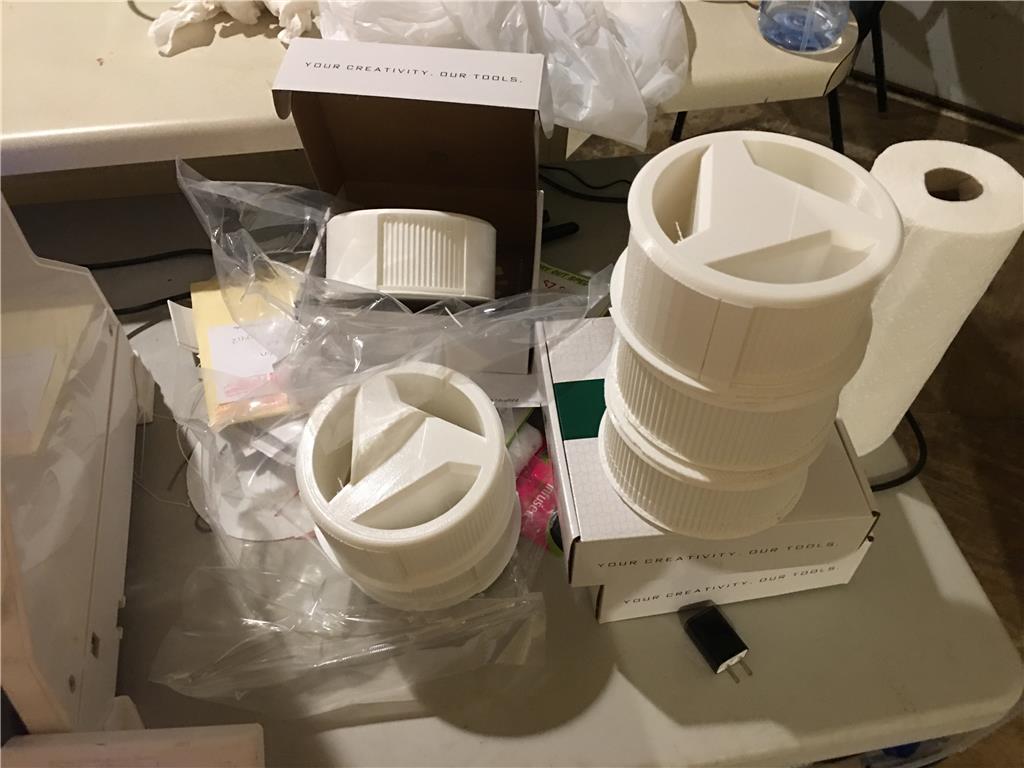

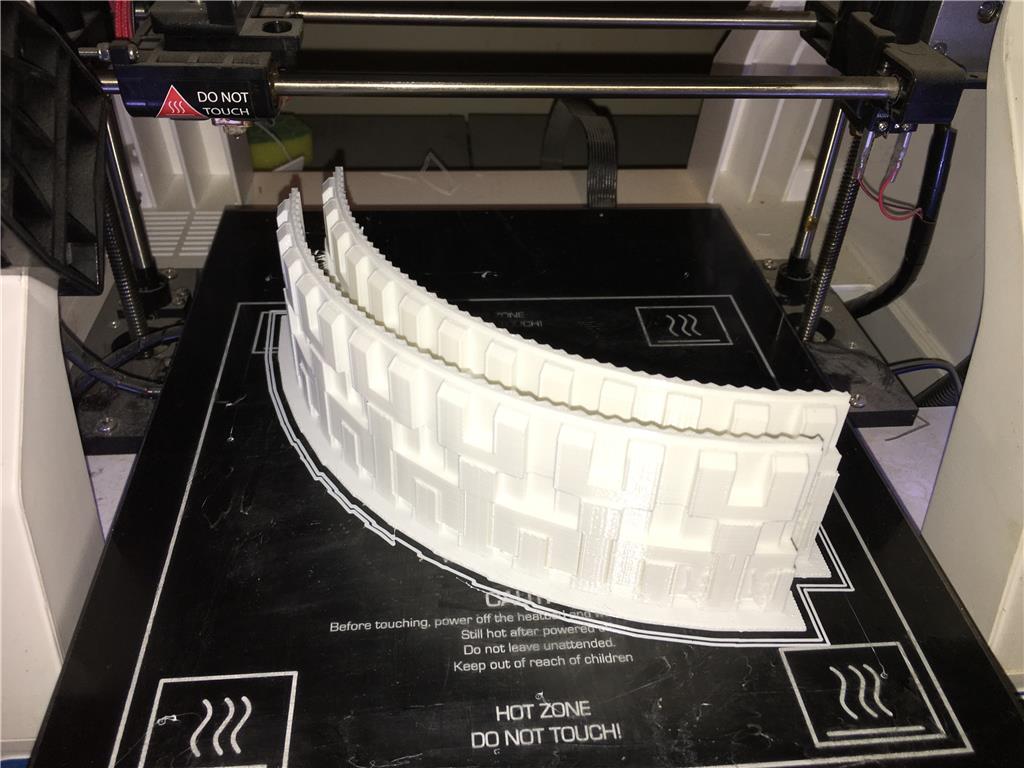

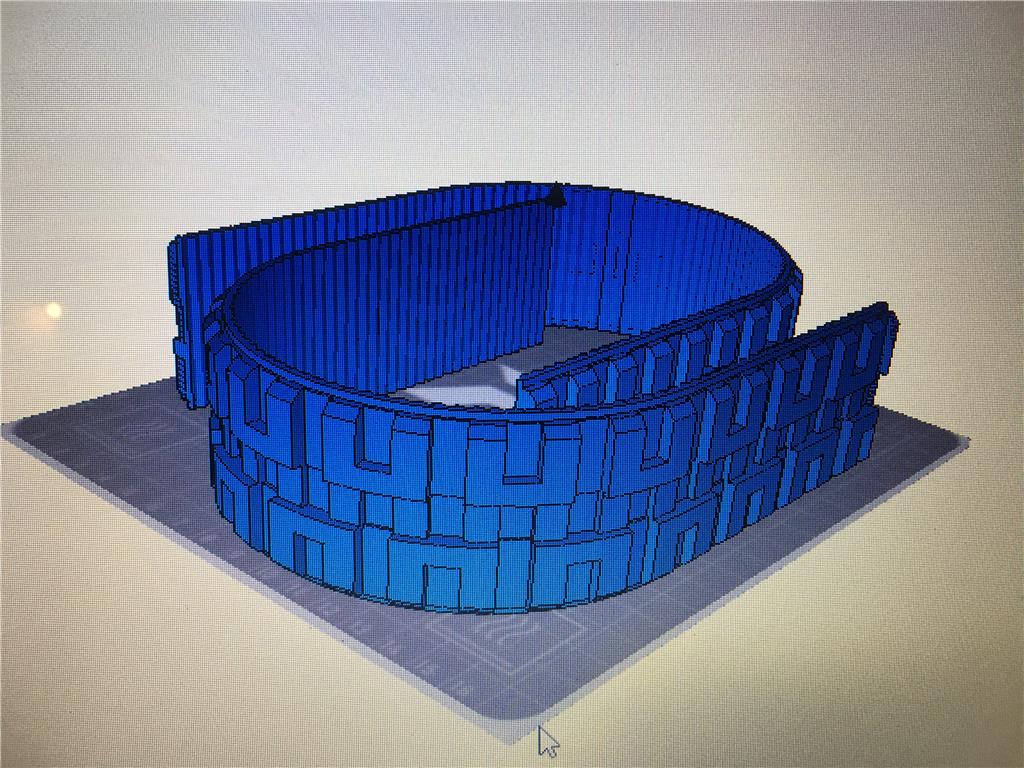

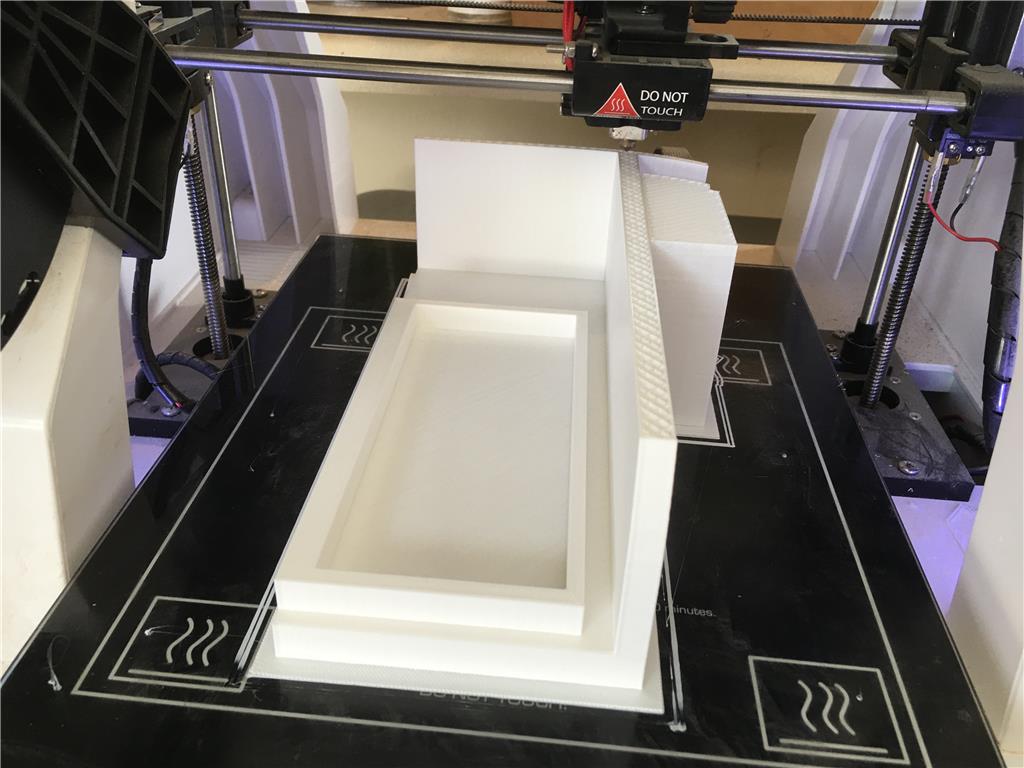

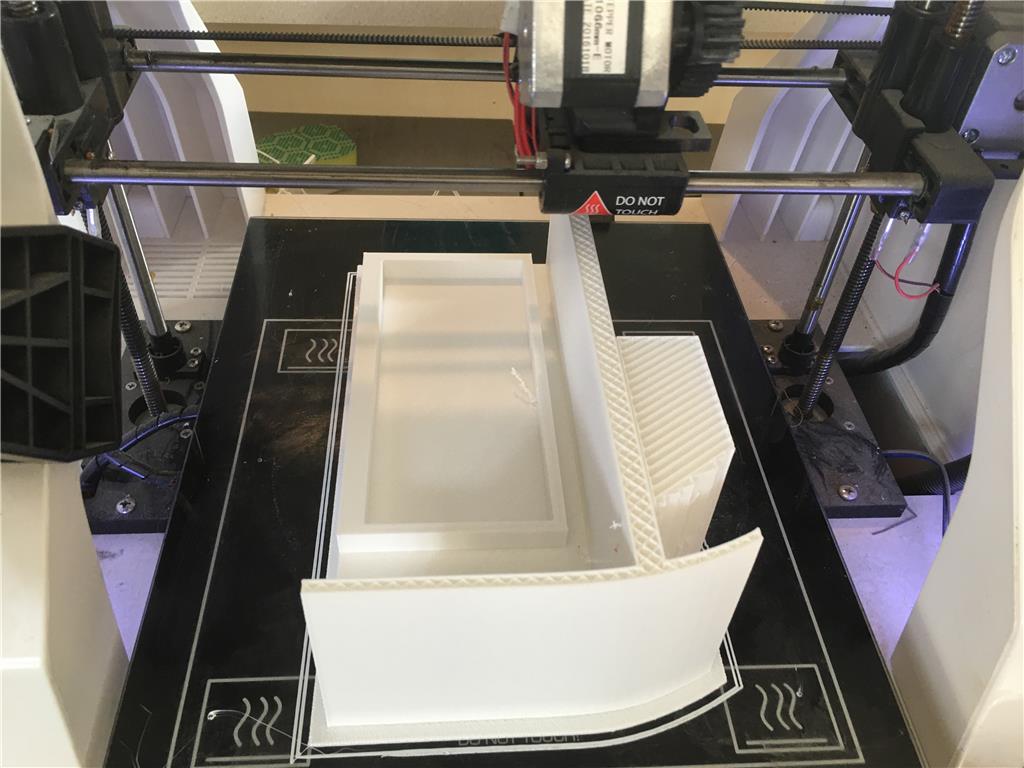

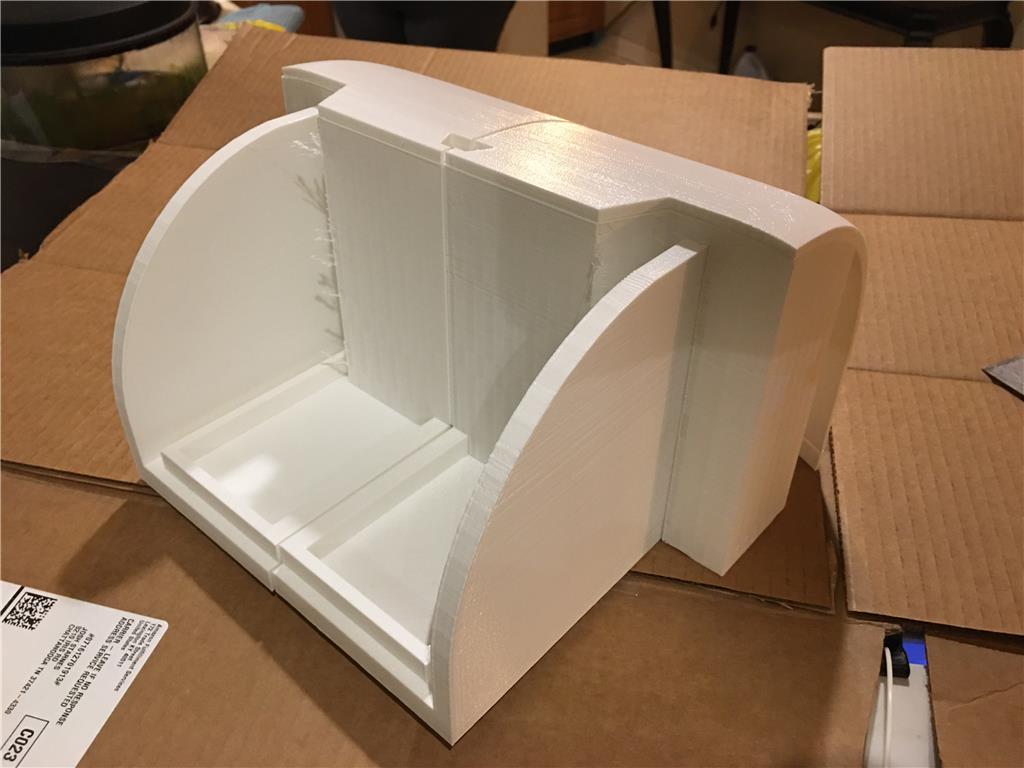

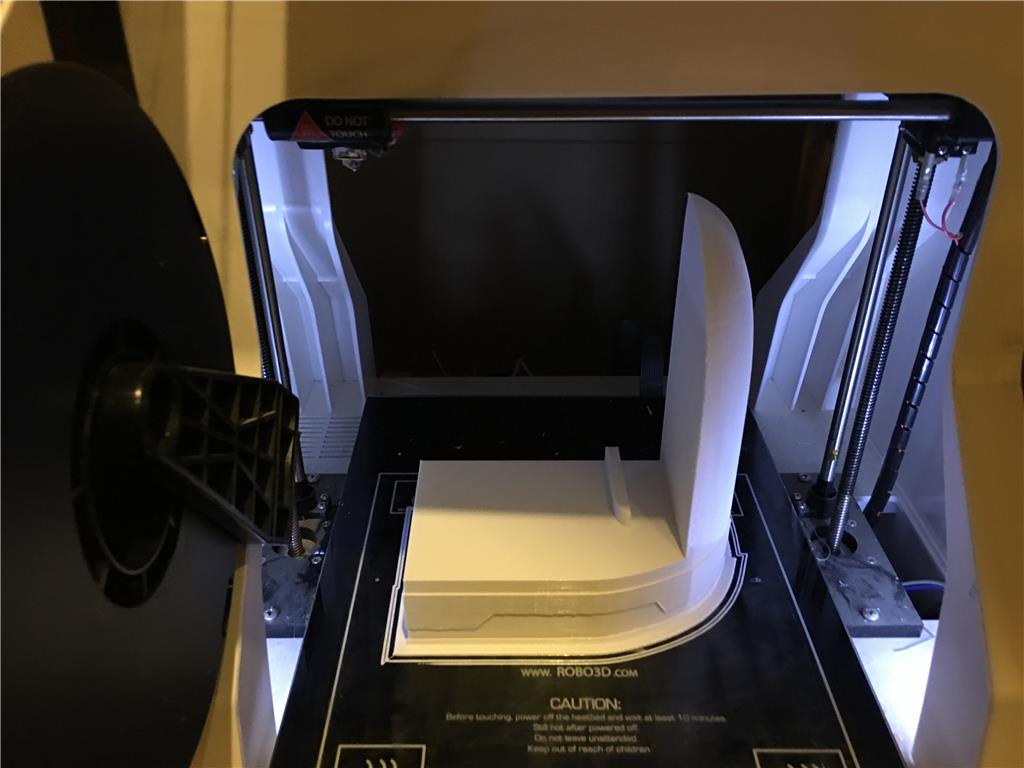

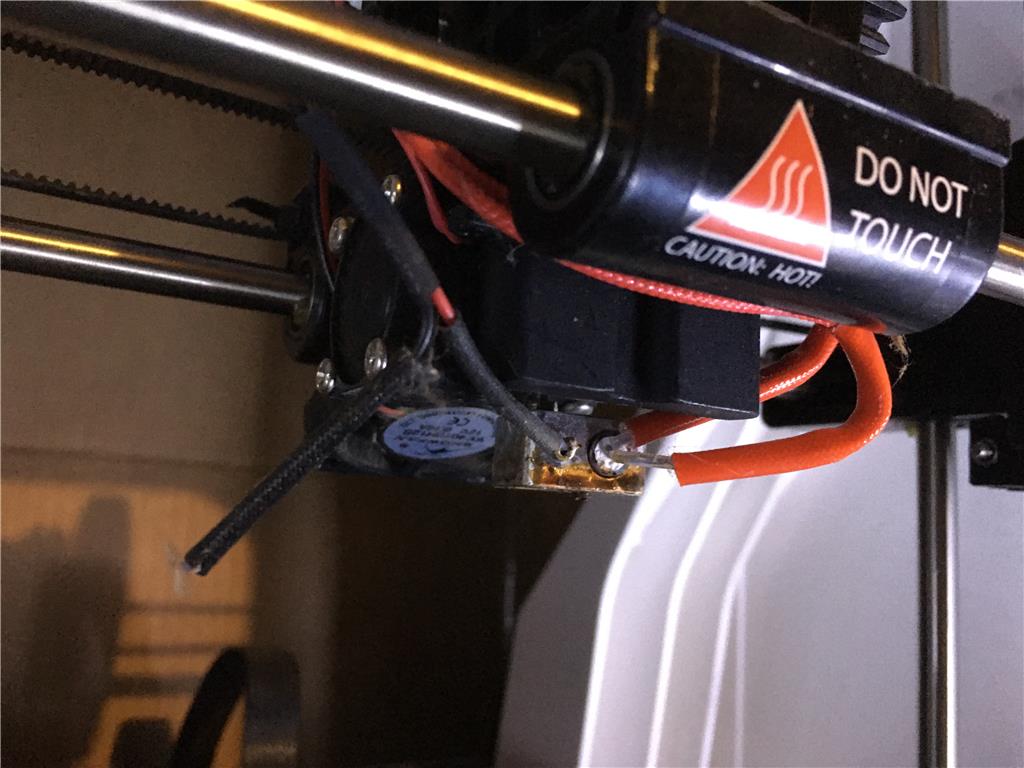

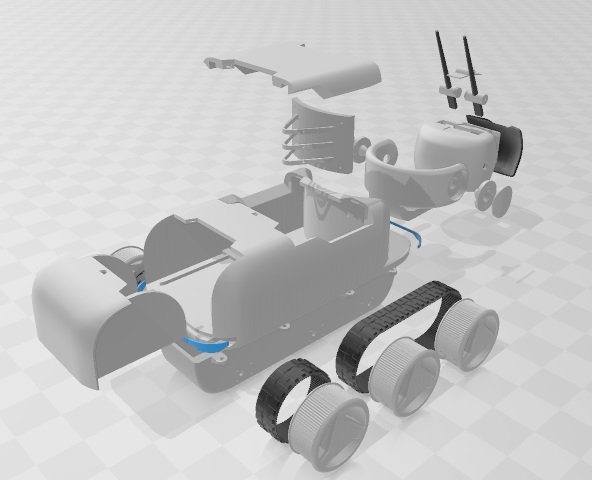

Hello all, this project has made some progress, I will share some images.

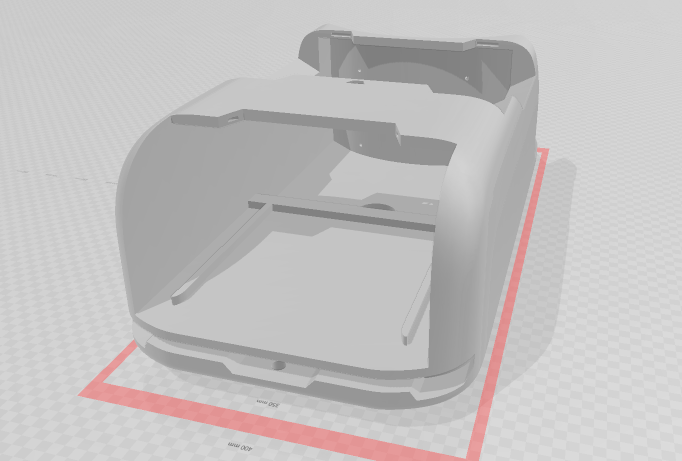

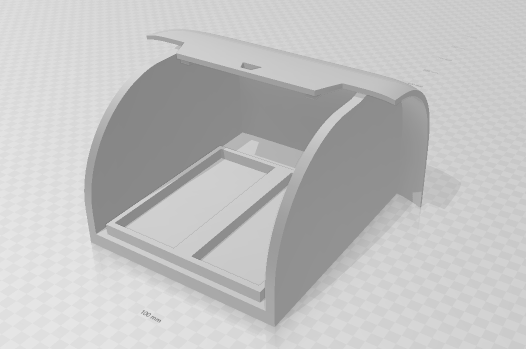

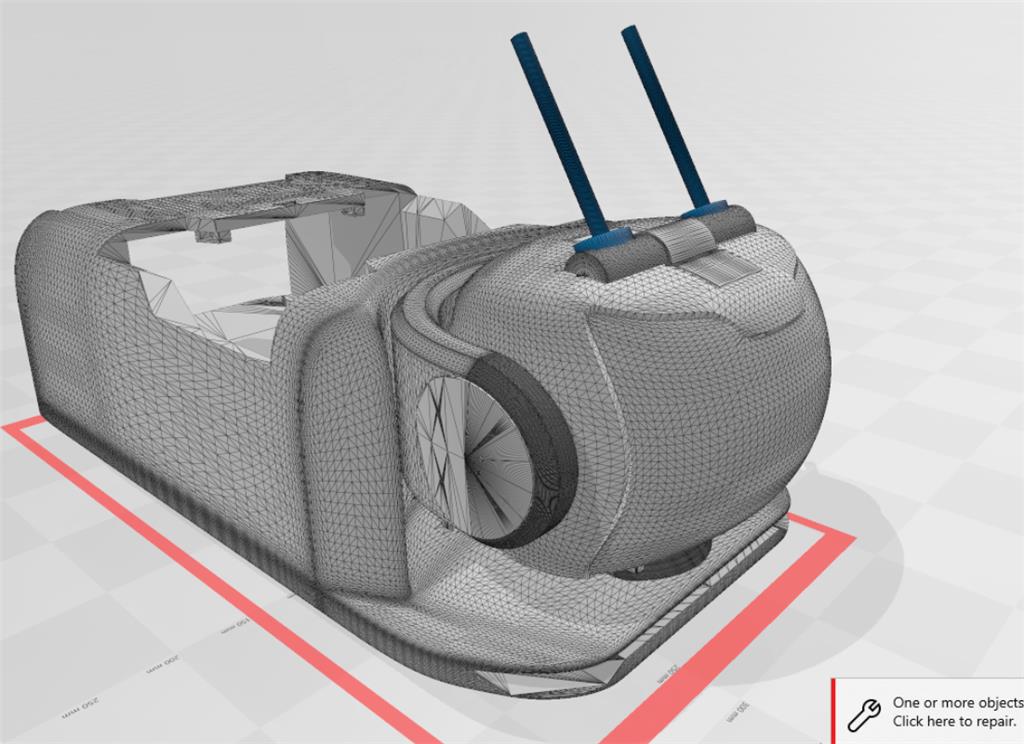

Here is a xray style view. There is a drawer for battery packs in the rear. Center mass is where two din rails are vertically mounted for all the electronics. You can see three of the 6 motors in this view.

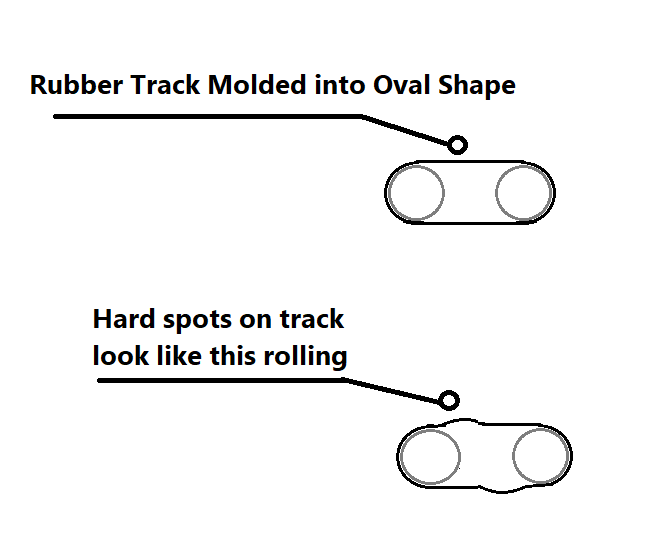

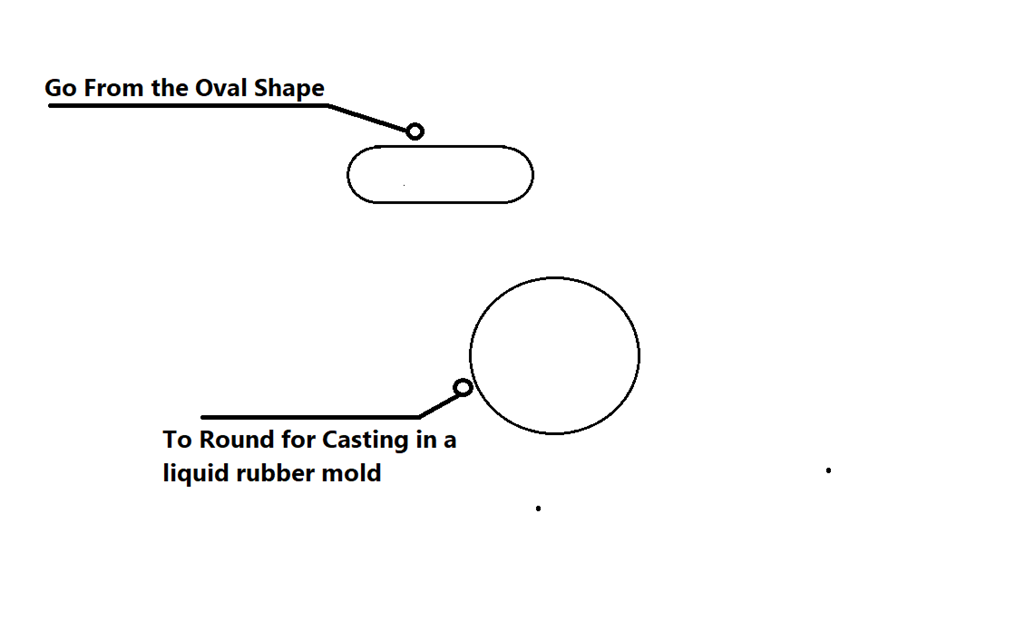

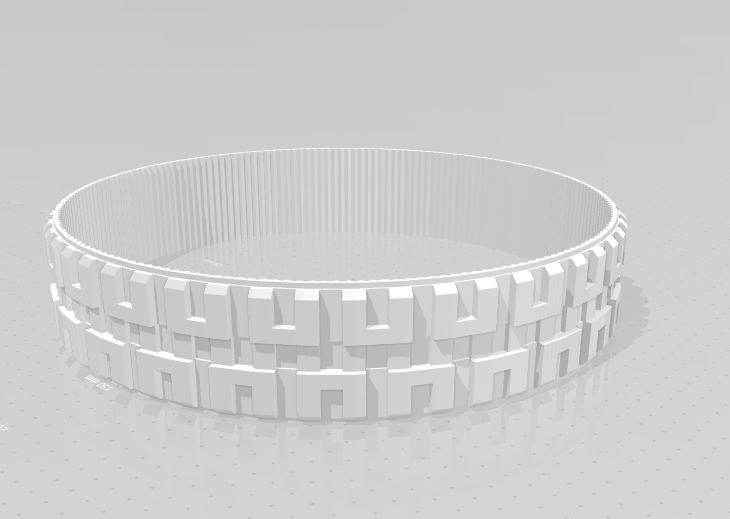

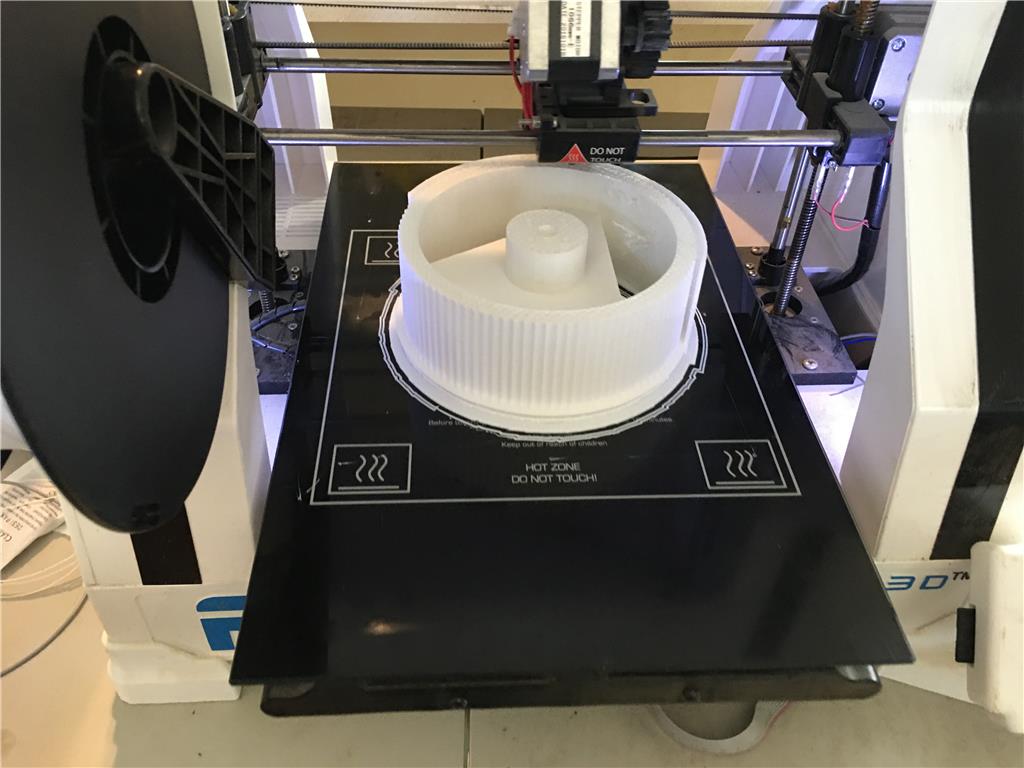

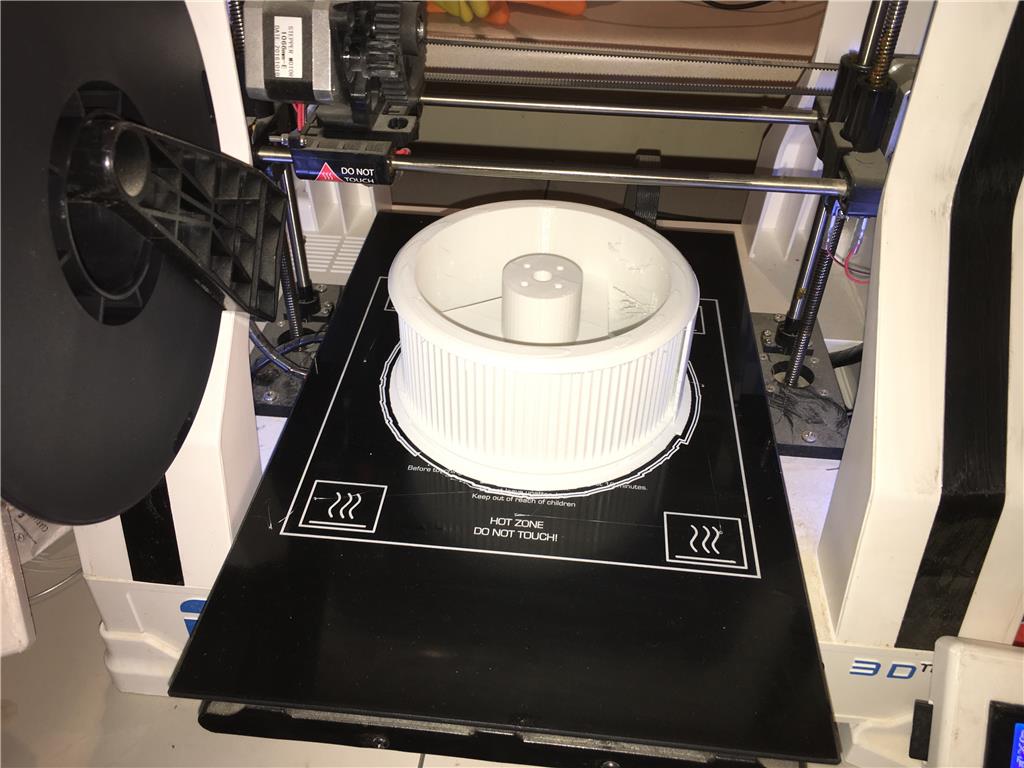

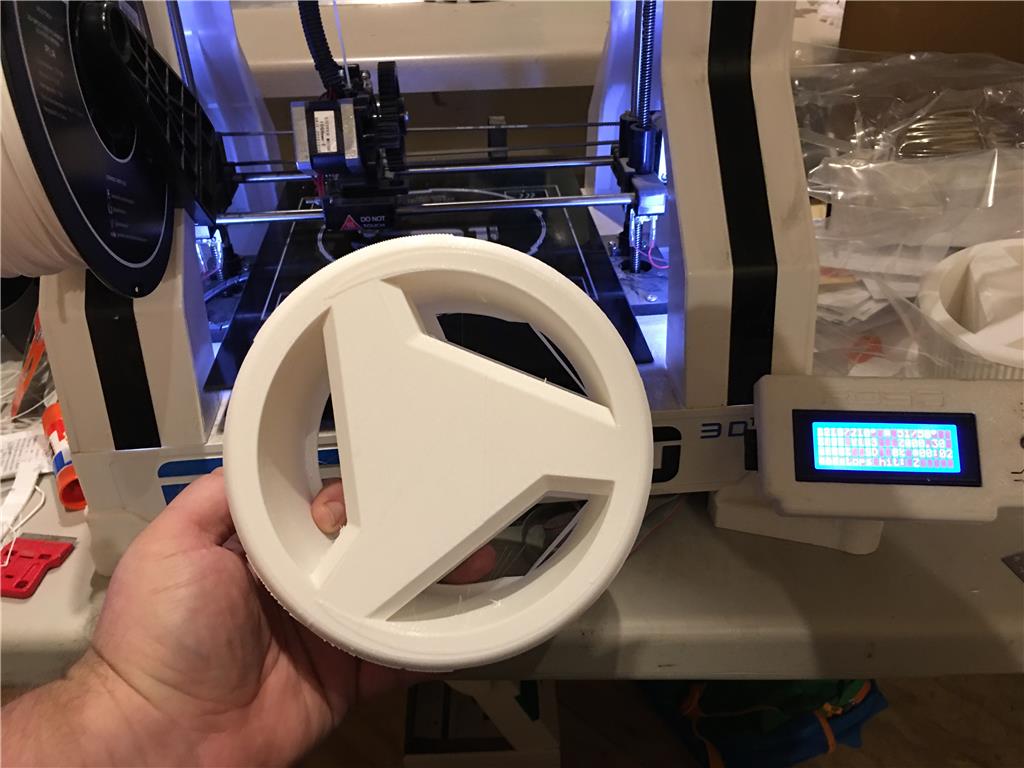

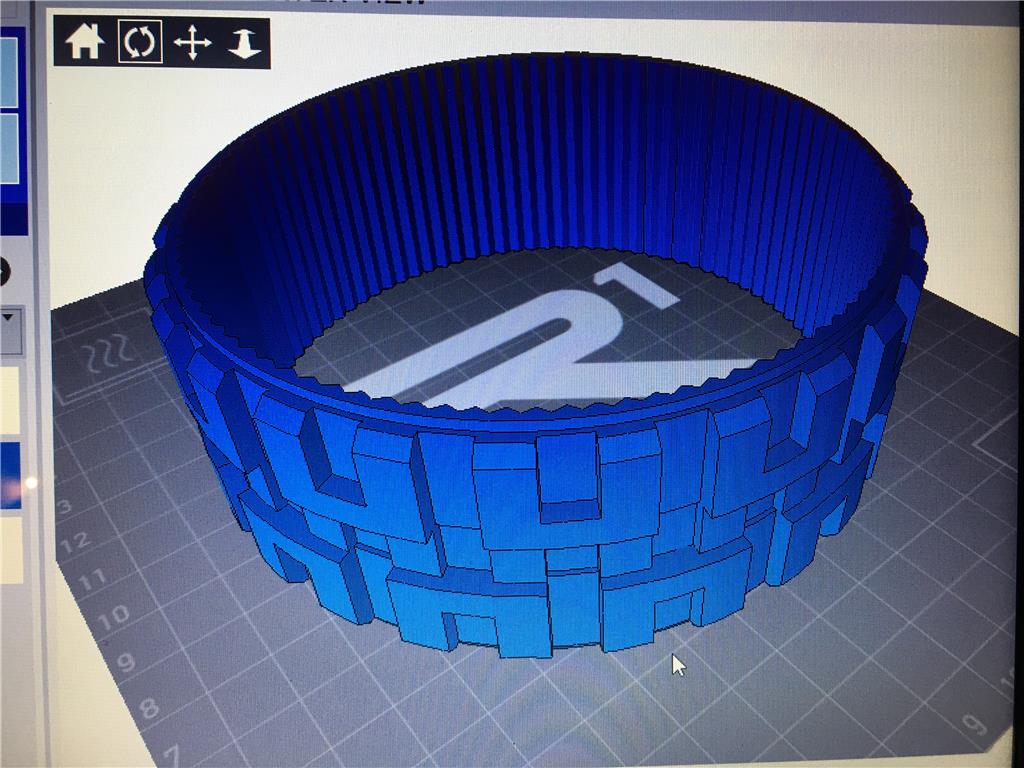

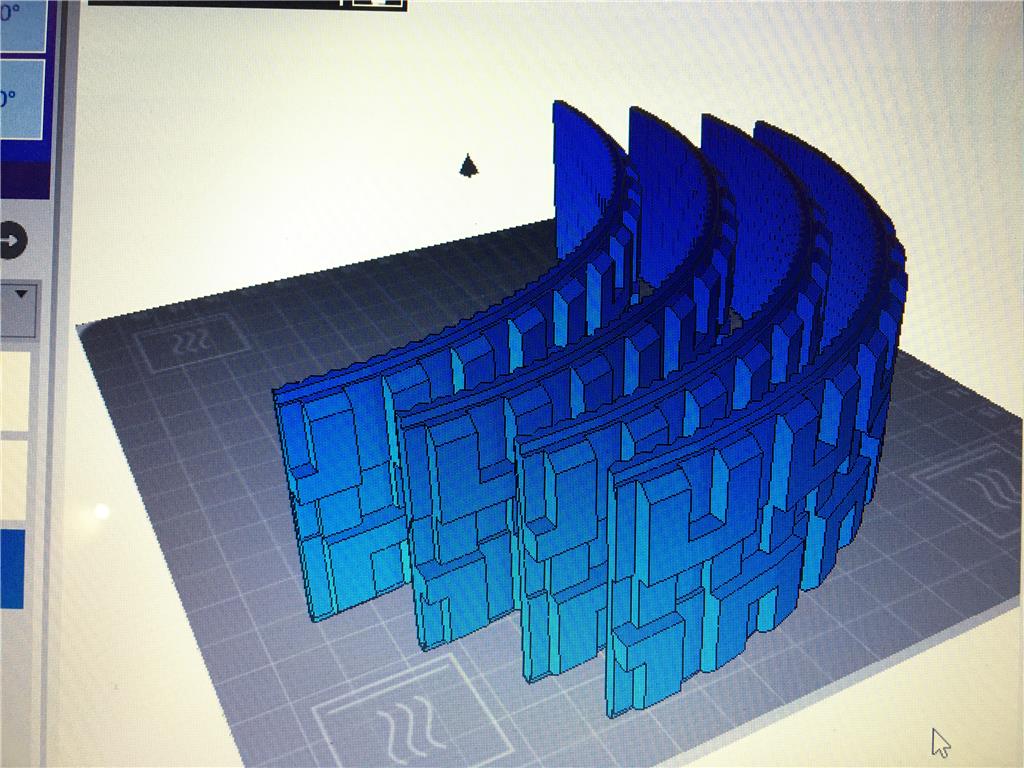

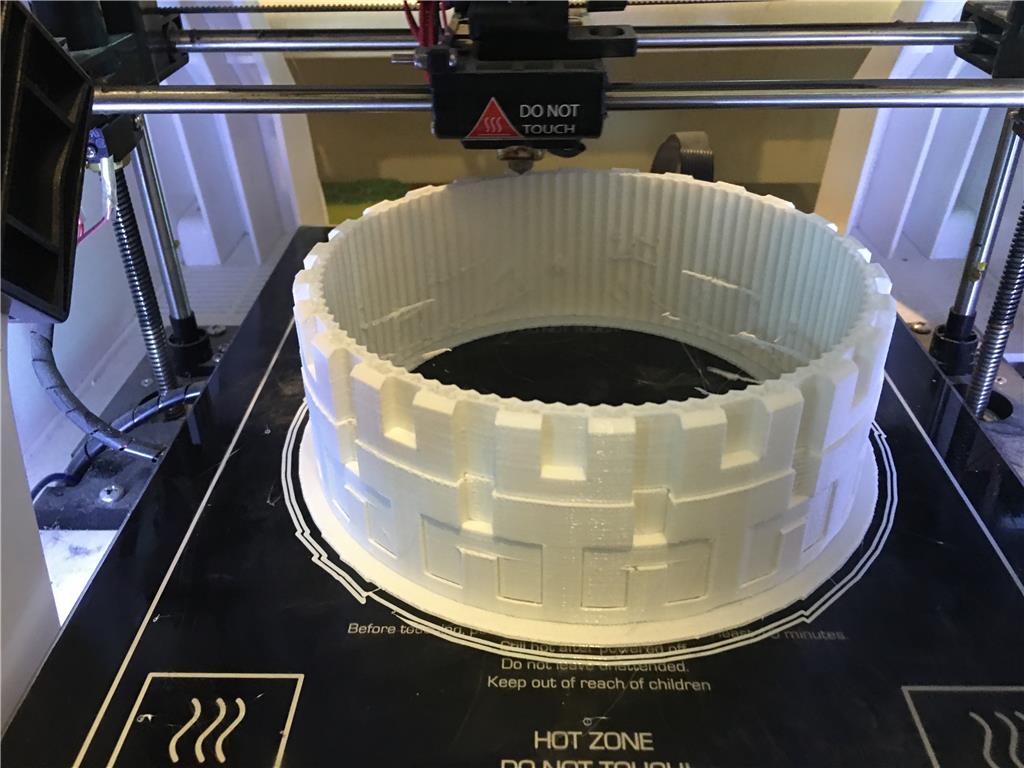

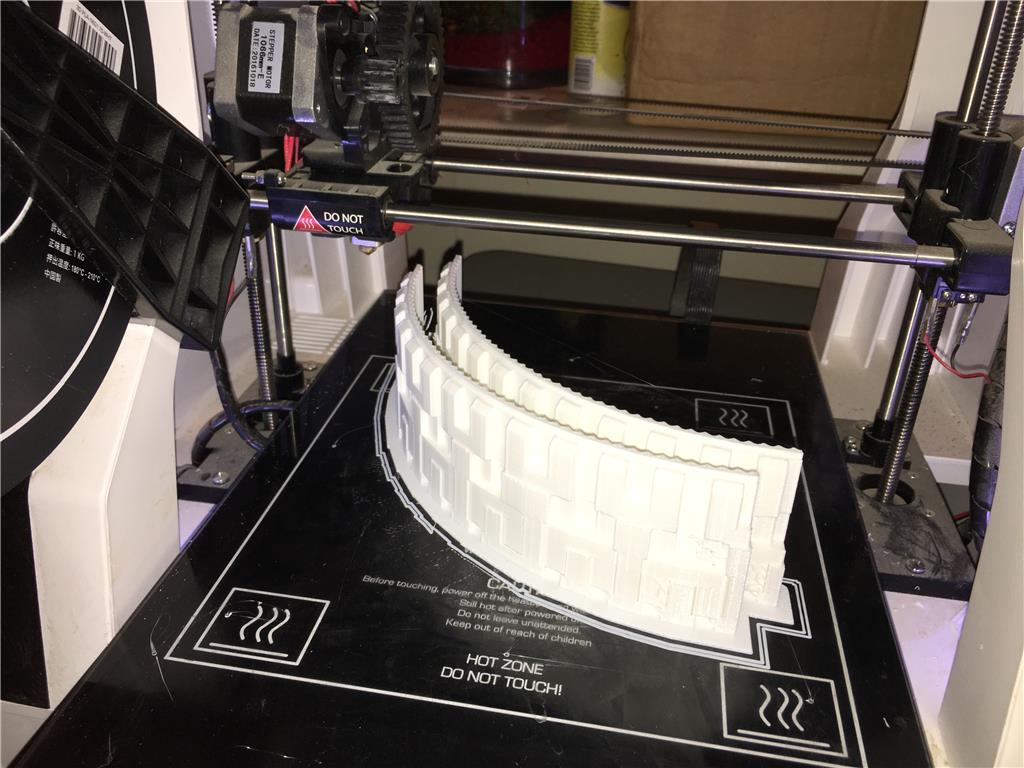

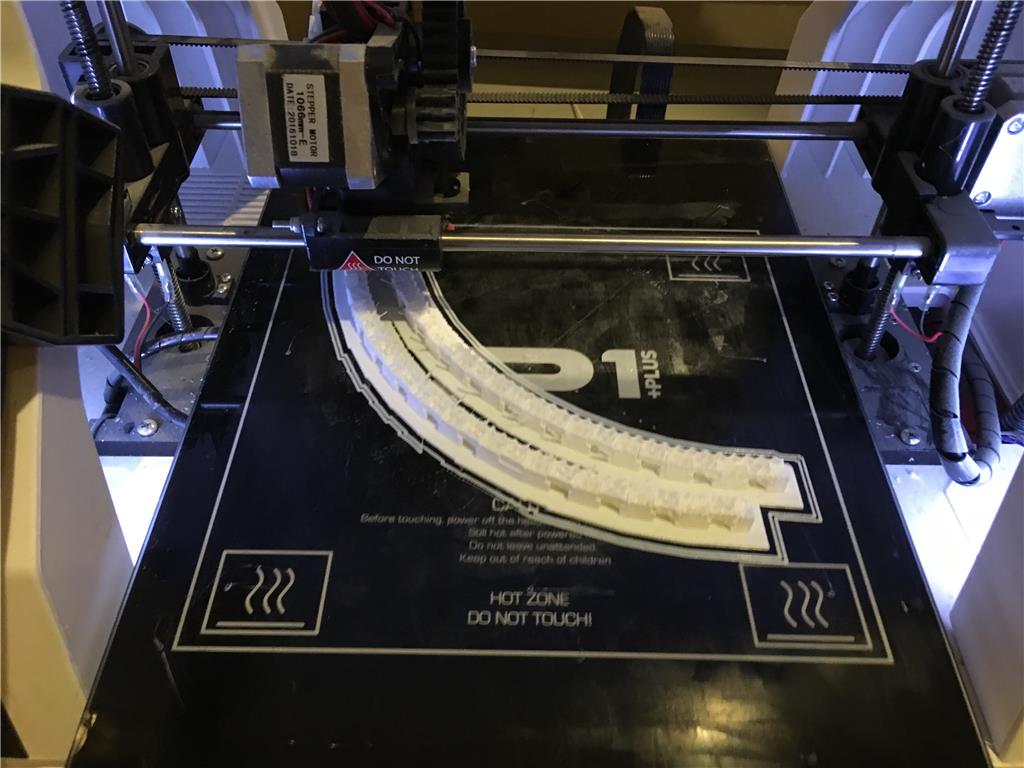

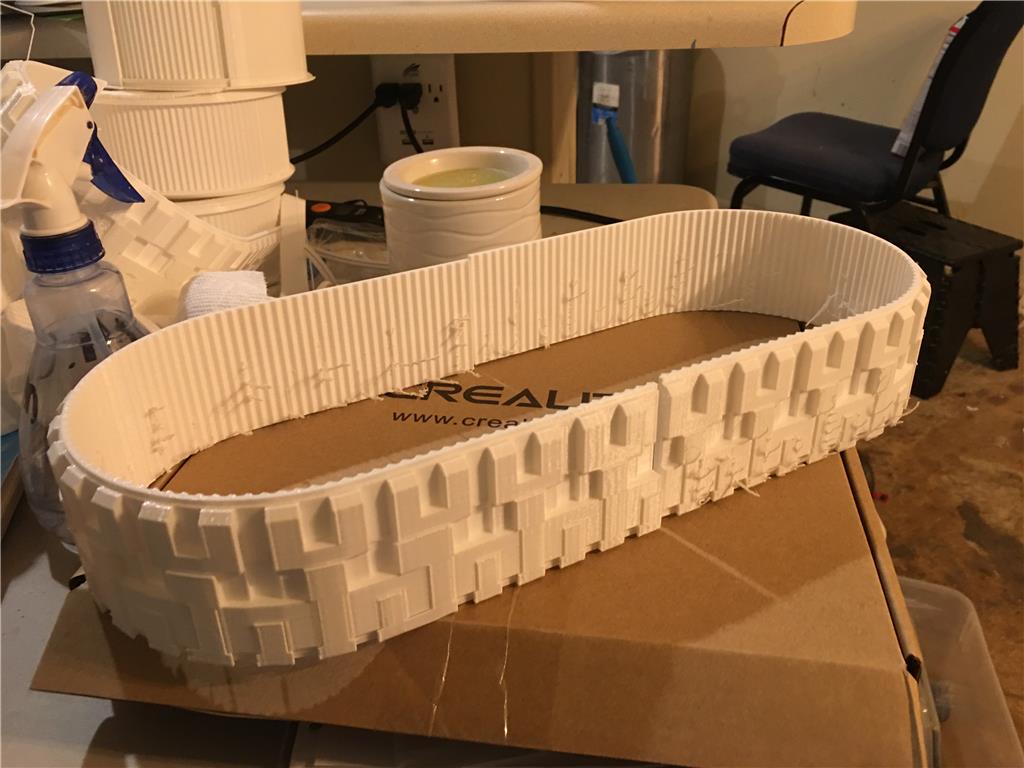

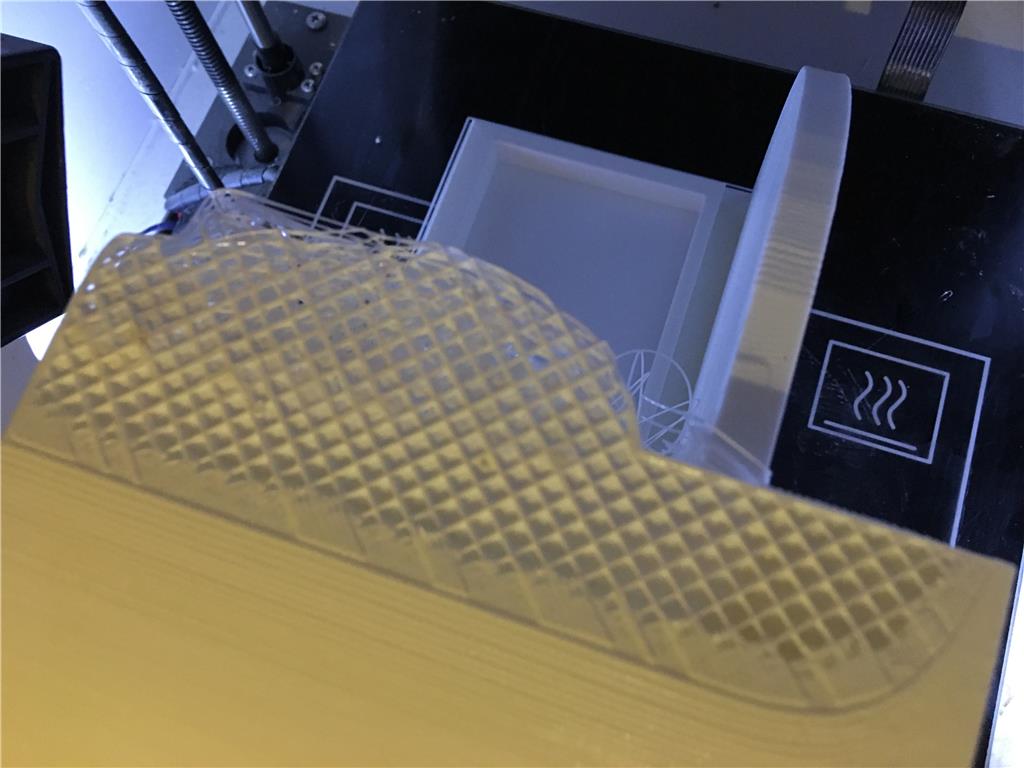

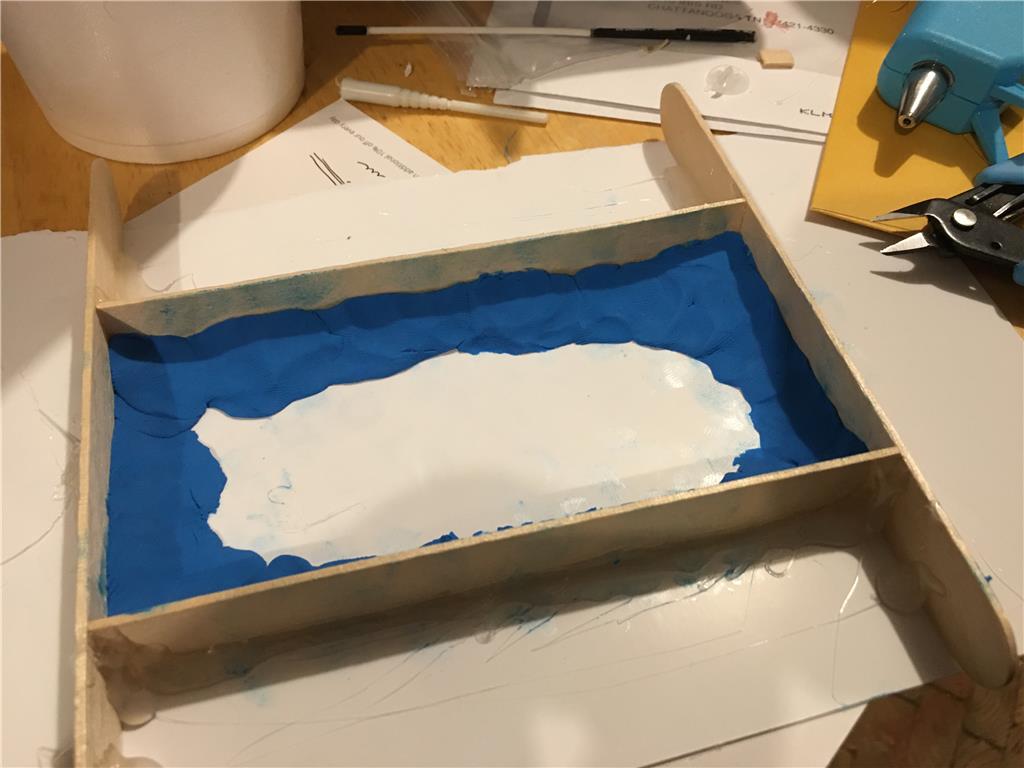

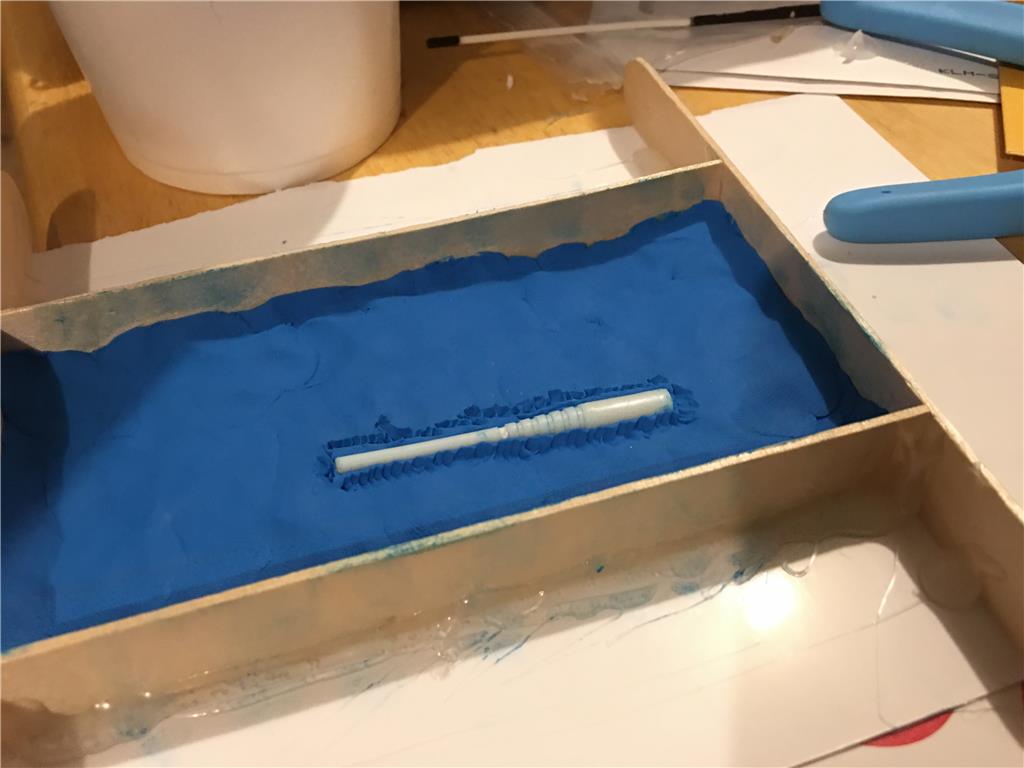

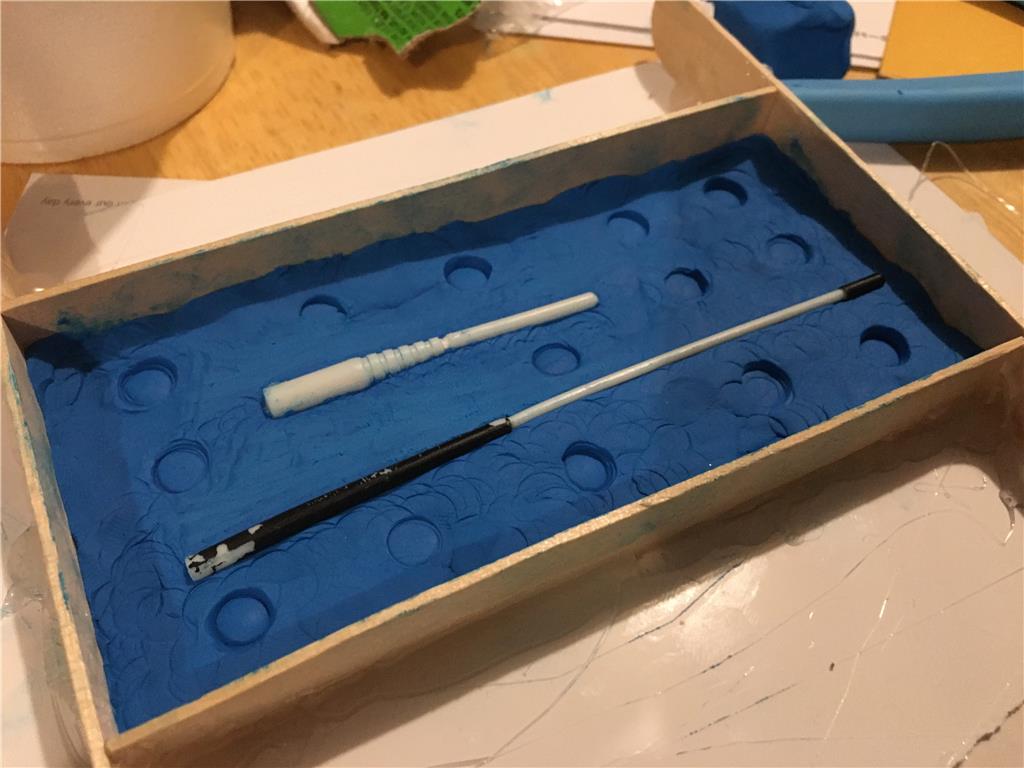

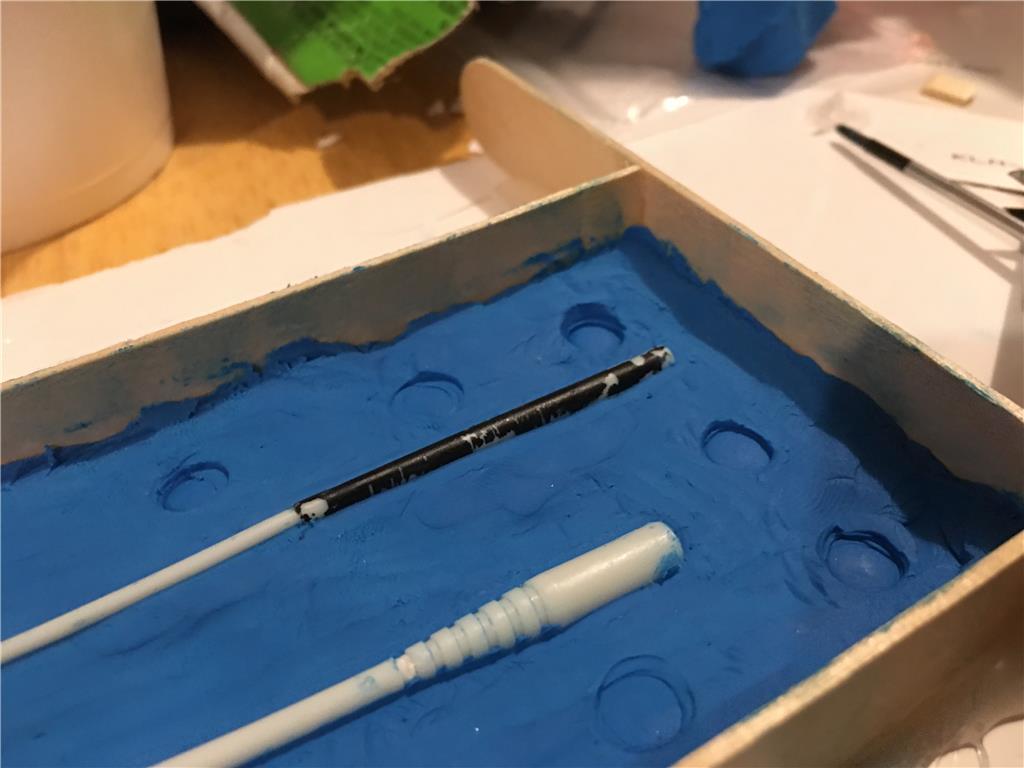

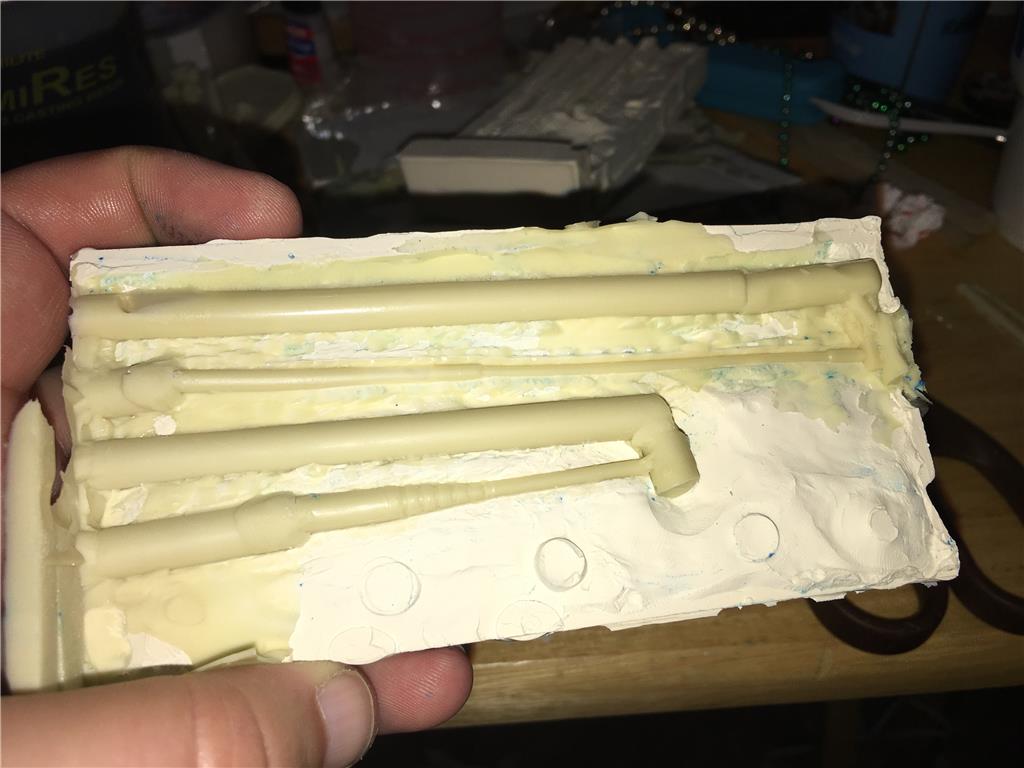

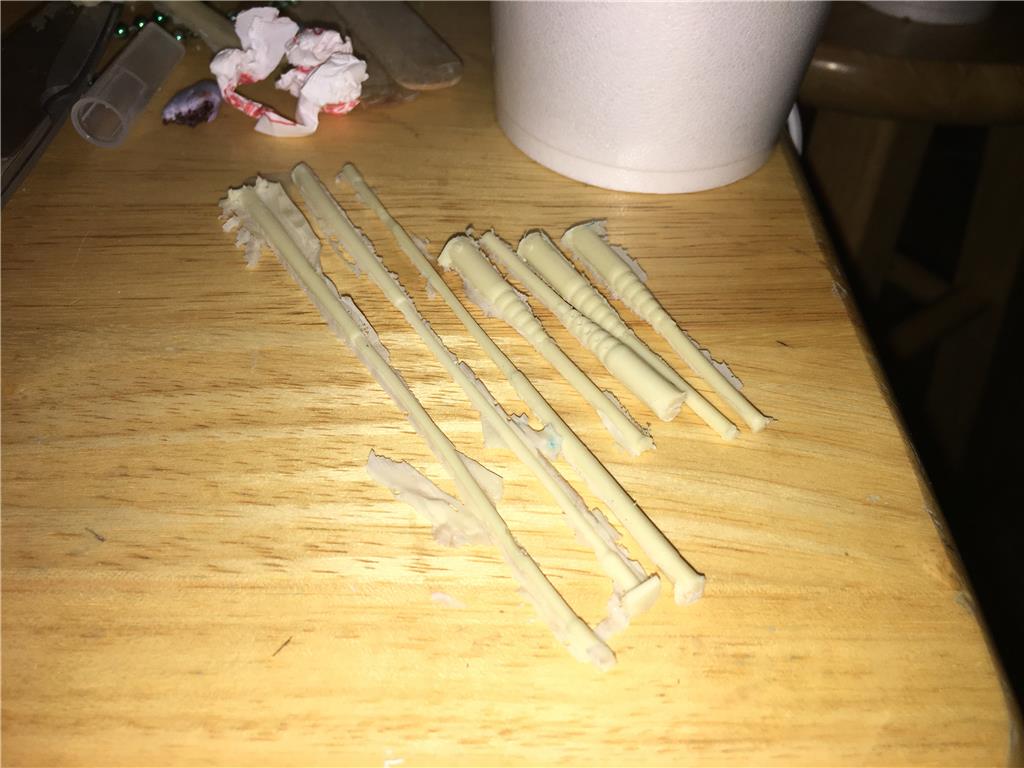

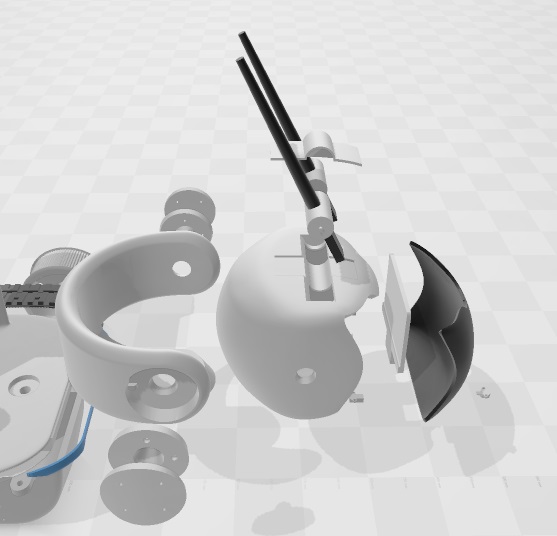

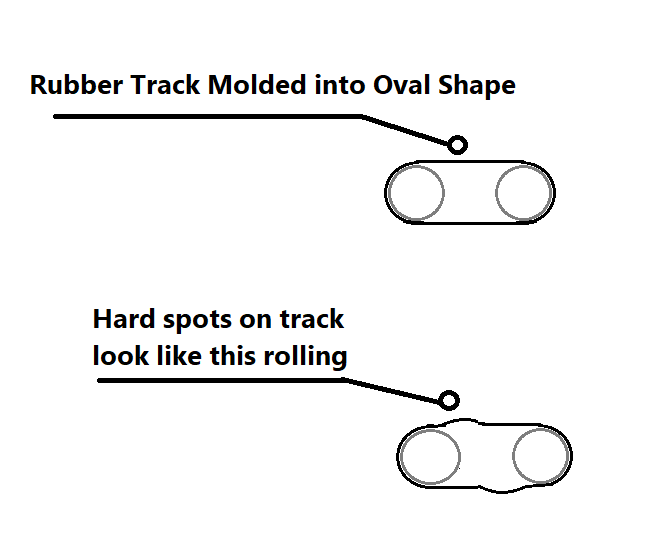

One of the things I am watching out for is hard spots in the track after they are molded into rubber. If they are molded in this shape then I will not have uniformity. So instead the 3d model has to be reoriented into a round shape but the same tread and grooves so that I can get that uniform shape.

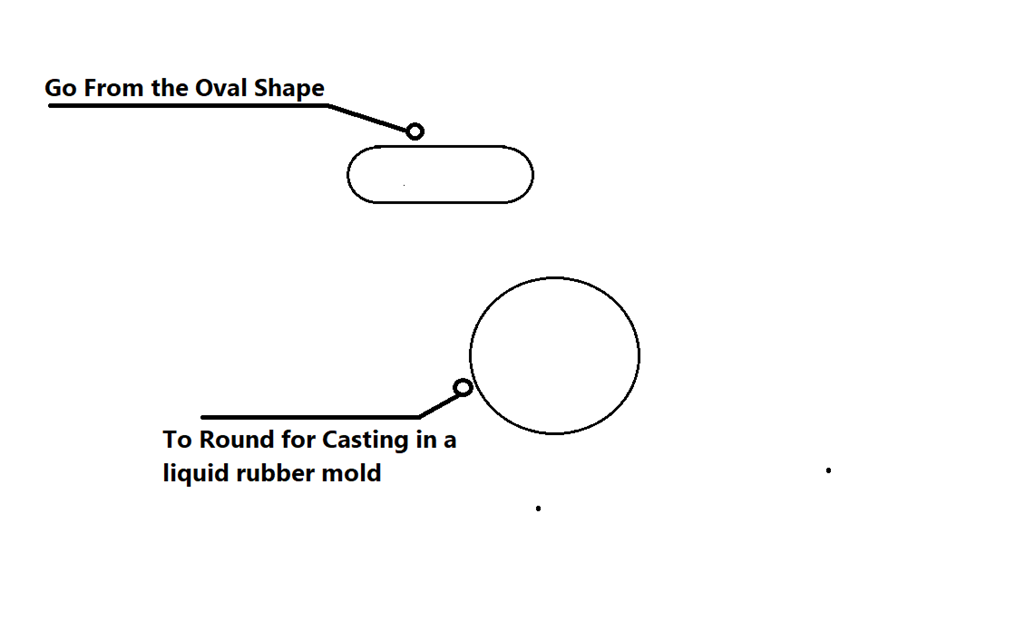

This is how the parts look off the robot , so lets change them into a mold-able shape.

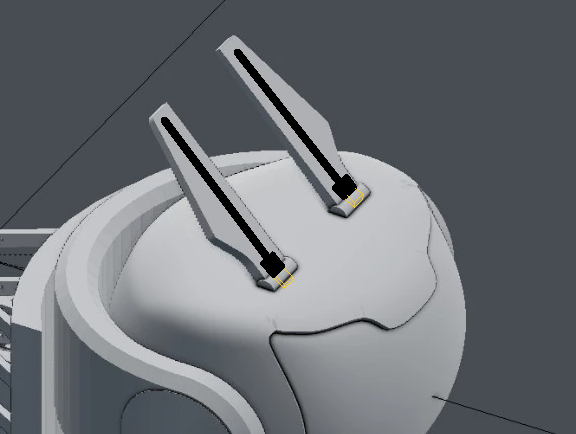

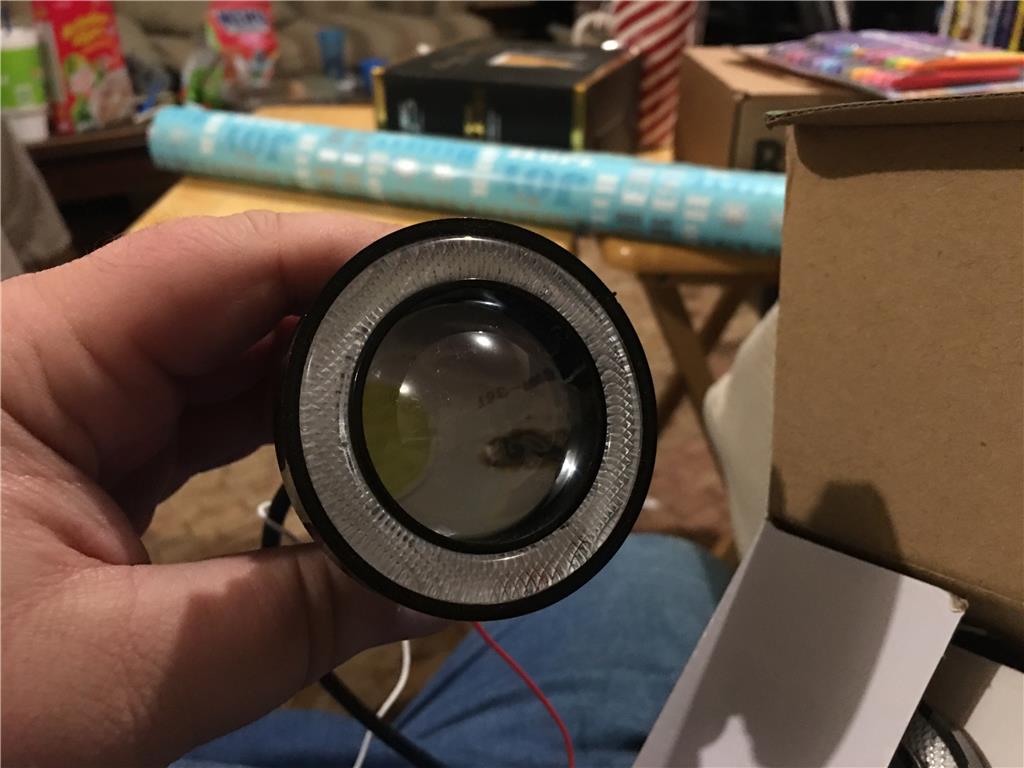

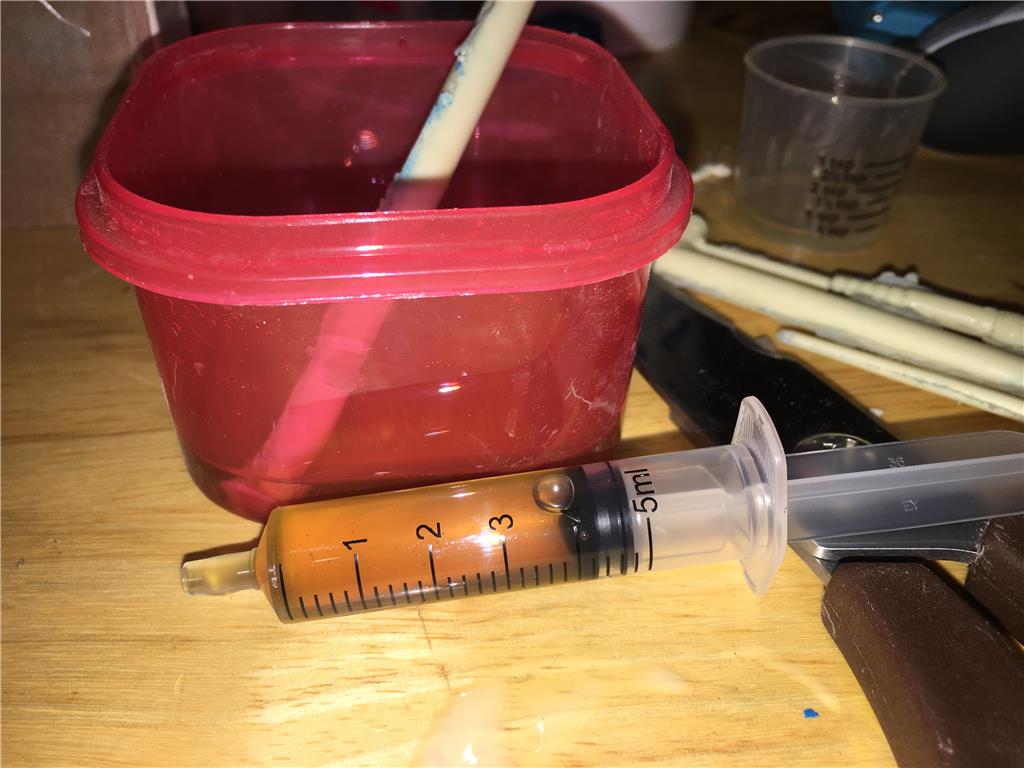

OK so now we have a mold friendly shape. I will need to print this track just like this. Likely in 2-4 pieces and then assemble them in the real world. Once they are finished and primed I can make a mold to cast rubber copies.The "ears" on top of the head are antenna holders. They are meant to house two AC1200 MIMO usb3 wifi adapters with -5 db antenna. The antennas would be positioned like this. I do plan to pop off the antenna outer shell to reduce the thickness of the wifi antenna cover for slightly better reception.