budel0

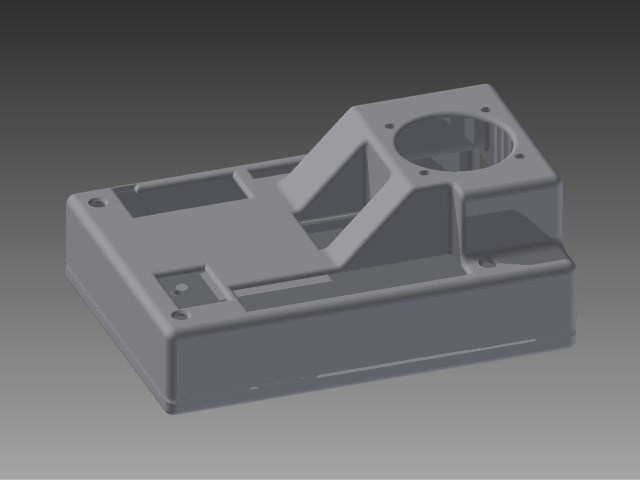

A few weeks back, while writing a report, I had it. The stroke of brilliance. I've always looked at my EZ-b as a fragile, I find that all electronic boards look fragile when they don't have a case or a housing that protects them. Eventhough they usually aren't, but I do.. So here comes the idea, a case for the EZ-b. A few hours of "Inventoring" and mesuring later:

I added all the holes you would need to plug in servo's and other things, but I also added a hole on top, so that you can add a fan to cool the heatsinks. Also I added a hole in the middle of the case. If I wanted to use an external communication system, like USB, Synapse, Xbee, WiFi, etc. And finally I added holes to the bottom of the case for easy mounting.

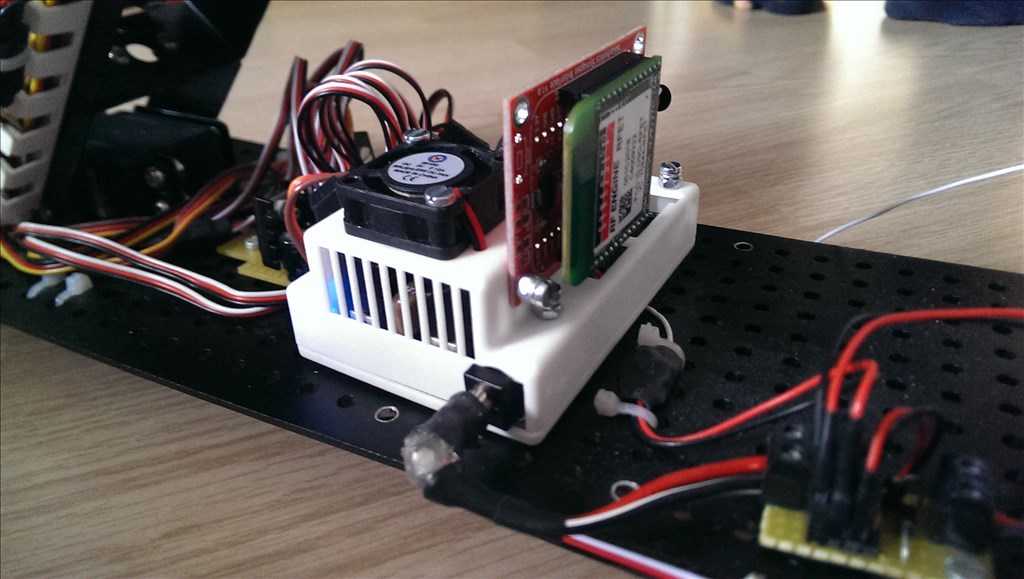

Last week I ordered it from ShapeWays, to have it 3D-printed and today it came in. Here and there some adjustments (it's always difficult to design something for an object if you don't have all dimensions or a CAD model of the object), threaded the holes made some spacers and taadaa:

Presenting the EZ-Case

It works, looks great and is easy to assemble.If anyone else likes it, wants one, you might be able to motivate(yell at me, "I want one!") me to design v2.0 that requires less "adjustments" ,is a little bit smaller and a few other things that I would change now I have my one.

Nice job, I love the allowance for a fan (although I'd have put it on the side right behind the regulators personally but your position is fine).

I'm sure people would be interested in it. Do you have the cad files or STL so others can get it printed (or modify it if needed)?

That is all nice for people like us who have one or two or more EZBs. But, what about the NEW EZB board? D.J. may discontinue selling it. But, I know he will continue to support it. Just a thought.

@aameralis when is your birthday?

@bude what 3d software are you using? Also how did you learn to use it?

Starting from the top:

@Rich My idea for the fan on the top came with the idea of heat rising, my theory is that adding a fan would speed up the airflow that already is rising. And I liked the way it looked . Maybe the next version will incorperate the fan, that

it wont sit on top, but it'll be inside the case, the will give a more smooth design.

. Maybe the next version will incorperate the fan, that

it wont sit on top, but it'll be inside the case, the will give a more smooth design.

@Aameralis I'll add the STL's at the end this post, but it will be the ones I used for the current version, I haven't changed them yet. When the EZ-B mini comes out, I can design a different case for that one, just need an EZ-B mini or a CAD model of it and some inspiration.

@Moviemaker Same answer as the last part for Aameralis, I can always design a new case. Designing, once I start, it's like an addiction for me. But I like to do it and I'm very good at it . Designing this case took me about 2 hours, but I had to messure the

EZ-B and had to make a few assumptions based on what I've mesured. But it isn't hard for me to design cases, I've designed

way more complex things than this case

. Designing this case took me about 2 hours, but I had to messure the

EZ-B and had to make a few assumptions based on what I've mesured. But it isn't hard for me to design cases, I've designed

way more complex things than this case with dozens of parts(time to show off

with dozens of parts(time to show off ), I designed the 3D printer from

This instructable at my internship and I'm currently working on V2.0 of the 3D-printer, the opensource consumer version,

visual attractive and stuff.

The initial design took about 60 hours, but it took way more time to optimize it so it could be build with the least amount of machining.

), I designed the 3D printer from

This instructable at my internship and I'm currently working on V2.0 of the 3D-printer, the opensource consumer version,

visual attractive and stuff.

The initial design took about 60 hours, but it took way more time to optimize it so it could be build with the least amount of machining.

@Jstarne1 I used Autodesk Inventor 2013 for this design, I learned how to use it at school . I'm currently(well after summer holiday again)

studying mechanical engineering where I learned how to design, calculate stuff and much more.

I designed the top part of the case starting with a block, "sculpting" it by removing shapes. But it depends on what

you are designing, I always generate a design plan in my head, where I plan what I'm going to add and remove and in

what order. But it usually changes while I'm designing.

. I'm currently(well after summer holiday again)

studying mechanical engineering where I learned how to design, calculate stuff and much more.

I designed the top part of the case starting with a block, "sculpting" it by removing shapes. But it depends on what

you are designing, I always generate a design plan in my head, where I plan what I'm going to add and remove and in

what order. But it usually changes while I'm designing.

The files EZ-bcaseSTL.zip Note: that I haven't done anything to it yet.

@BudeIO well thought out! Thank you so much for the contribution....Do you know Niek..from the Netherlands who is currently in the EZ-B hive recieving some great job experiance!

@Irobot58 Thanks man, I'm doing my best and I have many more ideas which will slowly(a budget thing, maybe I should offer

this for sale on the Shapeways website, but don't know the regulations with selling things on this forum) enter the forum.

The case came on impulse, you should guess what would come if I thought about something for a long time

and I have many more ideas which will slowly(a budget thing, maybe I should offer

this for sale on the Shapeways website, but don't know the regulations with selling things on this forum) enter the forum.

The case came on impulse, you should guess what would come if I thought about something for a long time

Well, I don't "know" Niek, but I've seen him on the forum, youtube, but I've never actually met him. I do keep track on the Niek EZ-robot experience, it's always fun to watch it.

That is fantastic! I love the creativity and the look. 3D Printers are the future, and this is a good way of showing off how it can be easy to design, and print off something very practical

Great job!