rgordon

USA

Asked

— Edited

Anyone interested in creating a team to brain storm ideas and designs for robot arms for large or small robots. Perhaps collectively we could come up with a universal design that many of us could use. We each could provide input, drawings and/or services.

Rex

and weigh about a ton

Close to 280 pounds already. But, the wheelchair motors, running at 24V, have great torque. The base section weighs 183 pounds. I sat on it and drove myself around (which was very fun BTW ) I weigh 180 pounds and it had no problem pulling me around. Using two Victor 883 variable speed drives which can handle 60A each. Cost a lot though. $150 each.

) I weigh 180 pounds and it had no problem pulling me around. Using two Victor 883 variable speed drives which can handle 60A each. Cost a lot though. $150 each.

@bret.tallent - now you see why I am having trouble finding a good motor for the elbow LOL.

Thanks for all the kind comments

I think you should look at using a linear actuator for the elbow.

AT ALMOST 300 LB unless you have a truck,when i build robots i make the low weight for one very big reason,so charging for many hours i have a robot using wheelchair motors and has enougth power to move me around plus the robot too doest use very large batteries and last 8 hours till next charge,i work the motors and electronics and sensors to use very little current,also has a on-board computer,next part is my hand design,since i did much testing and was able to use a torque tester from work,if you have the right equipment can design and build the best arm ,i work the design out to use very low current ,but still have more torque then needed about 20 lb to 30 lb lift,but can handle alot more,but current goes way up just like on saving on sensors since on all the time,all ultrasonic sensors draw 30 ma about,i am using ones at 2 ma and at 8 of them at 30 ma,is a lot of current

With all due respect, Rgordon, I think you went a little overkill on the shoulder. Did you happen to watch the movie "Real Steel" before you designed it?

(Only joking about that). But in all seriousness, you probably should consider going much lighter when it comes to the arm itself. Not only will the motors and joints be a problem, but if you have too much weight in front of him, combined with the ability to lift a huge amount of weight, he could easily try to pick something up and pull himself over.

For my arms, I am will be using PVC pipe. I'll put a " inside a 2" and fill the gap with expanding polyurethane foam. That will be plenty strong enough for what I need, but light. I have some universal joints from a car steering mechanism for the actual joints, but many things would work. As I said in an earlier post, I have some heavy "push/ pull" cables, like the ones that steer an outboard motor on a boat. They will bend the arms but leave the weight of the motors inside the torso. You might consider something like that.

Yeah.....got a little carried away....got tired of not having enough torque for the shoulders...................but it's so much fun! Muhahahahha!

@robotmaker -not to worried about power, I have two maintenance free 34 Ahr wheelchair batteries. If it's good enough for a wheelchair, it's good enough for Magnus.

Magnus will strictly be just a show robot. Totally remote controlled as far as movement goes. Does not need to run for very long periods of time. I do want to be able to steer and drive him when he is out of my line of sight and he will definitely need to have sensors to help with not bumping into things or running someone over. I will always have an assistant nearby to help keep an eye on things. Drop dead feature if he gets out of R/C range. Of course the EZ-B will allow me to automate certain features and make him appear more lifelike. See Project Magnus thread for details about Magnus. Hopefully, I can use Magnus to make a little money on the side (for buying more robots and parts:D) . I know there are places in California and Florida that rent out robots and an operator for a day for places like shopping malls, car dealerships, office parties, etc. for whopping amounts of money.

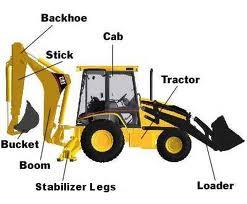

@bret.tallent -I am experimenting with a linear actuator to see if it will fit inside the arm bellows. I am thinking of making the elbow the same way as is used on a Backhoe

. I do think this is the only way I will get it to work. Also worried about his arms appearing too long...wouldn't look right.@Danger! - I share your concerns. All ideas are helpful. I think using PVC pipe is the way to go. I really like your idea about the expanding foam. Weight is definitely a problem so I am extremely interested in your idea about using the push/pull cables. I could easily route one through the hollow rod on my shoulder joint and use it for claw "open/close". Also, I may be able to use a cable like is used on a weed eater (that turns the cutting head) for wrist rotation. The problem is, whenever I need to work on the stuff inside the torso, I need to be able to remove the arms. I can do it now just by disconnecting a cable connector and pull a lock pin and his arm slides right off. So it might be tricky trying to figure out how to disconnect/reconnect the push/pull cables easily and quickly. Any ideas?

And BTW I really like the Real Steel movie!

Check out Surplus Center's DC Linear Actuators. Many unique kinds, great prices.

@ndavid79- Thanks. Definitely good prices! Good dc gear motor prices too!