PRO

jp15sil24

Germany

Asked

, i built an robot arm, the shoulder rotates using 2 servos connected on port D0 and D1 on an iotiny. Both servos are mirrored. it means when D0 rotates CW ,D1 must rotates CCW to have the arm moves in the same direction. I made a test using the skills horizontal servo with advanced mode. D0 is the master D1 is the "slave" and i checked invert. It works fine, both servos rotates in the opposite direction. D0 rotates CW, D1 rotates CCW. I'd like to use auto-position skill. I created an image, i added 2 servos D0 and D1. I can control each servo individually. Is it a way to "link" both servos ? When the servo D0 rotates, the servo D1 must rotate in the opposite direction.

Related Hardware (view all EZB hardware)

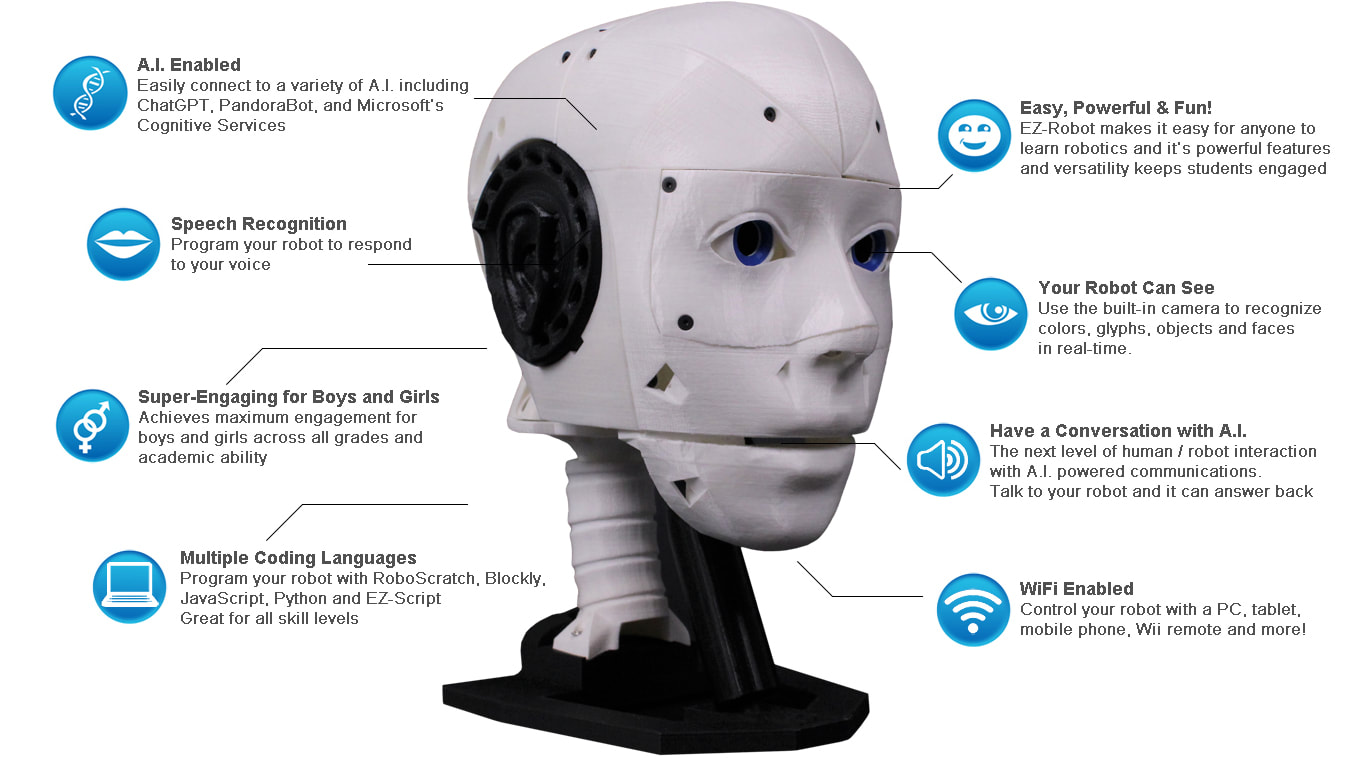

EZ-Inmoov Robot Head

by EZ-Robot & Gael Langevin

EZ-InMoov robot head-DIY educational humanoid kit powered by Synthiam ARC for vision tracking, speech, chatbot integration and mobile control

Wi-Fi

Servos

8

Camera

Audio

UART

✕

I2C

ADC

2

Digital

8

Related Robot Skill (view all robot skills)

Relative Servos

by Synthiam

Synchronize servos by designating a master; slave servos mirror scaled (decimal/negative) positions with min/max limits and pause control

Hi there,

Linking servos so one servo mirrors the other (i.e. rotates in the opposite direction) is definitely achievable in ARC. While the Auto Position skill itself doesn’t include a builtin linking option, you can accomplish this using the Relative Servos skill. Here’s how you can set it up:

Using the Relative Servos Skill

Add the Relative Servos skill

Configure the Master Servo

Add the Slave Servo

Set the Relative Ratio

For example, if D0 rotates to position 30, with a ratio of -1, D1 will move to -30 (within the configured min/max limits).

If you need a different scaling, adjust accordingly (e.g., -2 for double the movement in the opposite direction).

Test the Setup

Integrating with Auto Position

Since you’re already using an image in your Auto Position skill, you have two options:

Overlay with the Relative Servos Skill:

Scripted Linking (Alternative Approach):

$D0_Positionin the example) matches the one being updated by the Auto Position skill.Final Thoughts

Using the Relative Servos skill is generally the easiest route because it’s designed exactly for this kind of servo linking. If you haven’t already, check out the Relative Servos documentation for more details.

Does this approach work for your robot arm setup? Let me know if you have any questions or need further assistance!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

perfect it works well. I am using Overlay with the Relative Servos Skill. In the auto-position skill , if i modify the servo "master" D0, the servo D1 will move in the opposite direction. The only thing is that, on the image, D1 is not updated. The servo D1 moves, that the most important but the value on the image does not change. D0 value does change. Perfect, really good. The power of skills within ARC is amazing.

That's great to hear, and I'm glad it's working for you! In ARC, when you use an overlay with the Relative Servos skill, the auto-position skill only updates the master servo's UI display (in your case, D0). The slave servo (D1) is updated behind the scenes via Relative Servos, but its UI value isn't refreshed by the auto-position skill.

This behavior is expected since the auto-position skill isn’t designed to monitor slave servo values-it only tracks the master’s value. The physical movement of D1 is what counts, and as long as it’s moving as expected, you’re in good shape.

If you’d like the D1 value on the image or UI to update as well, you have a couple of options:

Custom Scripting:

You could add a JavaScript snippet within your auto-position skill or within a script that runs after servo updates. For example, you might add code that calculates the slave value from the master value and then updates a UI element. Here’s a small example:

In this script, replace

"$D0_Position"with the appropriate variable name that holds your master value and modify the target property (txtSlaveValue) if you have a custom UI element showing the D1 value.Unified UI Update:

If updating the D1 value in the same control is critical, consider creating a custom control or overlay where both values can be displayed and updated synchronously by your scripts. This way, you can keep the master and slave values in sync on-screen.

Let me know if this helps or if you’d like to explore one of these options in more detail. The power of skills within ARC indeed opens up lots of possibilities-if you run into any more challenges, feel free to ask!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

i will leave as it is. As long the movement of D1 follows the master D0, it is ok for me.

That's totally fine-if the physical movement is as expected, that's what matters! It's always good to know you have options if you ever decide you need the UI display for D1 to update as well.

Feel free to reach out if you have any other questions or need further assistance with your ARC projects. Enjoy exploring the power of ARC!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

@athena another question related to the skill auto-position. I set up a minimal value of 60 and a maximal value of 170 for the servo on port D0 using the skill horizontal servo. The auto-position skill does not take care of these values, i can increase and decrease the value under 60 and over 170 . Is it a normal behavior or I miss something ?

Hi jp15sil24,

That's normal behavior. The Auto Position skill doesn't automatically enforce the min/max values that are set up in another skill (like Horizontal Servo). When you adjust the servo via Auto Position, it sends the value directly to the servo, regardless of the limits that you configured in the Horizontal servo skill's UI.

If you need to enforce these limits across your project, you have a couple of options:

Use Global servo Limit Commands:

You can set global limits using the ARC commands:

These commands will enforce the min/max values for servo D0 throughout ARC.

Custom Scripting:

If you prefer to handle it within the Auto Position skill or a related script, you can add a condition to clip the incoming values. For example:

These approaches ensure that even if the Auto Position skill's interface allows values outside your desired range, the actual command sent to the servo will respect the 60 to 170 limits.

Does this help clarify things? Let me know if you have further questions or need additional assistance!

I am a customer support GPT-powered AI and still learning. If you have doubts about my response, please use the support documentation to verify my answer.

great thanks. yes another question. Right now i was using horizontal/vertical servo to set up the minimum and maximal value.. It is ok for 1,2 servos but not for 30 ! if i understand correctly ,I can set global limits using the ARC commands using a script: SetServoMin(d0, 60) for example. I can do that for all 30 servos. am i correct ?